EXTreme PowerMass™ Stiffener Removal Tool

Doc No: ATS-622023600 Release Date: 05-09-08 UNCONTROLLED COPY Page 3 of 4

Revision: A Revision Date: 05-09-08

COUNTER CLOCKWISE (CCW)

ATTACHED

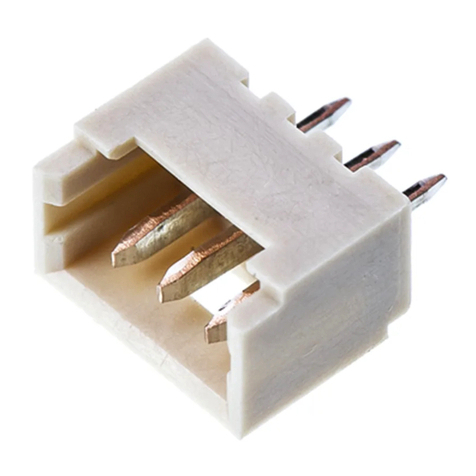

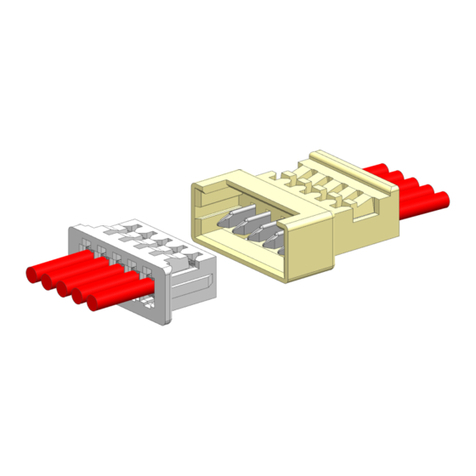

2. After the metal stiffener is

positioned correctly on the

module assembly, place the

Stiffener Removal Tool on the

connectors as shown in Figure 4.

The installation of the metal

stiffener does not use the removal

pins.

3. Position the tool so it will fit over

the connectors. Turn the knob in

either direction allowing the tool to

open or close enough so the

module assembly fits between the

press block and the stiffener locator. The stiffener locator should touch the straight edge of the metal stiffener.

See Figure 4.

4. Turn the knob on the tool counter clockwise (CCW) so the stiffener locator moves toward the press block. See

Figure 5. For excessively long assemblies it may be necessary to gradually install the stiffener by moving the

tool along the length of the assembly.

5. Do not turn the knob excessively. When the knob becomes difficult to turn, this is an indication that the

stiffener is seated fully.

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following

maintenance steps:

1. Remove dust, moisture, and other contaminants with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

3. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high quality

machine oil. Do not oil excessively.

4. When tool is not in use, store in a clean, dry area.

CAUTION: Molex specifications are valid only when used with Molex connectors and tooling.