page 4 of 27 File: SM1280_r7eng -April 2017 - Technical note: SM1280

SM 1280

Handling Warnings

The SM1280x has two handles on the front panel to help

unpacking and handling operations: never use only the

handles to lift the equipment but support the weight with

an appropriate base on bottom!

The handles do not withstand the off-center weight of the

equipment (35 kg = 77 lbs).

General Description

The SM1280x is able to supply the power required by a

magnetron type YJ1600 (National) or PM60 (Panasonic) or

H3881 (Hitachi) or E 3327 (Toshiba), with nominal power of

6 kW @ 2.45 GHz.

The output power can be adjusted continuously, from 10% up

to 100%, using an external analog signal from 1 to 10Vdc,

orbyremotecontrol,throughledbusinterfaceorbyfront

panel commands, depending from model. The basic model

does not have any local command.

The unit, in addition to power the magnetron, has several

features and commands to control and power the magnetron’s

accessories.

The SM1280x has been developed to power and monitor our

remotable microwave head type TMx6x.

The SM1280x unit may also be used to power microwave

generators (heads) developed by others manufacturers under

condition that they are electrically compatible: moreover it is

mandatorytouseourlamenttransformerFIL200toguarantee

aproperlamentreductioncurve.Seetheelectricalspecica-

tions of the unit on the next pages.

The reduced height of the rack (only 7 HE, corresponding

to 310 mm) allows to use small cabinet, even in big plant:

i.e. in a standard cabinet with an height of 2 meters, arranged

to receive 19” racks, up to 5 SM1280x units may be easily

installed.

Theusermustprovideapropercoolingow:thecoolingair

enter into the unit from the front side, it passes through the

internal circuits and components, then it goes out from the

back.Theintakeairowisapprox.200m3/h.

The SM1280 is designed to be an alternative of the existing

SM1180 serie, when is needed a network connectivity, not

available on the previous model.

The SM1280 is available in both European and Japanese/US

voltages.

The SM1280 carries new features mainly driven by the new

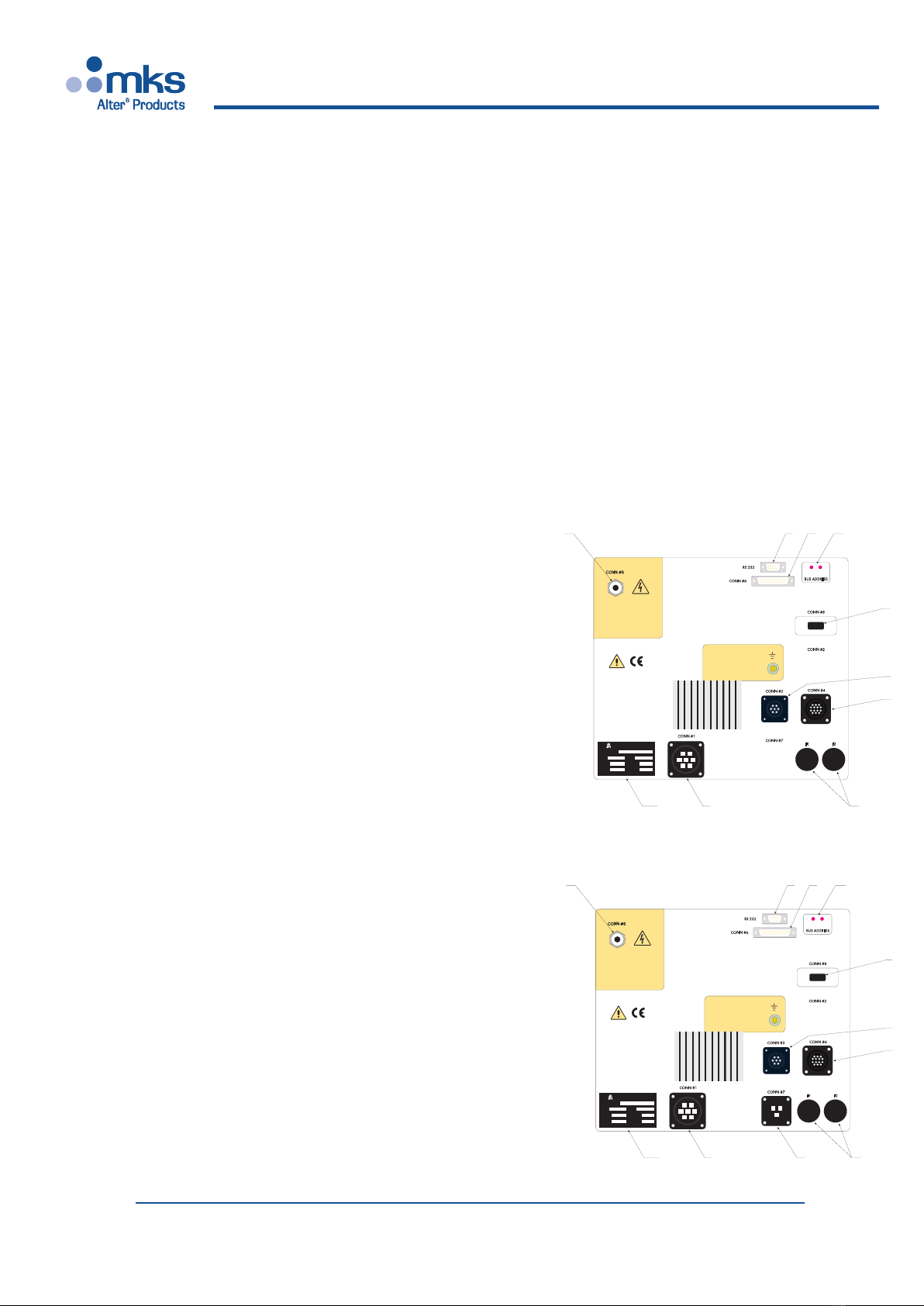

CPU core and is offered in 6 versions:

- “Basic” version (vers. 0) has only one RS 232 standard port,

which allows to drive/manage the unit with a simple software

(like our “Front Panel” package distributed freely).

- “Bus” version (vers. 1) which implements an industrial bus

interfacelikeModbus/TCPorProbusorProNET,etc.,

allowing connection of multiple devices on the same bus.

-”Display” version (vers. 2) includes front panel commands

and LCD display as well as the features of the basic version.

- “Aux IN” version (vers. 50-51) has a separate connector

for input of Auxiliary voltage which allows to manage safety

shut-down of main power but keeping alive the unit’s CPU.

Thevers.51hasthesamecongurationwiththeeldbus

connector.

- “Legacy SM1180” version (vers. 22) is a full replacement

for installation that uses the former SM1180, except minor

changes. See relevant chapter.

-Seethenalchapater“Howtoorder”formoredetailsand

p/n.

SM1280 Range Overview

MODELABBREV. BASIC BUS DISPLAY AUX-IN Legacy

SM1180

Version no. 0 1 2 50 51 22

External Control (PLC) possible

LED Panel Indicators n.a. n.a. n.a.

Local Commands (Manual) n.a. n.a. n.a. n.a.

Graphic Interface n.a. n.a. n.a. n.a.

Network Control n.a. n.a. n.a. n.a.

RS 232 Control n.a. n.a.

Separate Input for Aux Voltages n.a. n.a. n.a. n.a.

Firmware Upgrade

*: Version 20 & 32 are not described in this manual. See past revision 5.