molex TM42 User manual

Other molex Power Tools manuals

molex

molex 69020-0660 User manual

molex

molex TM-3000 User manual

molex

molex TM2000 User manual

molex

molex TM-3000 User manual

molex

molex TM-3000 User manual

molex

molex TM2000 User manual

molex

molex Mini Mi2 User manual

molex

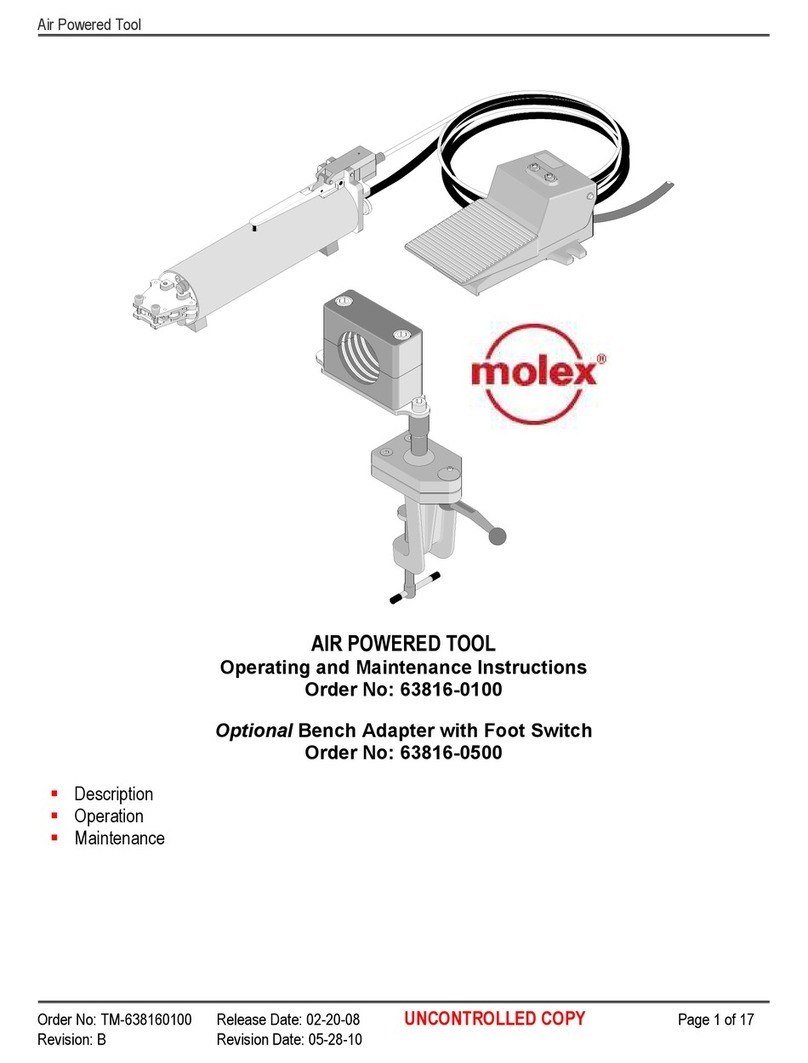

molex 63816-0100 Manual

molex

molex 63827-8800 User manual

molex

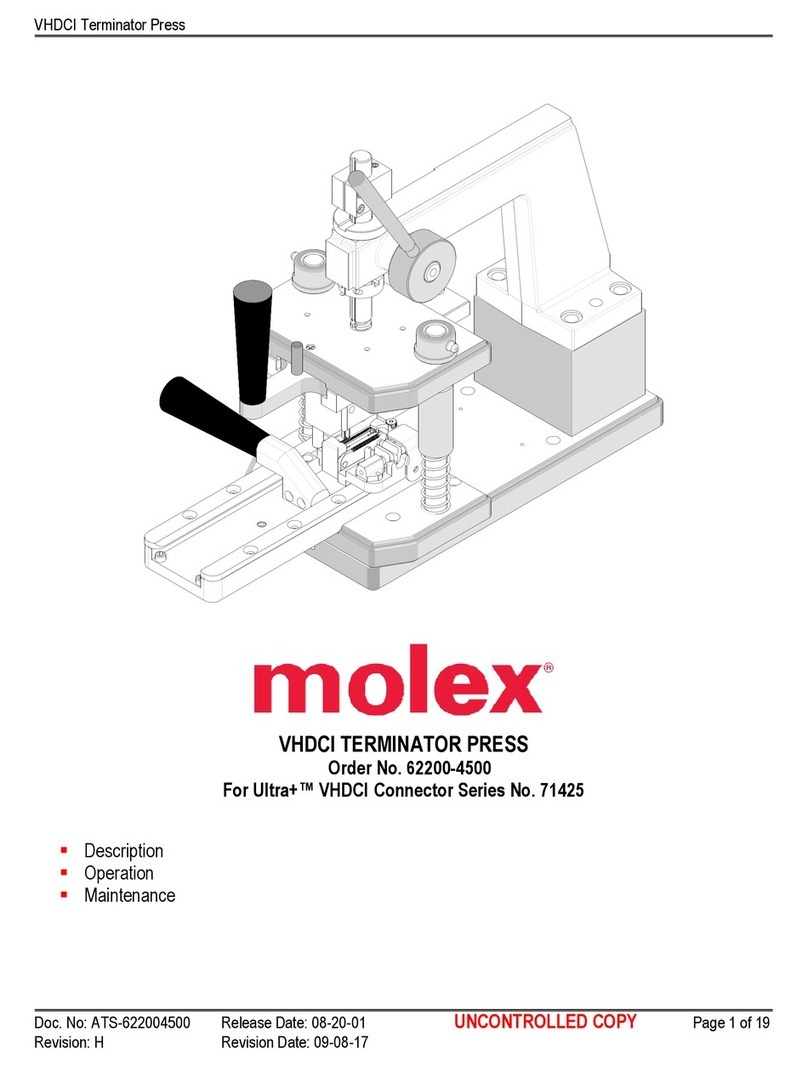

molex VHDCI User manual

molex

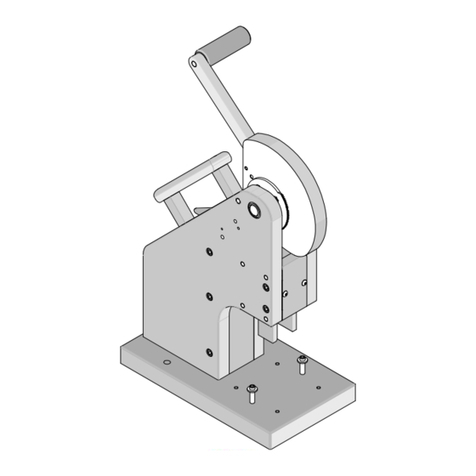

molex RAST 5.0 Arbor Press Terminator User manual

molex

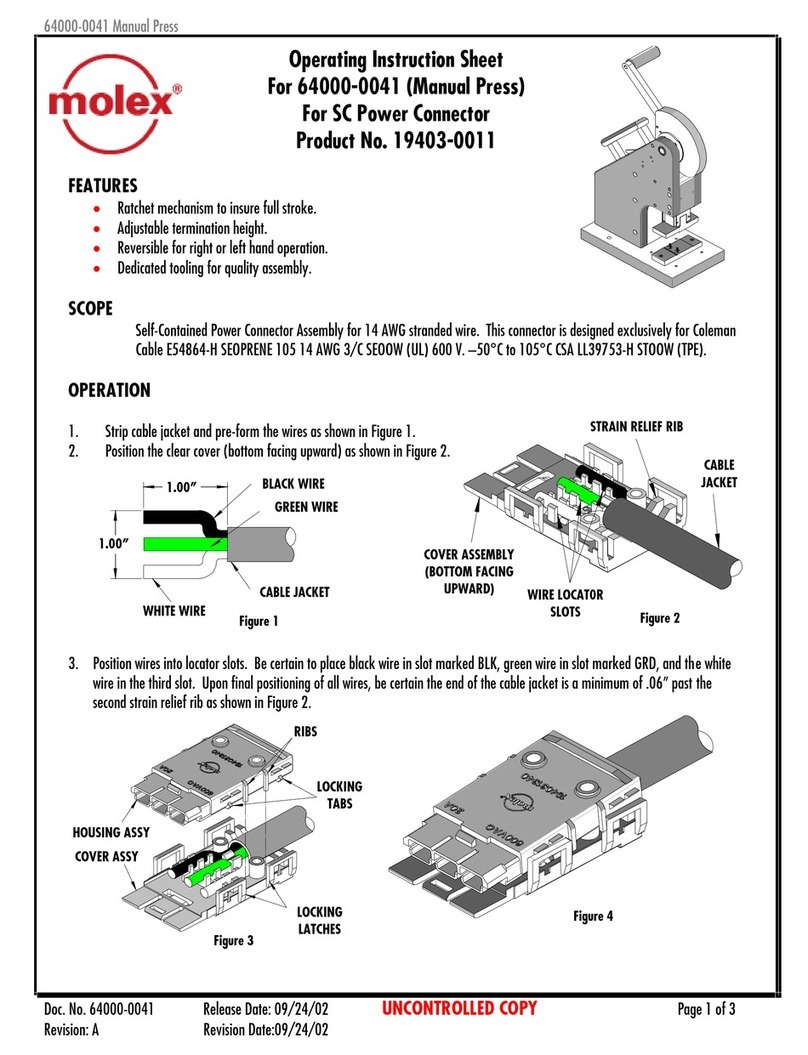

molex 64000-0041 User manual

molex

molex 63600-0478 User manual

molex

molex 11-31-6356 User manual

molex

molex 35477 Series User manual

molex

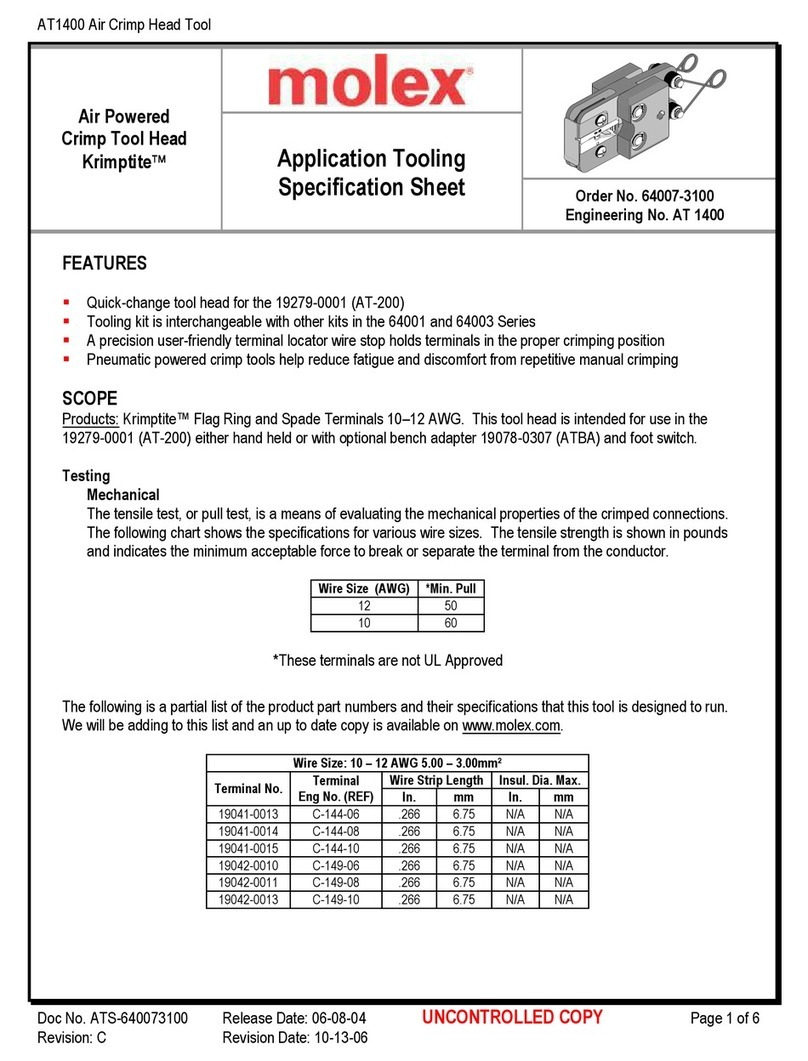

molex AT-200 Manual

molex

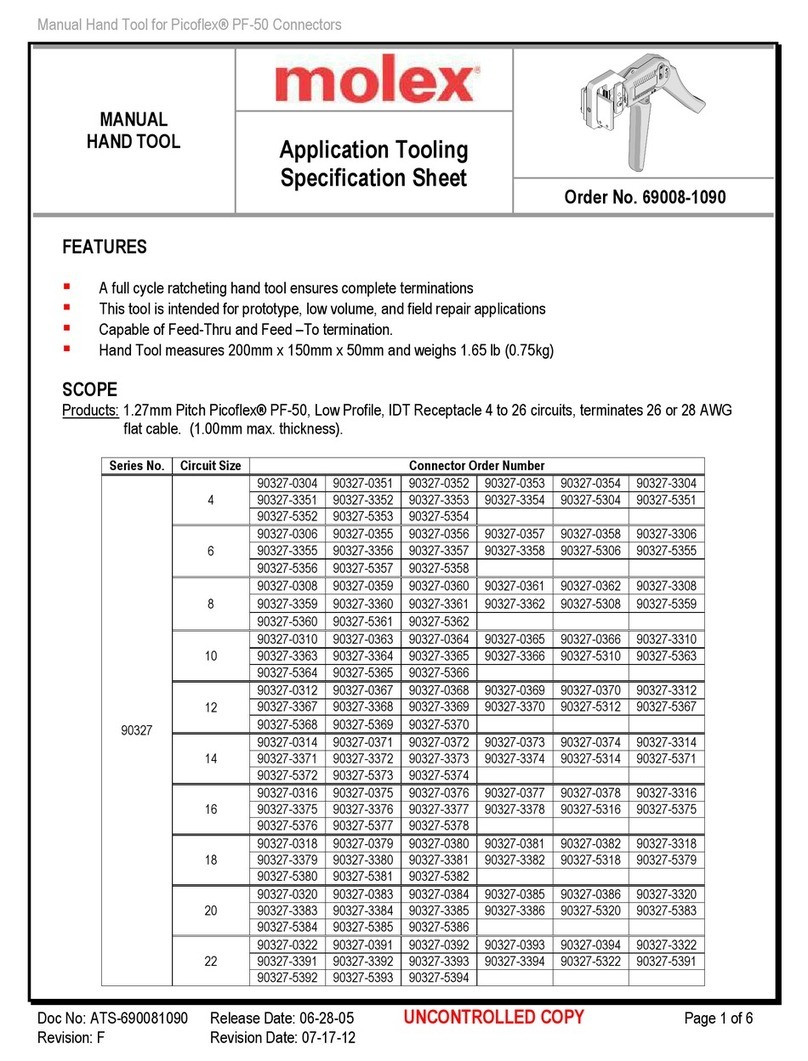

molex 90327 Series User manual

molex

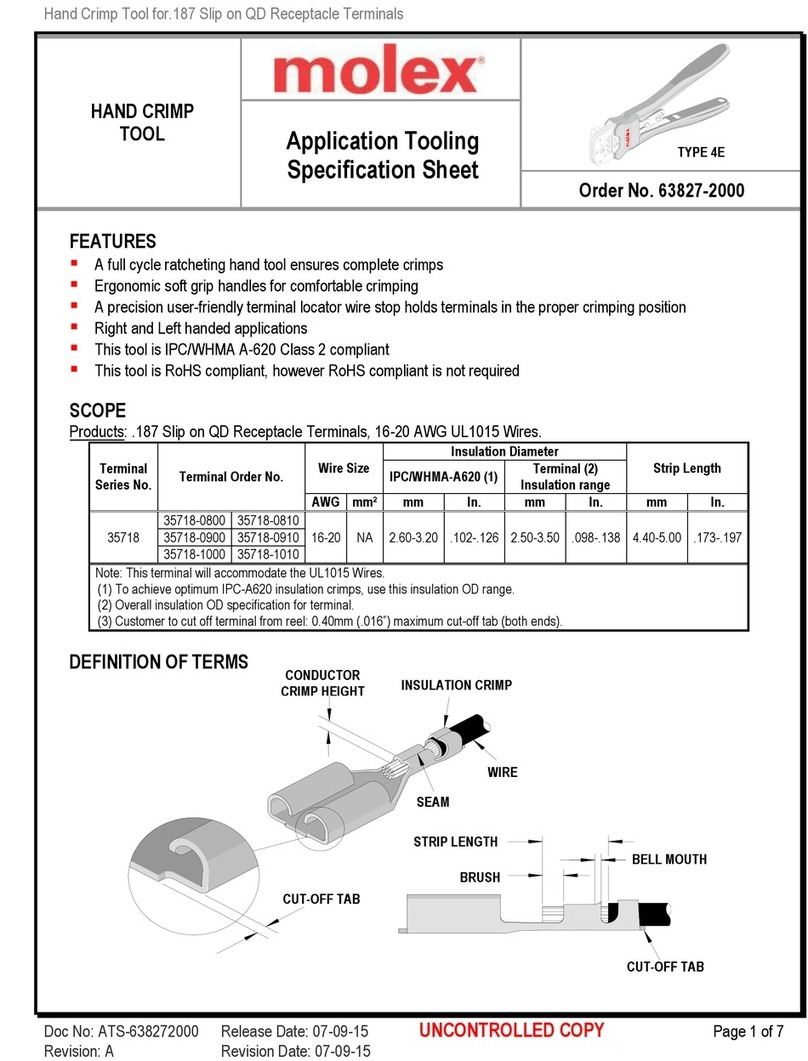

molex 63827-2000 User manual

molex

molex 207129 Series User manual

molex

molex 69020-1908 User manual