Product Warnings

Patient/Staff Safety

Patients, especially children must not be left unattended on or with a stretcher at any time.

Care must be taken in the operation of all moving parts and accessories to minimise risk of injury to

staff or patients.

This stretcher is not suitable for use as a ward bed. Use for more than a few hours could contribute to

patient discomfort and increase the potential for injury, including development of pressure injury.

The stretcher top must be in the lowest position when patients are getting on or off the stretcher, with

access from either side only.

Maximum static patient load capacity on the backrest must not exceed 100kg distributed evenly or

damage to locking struts and frame may occur.

Maximum static patient load capacity on the stretcher is 300kg and must not be exceeded. Weight

must be distributed as evenly as possible on stretcher top. Any weight loading above 150kg must be

wheeled on smooth, level flooring and attended by more than one staff member.

Only apply brakes when stretcher is stationary.

Brakes are to be fully applied during bed / stretcher transfers and attended by qualified clinical staff.

General Use

The backrest must be raised and lowered with care to prevent possible strain to the operator.

Check that all fingers, hands, limbs or x-ray cassette components are clear before lowering backrest.

Check that there are no obstructions above or below the top before adjusting the height.

The stretcher must never be left on sloping surfaces unattended, even with brakes fully engaged.

Traversing side on, across slopes is to be avoided under any circumstances.

On wet or slippery flooring do not lean or apply unnecessary force against stretcher, as it may slide:

even with brakes fully applied.

This stretcher is specifically designed for indoor use in dry environments, with due care it may be used

to transit outdoor areas however additional controls and precautions specific to the environment will

be merited.

Clips, locks and retainers are supplied by the manufacturer for patient / staff safety and must not be

removed.

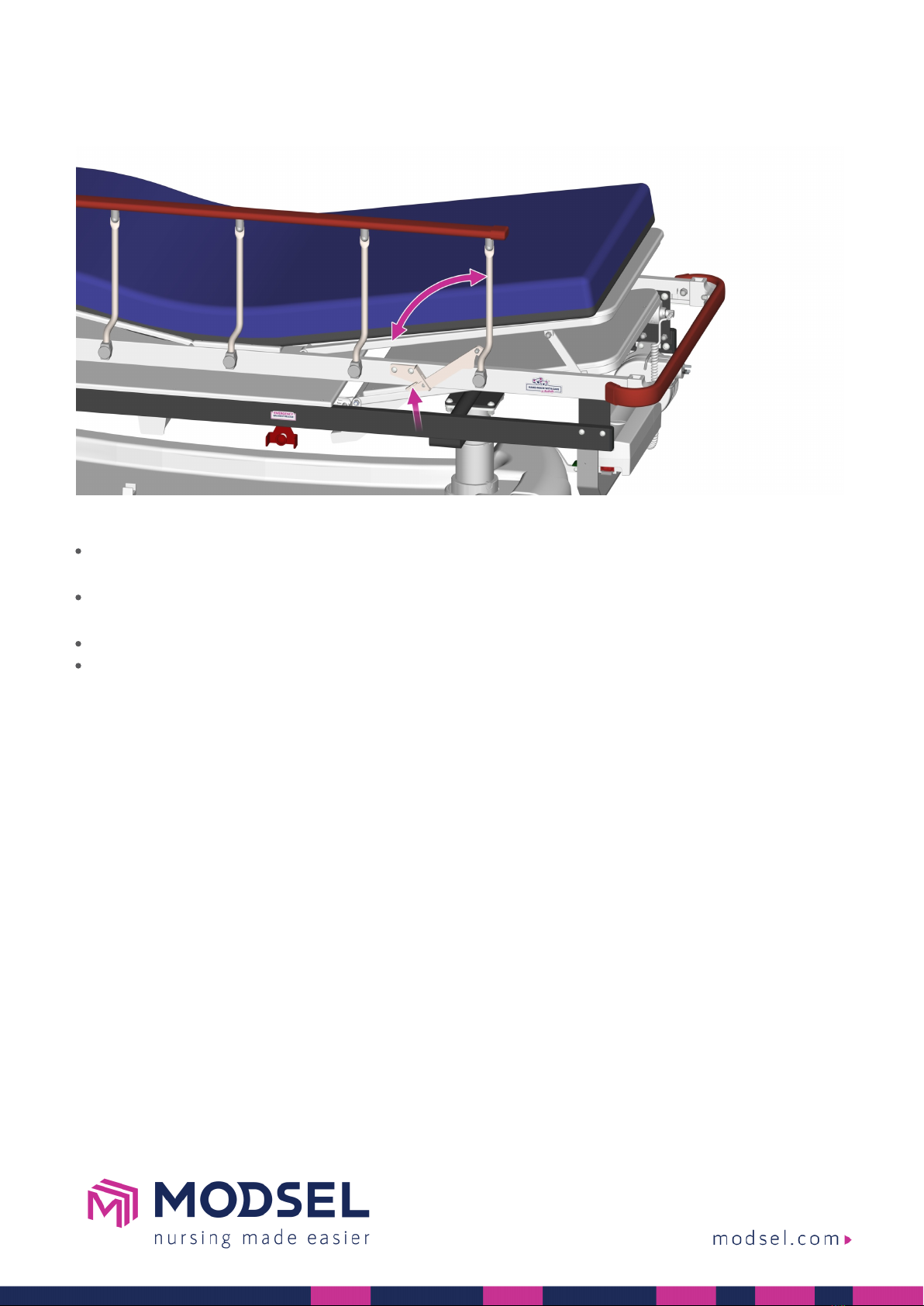

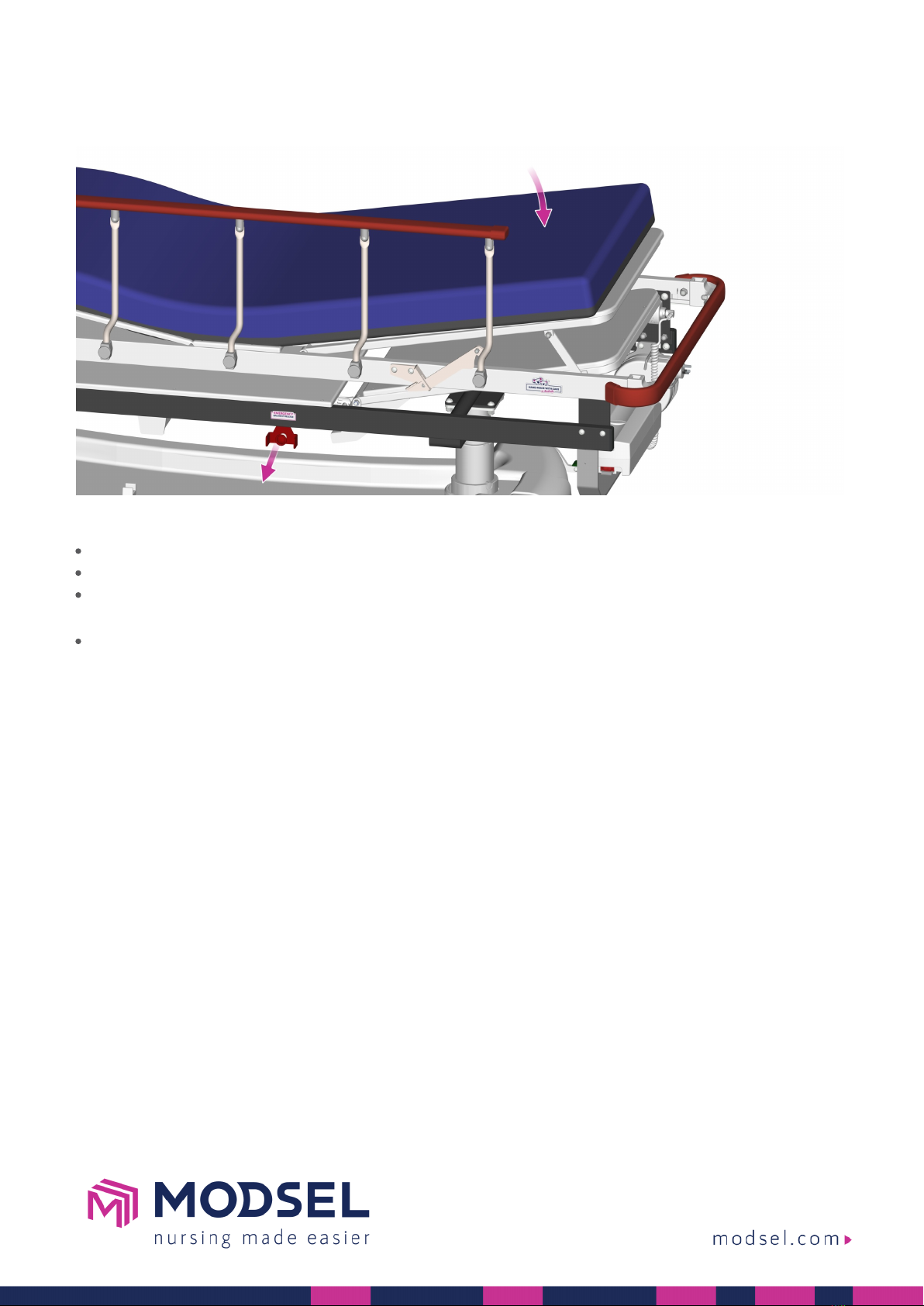

Dropsides

Stretcher must never be raised or moved with dropsides down.

Patients on a stretcher with dropsides down, must always be attended by qualified clinical staff.

Dropside releases must be operated only by suitably qualified clinical staff in attendance.

Check that all fingers, hands and limbs are clear before lowering dropsides.

Always ensure dropsides are locked firmly in position after raising.

Side loading on any dropsides should not exceed 80kg or damage to the stretcher may occur.

Dropsides locked in mid position should not be subjected to any downward force exceeding 30kg static

loading as this may result in damage to the stretcher or personal injury.

v-14092022 - Page 4

"Trusted products made for trusted professionals"