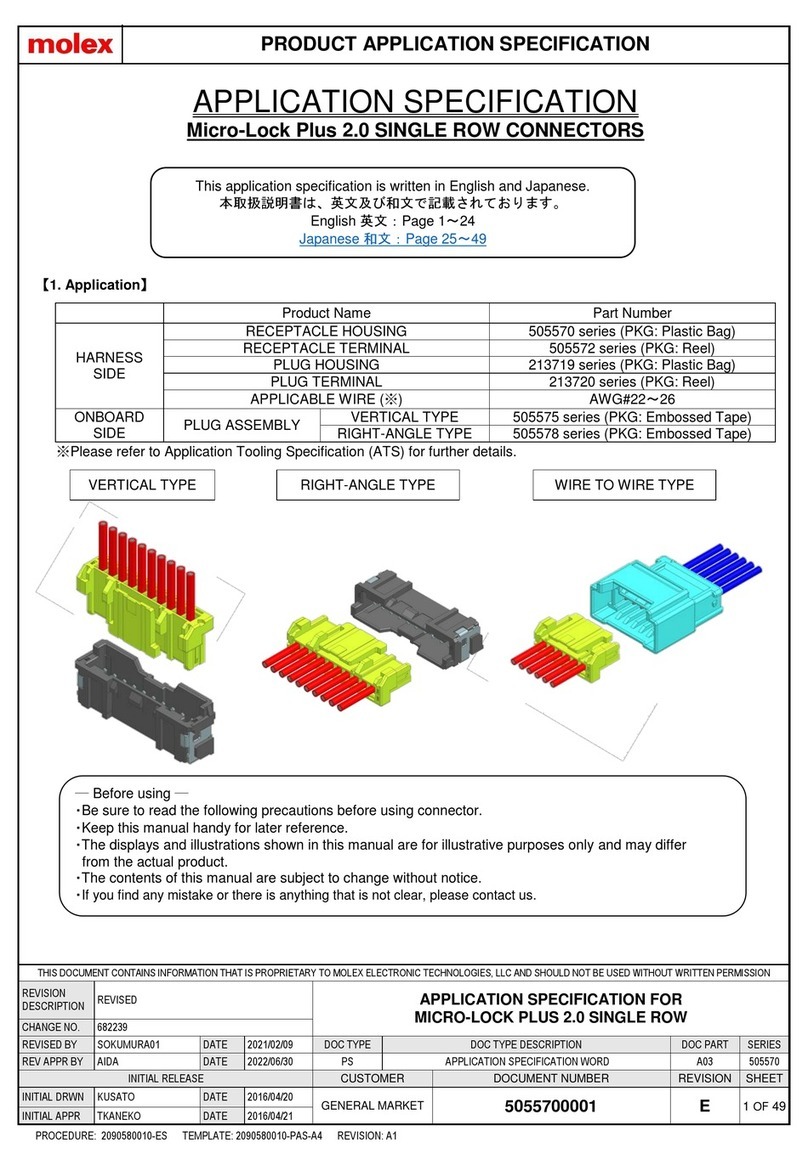

molex Mini50 series User guide

Other molex Cables And Connectors manuals

molex

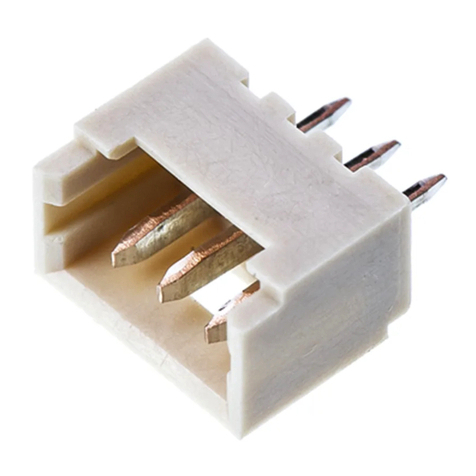

molex PicoBlade 1.25 DIP User guide

molex

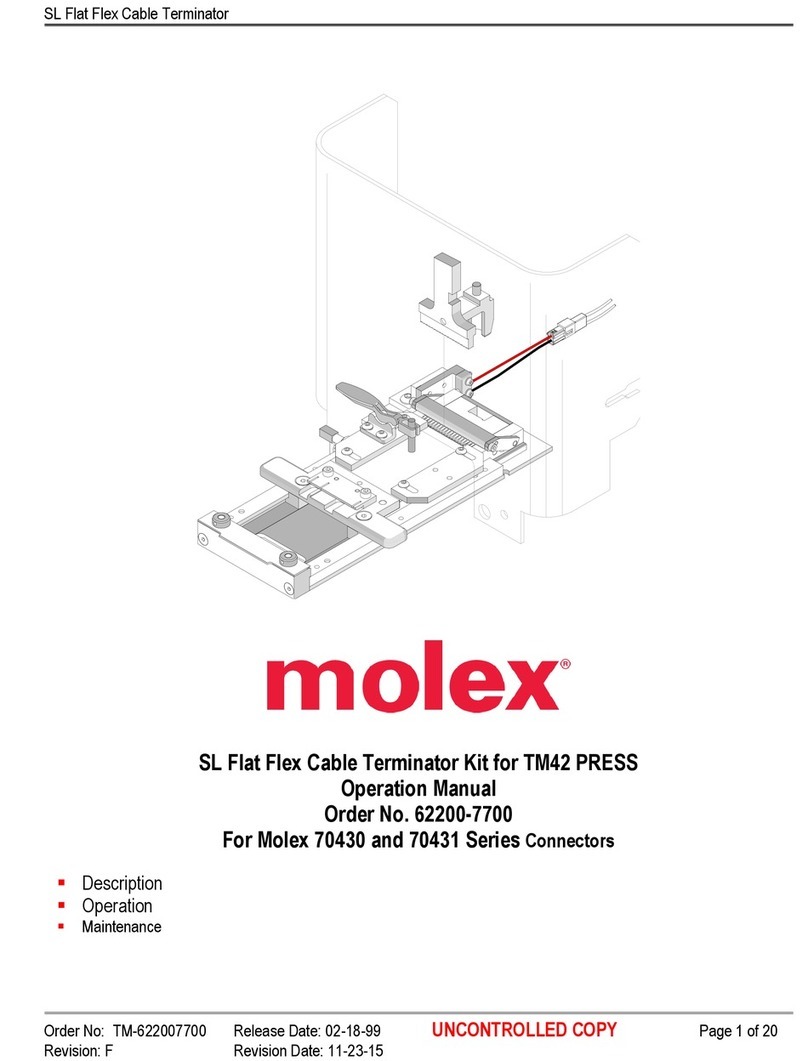

molex 62200-7700 User manual

molex

molex Milli-Grid Dual row 87568 Series User manual

molex

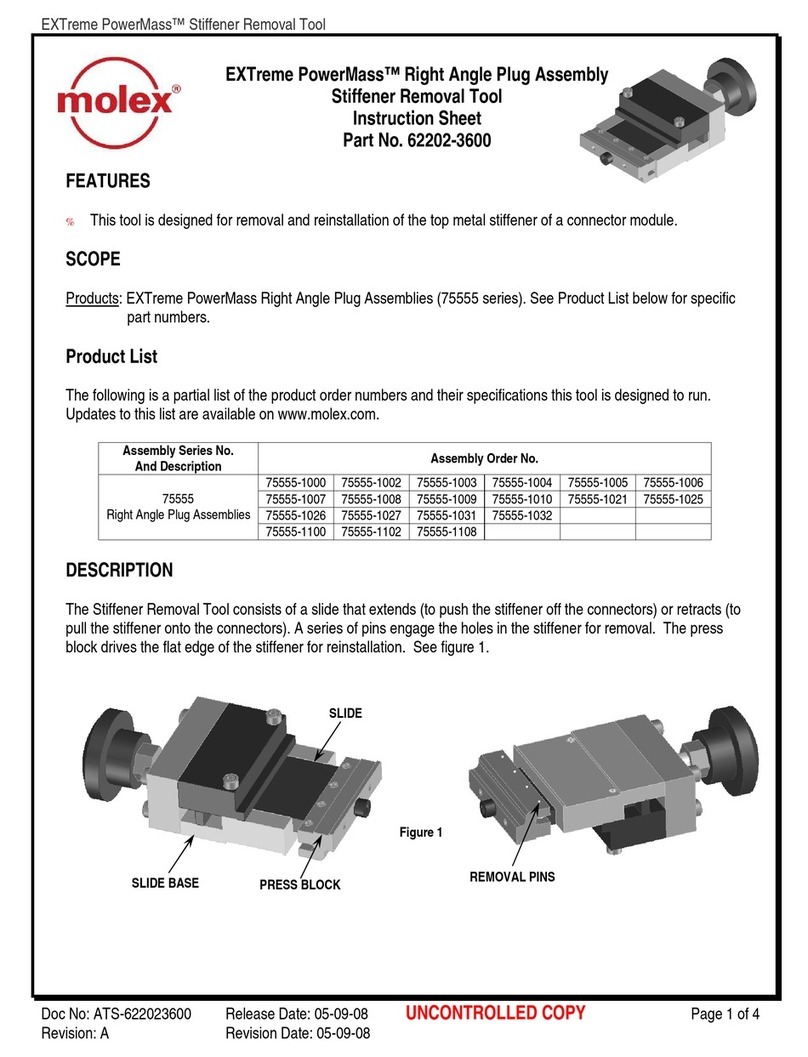

molex EXTreme PowerMass 75555 Series User manual

molex

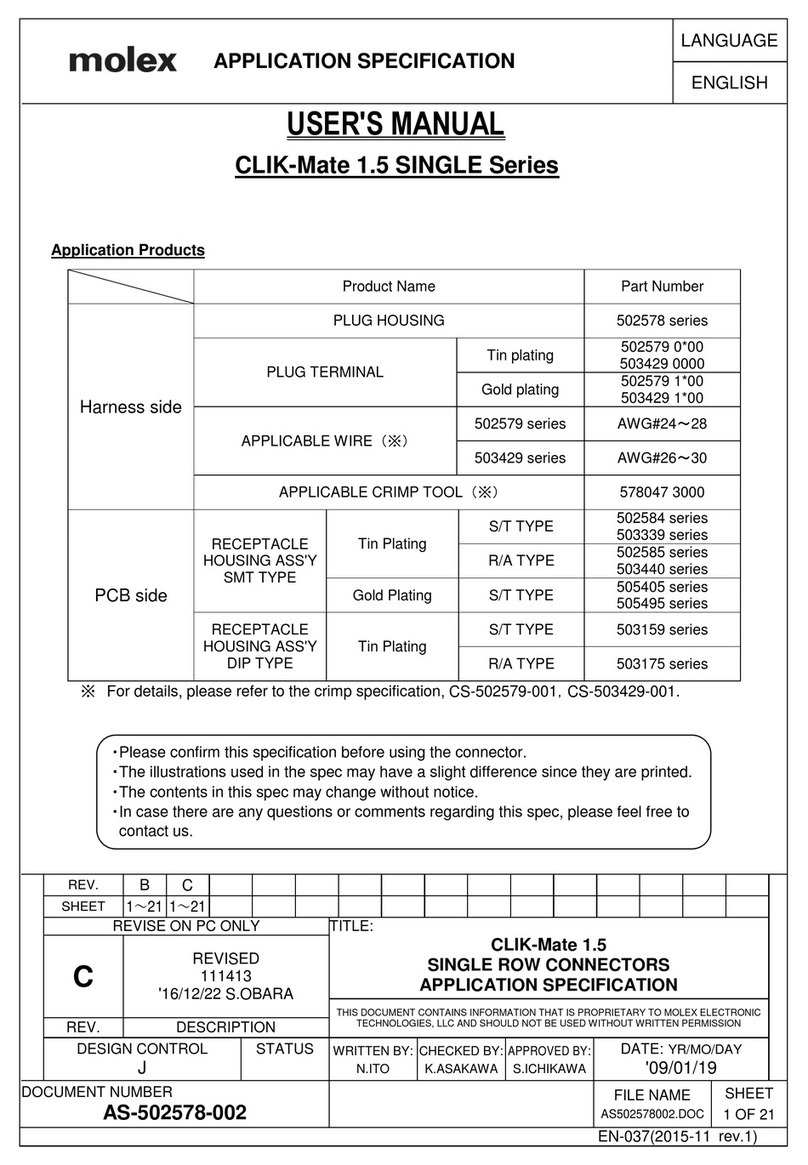

molex CLIK-Mate 1.5 SINGLE Series User manual

molex

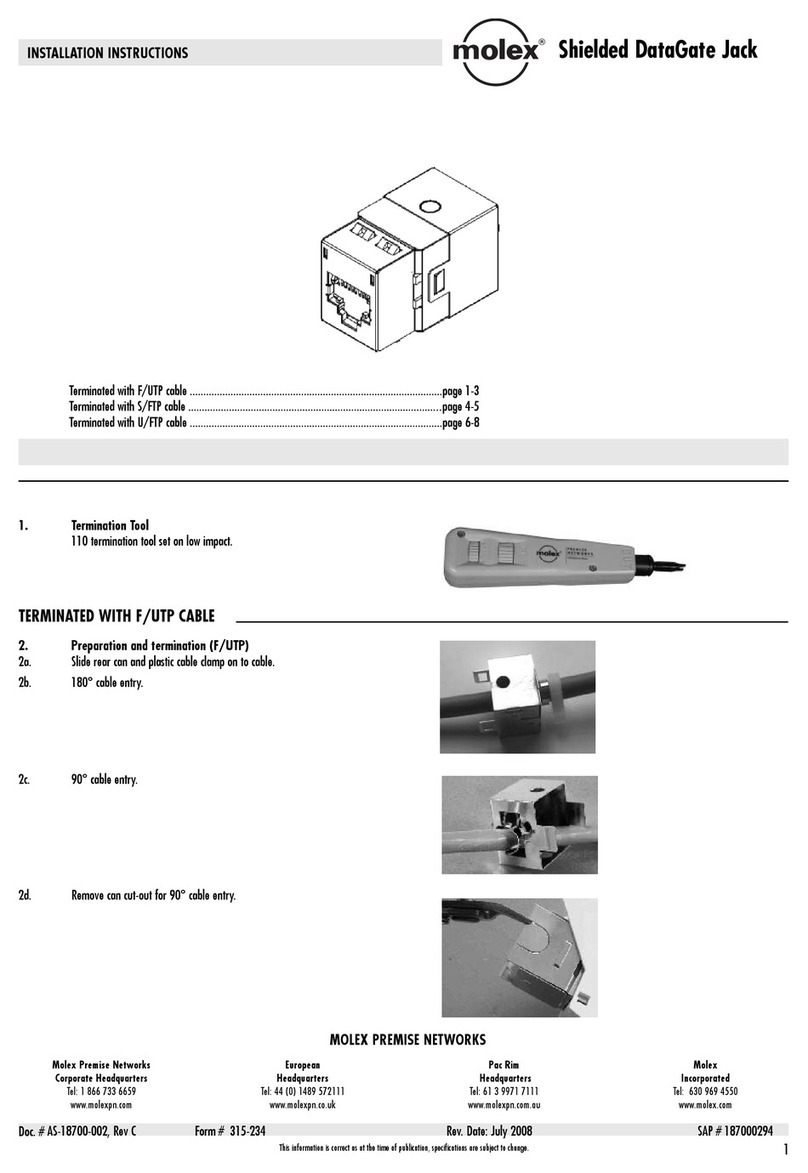

molex Shielded DataGate User manual

molex

molex HDAC .64 Series User manual

molex

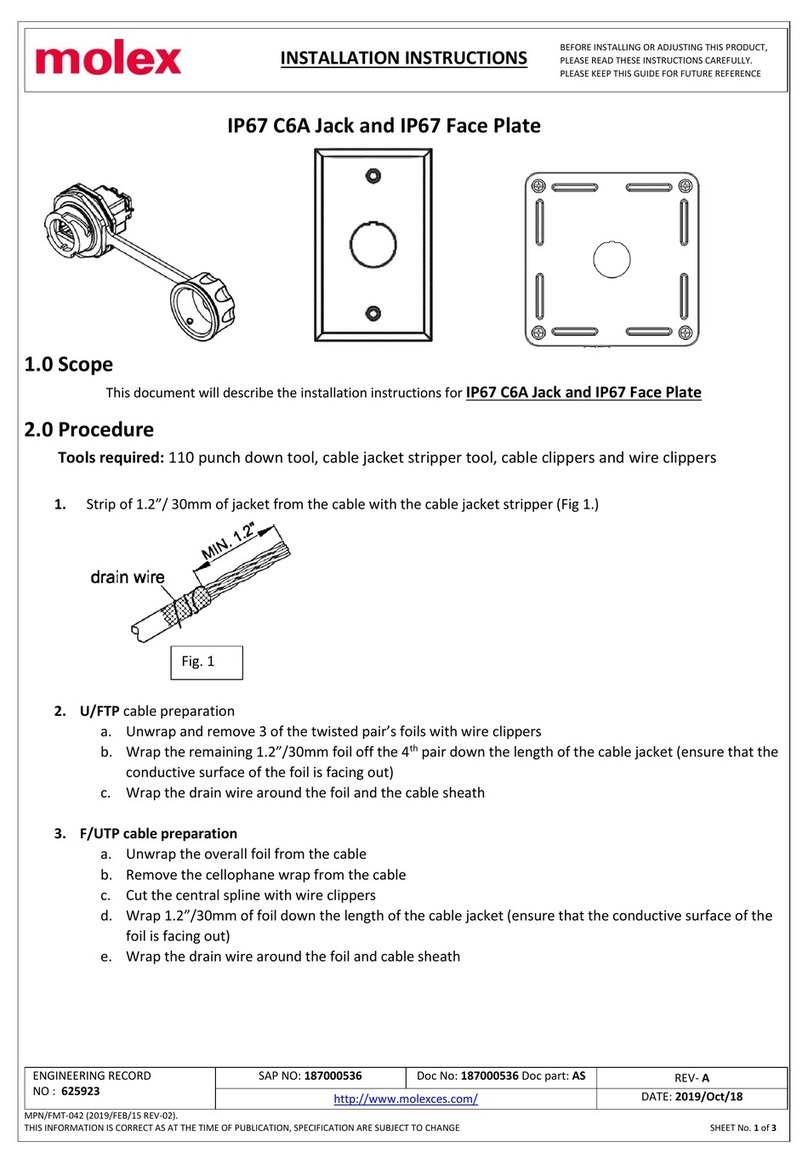

molex IP67 User manual

molex

molex MX123 User manual

molex

molex PicoBlade 1.25 W/W User guide