8

2.

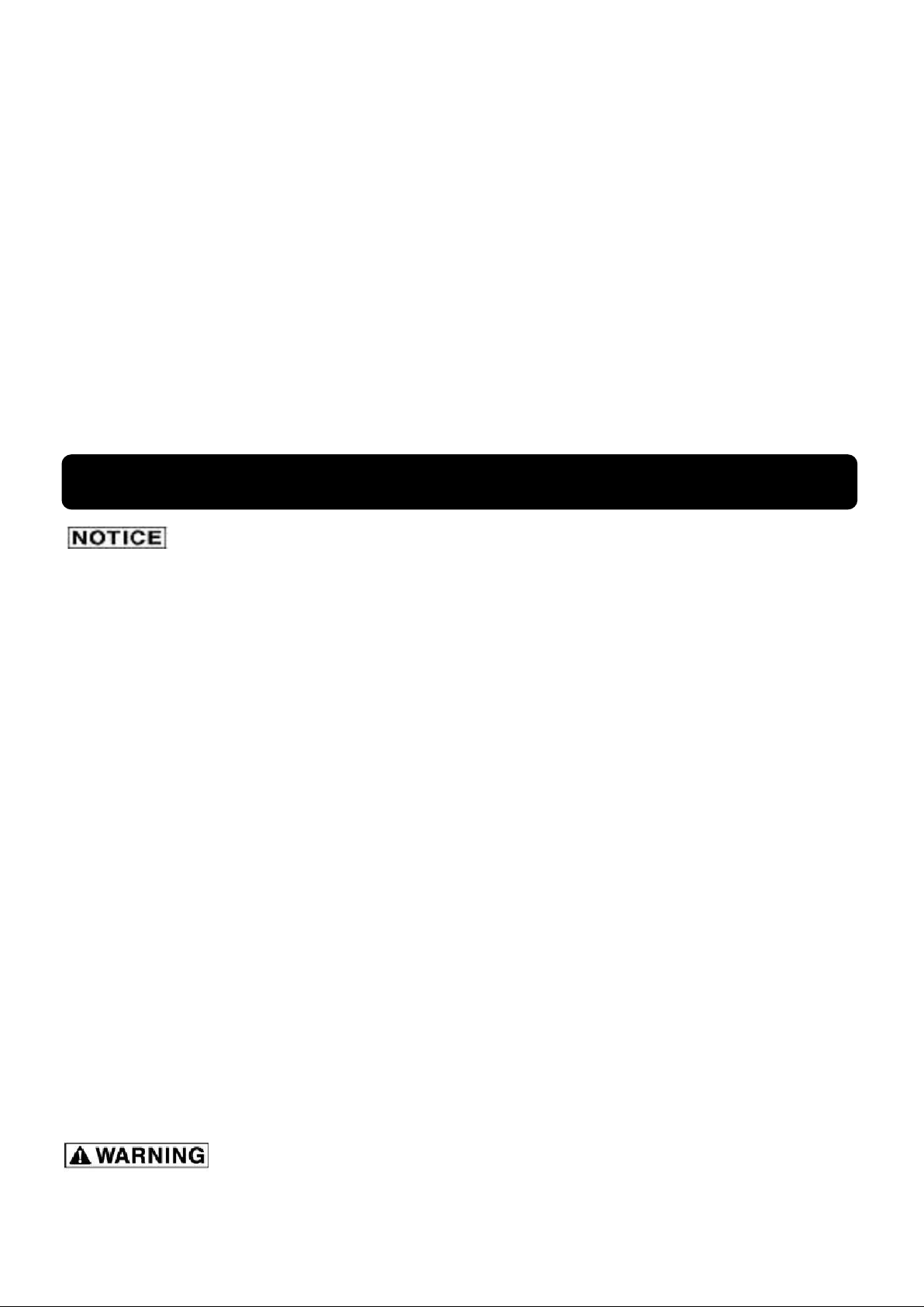

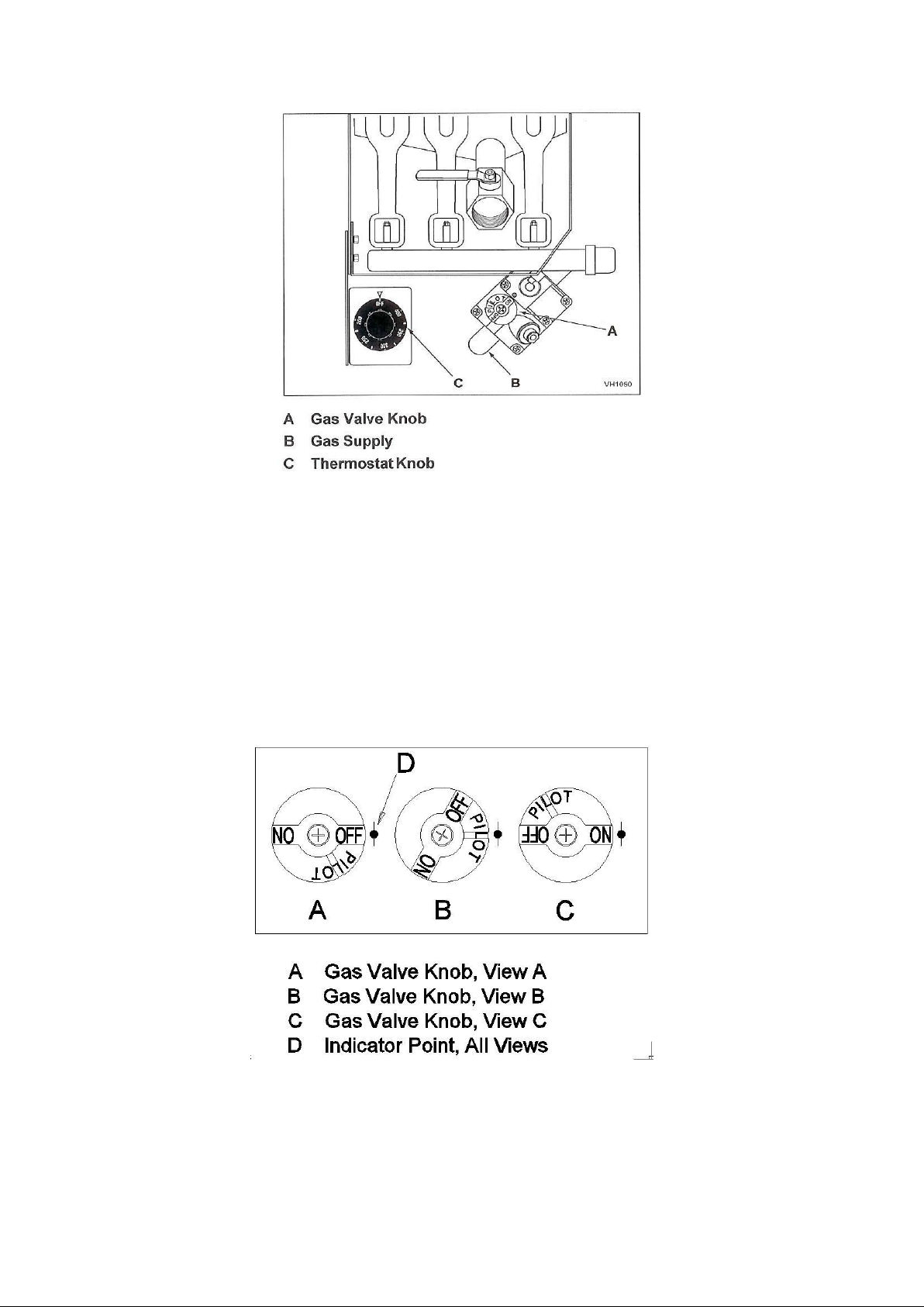

To keep the pilot lit, turn the gas valve to “L” in Pilot.

3.

To shut off all gas to the system, including the pilot, turn the gas valve knob to OFF.

EXTENDED SHUTDOWN

1.

Turn the thermostat knob to OFF.

2.

Push in the pilot knob and turn to OFF.

3.

Thoroughly drain the fryer. Refer to DRAINING THE FRYER.

4.

Clean the fryer according to CLEANING.

5.

Turn off the main gas shutoff valve.

BASIC FRYING INSTRUCTION

1. Set the desired temperature and allow shortening to heat up to that temperature.

2. Fry items that are about the same size together to ensure equal doneness.

3. Drain or wipe dry raw or wet foods to minimize splatter when lowering into hot shortening.

4. Do not overfill baskets.

5. Carefully lower basket into oil.

6. When frying doughnuts and fritters, turn product only once during frying.

7. When cooking French fries or onion rings, shake the basket several times in a way that does not splatter the

shortening.

8. Batter-covered foods should be dropped carefully, one by one, into shortening or basket. If you use the basket,

first dip the basket into the shortening to reduce batter-build up on basket surfaces.

9. When frying is completed, remove basket or product. Hang basket on rear hanger.

EXTENDING SHORTENING MAINTENANCE

Shortening life can be extended by the following guidelines:

Do not salt foods over the fryer.

Use good-quality shortening.

Filter shortening daily (at a minimum).

Replace shortening if it becomes poorly flavored.

Keep equipment and surrounding clean.

Set thermostat correctly.

Remove excess moisture and particles from food products before placing on fryer.

DRAINING THE TANK

1.

Turn the thermostat to OFF.

2.

To keep the pilot lit, turn the gas valve to PILOT.

3.

Direct the drain spout into the container to drain the tank.

4.

Open the drain valve. The oil will drain into the container. When the container is full or the fryer tank is

empty, close the valve. Repeat this step until the fryer is empty.

5.

Clean the tank once a week if necessary.

6.

Once tank is completely empty, add new shortening and set thermostat to desired temperature.

DAILY FILTERING

Hot oil and hot parts can cause burns. Use care when operating, cleaning, and

servicing the fryer.

a. Filter shortening at least once a day. Refer to the instructions provided with the filtering equipment.

b. A cold fryer will not drain properly. Always filter shortening between 250F and 350F. The shortening in the cold

zone area will remain hard if the heat is only on for a few minutes. If necessary, use the clean-out rod to

carefully stir the hard shortening to an area above the cold zone where it will melt. Use the tank brush to help

clear sides and tubes of debris.