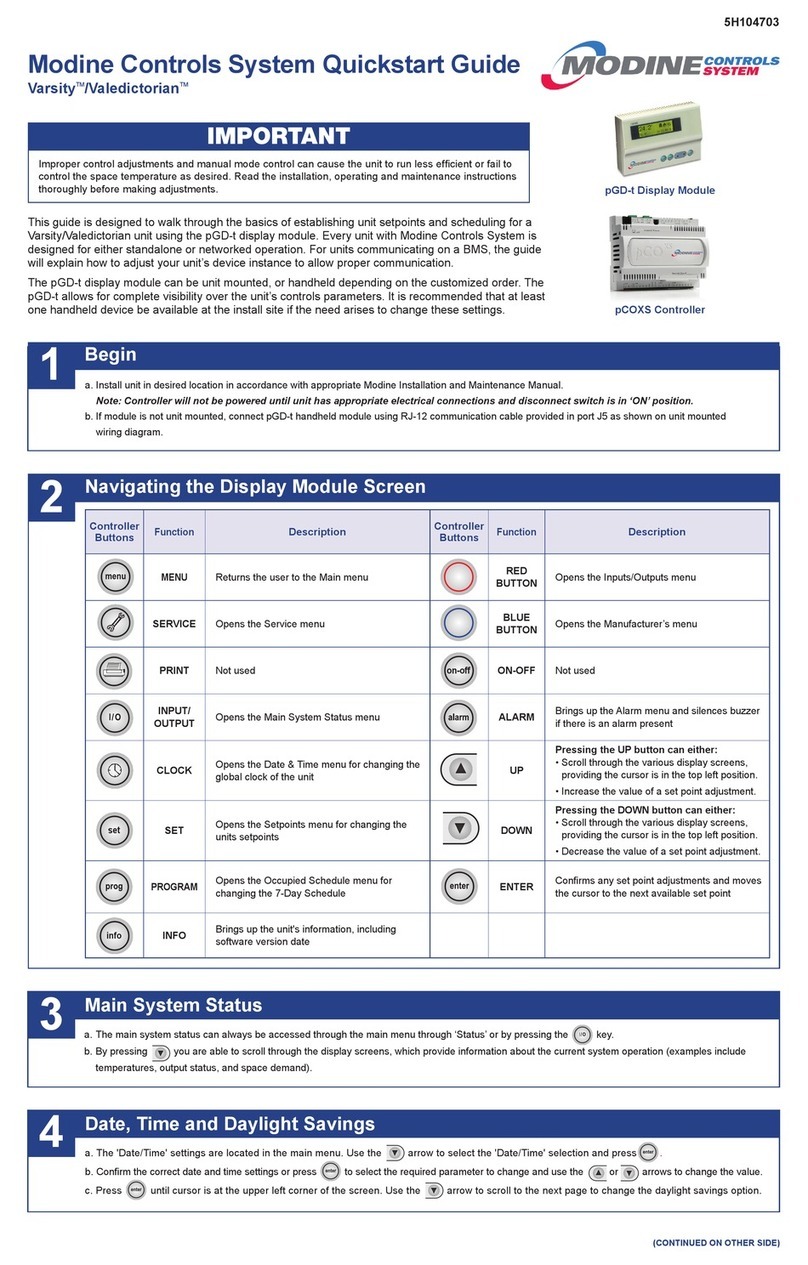

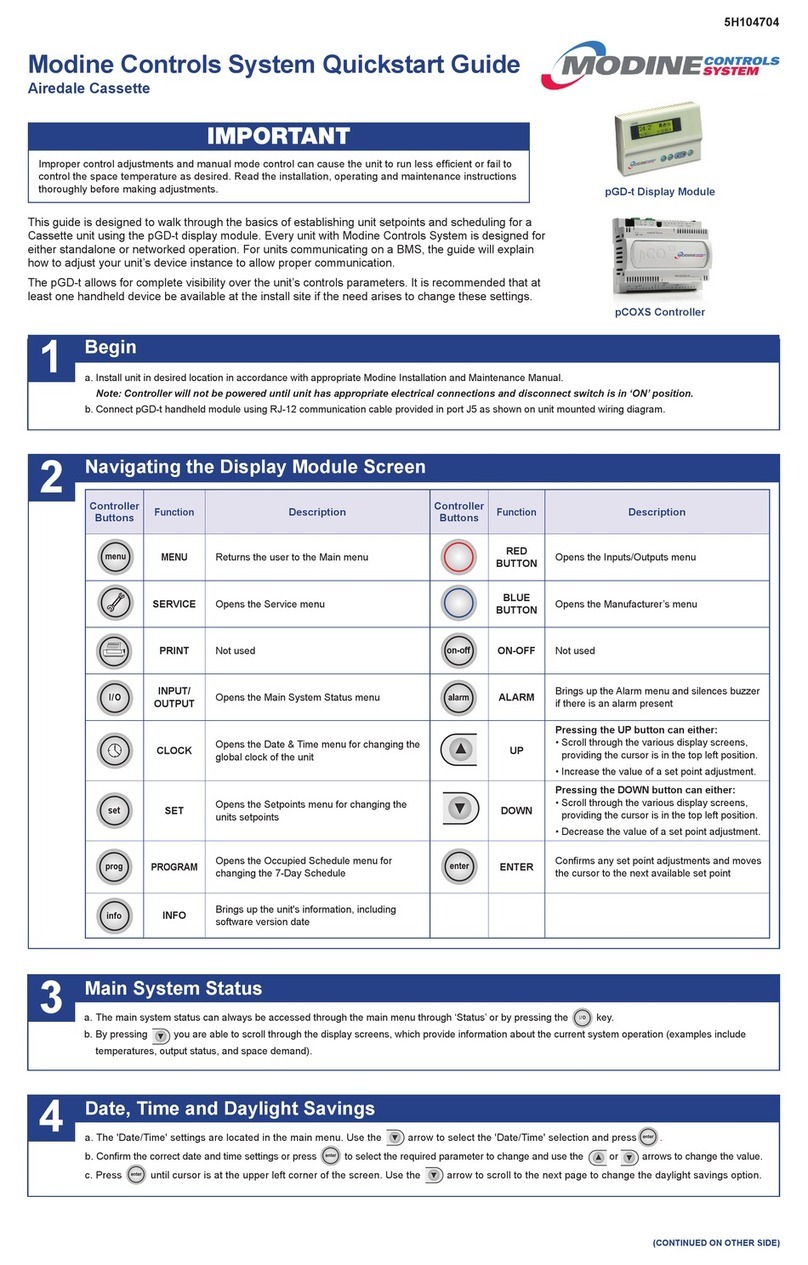

Modine Controls System Quickstart Guide

Airedale Sentinel®- Chilled and/or Hot Water Vertical Unit Ventilator (UVV and UVD)

a. Install unit in desired location in accordance with appropriate Modine Installation and Maintenance Manual.

Note: Controller will not be powered until unit has appropriate electrical connections and disconnect switch in “ON” position.

b. If display module is not unit mounted, connect pGD1 handheld module using RJ-12 communication cable provided in port J15 as shown on unit mounted

wiring diagram.

a. The main screen (shown at right) is the default navigation page, and can always be recalled by pressing . This

may need to be pressed more than once depending on which menu is active.

b. By pressing you are able to scroll through the display screens which provide information about the current

system operation (examples include temperatures, output status, and space demand).

i. OVERRIDE MODE: Unit can be placed in override mode on the 'Local Occ. Ovr.' screen (unit will run in

occupied mode, regardless of clock schedule) by moving the cursor to the “Clock Override” eld and changing

the value to ‘YES’. The override mode duration can be set on this same screen, and is defaulted to 1 hour.

a. Enter the main menu by pressing and scroll down to line ‘A. On/O Unit’ and press .

b. Press to move cursor, to ‘Power By Display’ line and the or arrow to change the value

between ‘ON’ and ‘OFF’. This parameter must be ‘ON’ for unit to have any functionality (shown at right).

a. Customizing the 7-Day Schedule

i. For units running without BMS communication, the controller has a preset 7-day schedule dened by the internal

timeclock. The unit will run in occupied mode from 6:00am to 4:00pm, Monday through Friday, with no holidays.

ii. Enter the main menu by pressing and scroll down to line ‘C. Clock/Scheduler’ (shown at right) and press .

iii. The rst screen displays the current date and time. If this is not correct press to highlight the eld that needs

to be changed. Use the or arrows to adjust the number as needed.

iv. Press to move through adjustable setpoints until cursor is at the upper left corner of the screen. Use the arrow to scroll to the next page.

v. Select the amount of schedules desires by pressing to highlight ‘Number of Schedules’ eld and adjust the number. Press until cursor is at the

upper left corner of the screen. Use the arrow to scroll to the next page.

Begin

Navigating the Display Module Screen

Main Screen and System Status

Turning Unit On / O

Schedule

1

2

3

4

5

(CONTINUED ON OTHER SIDE)

5H104766

This guide is designed to walk through the basics of establishing unit setpoints and scheduling for a chilled water/hot water vertical unit ventilator using the

pGD1 display module. Every unit with Modine Controls System is designed for either standalone or networked operation. For units communicating on a BMS,

the guide will also explain how to adjust your unit’s device instance to allow proper communication.

The pGD1 allows for complete visibility over the unit’s controls parameters. It is recommended that at least one handheld device be available at the install site

if the need arises to change these settings.

pGD1 Display Module

pGD1

Remote

Buttons

Function

Description

pGD1

Remote

Buttons

Function

Description

ALARM

When one or more alarms are active the ALARM

button will blink/ash red. Pressing the ALARM

button once will indicate information regarding any

active alarms. Pressing the ALARM button twice

will reset any active manual-reset alarms.

UP

Pressing the UP button can either:

Scroll through the various display screens,

provided the cursor is in the top left position.

Increase the value of a setpoint adjustment.

PRG Pressing the PRG button will select the main

navigation menu. ENTER

Pressing the ENTER button will conrm any

setpoint adjustments and move the cursor to

the next available setpoint.

ESC Pressing the ESC button will return the user to the

main display screen showing unit status. DOWN

Pressing the DOWN button can either:

Scroll through the various display screens,

provided the cursor is in the top left position.

Decrease the value of a setpoint adjustment.

Installing, starting up and servicing heating, ventilation and air conditioning equipment poses signicant

hazards and requires specialized knowledge of Modine products and training in performing those services.

Failure to have any service properly performed by, or making any modication to Modine equipment

without the use of qualied service personnel could result in serious injury to person and property,

including death. Therefore, only qualied service personnel should work on any Modine products.

These instructions must also be used in conjunction with the Installation and Service Manual (latest

revision of AIR3-500) that originally shipped with the unit, in addition to any other accompanying

component supplier literature.

W

ARNING

IMPORTANT

AIR74-536.2