3. Name of Each Part and their settings

3.1 Name of Each Part

The name of each part and their settings in the AJ65BT-64AD are shown.

MITSUBISHI AJ65BT-64AD X10 X1

STATION NO.B RATE

CH. OFFSET GAIN. RESET

PW

RUN

L RUN

SD

RD

L ERR.

MELSEC

012

3

4

012

3

4

5

6

012

3

4

5

6

7

89

12

3

4

(Side)

2) 1) 9)

8) 7) 3) 4) 5) 6)

No. Name and

appearance

Description

1) Station number

setting switch

1) 10

1) 1

The station number for the AJ65BT-64AD is set in

the range 1 to 64.

(factory default: 00)

2) Transmission

baud rate setting

Setting

number

Transmission baud rate

switch 0 156kbps (factory default)

1 625kbps

2 2.5Mbps

3 5Mbps

4 10Mbps

Other than

0 to 4

Unusable.

(The L ERR. LED turns on, and results in a

communication error.)

3) Channel

selection switch

Selects the channel (1 to 4) to perform the offset and gain

adjustment. When a value other than 1 to 4 is selected, no

processing is performed. (factory default: 1)

4) OFFSET switch By turning this switch on during the test mode, the analog input

value at that time is stored in the AJ65BT-64AD as an offset value.

5) GAIN switch By turning this switch on during the test mode, the analog input

value at that time is stored in the AJ65BT-64AD as a gain value.

6) RESET switch The initialization of the I/O signals, remote register, and operation

processing is performed for the AJ65BT-64AD. By turning this switch

on, the AJ65BT-64AD initial data processing request flag turns on.

7) Operation status LED Name Description

display LED PW LED ON : Power supply ON

OFF : Power supply OFF

RUN LED Normal mode ON : Normal operation.

Flashing : Read/write data error

occurred.

OFF : 24VDC power supply

shutoff or watchdog

timer error occurred.

Test mode ON : Offset switch or gain switch

is ON.

OFF : Offset switch or gain switch

is OFF.

L RUN LED ON : Normal communication

OFF : Communication cutoff (time expiration error)

SD LED ON during data transmission

RD LED ON during data receive

L ERR. LED ON : Communication data error

Flashing : Communication data error

OFF : Normal communication

8) Terminal module 13579111315171921232527

2 4 6 8 101214161820222426

DA DG

DB SLD SLD(FG) TEST TEST

CH3

I+

CH1

I+

CH2

I+

CH3

V+

CH4

I+

+24V 24G FG1

AG

SLDSLD

CH1

V+

CH2

V+

CH4

V+

COM COM

COM COM

+24V 24G COM COM

COM COM

Test mode setting terminal: By short-circuiting between the

terminals, the test mode is started.

9) Analog input

range setting pin

C

D

A

B

Set the analog input range.

(Factory default : A)

* When using in the range 0 to 20mA, use D.

3.2 Offset/Gain Setting

When changing the I/O conversion characteristics, follow the procedure below.

RUN

CH

RUN OFFSET

V

V+

V+

COM

COM

A

I+

V

V+

V+

COM

COM

A

I+

OFF

ON

RUN GAIN

ON

Start

End

No

Yes

Set the setting pin to the range to use.

Short-circuit the test mode terminal

(between 8 to 10).

Set the "channel selection switch" to the

channel to be changed.

Set to the

channel to

be set.

Add the voltage or current that will be the

offset value.

For voltage

For current

For voltage

For current

Turn on the offset switch.

Add the voltage or current that will be the

gain value.

Turn on the gain switch.

Adjust other channels?

Release the test mode terminal

(between 8 to 10).

Remark

The offset value and gain value are as follows.

(a) The offset value is the analog input value (voltage or current) which a

minimum digital output value.

(b) The gain value is the analog input value (voltage or current) which a

maximum digital output value.

4. Loading and Installation

The following is explanations of the handling precautions and installation

environment which is common to modules when handling AJ65BT-64AD from

unpacking to installation.

For the details of loading and installation of the module, refer to User's Manual of

programmable controller CPU module to be used.

4.1 Handing Precautions

The precaution when handling the AJ65BT-64AD are described below:

(1) Because the case of the module is mad of resin, be careful not to drop it or

expose it to strong impact.

(2) Perform the tightening of the module mounting screws in the folowing range.

Screw position Tightening torque range

Module mounting screw (M4 screw) 78 to 118 N⋅cm

Terminal block terminal screw (M3.5 screw) 59 to 88 N⋅cm

Terminal block mounting screw (M4 screw) 78 to 118 N⋅cm

4.2 Installation Environment

Do not install the A series programmable controller in the following environments.

(1) Where the ambient temperature exceeds the 0 to 55°C range.

(2) Where the ambient humidity exceeds the 10 to 90 % RH range.

(3) Where condensation is produced by sudden temperature changes.

(4) Where corrosive or combustible gas is present.

(5) Where dust, iron powder and other conductive powder, oil mist, salt, or

organic solvents are prevalent.

(6) In direct sunlight.

(7) Where a strong electric or magnetic field is generated.

(8) Where vibration and shock may be applied directly to the module.

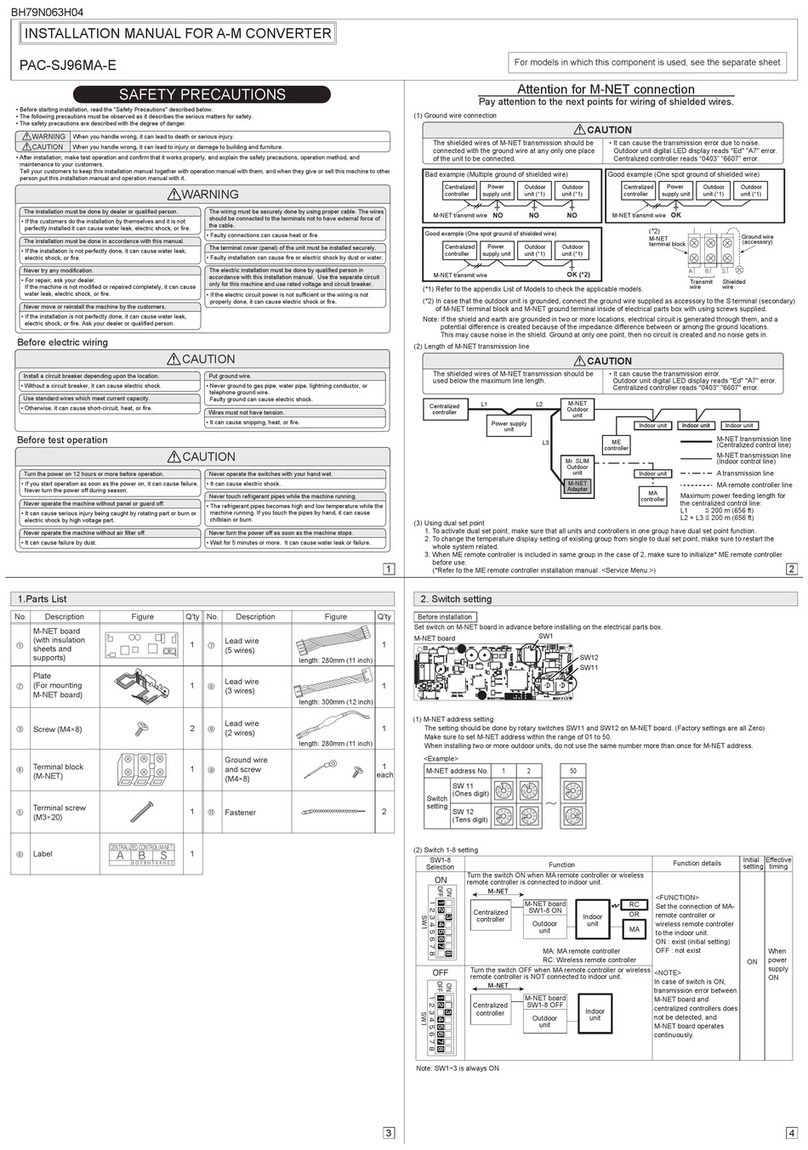

5. Data Link Cable Wiring

The wiring of the CC-Link dedicated cable which connects the AJ65BT-64AD and

the master module is described.

5.1 CC-Link dedicated cable connections

The CC-Link dedicated cable connections between the AJ65BT-64AD and

master module are as follows:

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

Terminate

resistor

DA

DB

DG

SLD

FG

Terminate

resistor

CC-Link dedicated

cable

CC-Link dedicated

cable

J65BT-64AD I/O module, etc.Master module side

Terminate

resistor

(Blue)

(White)

(Yellow)

6. Wiring

The precautions and module connection example for wiring are described.

6.1 Wiring Precautions

To obtain maximum performance from the functions of AJ65BT-64AD and

improve the system reliability, an external wiring with high durability against noise

is required.

The precautions when performing external wiring are as follows:

(1) Use separate cables for the AC and AJ65BT-64AD external input signals, in

order not to be affected by the AC side surge or conductivity.

(2) Do not bundle or place with load carrying wires other than the main circuit

line, hight voltage line, or programmable controller. Noises, surges, or

conductivity may affect the system.

(3) Place a one-point grounding on the programmable controller side for the

shielded line or shielded cable. However, depending on the external noise

conditions, it may be better have a grounding externally.

6.2 Module Connection Example

The connection examples for voltage input and current input are shown below:

(1) For voltage input

V+

I+

COM

SLD

*4 CH1

*1 Shield

*1 Shield

*3

*2

250

500k

500k

V+

I+

COM

SLD

CH4

*5

250

500k

500k

AG

FG1

Signal source 0 to ±10V

Signal source 0 to ±20mA

*1 Use a two-core twisted shield line for the power cable.

*2 Indicates the AJ65BT-64AD input resistor.

*3 For the current input, be sure to connect the (V+) and (I+) terminals.

*4 When noise or ripple occurs with the external cable, connect a condenser

with about 0.1 to 0.47μF25WV between the terminal V and COM.

*5 Always perform grounding for FG1. When there is a lot of noise, it may be

better to ground AG as well.

If the grounding wiring (grounding yes/no) is changed after the offset and

gain are set, perform the setting of the offset/gain values again.

7. External Dimension Diagram

(0.37)

2- 4.5 (0.18)

installation hole

Unit: mm (inch)

MITSUBISHI AJ 65BT-64AD X10 X1

STATION N O.B RATE

CH. OFFSET GAIN. RESET

PW

RUN

L RUN

SD

RD

L ERR.

MELSEC

012

3

4

012

3

4

5

6

012

3

4

5

6

7

89

12

3

4

NP

9.5

63(2.48)

142.9 (2.63)

151.9 (5.98)

56(2.2)

65(2.56)

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be

the cause of Mitsubishi; machine damage or lost profits caused by faults in the

Mitsubishi products; damage, secondary damage, accident compensation

caused by special factors unpredictable by Mitsubishi; damages to products

other than Mitsubishi products; and to other duties.

For safe use

yThis product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in a

device or system used in purposes related to human life.

yBefore using the product for special purposes such as nuclear power, electric

power, aerospace, medicine or passenger movement vehicles, consult with

Mitsubishi.

yThis product has been manufactured under strict quality control. However, when

installing the product where major accidents or losses could occur if the product

fails, install appropriate backup or failsafe functions in the system.

Country/Region Sales office/Tel

When exported from Japan, this manual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permission.

Specifications subject to change without notice.

Printed in Japan on recycled paper.

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI 5-CHOME, HIGASHI-KU, NAGOYA, JAPAN

Country/Region Sales office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061, U.S.A.

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria

Tecnica Ltda.

Rua Correia Dias, 184,

Edificio Paraiso Trade Center-8 andar

Paraiso, Sao Paulo, SP Brazil

Tel : +55-11-5908-8331

Germany Mitsubishi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Hertfordshire.,

AL10 8XB, U.K.

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo-Ingr.2

Via Paracelso 12, I-20041 Agrate Brianza.,

Milano, Italy

Tel : +39-039-60531

Spain Mitsubishi Electric Europe B.V. Spanish

Branch

Carretera de Rubi 76-80,

E-08190 Sant Cugat del Valles,

Barcelona, Spain

Tel : +34-93-565-3131

France Mitsubishi Electric Europe B.V. French

Branch

25, Boulevard des Bouvets, F-92741

Nanterre Cedex, France

TEL: +33-1-5568-5568

South Africa Circuit Breaker Industries Ltd.

Private Bag 2016, ZA-1600 Isando,

South Africa

Tel : +27-11-928-2000

Hong Kong Mitsubishi Electric Automation

(Hong Kong) Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, Hong Kong

Tel : +852-2887-8870

China Mitsubishi Electric Automation

(Shanghai) Ltd.

4/F Zhi Fu Plazz, No.80 Xin Chang Road,

Shanghai 200003, China

Tel : +86-21-6120-0808

Taiwan Setsuyo Enterprise Co., Ltd.

6F No.105 Wu-Kung 3rd.Rd, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea Mitsubishi Electric Automation Korea

Co., Ltd.

1480-6, Gayang-dong, Gangseo-ku

Seoul 157-200, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 Alexandra Road #05-01/02,

Mitsubishi Electric Building,

Singapore 159943

Tel : +65-6470-2460

Thailand Mitsubishi Electric Automation (Thailand)

Co., Ltd.

Bang-Chan Industrial Estate No.111

Moo 4, Serithai Rd, T.Kannayao,

A.Kannayao, Bangkok 10230 Thailand

Tel : +66-2-517-1326

Indonesia P.T. Autoteknindo Sumber Makmur

Muara Karang Selatan, Block A/Utara

No.1 Kav. No.11 Kawasan Industri

Pergudangan Jakarta - Utara 14440,

P.O.Box 5045 Jakarta, 11050 Indonesia

Tel : +62-21-6630833

India Messung Systems Pvt, Ltd.

Electronic Sadan NO:III Unit No15,

M.I.D.C Bhosari, Pune-411026, India

Tel : +91-20-2712-3130

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, Rydalmere,

N.S.W 2116, Australia

Tel : +61-2-9684-7777

Voltage Current

A 0 to 10V (0 to 20mA)*

B 1 to 5V 4 to 20mA

C -10 to 10V -20 to 20mA

D 0 to 5V 0 to 20mA

(2) For current input