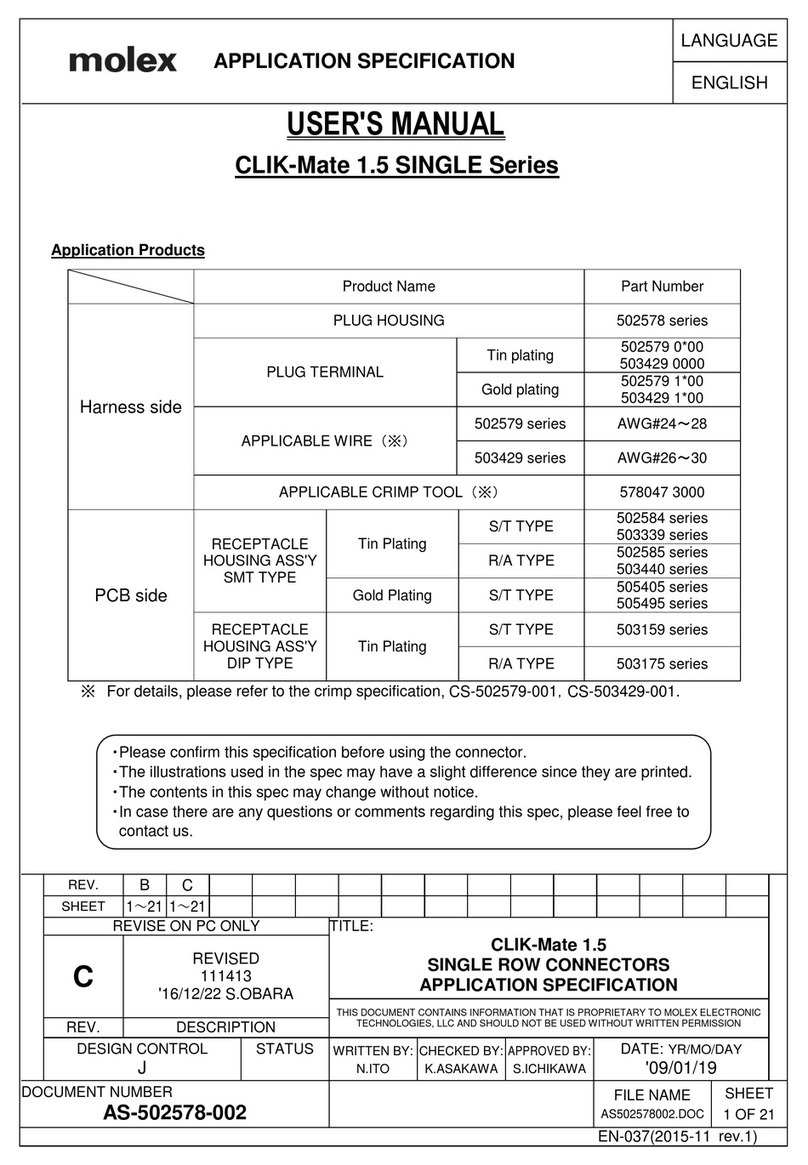

PROCEDURE: 2090580010-ES TEMPLATE: 2090580010-PAS-A4 REVISION: A1

3-4. Harness process and surface mount process instruction

1. Please confirm if the products and crimp machine, crimp condition, an applicable wire are equal to product

drawing, crimp specifications before use.

2. Beware of unintended damage caused by dust, debris, or foreign objects before using this product. It may result

in unsatisfaction of the insertion performance to the housing and electric performance.

3. Please do not touch the terminal by bare hand.

4. When a terminal is twisted or tangled before or after crimping, please do not pull it by force. The terminal may

become damaged.

5. Do not apply force to the product during work in process or in finishing goods. Product may be damaged and

may not function properly as a connector.

6. Please do not expose a product and a harness half-finished goods to the following condition.

・Dust

・Corrosive material

・Corrosive gas

・High temperature and high humidity

・Direct sunlight

The above-mentioned conditions may cause poor contact and the corrosion of the terminal and the insulation

performance deterioration of the housing.

Please keep in boxes.

7. Please do not add loads to connector and harness half-finished goods during production, packaging,

transportation, or storage. It may cause damage and result in poor performance.

8. When pulling the electric wire of harness half-finished goods, contact defect may be caused by adding load to

contacts, crimp parts and lock parts. When performing the guidance wiring of the electric wire, do not apply

excessive forces that the connector can’t withstand.

9. Do not damage receptacle crimp housing and a crimp terminal intentionally. Product performance can be

affected by this condition.

10. Please use the product within the day the package is opened. Moisture absorption or drying may cause the

deterioration of materials by neighboring atmospheres. When you cannot use it up, please seal the bag again

and keep it in a box.

11. Please be careful not to be injured by the edges part such as metal parts when handling a connector.

12. To avoid injury, please be careful when handling the paper between terminals and metal carrier on reels.

13. Our evaluation is with the use of standard rigid PCB. When the product is used on flexible printed circuits (FPC)

please evaluate in advance.

14. Please solder all the terminal departments and the nail part. Non-soldered part may cause defect.

15. In the case of changing our recommended board pattern size or design, please consult us in advance because

such changes may cause defects.

16. Please do not apply to load the connector. For example, carrying the PCB when connector is mated may cause

damage.

17. Please do not stack PCB after connector has soldered to PCB.

18. Please follow the conditions of specifications, when the connecting connector with a soldering iron.

For conditions exceeding specifications, the connector may be damaged.

19. When using a solder iron, please do not use excessive solder and flux. It may cause poor contact performance

by solder wicking and flux wicking.