CONTENTS

Contents

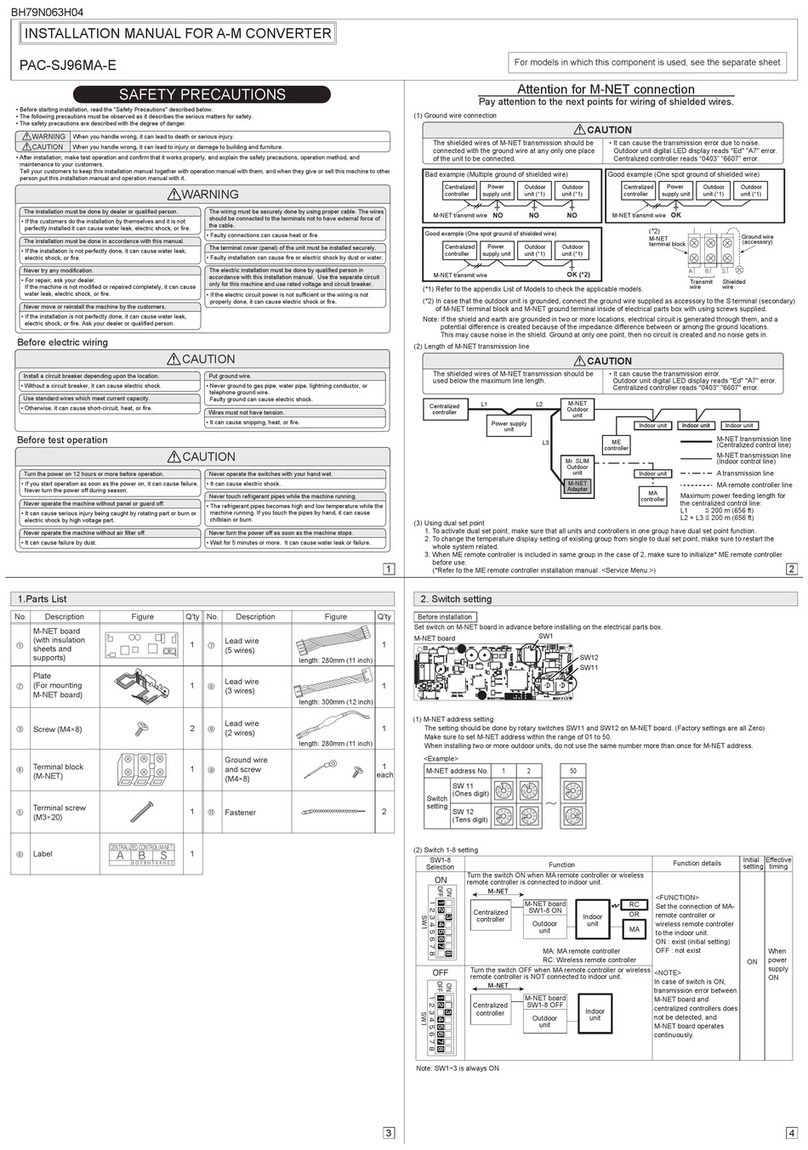

Safety precautions ................................................................................ 1-3

Special features .................................................................................... 4

Features and functions.......................................................................... 5-7

Front panel ............................................................................................. 5

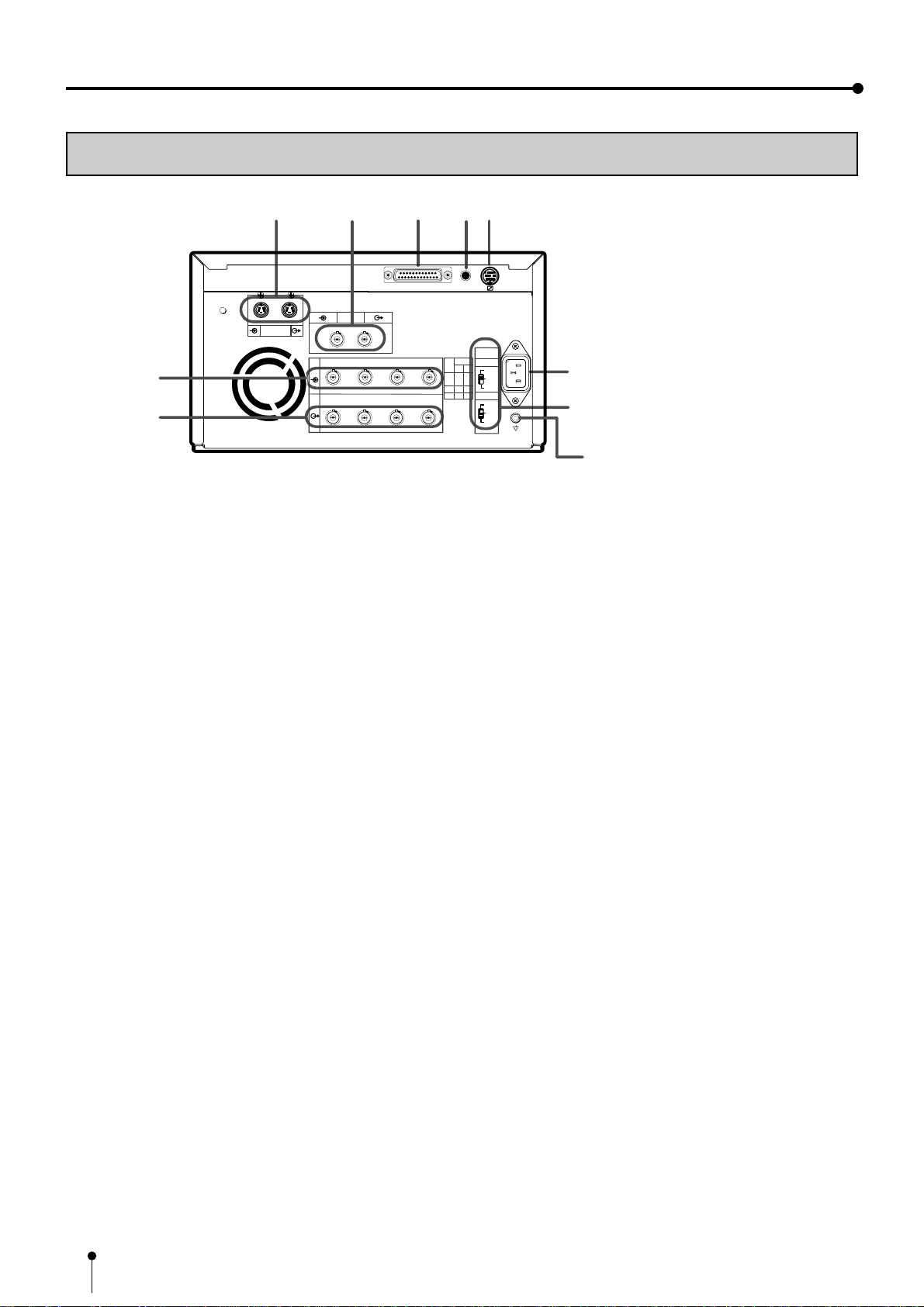

Rear panel ............................................................................................. 6

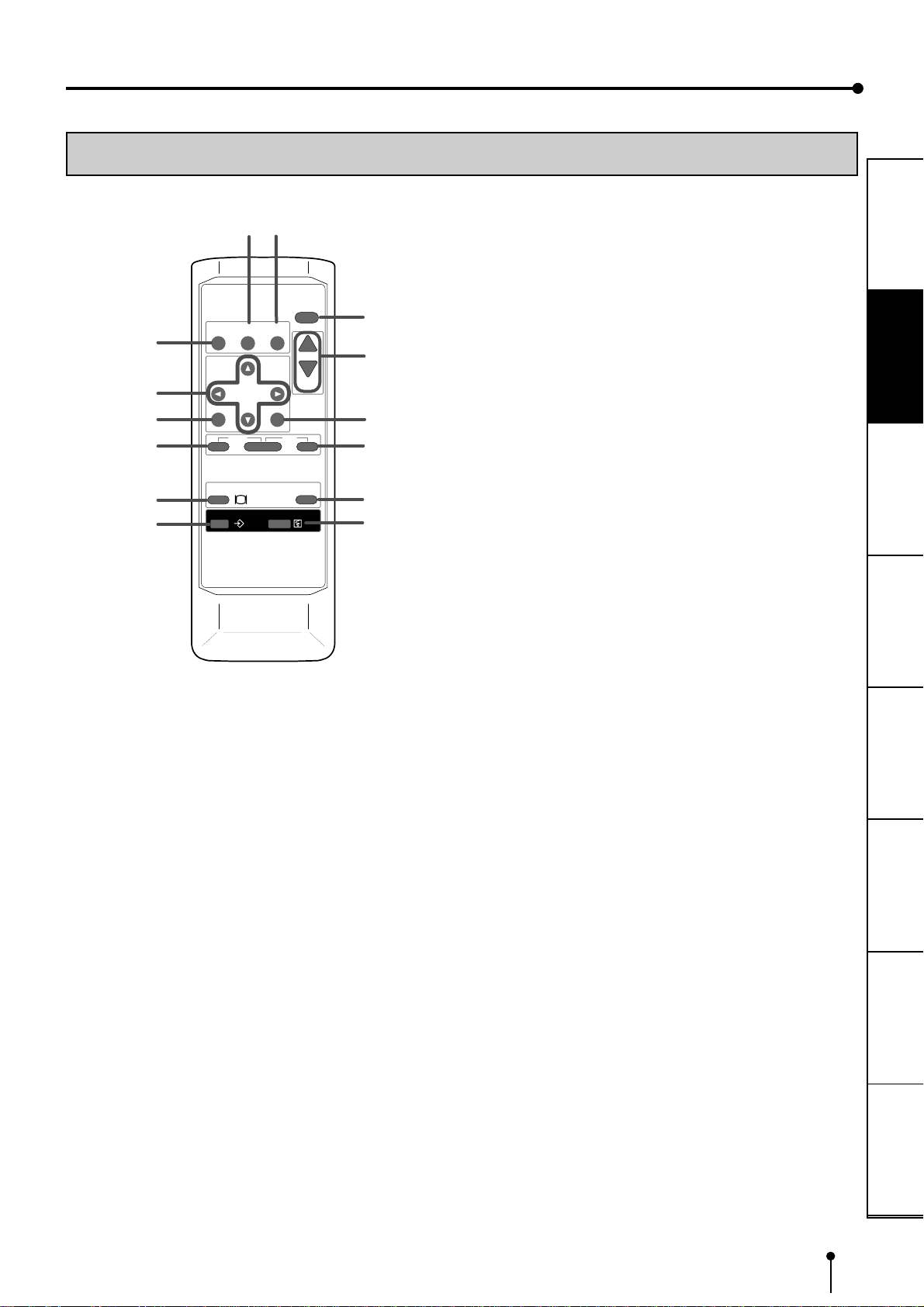

Remote control....................................................................................... 7

Connections .......................................................................................... 8-13

Connection with a monitor ..................................................................... 8-10

Connection with video or S-video signal equipment .............................. 10

Connection with RGB analog signal equipment..................................... 11

Connection with RS-232C equipment.................................................... 12-13

Before operation.................................................................................... 14-18

Paper sheet set and ink sheet................................................................ 14

Removing transport screw and protective cushion ................................ 14-15

Installation of print paper........................................................................ 15-16

Installation of ink sheet .......................................................................... 16-17

Usage and keeping of paper sheet set .................................................. 18

Printing (Basic)...................................................................................... 19-25

Before printing........................................................................................ 19-21

Memory print .......................................................................................... 22-25

Memorizing and printing an image...................................................... 22

Selecting memorized image to print.................................................... 23

Image memorizing with page increment set on .................................. 23

Image size and number of memory pages.......................................... 24

Multiple copy or continuous printing.................................................... 25

Printing (Special)................................................................................... 26-31

Multi print ............................................................................................... 26-27

Separate print ........................................................................................ 28

External remote terminal 1..................................................................... 29

External remote terminal 2..................................................................... 30-31

Setting the functions (Menu chart) ........................................................ 32-35

Monitor display chart.............................................................................. 32-33

LCD display chart................................................................................... 34-35

Adjustments & settings (MAIN MENU).................................................. 36-44

MAIN MENU items................................................................................. 36

Operating MAIN MENU.......................................................................... 36-37

COLOR ADJ (Colour adjustment).......................................................... 38

ANALOG ADJ (Analog image adjustment) ......................................... 38

INPUT (Signal selection)........................................................................ 38

ADDITIONAL (Special print setting)....................................................... 39

PRINT (Print setting) .............................................................................. 40-41

COMMENT (Making a comment)........................................................... 42-43

SIZE/TIMING (Setting size and timing) .................................................. 43-44

Adjustments & settings (SERVICE MENU)........................................... 45-50

SERVICE MENU items .......................................................................... 45

Operating SERVICE MENU ................................................................... 45

KEY SET (Setting functions of buttons) ................................................. 46-47

SIGNAL SET1(Signal setting display).................................................... 47-48

SIGNAL SET2(Signal setting display).................................................... 48

PRINT SET (Print setting display).......................................................... 48-49

SYSTEM SET(System setting display) .................................................. 49

REMOTE SET(Remote signal setting display)....................................... 49-50

PREVIOUS ERROR(Error display) ........................................................ 50

Adjusting image without using remote control ....................................... 50

Error messages..................................................................................... 51

Before calling for service....................................................................... 52-53

Overcoming paper jams ........................................................................ 54

Cleaning ................................................................................................ 55-56

Spec & options ...................................................................................... 57