6

6. Electrical Work

Electrical work must be performed according to

the standards of each country. Never perform

connection by hand-twisting wires. Furthermore,

power lines must be connected inside a box and

box cover for rigid metal conduit

- Connection failure and faulty wiring work could

result in electric shock or fire.

CAUTION

Do not use the fan at other than the

rated voltage and frequency

- Failure to heed this warning may result

in fire or electric shock.

Be sure to install the ground wire

- Device failure and electric leakage

may cause electric shock.

WARNING

Perform connection after checking that the power supply

is correct. If the fan is operated with the wrong power

supply, the motor could burn out.

Be sure to install an electric leakage breaker.

Always ground the grounding terminal.

Circuit breakers conforming to EN60947-2 must be used.

Circuit breakers of which contact gaps are 3 mm or more

must be used. We recommended a Mitsubishi Electric

non-fuse circuit breaker (Model: NF32-SVF [Rated

current: 15 A, number of poles: 3]).

Connect the TN system to a 3-phase, 3-wire power supply.

The ground wire must always be connected.

For wires that are to be connected to the power cord

including the grounding wire, use electrical wire with a

copper conductor size of 0.75 mm2or above rated for a

voltage of 300 V between conductor and ground and a

voltage of 500 V, 7 A, or above between conductors.

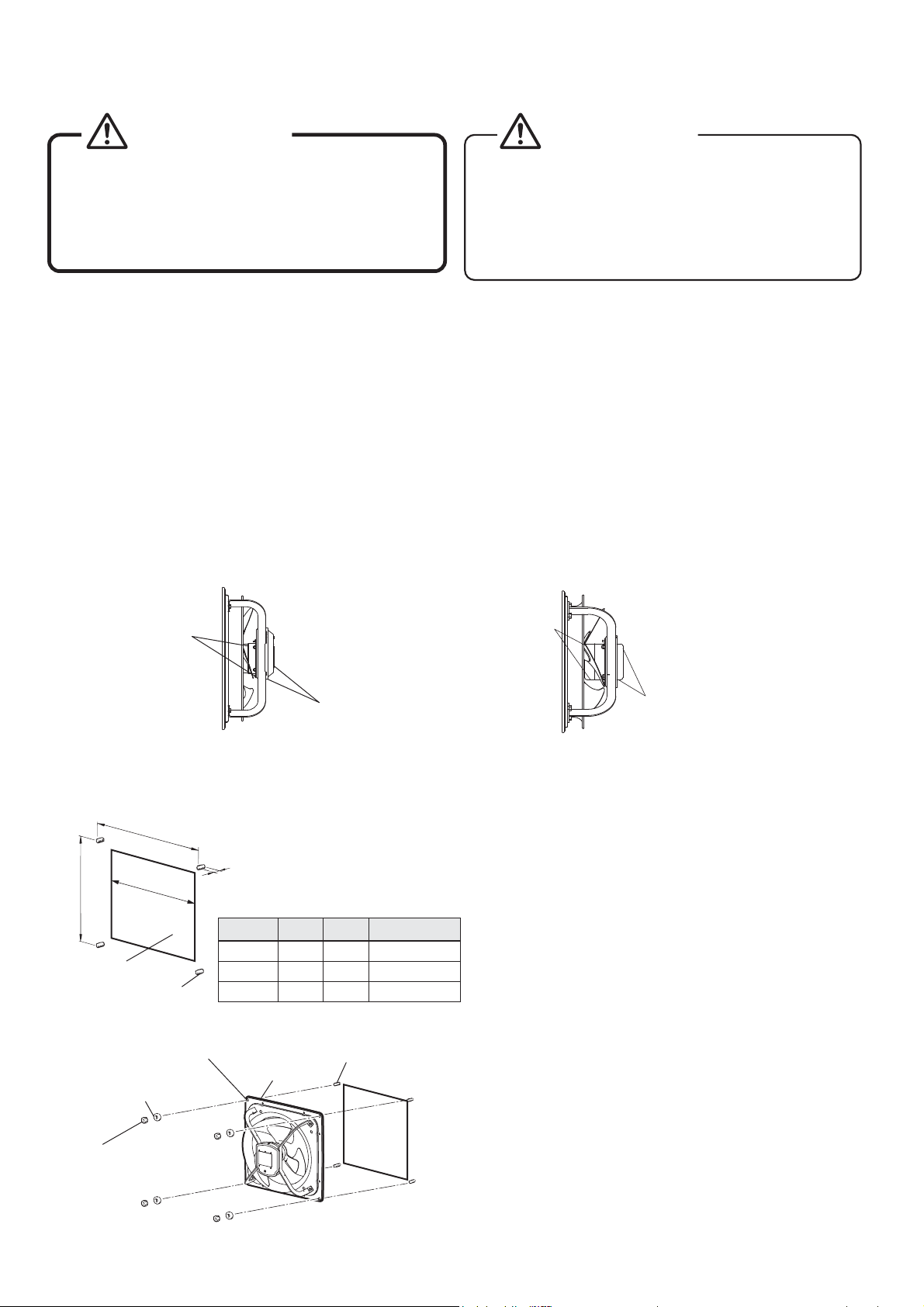

To connect to the power supply, install a metal electrical

conduit box near the fan installation area (within 0.8 m in

direct distance) and make connections inside the box.

Install another separate metal box, and connect the

circuit breaker and the electromagnetic switch together

inside the box.

Metal electrical

conduit box

Within

0.8 m

Fan

Motor

PE

L1

L2

L3

Connection Diagram

The terminals are labeled on the end of

the power cord as shown left. (Ground

is marked with this symbol: )

The conductor wire gauge for the power

cord is 18 AWG (Min 0.824 mm

2

).

Metal electrical conduit box (ventilator's power cord connection)

Electromagnetic

switch

Circuit

breaker

To protect against overload on the motor, use overload

protection equipment that employs a magnetic switch

(magnetic contact + thermal relay). Overload protection

equipment must be attached for every unit. A magnetic

switch conforming to EN60947-4-1 must be used.

We recommend a magnetic switch manufactured by

Mitsubishi (model: MSO-N10 (The specification is

described in Table 1)). The setting current value of

the magnetic switch must be set per the information

described in Table 2.

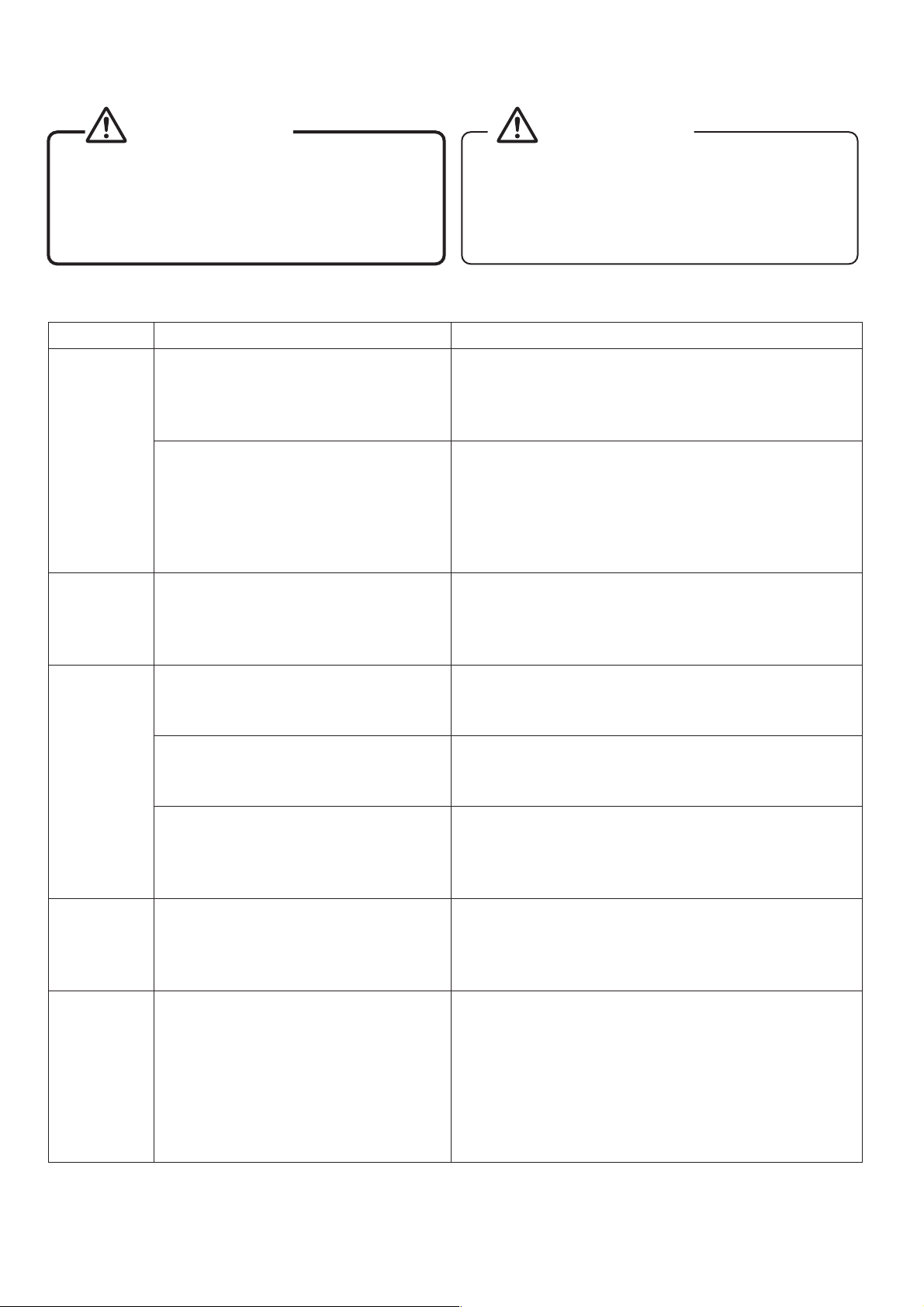

Table 2. Magnetic Switch Setting Current Value

Power Supply Model

Magnetic Switch Setting

Current Value (A)

Heater

Desig.

(A)

50Hz 60Hz

Three-phase

50/60Hz

200-220V

EF-35UDT-GL

1.3 1.4 1.3

EF-40UET-GL

2.3 2.7 2.5

EF-50UFT-GL

3.2 3.2 3.6

Three-phase

50/50/50/60/60Hz

380/400/415/400/440V

EF-35UDT40A-GL

0.70.650.7

EF-40UET40A-GL

1.2 1.2 1.3

EF-50UFT40A-GL

1.7 1.7 1.7

7. Trial Operation

After installation work, check the

following items.

1. Is the fan installed correctly?

2. Is not the power cord damaged?

3.

Has grounding work been performed correctly?

4. Is the power supply voltage correct?

Turn ON the breaker to perform trial operation.

5. Is not there abnormal vibration or noise?

(Where there is an abnormality, stop operation

and check the electrical work.)

6. Is the rotation direction reversed?

(If the rotation direction is reversed, switch two

of the three power wires.)

7DEOH6SHFL¿FDWLRQRI0621

Coil (kW) Auxiliary Contact

Standard (spec.)

220-220V 380-440V 500-550V

2.2 2.7 2.7 1a (1b)

Combination with Thermal Relay

Model Heater Desig.(A)

TH-N12

(KP)

0.12, 0.17, 0.24, 0.35, 0.5, 0.7, 0.9, 1.3,

1.7, 2.1, 2.5, 3.6, 5, 6.6, 9