-5

CONTENTS

SAFETY PRECAUTIONS ...............................................................................A-1

REVISIONS ....................................................................................................A-3

CONTENTS....................................................................................................A-4

About the Manuals..........................................................................................A-4

Conformance to the EMC Directive/Low Voltage Directive .............................A-4

1. OVERVIEW ................................................................................................... 1

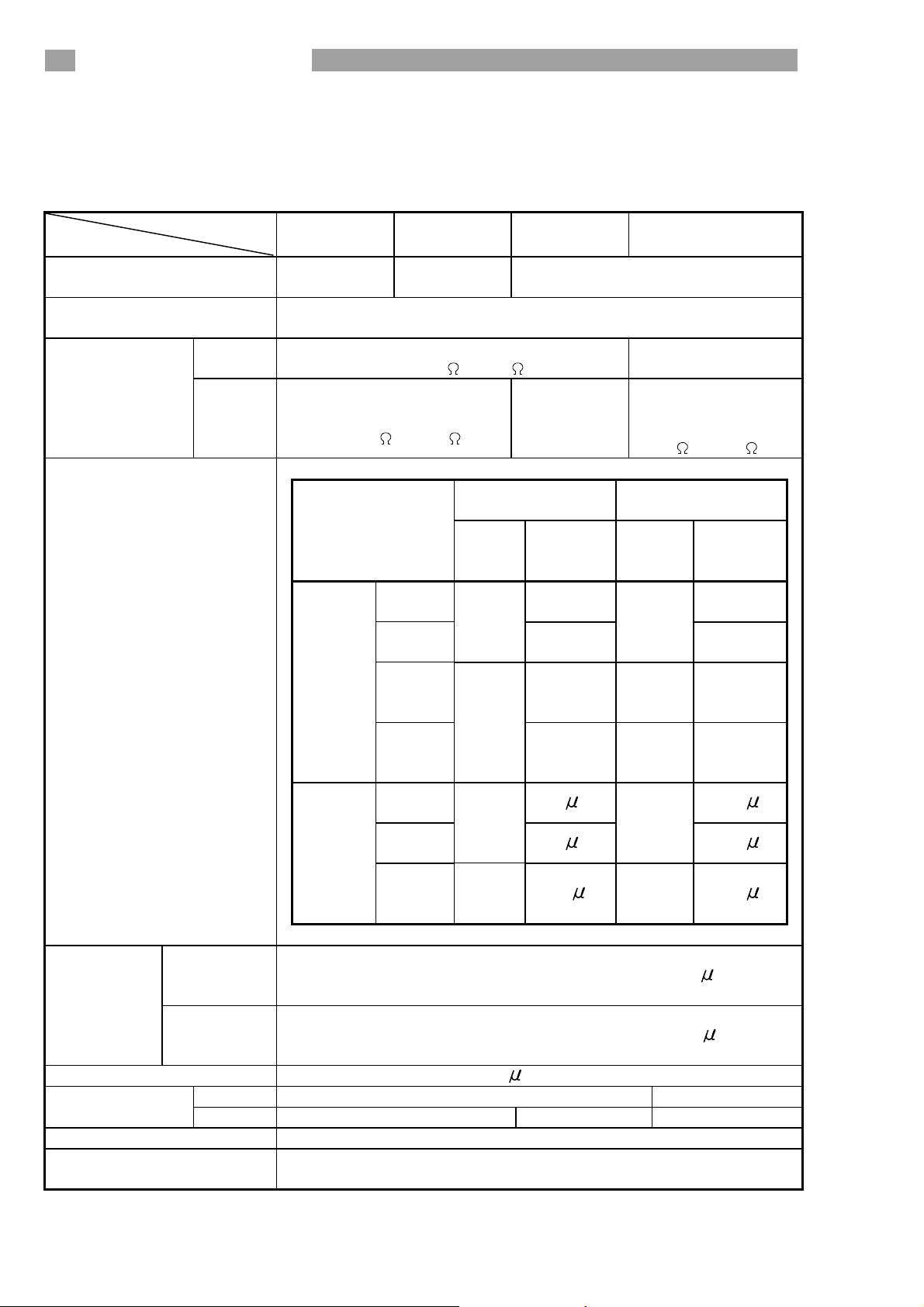

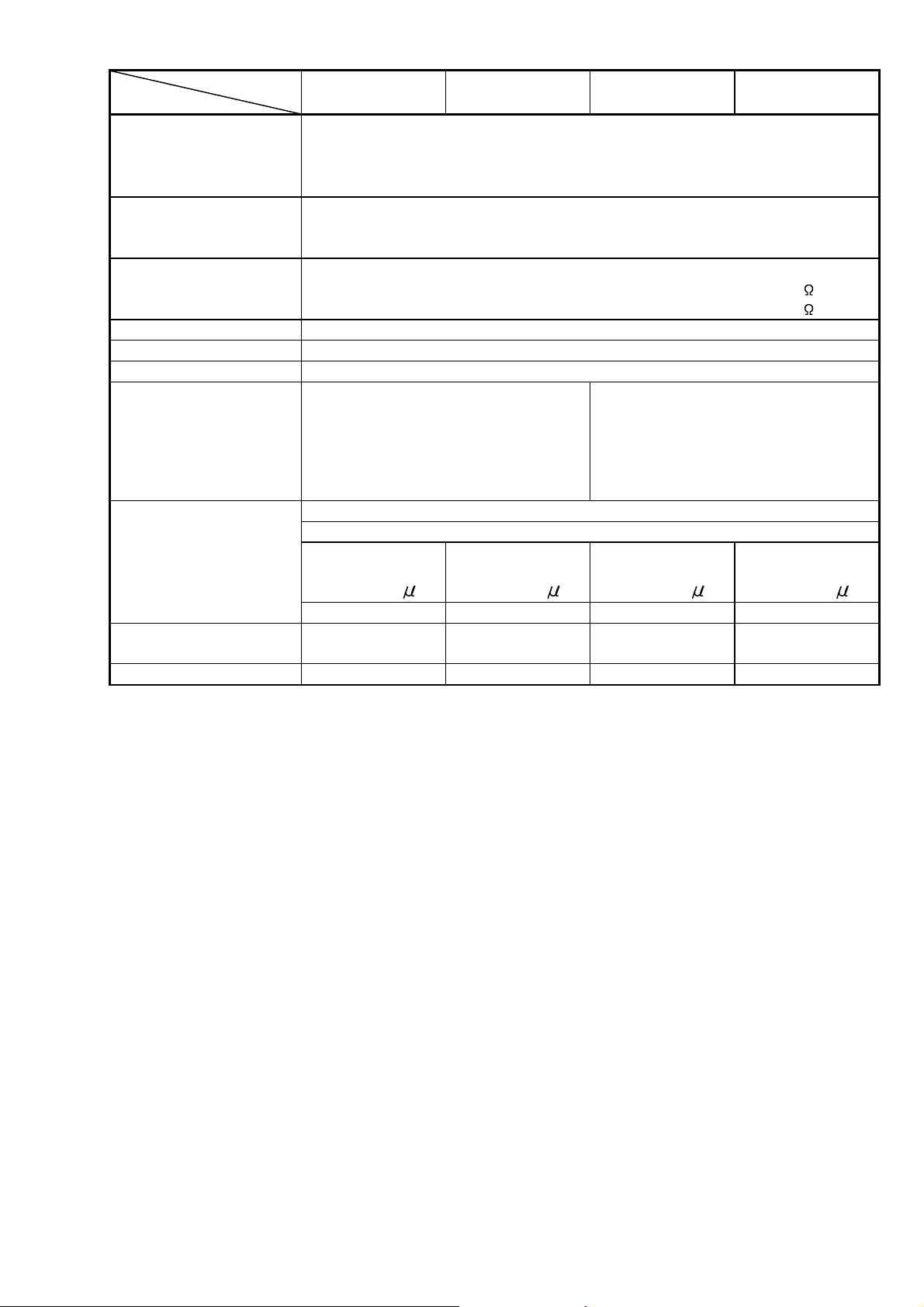

2. SPECIFICATIONS......................................................................................... 2

3. PART NAMES ............................................................................................... 4

4. HANDLING PRECAUTIONS.......................................................................... 6

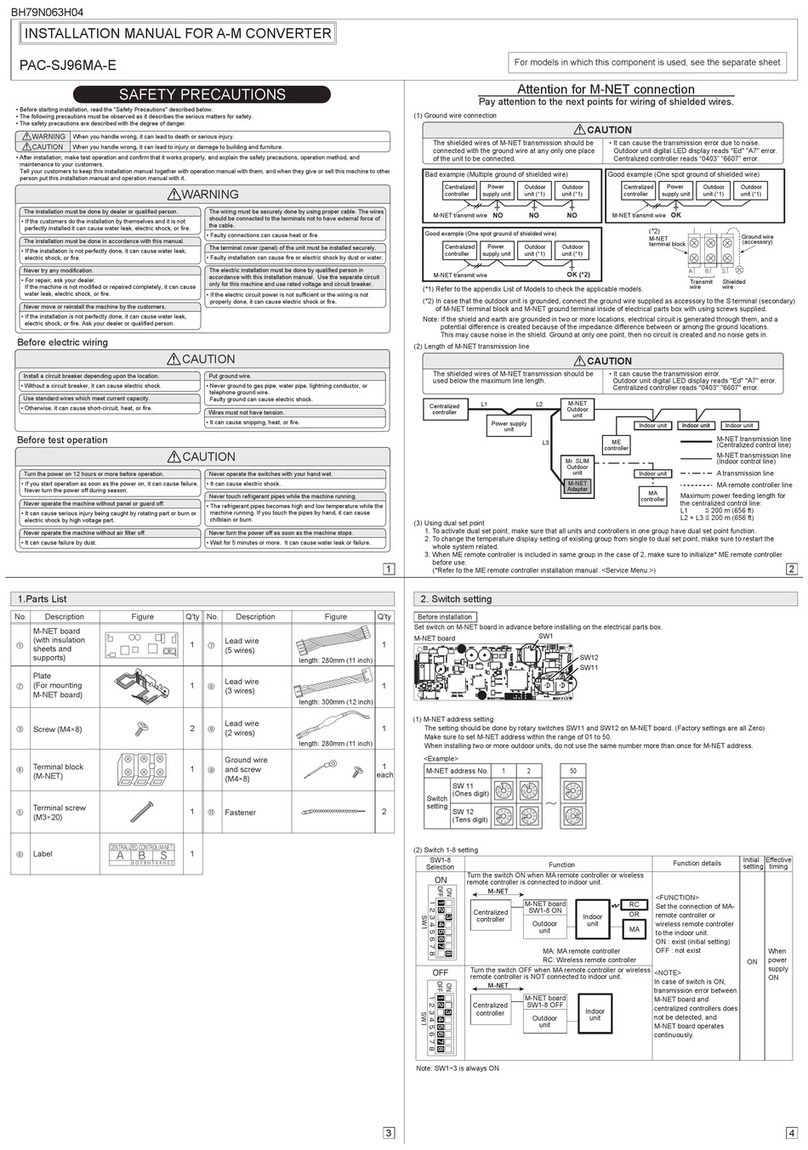

5. WIRING ......................................................................................................... 6

5.1 Wiring Precautions ................................................................................... 6

5.2 External Wiring......................................................................................... 7

5.3 Switch setting for intelligent functional module ......................................... 9

6. EXTERNAL DIMENSIONS .......................................................................... 11

About Manual

The following manual is also related to this product.

In necessary, order it by quoting the details in the table below.

Related Manual

Manual Name Manual Number

(Model Code)

Digital-Analog Converter Module User's Manual

Q62DAN/Q64DAN/Q68DAVN/Q68DAIN/Q62DA/

Q64DA/Q68DAV/Q68DAI/GX Configurator-DA

(SW2D5C-QDAU-E)

SH-080054

(13JR02)

Compliance with the EMC and Low Voltage Directives

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low

Voltage Directives when incorporating the Mitsubishi programmable

controller (EMC and Low Voltage Directives compliant) into other

machinery or equipment, refer to Chapter 9 "EMC AND LOW VOLTAGE

DIRECTIVES" of the QCPU User's Manual (Hardware Design,

Maintenance and Inspection).

The CE mark, indicating compliance with the EMC and Low Voltage

Directives, is printed on the rating plate of the programmable controller.

(2) For the product

For the compliance of this product with the EMC and Low Voltage

Directives,refer to Section 9.1.3 "Cables" in Chapter 9 "EMC AND LOW

VOLTAGE DIRECTIVES" of the QCPU User's Manual (Hardware Design,

Maintenance and Inspection).