Molecular Devices Sofnolime HiCap CO2 User manual

Other Molecular Devices Laboratory Equipment manuals

Molecular Devices

Molecular Devices StakMax User manual

Molecular Devices

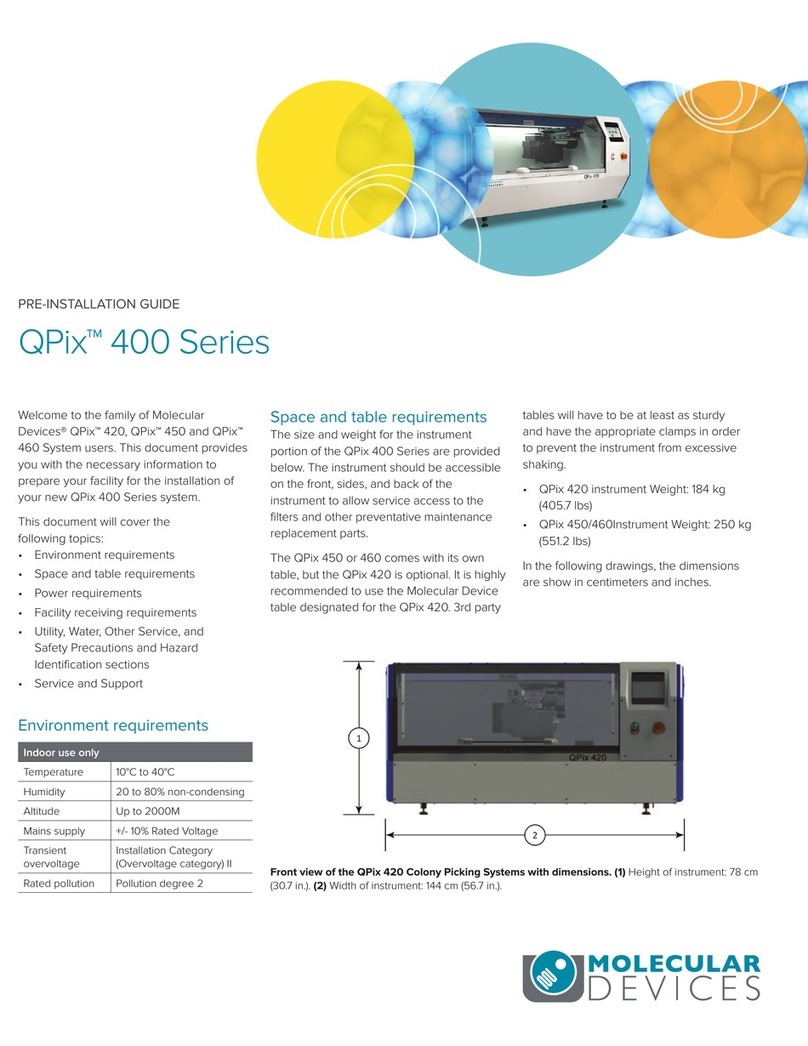

Molecular Devices QPix 420 User manual

Molecular Devices

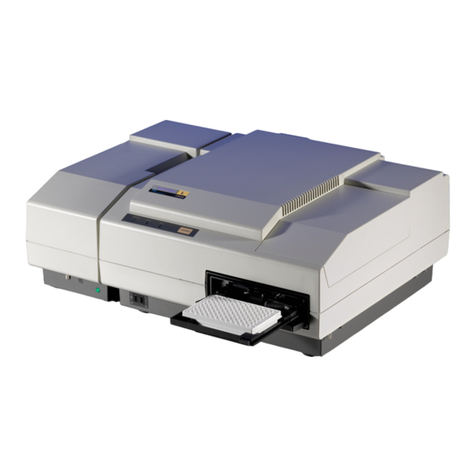

Molecular Devices SpectraMax M2 User manual

Molecular Devices

Molecular Devices SpectraMax MiniMax 300 User manual

Molecular Devices

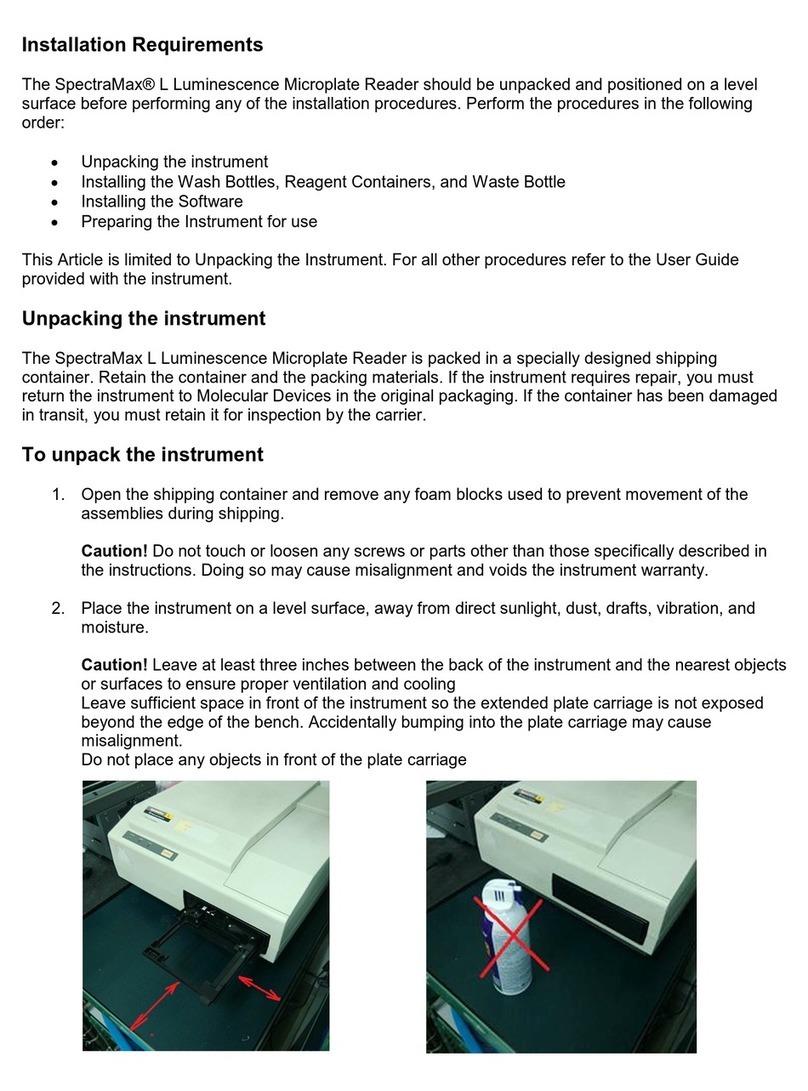

Molecular Devices SpectraMax L Operating and maintenance manual

Molecular Devices

Molecular Devices ClonePix 2 User manual

Molecular Devices

Molecular Devices StakMax User manual

Molecular Devices

Molecular Devices SpectraMax ABS User manual

Molecular Devices

Molecular Devices ImageXpress Pico User manual

Molecular Devices

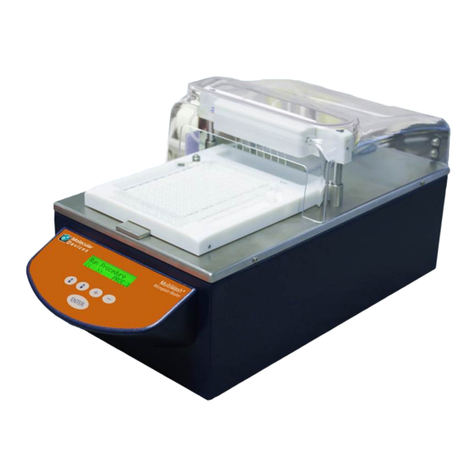

Molecular Devices SkanWasher 400 User manual

Molecular Devices

Molecular Devices Digidata 1550 User manual

Molecular Devices

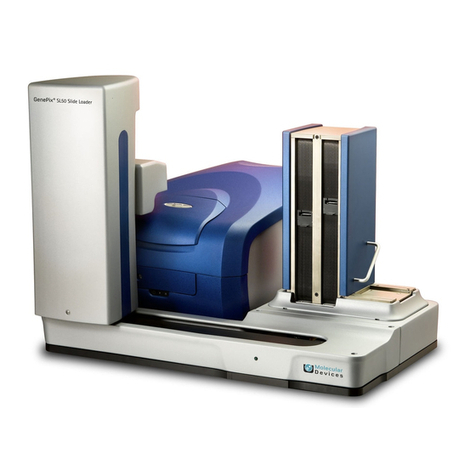

Molecular Devices GenePix SL50 User manual

Molecular Devices

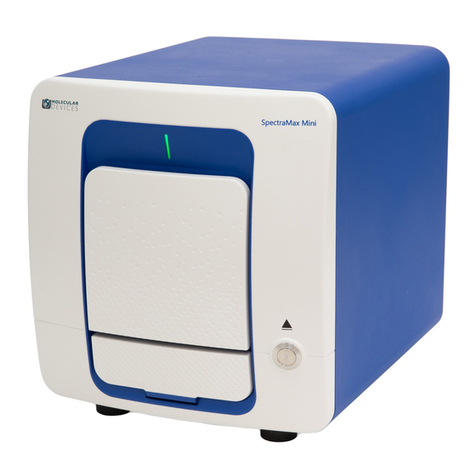

Molecular Devices SpectraMax Mini User manual

Molecular Devices

Molecular Devices StakMax User manual

Molecular Devices

Molecular Devices QPix 450 User manual

Molecular Devices

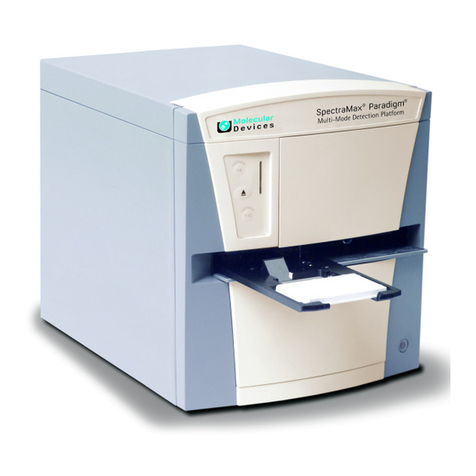

Molecular Devices SpectraMax M3 User manual

Molecular Devices

Molecular Devices SpectraMax L User manual

Molecular Devices

Molecular Devices FilterMax F3 User manual

Molecular Devices

Molecular Devices SpectraMax Mini User manual

Molecular Devices

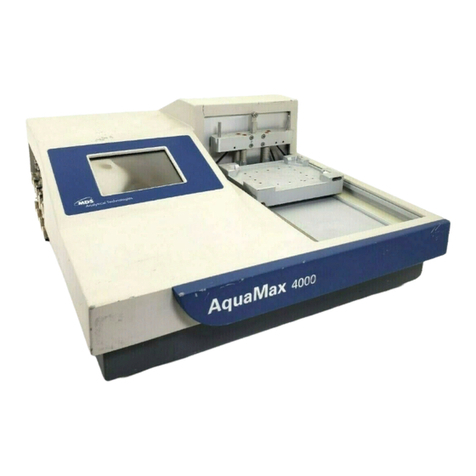

Molecular Devices AquaMax 2000 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual