APPLICATION SPECIFICATION

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No: ABC2001-9999

1 DATE: 2008/16/03

TITLE:

MX150 Application Guide 4of 62

DOCUMENT NUMBER: CREATED / REVISED BY: CHECKED BY: APPROVED BY:

Brian Zelinski Steve Verzyl Scott Marceau

TEMPLATE FILENAME: APPLICATION_SPEC[SIZE_A](V.1).DOC

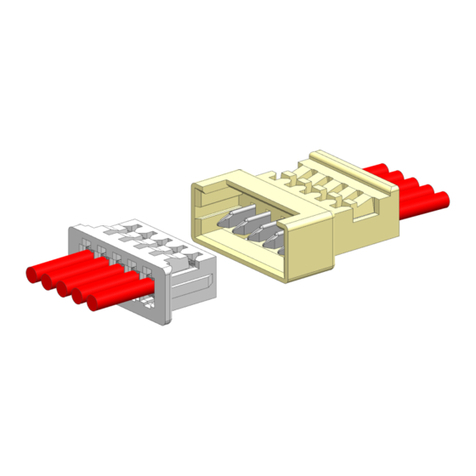

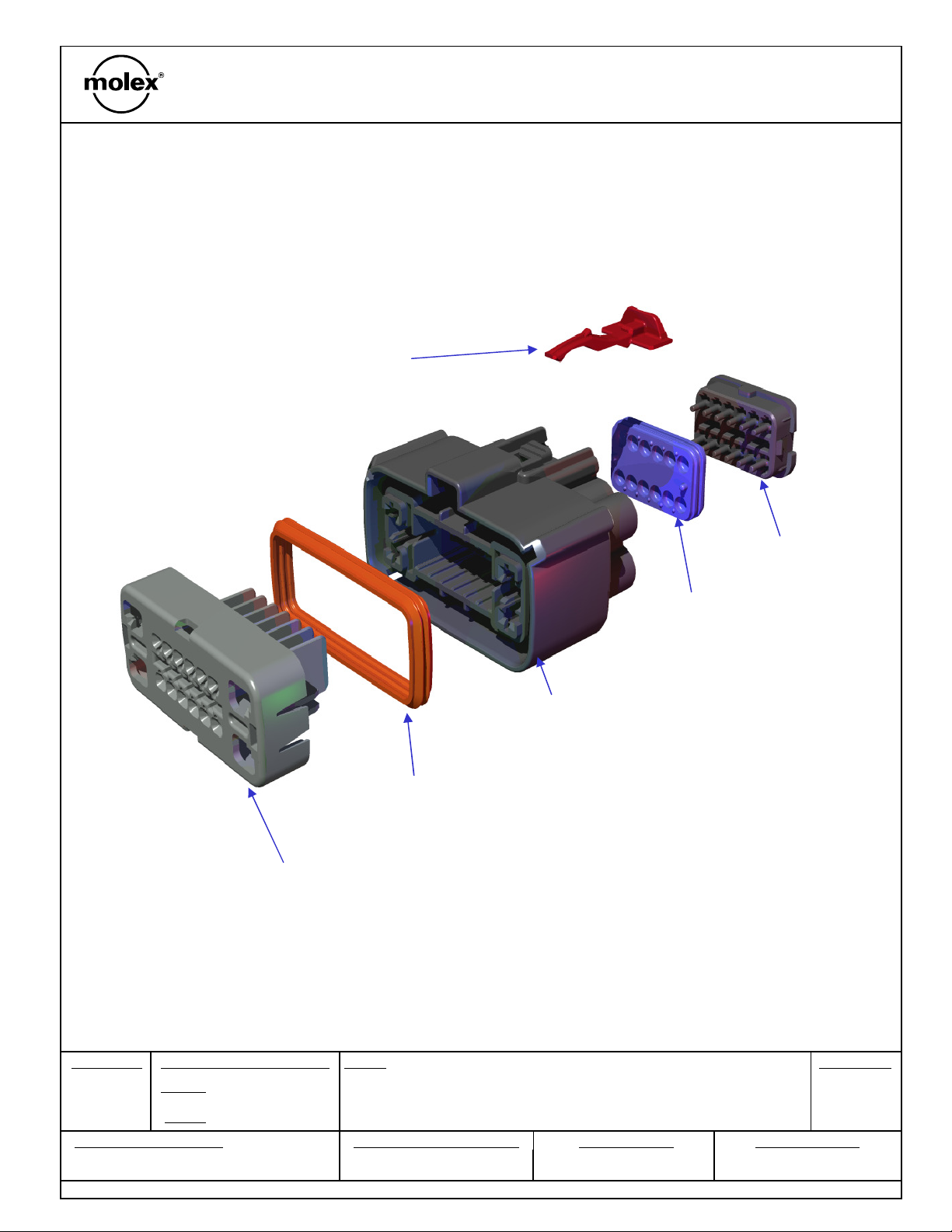

Section 1: Product Introduction MX150 System

Features and Benefits:

•Pre-assembled connector housings, seals and TPA components

•Simple crimp, poke and plug application

•Integral Terminal Position Assurance (TPA)

•Integral two way, mat and interface seals designed and tested to IP

67 and SAE USCAR-2, Rev 3 standards

•Easy terminal extraction and insertion

•Compatible with a wide range of UL (22 to 14 AWG) and SAE

Automotive (22 to 14) style wires

•Integral locking latch with secondary connector position assurance

(CPA) option

•Applied cost savings

•No need to crimp individual wire seals

•Locks terminals into housings and prevents terminals from backing

out

•More than just waterproof, a true sealed connector system tested

under submersed conditions

•Quick, low cost field repairs

•Supports a wide range of power and signal applications

•Assures positive mating of connector and prevents accidental

disengagement during high vibration and severe shock application