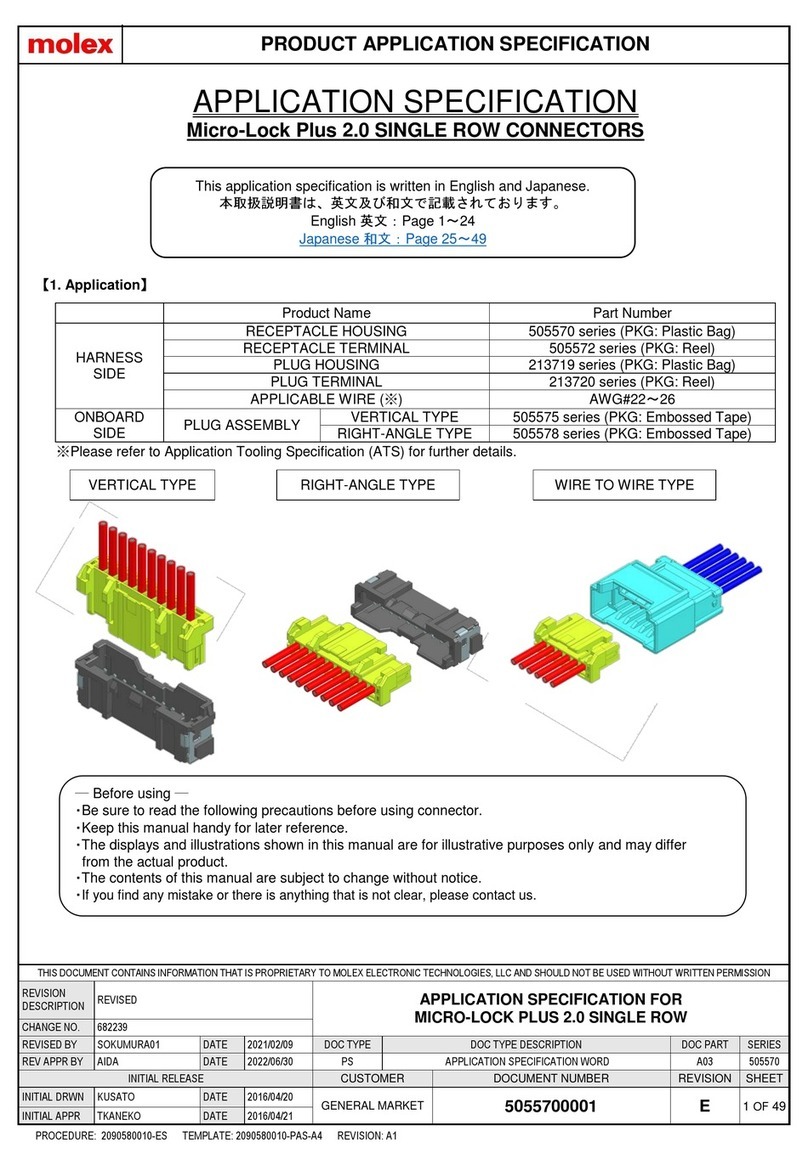

APPLICATION SPECIFICATION

TITLE: CLIK-Mate 1.5

SINGLE ROW CONNECTORS

APPLICATION SPECIFICATION

THIS DOCUMENT CONTAINS INFORMATION THAT IS PROPRIETARY TO MOLEX ELECTRONIC

TECHNOLOGIES, LLC AND SHOULD NOT BE USED WITHOUT WRITTEN PERMISSION

DOCUMENT NUMBER

AS-502578-002

FILE NAME

AS502578002.DOC

EN-037(2015-11 rev.1)

【1. Storage before usage】

①Please store the products in our boxes, in a cool, non-humid location avoiding direct sunshine.

This is necessary in order to keep the material from deforming or degradation.

②Please store in a condition avoiding pressure. This is necessary in order to keep the material

from deforming or degradation.

③When transferring the products, please be careful not to apply shock from dropping or hitting

the boxes.

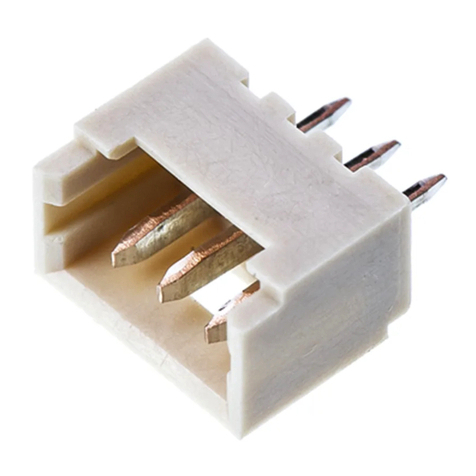

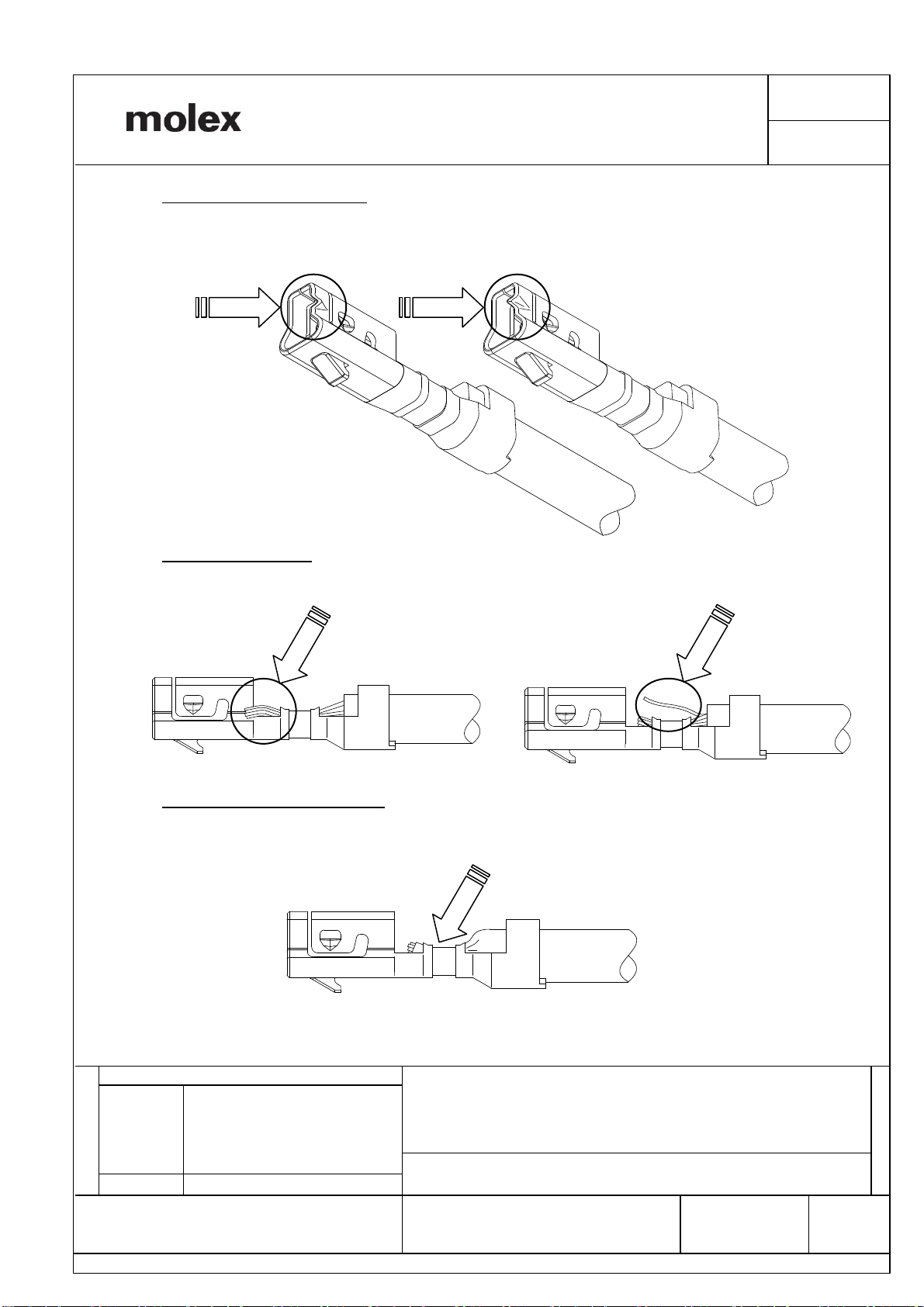

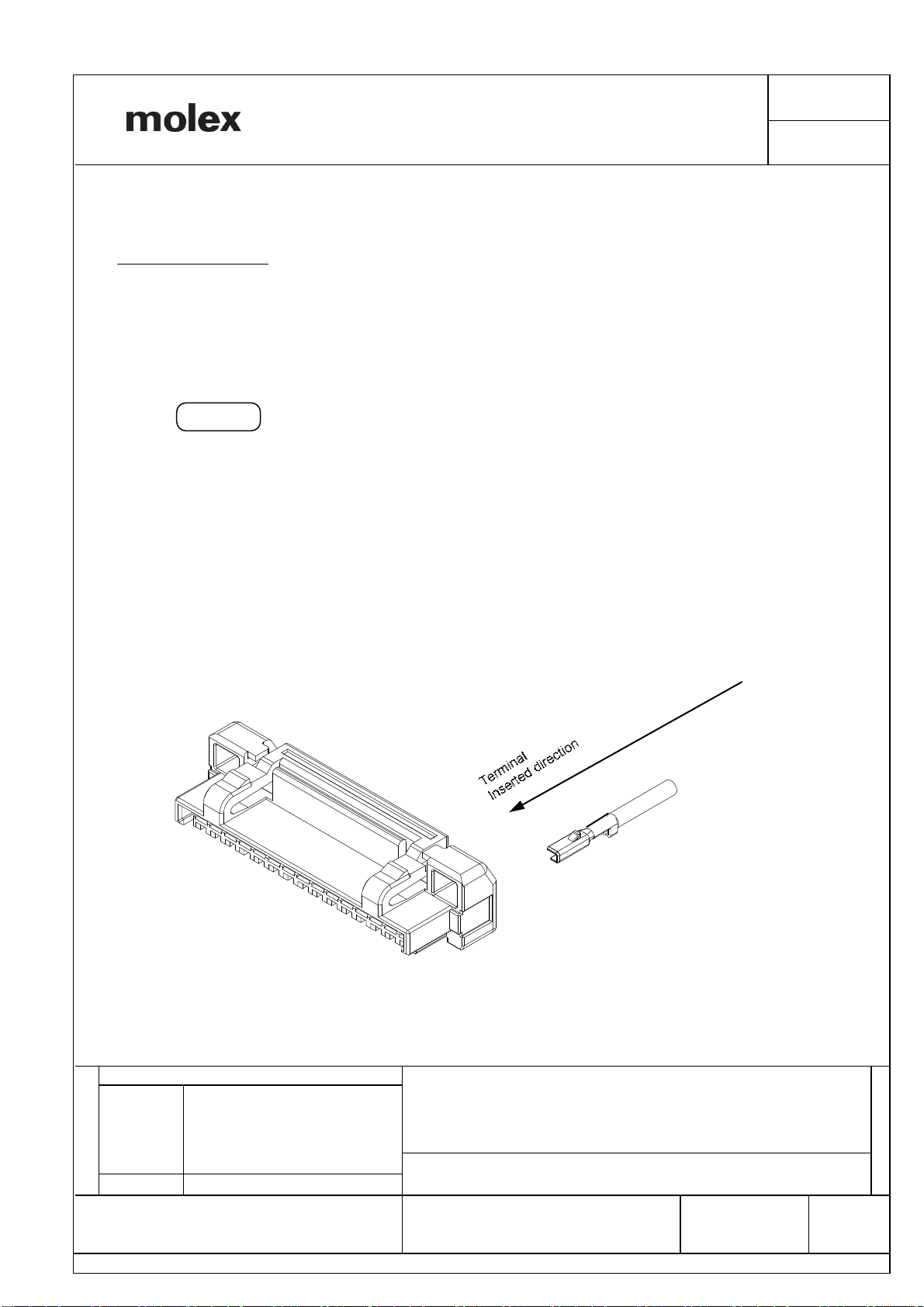

【2. Instructions during harnessing】

①Please confirm if you the Plug. HS'G, terminal, crimp condition, wire meets the crimp

specification before starting the harnessing. (In case they do not meet, please inform our sales)

②Do not use terminals with deformation on the contact boxes. These terminals may not meet the

required insertion force to the Plug. HS'G or not meet electrical requirements.

③Do not touch the terminals with your hands directly. The oil and the organic substances could

apply negative effect to the plating leading to electrical failure.

④Do not pull the terminals robustly when the terminals have problem fitting. It could deform the

terminal.

⑤Do not apply extended force to the Plug. HS'G, terminals, products in line, harnesses. This

could cause connector deforming which leads to failure meeting connector requirements.

⑥Keep away Plug. HS'G, terminals, products in line, and harnesses from dust, corrosive

properties, corrosive gas, high temperature, high humidity, and direct sunshine. This could lead

to product failure caused by contact failure, terminal corrosion, and HS'G insulation failure.

Please be careful when storing the products.

⑦Do not deform the Plug. HS'G and terminals on purpose. It would lead to product failure.

⑧Please use all products on that day after un–packing the box. The surrounding air condition

could cause material degradation. In case you have to store the parts for a while, please seal

the parts and keep them in the box.

⑨Please look out for sharp edges to avoid injury.

⑩Please look out for paper in the reels, to avoid paper cuts.