12 13

WARNING!

To reduce the risk of explosion,

never burn a battery pack even if

it is dama ed, dead or completely

dischar ed.

MAINTENANCE

WARNING!

To reduce the risk of personal

injury, always unplu the char er

and remove the battery pack from

the char er or tool before per-

formin any maintenance. Never

disassemble the tool, battery

pack or char er. Contact a

MILWAUKEE service facility for

ALL repairs.

WARNING!

To reduce the risk of personal

injury and dama e, never

immerse your tool, battery pack

or char er in liquid or allow a liquid

to flow inside them.

Maintainin Tool

Keep your tool, battery pack and charger

in good repair by adopting a regular main-

tenance program. After six months to one

year, depending on use, return the tool,

battery pack and charger to a MILWAUKEE

ser ice facility for:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

Electrical inspection (battery pack,

charger, motor)

Testing to assure proper mechanical

and electrical operation

If the tool does not start or operate at full

power with a fully charged battery pack,

clean the contacts on the battery pack. If

the tool still does not work properly, return

the tool, charger and battery pack to a

MILWAUKEE ser ice facility for repairs.

Maintainin Battery Pack

MILWAUKEE battery packs will operate

for many years and/or hundreds of cycles

when they are maintained and used ac-

cording to these instructions.

A battery pack that is stored for six months

without being used will discharge itself.

Batteries discharge at a rate of about 1%

per day. Charge the battery e ery six

months e en if it is unused to maximize

battery life. Do not tape the trigger in the

ON position and lea e the tool unattended

as this may discharge the battery to a point

where it will no longer be able to recharge.

Use a MILWAUKEE battery pack only until

it no longer performs with the power and

torque needed for your application.

ACCESSORIES

For a complete listing of accessories refer

to your MILWAUKEE Electric Tool catalog

or go on-line to www.milwaukeetool.com.

To obtain a catalog, contact your local dis-

tributor or a ser ice center.

Store your battery pack in a cool, dry place.

Do not store it where the temperature may

exceed 120°F (50°C) such as in a ehicle

or metal building during the summer. High

temperatures will o erheat the battery pack,

reducing battery life. If it is stored for se -

eral months, the battery pack will gradu-

ally lose its charge. One to three cycles of

charging and discharging through normal

use will restore the capacity of the battery

pack. During the life of the battery pack,

the operating time between charges be-

comes shorter. If the operating time be-

comes extremely short after a proper

charge, the usable life of the battery pack

has been reached and it should be replaced.

Cleanin

Clean dust and debris from charger and

tool ents. Keep tool handles clean, dry and

free of oil or grease. Use only mild soap and

a damp cloth to clean the tool, battery pack

and charger since certain cleaning agents

and sol ents are harmful to plastics and

other insulated parts. Some of these in-

clude gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning sol ents,

ammonia and household detergents con-

taining ammonia. Ne er use flammable or

combustible sol ents around tools.

Rechargeable Battery Recycling Corporation

(RBRC). At the end of your battery pack's

useful life, return the battery pack to a

MILWAUKEE Branch Office/Ser ice Center

or the participating retailer nearest you. For

more information, isit the RBRC web site at

www.rbrc.org.

Disposin of Nickel-Cadmium Battery

Packs

Nickel-Cadmium battery packs are recy-

clable. Under arious state and local laws,

it may be illegal to dispose of this battery

into the municipal waste stream. Dispose

of your battery pack according to federal,

state and local regulations.

Repairs

For repairs, return the tool, battery pack

and charger to the nearest ser ice center

listed on the back co er of this operator's

manual.

Battery Pack Warranty

Battery packs for cordless tools are war-

ranted for one year from the date of pur-

chase.

WARNING!

Always remove battery pack be-

fore chan in or removin acces-

sories. Only use accessories spe-

cifically recommended for this

tool. Others may be hazardous.

RBRC Battery Recyclin Seals

The RBRC Battery Recycling Seals (see

"Symbology") on your tool battery packs in-

dicate that MILWAUKEE has arranged for

the recycling of that battery pack with the

FIVE YEAR TOOL

LIMITED WARRANTY

E ery MILWAUKEE tool is tested before

lea ing the factory and is warranted to be

free from defects in material and work-

manship. MILWAUKEE will repair or

replace (at MILWAUKEEs discretion),

without charge, any tool (including battery

chargers) which examination pro es to be

defecti e in material or workmanship from

fi e (5) years after the date of purchase.

Return the tool and a copy of the purchase

receipt or other proof of purchase to a

MILWAUKEE Factory Ser ice/Sales

Support Branch location or MILWAUKEE

Authorized Ser ice Station, freight prepaid

and insured. This warranty does not co er

damage from repairs made or attempted

by other than MILWAUKEE authorized

personnel, abuse, normal wear and tear,

lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are

warranted for one (1) year from the date

of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL MILWAUKEE BE LIABLE

FOR ANY INCIDENTAL, SPECIAL, OR

CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL,

EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gi es you specific legal

rights. You may also ha e other rights that

ary from state to state and pro ince to

pro ince. In those states that do not allow

the exclusion of implied warranties or

limitation of incidental or consequential

damages, the abo e limitations or

exclusions may not apply to you. This

warranty applies to the United States,

Canada, and Mexico only.

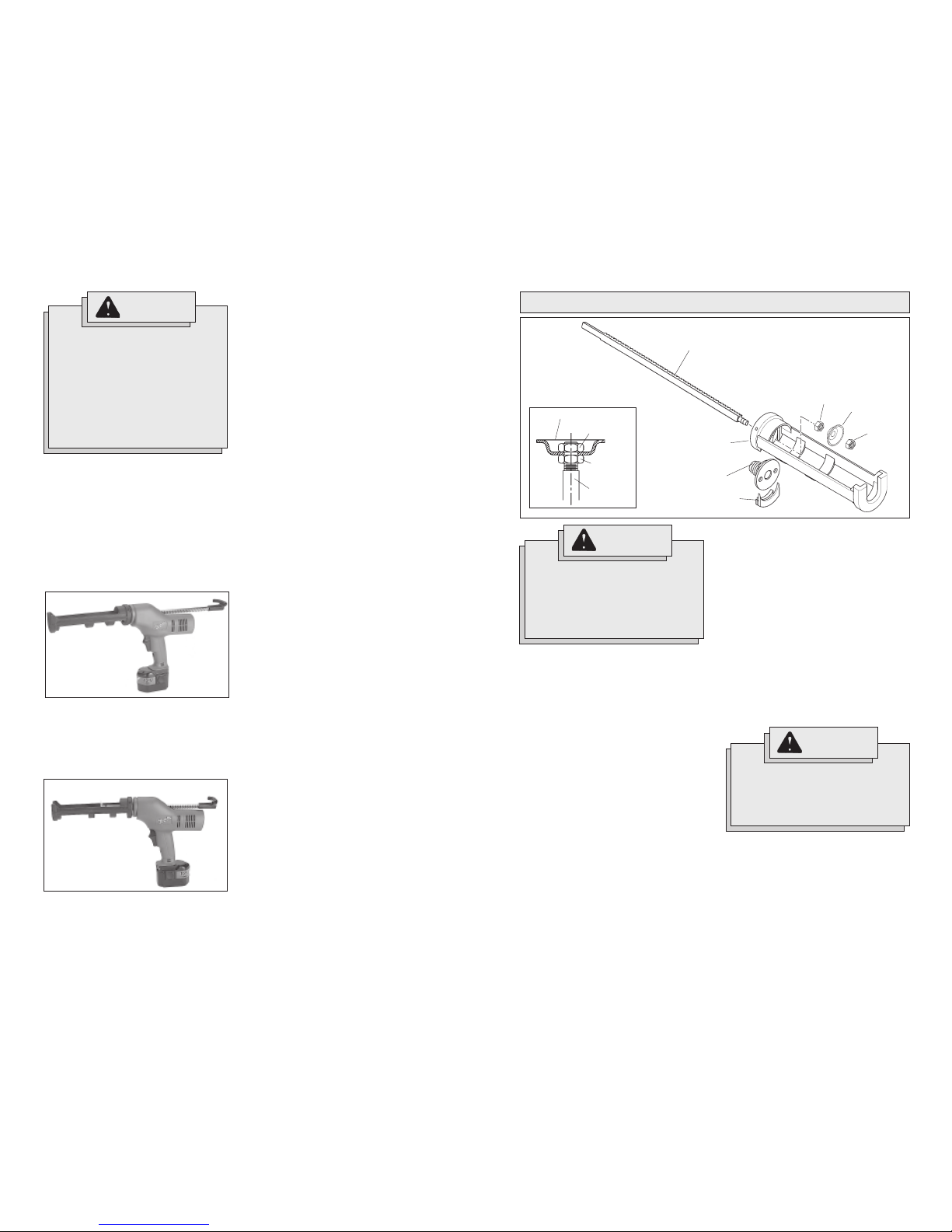

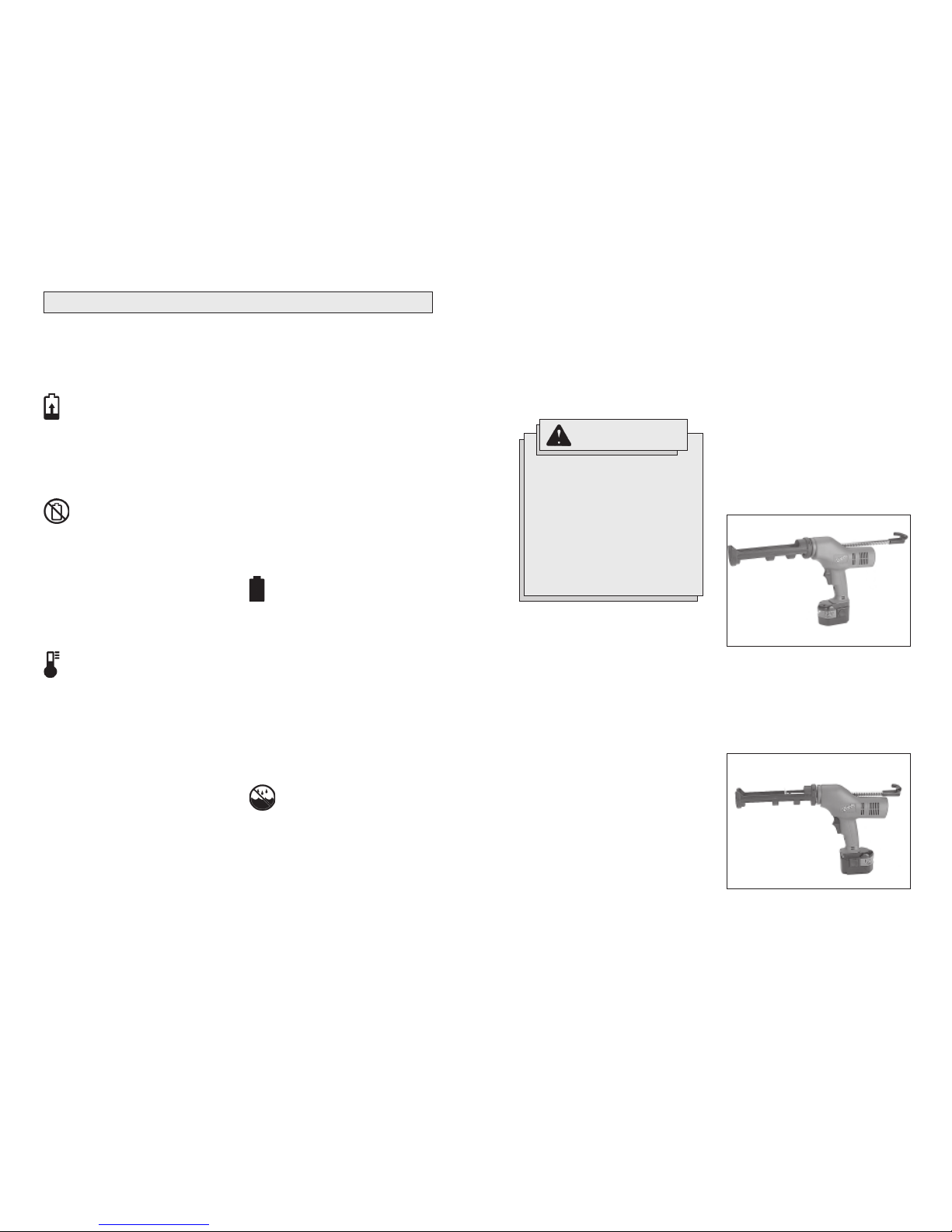

10oz. Carriage Frame Kit

Cat. No. 48-08-1000, must use 49-52-0500 Rack

30oz. Carriage Frame Kit

Cat. No. 48-08-1010, must use 49-52-0525 Rack

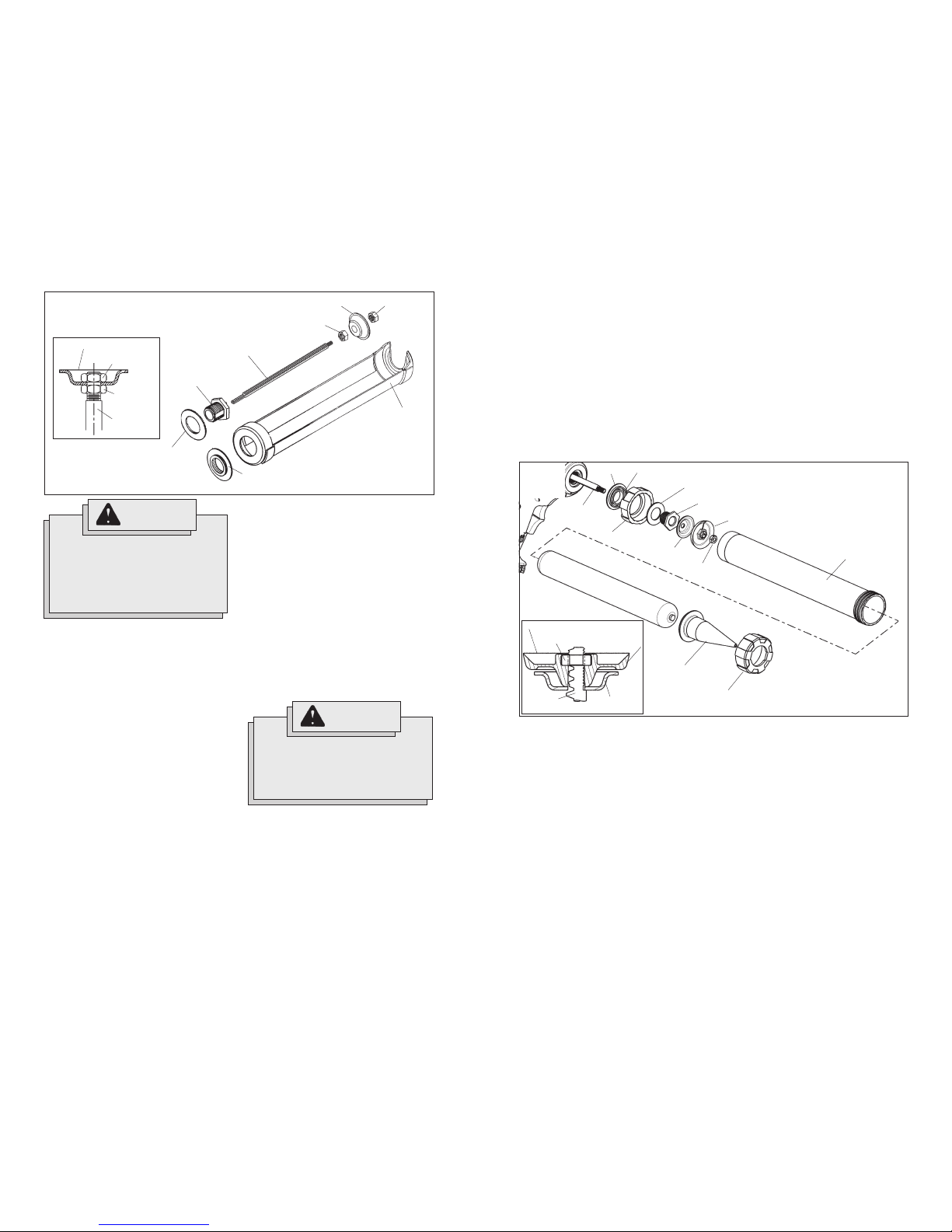

10oz. Sausage Pack Barrel Kit

Cat. No. 48-08-1020, must use 49-52-0500 Rack

20oz. Sausage Pack Barrel Kit

Cat. No. 48-08-1030, must use 49-52-0515 Rack