4) Lock the DIN rail mounting hooks (below fig.B) while pressing the

PLC against the DIN rail.

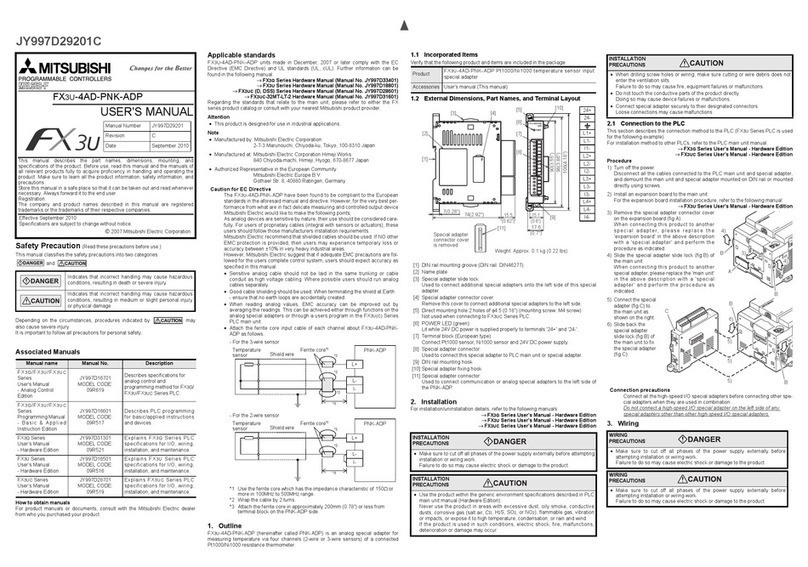

2.4 Procedures for installing directly (with M4

screws)

The product can be installed directly on the panel (with screws).

2.4.1 Mounting hole pitches

Refer to the External Dimensions (section 1.2) for the product's

mounting hole pitch information.

As for the details of the mounting hole pitches for extension unit/

block and special adapters, refer to the following manual.

→Refer to FX3U Series User's Manual - Hardware Edition.

2.4.2 Installation

1) Make mounting holes in the

mounting surface referring to

the external dimensions

diagram.

2) Fit the main unit (A in the right

figure) based on the holes, and

secure it with M4 screws (B in

the right figure).

The mounting hole pitches and

number of screws depend on

the product. See the external

dimensions diagram.

3. Power supply/input/output specifications

and examples of external wiring

As for the details of the power supply wiring and input/output wiring,

refer to FX3U Series User's Manual - Hardware Edition.

DESIGN

PRECAUTIONS

•Provide a safety circuit on the outside of the PLC so that the

whole system operates to ensure the safety even when external

power supply trouble or PLC failure occurs.

Otherwise, malfunctions or output failures may result in an

accident.

1) An emergency stop circuit, a protection circuit, an interlock

circuit for opposite movements, such as normal and

reverse rotations, and an interlock circuit for preventing

damage to the machine at the upper and lower positioning

limits should be configured on the outside of the PLC.

2) When the PLC CPU detects an error, such as a watch dog

timer error, during self-diagnosis, all outputs are turned off.

When an error that cannot be detected by the PLC CPU

occurs in an input/output control block, output control may

be disabled.

Design external circuits and mechanisms to ensure safe

operations of the machine in such a case.

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

0312 645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

Y12Y10 Y16Y14 Y22Y20 Y26 COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1 COM3 Y15 Y17COM4 Y23 Y25 Y27Y21

X5

X0

X1

X2

X3 X7 X11 X13

X40VS/S

N24V

X6 X10 X12 X14 X16 X20

LX27X23 X25X15 X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

0312 645

21

7

20 24

22 23 2625

10 11 1312 1614 15 17

27

Y12Y10 Y16Y14 Y22Y20 Y26 COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1 COM3 Y15 Y17COM4 Y23 Y25 Y27Y21

X5

X0

X1

X2

X3 X7 X11 X13

X40VS/S

N24V

X6 X10 X12 X14 X16 X20

LX27X23 X25X15 X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0 31 2

IN

OUT

64 5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

0 31 2 64 5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

Y12

Y10

Y16

Y14

Y22

Y20

Y26

COM5

COM1

Y24

Y6

Y4

Y2

Y0

Y7

Y11

Y13

Y5

COM2

Y3

Y1

COM3

Y15

Y17

COM4

Y23

Y25

Y27

Y21

X5

X0

X1

X2

X3

X7

X11

X13

X4

0V

S/S

N24V

X6

X10

X12

X14

X16

X20

LX27

X23

X25

X15

X17

X21

X24

X26

X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0 31 2

IN

OUT

64 5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

0 31 2 64 5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

Y12

Y10

Y16

Y14

Y22

Y20

Y26

COM5

COM1

Y24

Y6

Y4

Y2

Y0

Y7

Y11

Y13

Y5

COM2

Y3

Y1

COM3

Y15

Y17

COM4

Y23

Y25

Y27

Y21

X5

X0

X1

X2

X3

X7

X11

X13

X4

0V

S/S

N24V

X6

X10

X12

X14

X16

X20

LX27

X23

X25

X15

X17

X21

X24

X26

X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

0312 645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

Y12Y10 Y16Y14 Y22Y20 Y26 COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1 COM3 Y15 Y17COM4 Y23 Y25 Y27Y21

X5

X0

X1

X2

X3 X7 X11 X13

X40VS/S

N 24V

X6 X10 X12 X14 X16 X20

LX27X23 X25X15 X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

0312 645

21

7

20 2422 23 2625

10 11 1312 1614 15 17

27

Y12Y10 Y16Y14 Y22Y20 Y26 COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1 COM3 Y15 Y17COM4 Y23 Y25 Y27Y21

X5

X0

X1

X2

X3 X7 X11 X13

X40VS/S

N 24V

X6 X10 X12 X14 X16 X20

LX27X23 X25X15 X17 X21

X24 X26X22

D4) D4)

FX

3U

-48M

FX

3U

RUN

POWER

ERROR

BATT

FX

3U

-48M

FX

3U

ERROR

RUN

BATT

POWER

03

12

IN

OUT

6

45

21

7

2024

222326

25

101113

1216

141

51

7

27

03

126

45

21

7

2024

222326

25

101113

1216

141517

27

B

A

B

3) When some sort of error occurs in a relay, triac or transistor

of the output unit/block, output may be kept on or off.

For output signals that may lead to serious accidents,

design external circuits and mechanisms to ensure safe

operations of the machine in such cases.

DESIGN

PRECAUTIONS

•Do not bundle the control line together with the main circuit or

power line. Do not lay the control line near them.As a rule, lay

the control line at least 100mm(3.94") or more away from the

main circuit or power line.

Noise may cause malfunctions.

•Install in a manner which prevents excessive force from being

applied to the connectors for peripheral device connections.

Failure to do so may result in wire breakage or failure of the

PLC.

Notes

•Simultaneously turn on and off the power supplies of the main

unit and extension devices.

•Even if the power supply causes an instantaneous power failure

for less than 10 ms, the PLC can continue to operate.

•If a long-time power failure or an abnormal voltage drop occurs,

the PLC stops, and output is turned off. When the power

supply is restored, it will automatically restart (when the RUN

input is on).

WIRING

PRECAUTIONS

•Cut off all phases of the power source externally before

installation or wiring work in order to avoid electric shock or

damage of product.

WIRING

PRECAUTIONS

•Connect the AC power supply wiring to the power supply

terminal as stated in this manual.

If an AC power supply is connected to a DC input/output

terminal (connector) or power supply terminal, the PLC will be

burnt out.

•Do not wire vacant terminals externally.

Doing so may damage the product.

•The main unit requires a class D ground (grounding resistance:

100Ωor less), with a 2mm2or larger wire used at the ground

terminal.

Do not connect the terminal to a ground wire common to a

heavy electrical system (refer to section 3.3).

•When drilling screw holes or wiring, cutting chips or wire chips

should not enter ventilation slits. such an accident may cause

fire, failures or malfunctions.

Notes

•Input/output wiring 50 to 100 m (164’1” to 328’1”) long will

cause almost no problems of noise, but, generally, the wiring

length should be less than 20 m (65’7”) to ensure the safety.

•Extension cables are easily affected by noise. Lay the cables

at a distance of at least 30 to 50 mm (1.19” to 1.97”) away from

the PLC output and other power lines.

DESIGN

PRECAUTIONS

3.1 Cable end treatment and tightening torque

For the terminals of FX3U series PLC, M3 screws are used.

The electric wire ends should be treated as shown below.

Tighten the screws to a torque of 0.5 N.m to 0.8 N.m.

•When one wire is connected to one terminal

•When two wires are connected to one terminal

3.2 Power supply specifications and example of

external wiring

→Refer to FX3U Series User's Manual - Hardware Edition.

3.2.1 Power supply specifications

The specifications for the power supply of the main unit are

shown in the following table.

*1 Does not include the power consumption of extension units /

special extension units, and of the extension blocks / special

extension blocks connected to those units.

For the power (current) consumed by the extension units/

blocks for input/output, refer to FX3U Series User's Manual -

Hardware Edition.

For the power consumed by the special extension blocks/

units, refer to refer to the appropriate manual.

*2 When input/output extension blocks are connected, the 24V

DC service power supply is consumed by the blocks, and

the current value to be used by the main unit is reduced.

*3 Cannot be used to supply power to an external destination.

The power is supplied to input/output extension blocks,

special extension blocks, special adapters and expansion

boards.

3.2.2 Example of external wiring (power supply)

100 to 240 V AC power is supplied to the main unit. For the details

of wiring work, refer to section 3.1.

3.3 Grounding

Ground the PLC as stated below.

•

Perform class D grounding. (Grounding resistance: 100

Ω

or less)

•

Ground the PLC independently if possible.

If it cannot be grounded independently, ground it jointly as shown

below.

•Use ground wires thicker than AWG14 (2 mm2).

•Position the grounding point as close to the PLC as possible to

decrease the length of the ground wire.

Item Specification

Supply voltage 100 - 240V AC (+10%,-15%)

Allowable

supply voltage

range

85 - 264V AC

Rated frequency 50/60Hz

Allowable instantaneous power

failure time

Operation can be continued

upon occurrence of

instantaneous power failure for

10 ms or less.

When the supply voltage is 200

V AC, the time can be changed

to 10 to 100 ms by editing the

user program.

Power

fuse

FX3U-16Mto 32M250V AC 3.15A

FX3U-48Mto 80M250V AC 5A

Rush current 30 A max. 5 ms or less/100 V AC

65 A max. 5 ms or less/200 V AC

Consumed

power*1

FX3U-16M30W

FX3U-32M35W

FX3U-48M40W

FX3U-64M45W

FX3U-80M50W

24-VDC

service

power

supply*2

FX3U-16Mto 32M400 mA or less

FX3U-48Mto 80M600 mA or less

5-VDC built-in power supply*3 500 mA or less

φ

3.2 (0.13")

6.2 mm (0.24")

or less

’[Žq

Terminal

screw Solderless

terminal

Terminal

6.2 mm (0.24")

or less

φ

3.2 (0.13")

6.3 mm(0.25")

or more

6.3 mm(0.25")

or more

Terminal

screw Solderless

terminal

Terminal

6.2 mm (0.24")

or less

6.2 mm (0.24")

or less

φ

3.2 (0.13")

φ

3.2 (0.13")

AC power supply of

100 - 240 V AC

PL

Power on Emer-

gency

stop

MC

MC

DC power

supply

Power supply for loads connected

to PLCoutput terminals

DC AC

MCMC

*

Fuse

L

N

PLC

*Class D grounding

See section 3.3 for

details.

PLC Other

device PLC Other

device PLC Other

device

Joint grounding

(acceptable) Common grounding

(unacceptable)

Independent

grounding (best)