Hydraulic Dieless Crimping Tool

Doc No. TM-638161700 Release Da e: 03-21-14 UNCONTROLLED COPY Page 4 of 29

Revision: D Revision Da e: 05-10-17

Never use his ool wi hou guards or safe y devices

ha are in ended o preven hands from remaining

in he die space.

Failure o observe his warning could resul

In severe injury or dea h.

his equipmen .

The forces crea ed by compressed

air can force debris in o he ool.

Failure o observe hese precau ions may

resul in injury or proper y damage.

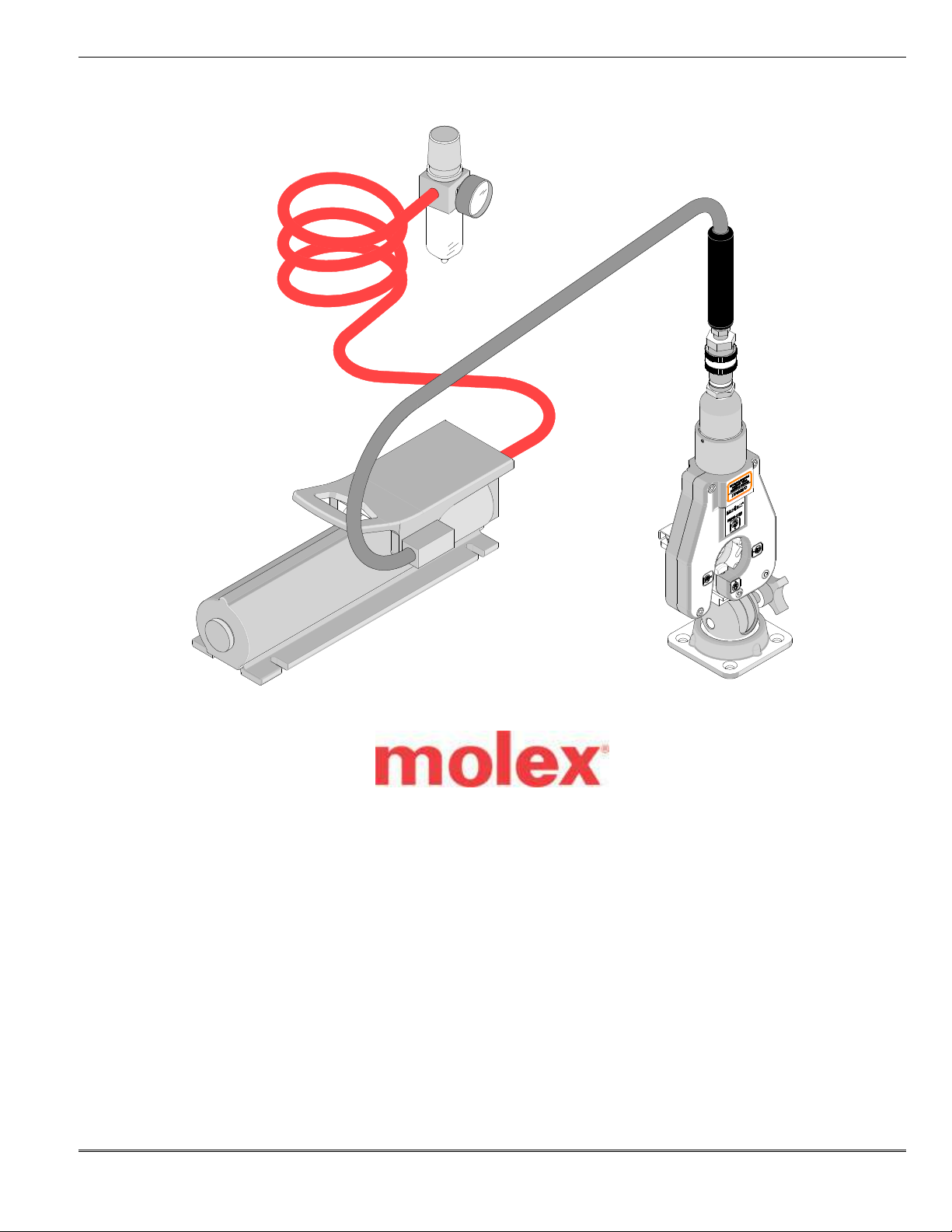

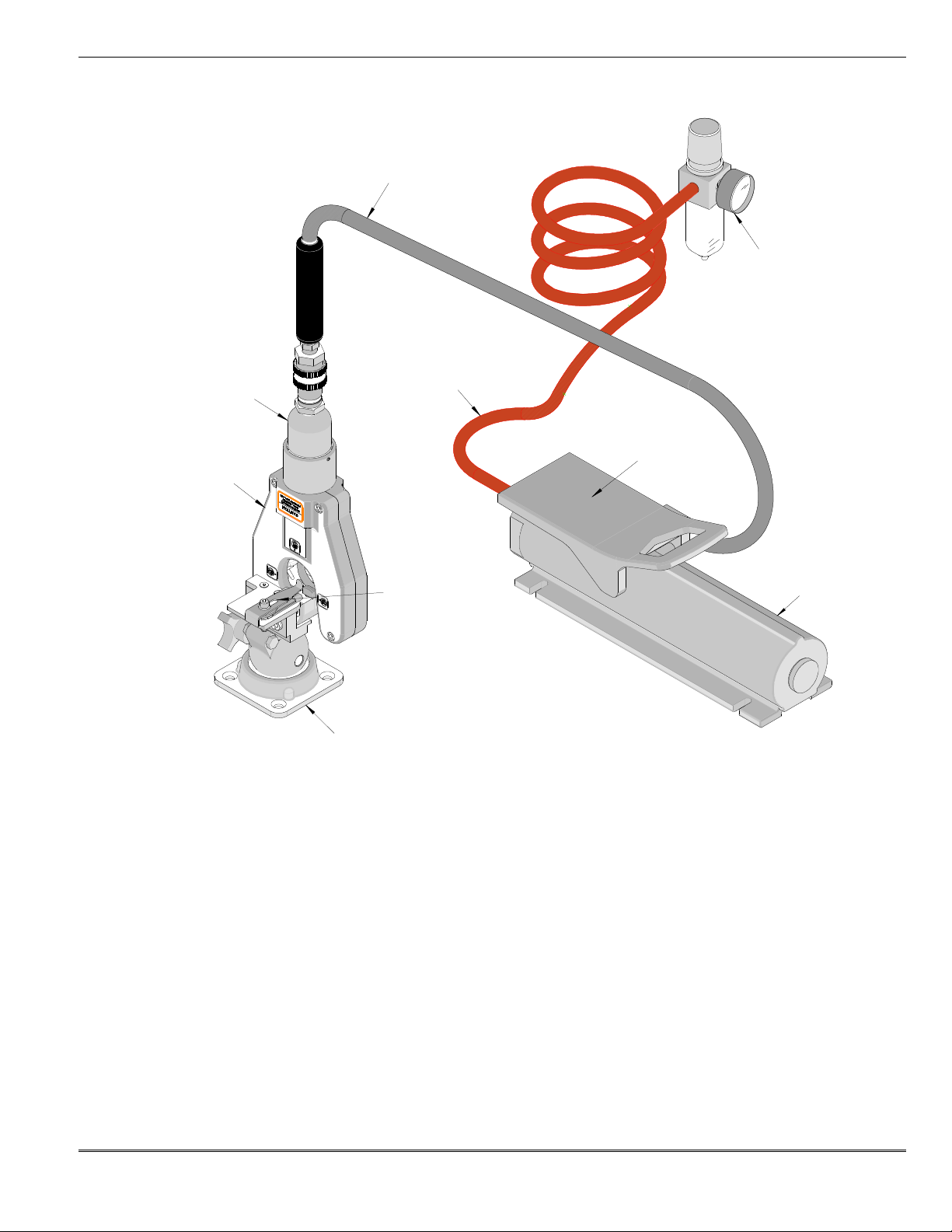

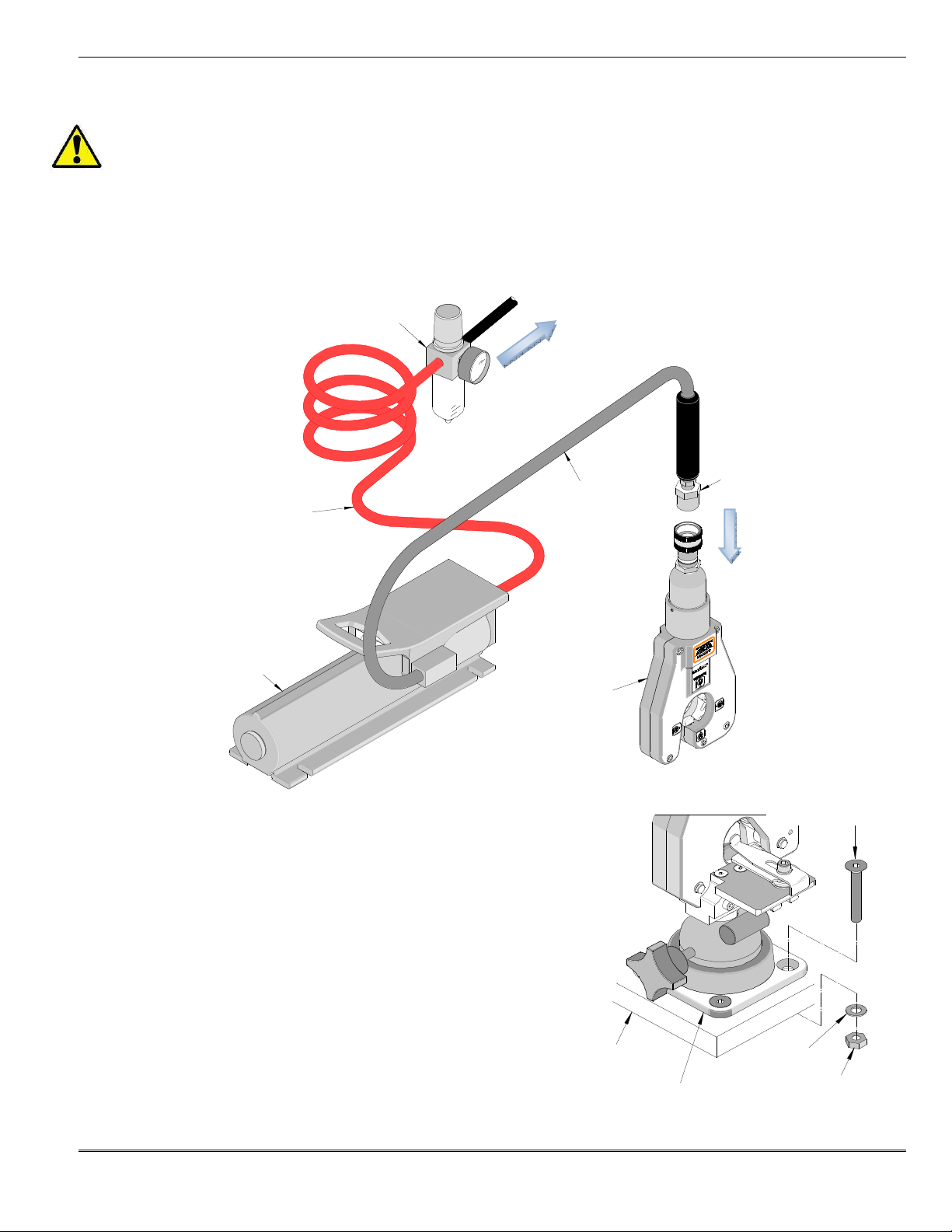

Air

Hydraulic

Pump

Pump

Maximum Capacity: 10,000 P I

Before opera ing he hydraulic pump, all hose

connec ions mus be igh ened wi h proper ools.

Do not over- igh en. Connec ions need only be

igh ened securely and leak-free. Over- igh ening

may cause prema ure hread failure or may cause

high-pressure fi ings o spli a pressures lower

han heir ra ed capaci ies

Should a hydraulic hose ever rup ure, burs , or need

o be disconnec ed, immedia ely shu off he pump

and shif he con rol valve wice o release all pressure.

Never a emp o grasp a leaking hose under pressure

wi h your hands. The force of escaping hydraulic fluid

could cause serious injury.

Do not subjec he hose o po en ial hazard such as fire,

ex reme hea or cold, sharp surfaces, or heavy impac .

Do not allow he hose o kink, wis , curl, or bend so

igh ly ha he oil flow wi hin he hose is blocked or

reduced. Periodically inspec he hose for wear because

any of hese condi ions can damage he hose and

possibly resul in personal injury.

Do not use he hose o move a ached equipmen .

S ress may damage hose and possibly cause personal

injury.

Hose ma erial and coupler seals mus be compa ible

wi h he hydraulic fluid used. Hoses mus no encoun er

corrosive ma erials such as creoso e-impregna ed

objec s and some pain s. Consul he manufac urer

before pain ing a hose.

Never pain he couplers. Hose de eriora ion due o

corrosive ma erials may resul in possible personal injury

Do not exceed he PSI hydraulic ra ing no ed

on he pump namepla e or amper wi h he

in ernal high-pressure relief valve.

Crea ing pressure beyond ra ed capaci ies

may resul in personal injury.

Before replenishing he oil level, re rac he

sys em o preven overfilling he pump reservoir.

An overfill may cause personal injury due

o excess reservoir pressure crea ed when

cylinders are re rac ed.

Cylinder

Do not exceed ra ed capaci ies of he cylinders.

Excess pressure may resul in personal injury.

Do not se poorly balanced or off- cen er

loads on a cylinder. The load may ip and

cause personal injury.

Air

upply

Shu off and disconnec he air supply when

he pump is no in use or before breaking

any connec ion in he sys em.