For Units being Converted from Natural Gas

to Propane Gas Concurrently

Follow carefully the propane conversion instructions, found

in Bulletin 75-511, using the proper high altitude main burner

orifices called out in this literature (75-535) instead of the

orifices in propane conversion kit.

SELECTION OF THE PROPER KIT

To select the proper high altitude kit you need to know the

specifics of the heater you will be converting, and the altitude

it will be going into. If the high altitude kits are ordered at the

same time as the unit heater, all pertinent information relative to

the heater can be obtained from the catalog. If the high altitude

kit is needed after the unit heater is in the field, you need to

refer to the carton label or unit heater serial plate to obtain the

necessary information. Figure 8.2 shows a portion of the unit

heater serial plate where this information may be obtained.

Referring to this figure, the prefix letters and successive

numbers which are needed for kit selection are BV 100. The

letters identify the model and the numbers the size of the unit.

To determine the type of gas the unit is designed for, see the

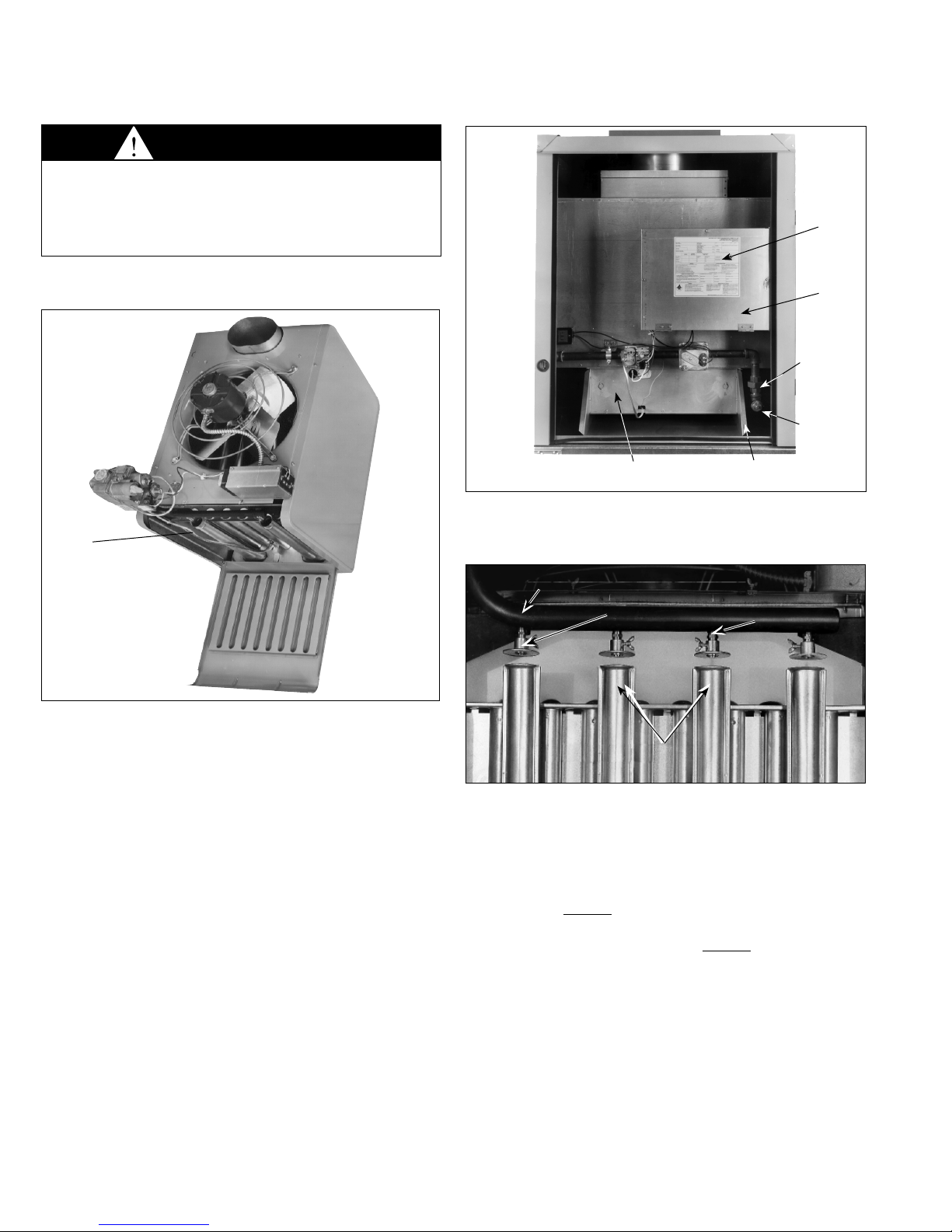

gas designation disc (Figure 1.1) and the type of gas, located on

the serial plate.

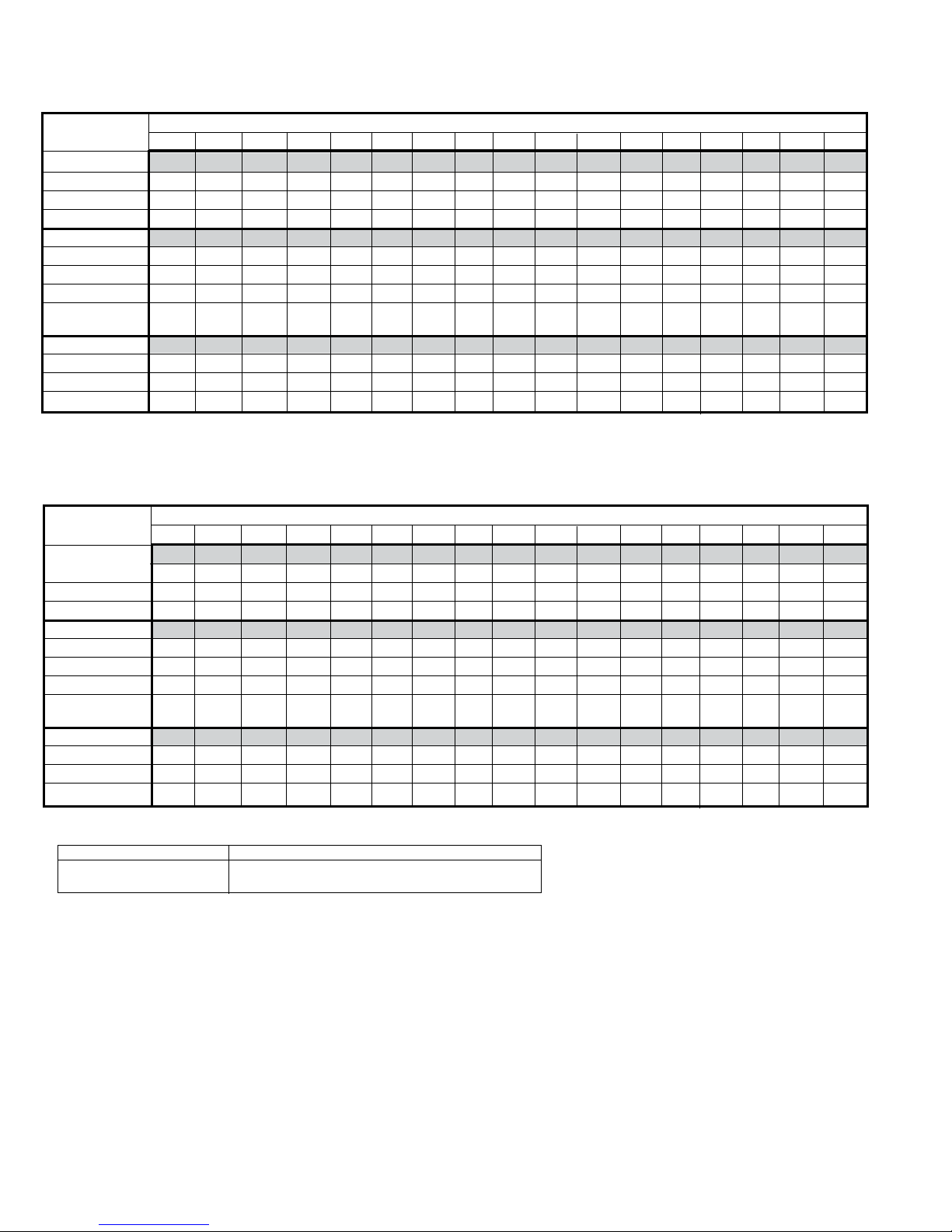

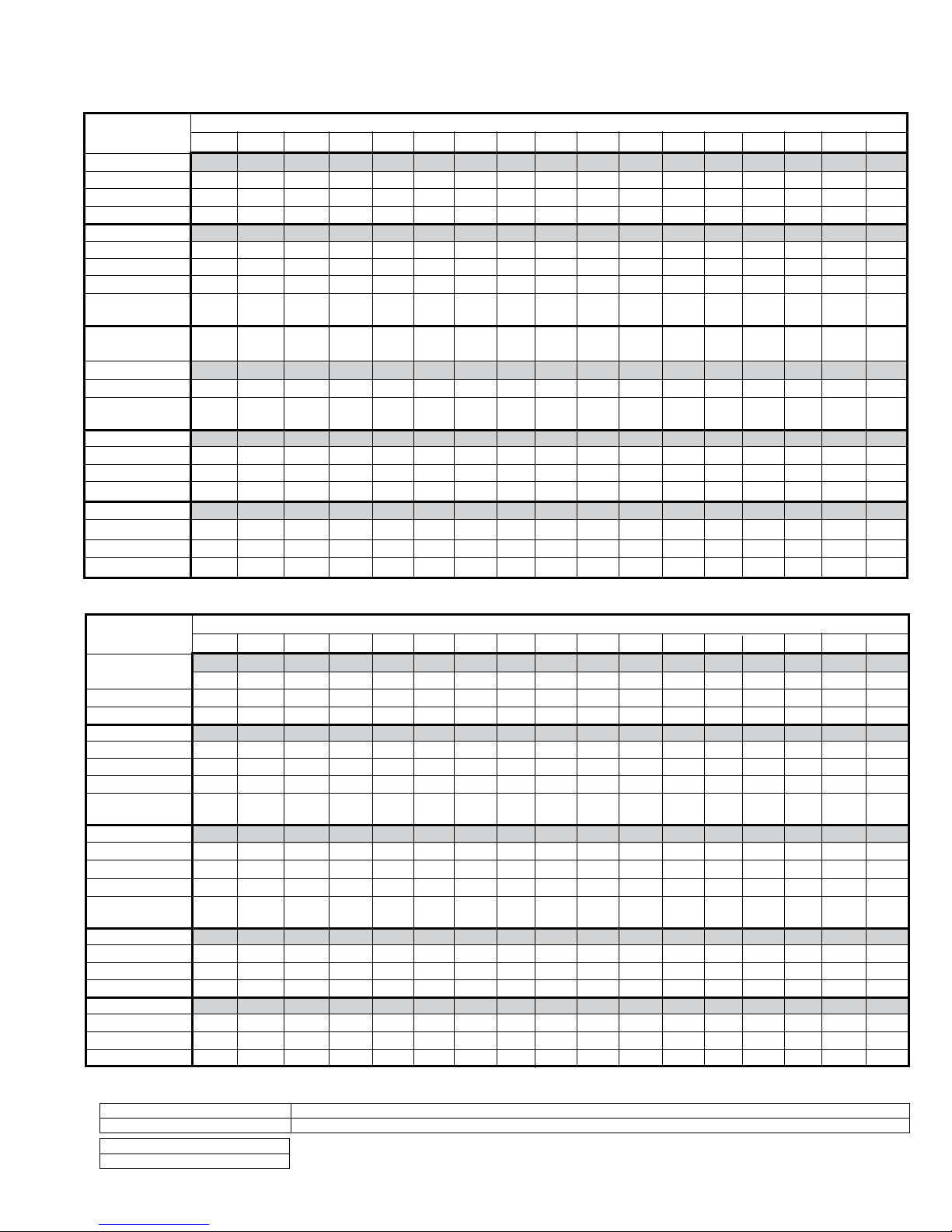

After obtaining this information, refer to the proper selection

chart. The selection charts are differentiated by product type,

altitude and fuel type. Remember, if you are converting from

natural gas to propane gas and want to operate at high altitude,

both a propane conversion kit and a propane high altitude kit

must be used. Selection charts include the proper kit suffix, the

orifice drill size, and the number of orifices required for the unit

being converted. Drill sizes are also stamped on each orifice.

HIGH ALTITUDE CONVERSION

For Existing Natural or Propane Gas Units

Gas-fired equipment ratings are certified by C.S.A. For

elevations above 2000 ft., ANSI Z223.1 requires ratings be

reduced 4 percent for each 1000 ft. above sea level. C.G.A.

requires that ratings be reduced 10% at elevations above 2000

ft. To accommodate higher altitude operation, equipment

must be converted by changing orifices as explained in

this instruction sheet. Tables 2.1 thru 5.2 list orifice kits which

comply with both ANSI Z223.1 recommendations and C.S.A.

requirements.

Table of Contents Pages

High altitude conversion ......................................................... 1

High altitude propane gas

conversion from natural gas ............................................. 1

Selection of the proper kit....................................................... 1

Installation of kits.................................................................... 6

Cross reference...................................................................... 8

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH HIM WHEN YOU LEAVE THE JOB.

SELECTION AND INSTALLATION INSTRUCTIONS

high altitude orifice kit

models PD/BD, PDP/BDP, PSH/BSH

and model series “D”, “H”, “I”, “O” duct furnace/make up air units

(not including separated combustion)

Figure 1.1 - Gas Designation Disc

EQUIPPED

FOR USE

WITH

PROPANE

GAS

NTRL

5H604841A

NRTL

IMPORTANT

Conversion from natural gas to propane gas is allowed for

PD/BD, PDP/BDP, and PSH/BSH models with 11,12, 30,

or 31 control codes, built in January, 1987 or later. For this

conversion, both a propane conversion kit and a propane

high altitude kit must be used.

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas supply shall be shut-off and the electrical power

disconnected before proceeding with the conversion.

Failure to do so could result in fire, explosion or electrical

shock.

1. The use of this manual is specifically intended for a

qualified installation and service agency. All installation

and service of these kits must be performed by a qualified

installation and service agency.

2. These instructions must also be used in conjunction with

the Installation and Service manual originally shipped with

the appliance being converted, in addition to any other

accompanying component supplier literature.

IMPORTANT

As Modine Manufacturing Company has a continuous

product improvement program, it reserves the right

to change design and specifications without notice.

75-535.11

5H605846A Rev. Ul

December, 2008