7

WALL-MOUNTED SWIMMING POOL DEHUMIDIFIER - USER´S MANUAL

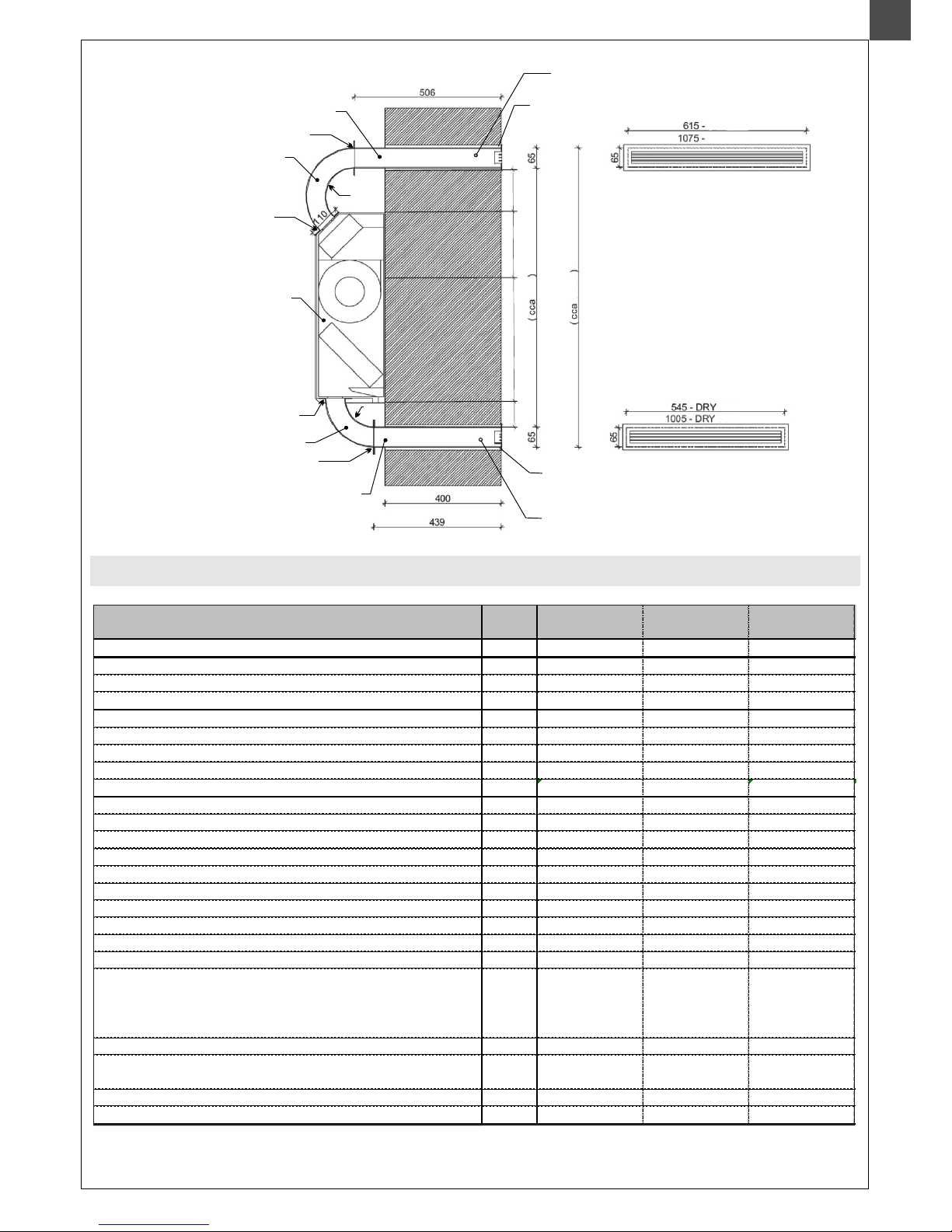

LOCATION OF THE EQUIPMENT

ZONE 1, IPX4

ZONE 2, IPX2

OUTSIDE THE ZONES

In the distance of 1250 mm or less

from the swimming pool edge, the

bottom edge of the unit must be in

the height of 2500 mm from the

swimming pool surface; if it is

embedded under the floor, then

2500 mm from the floor.

At least 1250 mm (i.e. out of the reach of the hand) from the lateral edge

of the wash basin, in the minimum height of 1200 mm above ground. It

cannot be placed above the wash basin.

In the distance of at least 1500 mm

from the vertical plane around the

jumping platforms, diving boards

and 2500 mm above the highest

surface, where persons are likely to

stay.

If the unit is in the distance of less

or equal to 1250 mm horizontally

from the edge of the swimming

pool, then it must be raised up to

the height of 2500 mm from the

swimming pool surface; if the

pool is embedded under the floor,

then the unit must be raised up to

the height of 2500 mm from the

floor.

It is inevirable to locate the unit outside the zones, where cleaning by jet water is supposed. Connection of the unit to the mains and

its protection must correspond with the applicable standards. Electrical supply of the unit must be carried out by a protective

isolating transformer or it must be protected by a current protective switch with a nominal differential cut-off current not exceeding

30 mA.

SWIMMING POOL

The location must be in compliance with the HD 384.7.702 S1, IEC 60364-7-702 standard.

It is recommended to situate the unit outside zones 0, 1 and 2.

In case the unit is situated into zones 2 or 1, it must be adhered to the HD, IEC standard.

SWIMMING POOL

Swimming pools which are not

cleaned by jet water

in the distance of 1250 to 2000 mm from the swimming pool edge,

the unit must adhere to the HD, IEC standard and in the height

of at least 300 mm from the floor

Swimming pools which

are not cleaned by jet water

In the distance of 2000 to 3500 mm

from the swimming pool edge, the

unit must adhere to the HD, IEC

standard and a minimum 150 mm

elevation above the ground is

required for sufficient air flow.

Installing the unit on the floor is

prohibited.

At least 1250 mm (i.e. out of the reach of the hand)

from the lateral edge of the shower cabinet. It cannot

be placed above the shower cabinet.

OUTSIDE THE ZONES OUTSIDE THE ZONES