OM-253555 Page 1

SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING

Protect yourself and others from injury—read, follow, and save these important safety precautions and operating instructions.

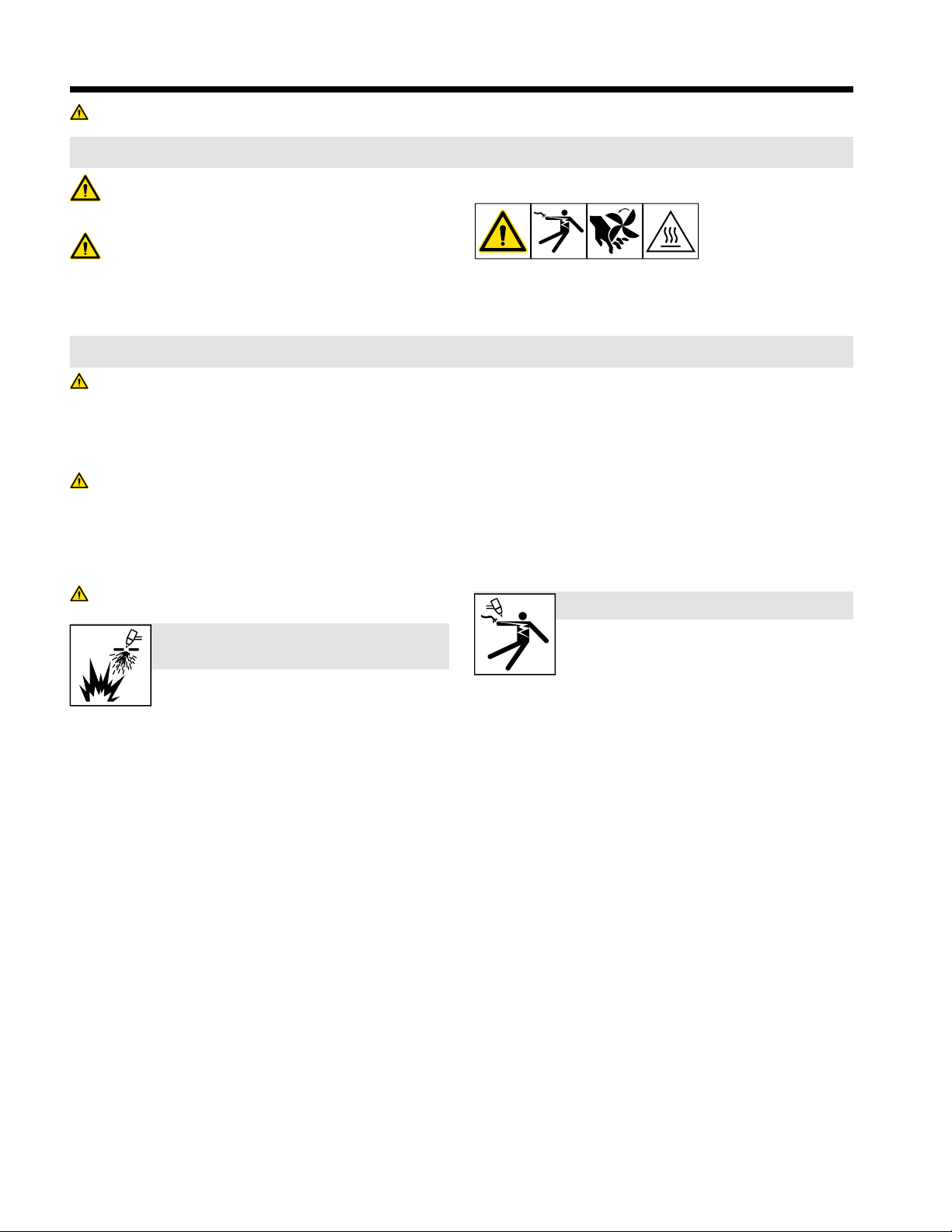

1-1. Symbol Usage

DANGER! – Indicates a hazardous situation which, if not

avoided, will result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained

in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible haz-

ards are shown in the adjoining symbols or explained in

the text.

NOTICE – Indicates statements not related to personal injury.

F

Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING PARTS, and HOT PARTS hazards. Consult

symbols and related instructions below for necessary actions to

avoid these hazards.

1-2. Plasma Arc Cutting Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instruc-

tions to avoid the hazard. The safety information given be-

low is only a summary of the more complete safety

information found in the Principal Safety Standards listed in

Section 1-5. Read and follow all Safety Standards.

Only qualified persons should install, operate, maintain,

and repair this equipment. A qualified person is defined as

one who, by possession of a recognized degree, certificate,

or professional standing, or who by extensive knowledge,

training and experience, has successfully demonstrated the

ability to solve or resolve problems relating to the subject

matter, the work, or the project and has received safety

training to recognize and avoid the hazards involved.

During operation, keep everybody, especially children,

away.

CUTTING can cause fire or

explosion.

Hot metal and sparks blow out from the cutting arc.

The flying sparks and hot metal, hot workpiece,

and hot equipment can cause fires and burns.

Check and be sure the area is safe before doing any cutting.

lRemove all flammables within 35 ft (10.7 m) of the cutting arc. If

this is not possible, tightly cover them with approved covers.

lDo not cut where flying sparks can strike flammable material.

lProtect yourself and others from flying sparks and hot metal.

lBe alert that sparks and hot materials from cutting can easily go

through small cracks and openings to adjacent areas.

lWatch for fire, and keep a fire extinguisher nearby.

lBe aware that cutting on a ceiling, floor, bulkhead, or partition can

cause fire on the hidden side.

lDo not cut or weld on tire rims or wheels. Tires can explode if

heated. Repaired rims and wheels can fail. See OSHA 29 CFR

1910.177 listed in Safety Standards.

lDo not cut on containers that have held combustibles, or on closed

containers such as tanks, drums, or pipes unless they are properly

prepared according to AWS F4.1 and AWS A6.0 (see Safety

Standards).

lConnect work cable to the work as close to the cutting area as

practical to prevent cutting current from traveling long, possibly un-

known paths and causing electric shock, sparks, and fire hazards.

lDo not use plasma cutter to thaw frozen pipes.

lNever cut containers with potentially flammable materials inside -

they must be emptied and properly cleaned first.

lDo not cut where the atmosphere can contain flammable dust,

gas, or liquid vapors (such as gasoline).

lDo not cut pressurized cylinders, pipes, or vessels.

lWear body protection made from durable, flame-resistant material

(leather, heavy cotton, wool). Body protection includes oil-free

clothing such as leather gloves, heavy shirt, cuffless trousers, high

shoes, and a cap.

lDo not locate unit on or over combustible surfaces.

lRemove any combustibles, such as a butane lighter or matches,

from your person before doing any cutting.

lAfter completion of work, inspect area to ensure it is free of sparks,

glowing embers, and flames.

lUse only correct fuses or circuit breakers. Do not oversize or by-

pass them.

lFollow requirements in OSHA 1910.252 (a) (2) (iv) and NFPA 51B

for hot work and have a fire watcher and extinguisher nearby.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal

shocks or severe burns. The torch and work circuit

are electrically live whenever the output is on. The

input power circuit and machine internal circuits

are also live when power is on. Plasma arc cutting requires higher vol-

tages than welding to start and maintain the arc (200 to 400 volts dc

are common), but can also use torches designed with safety interlock

systems which turn off the machine when the shield cup is loosened

or if tip touches electrode inside the nozzle. Incorrectly installed or im-

properly grounded equipment is a hazard.

lDo not touch live electrical parts.

lWear dry, hole-free insulating gloves and body protection.

lInsulate yourself from work and ground using dry insulating mats

or covers big enough to prevent any physical contact with the work

or ground.

lDo not touch torch parts if in contact with the work or ground.

lTurn off power before checking, cleaning, or changing torch parts.

lDisconnect input power before installing or servicing this equip-

ment. Lockout/tagout input power according to OSHA CFR

1910.147 (see Safety Standards).

lProperly install, ground, and operate this equipment according to

its Owner’s Manual and national, state, and local codes.

lCheck and be sure that input power cord ground wire is properly

connected to ground terminal in disconnect box or that cord plug

is connected to a properly grounded receptacle outlet - always ver-

ify the supply ground.

lWhen making input connections, attach proper grounding conduc-

tor first.

lKeep cords dry, free of oil and grease, and protected from hot met-

al and sparks.

lFrequently inspect input power cord and ground conductor for

damage or bare wiring – replace immediately if damaged – bare

wiring can kill.

lTurn off all equipment when not in use.