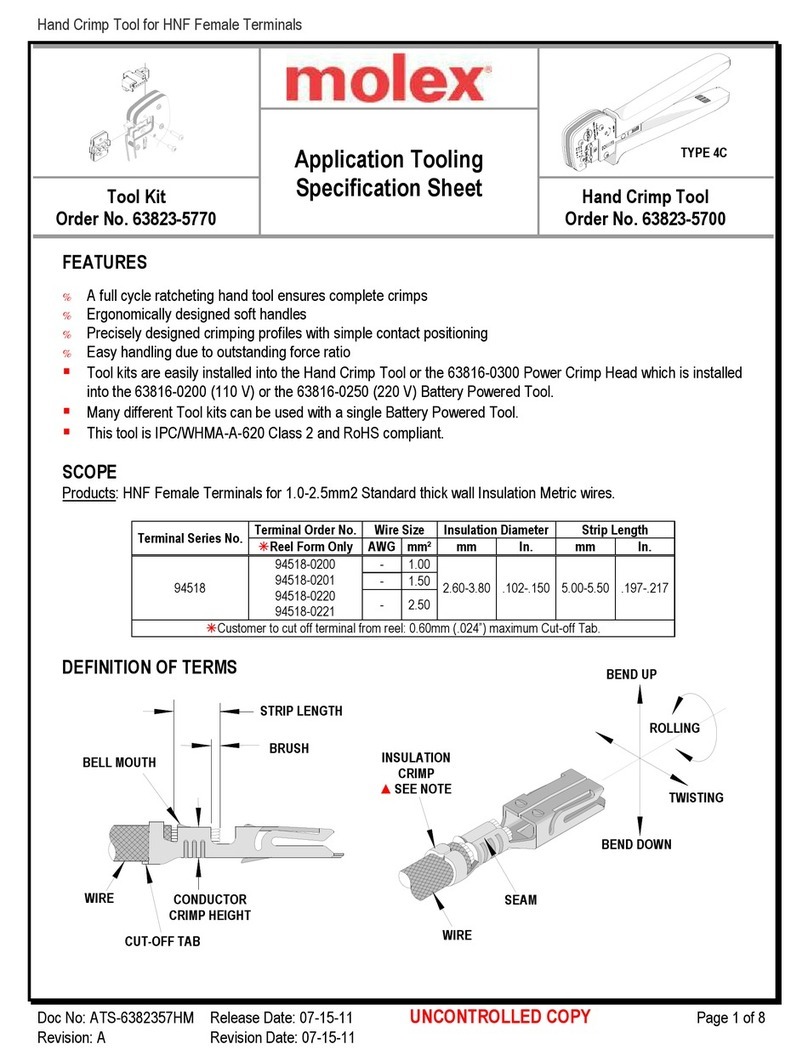

Tool Kit for Quick Disconnect, Female, Flag Crimp Terminals

Doc No: ATS-63 1932HM Release Date: 03-23-09 UNCONTROLLED COPY Page 3 of

Revision: B Revision Date: 10-04-10

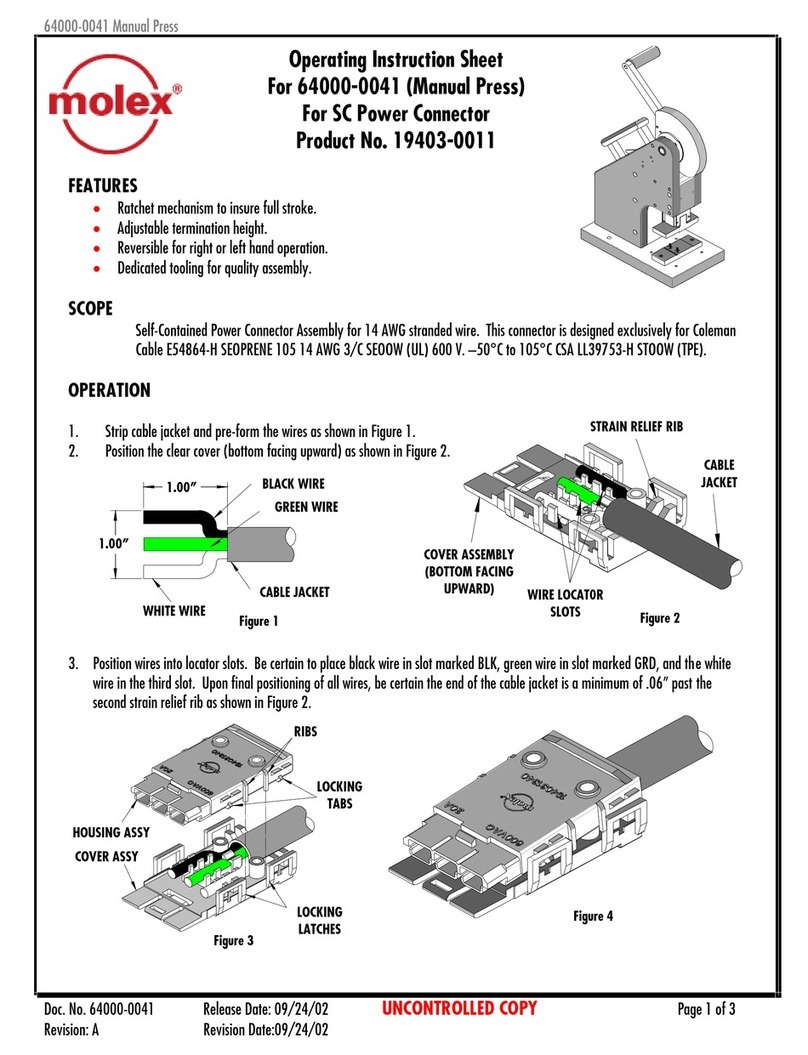

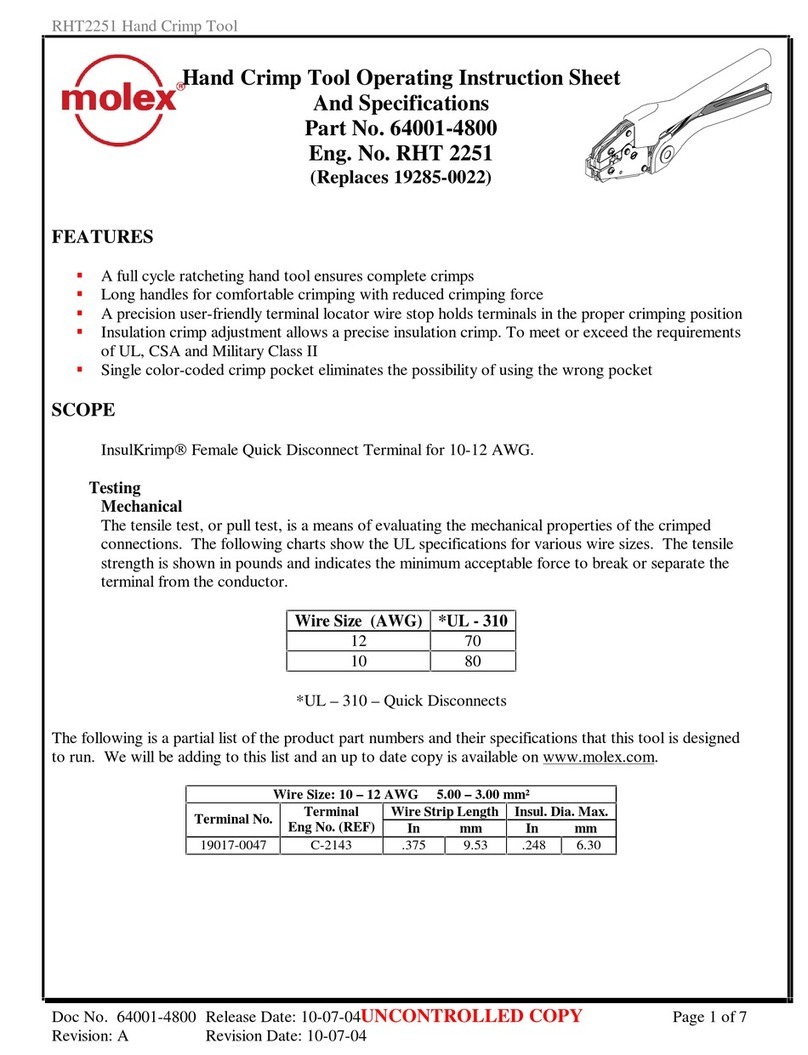

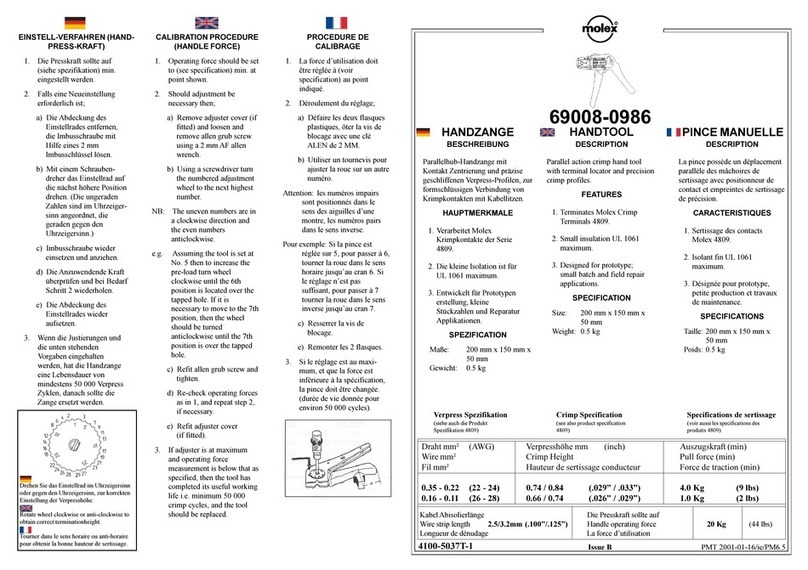

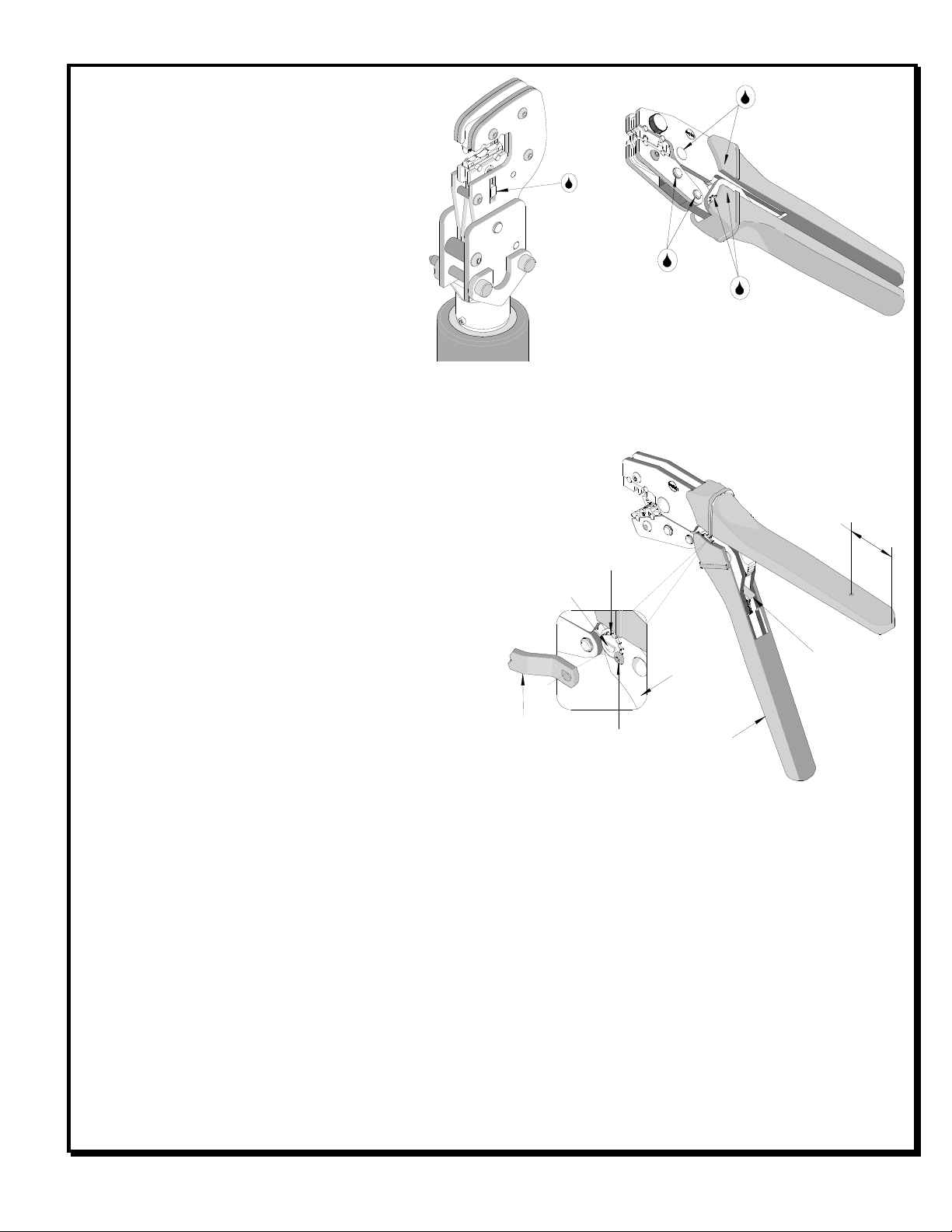

Figure 2

JAWS

OPEN

TERMINAL

NURLED FASTENER

UPPER

TOOLING

OPERATION

Open the tool by squeezing the handles together, at the end of the

closing stroke, the ratchet mechanism will release the handles, and the

hand tool will spring open.

Crimping Terminals

1. Select the desired terminal listed in the preceding charts.

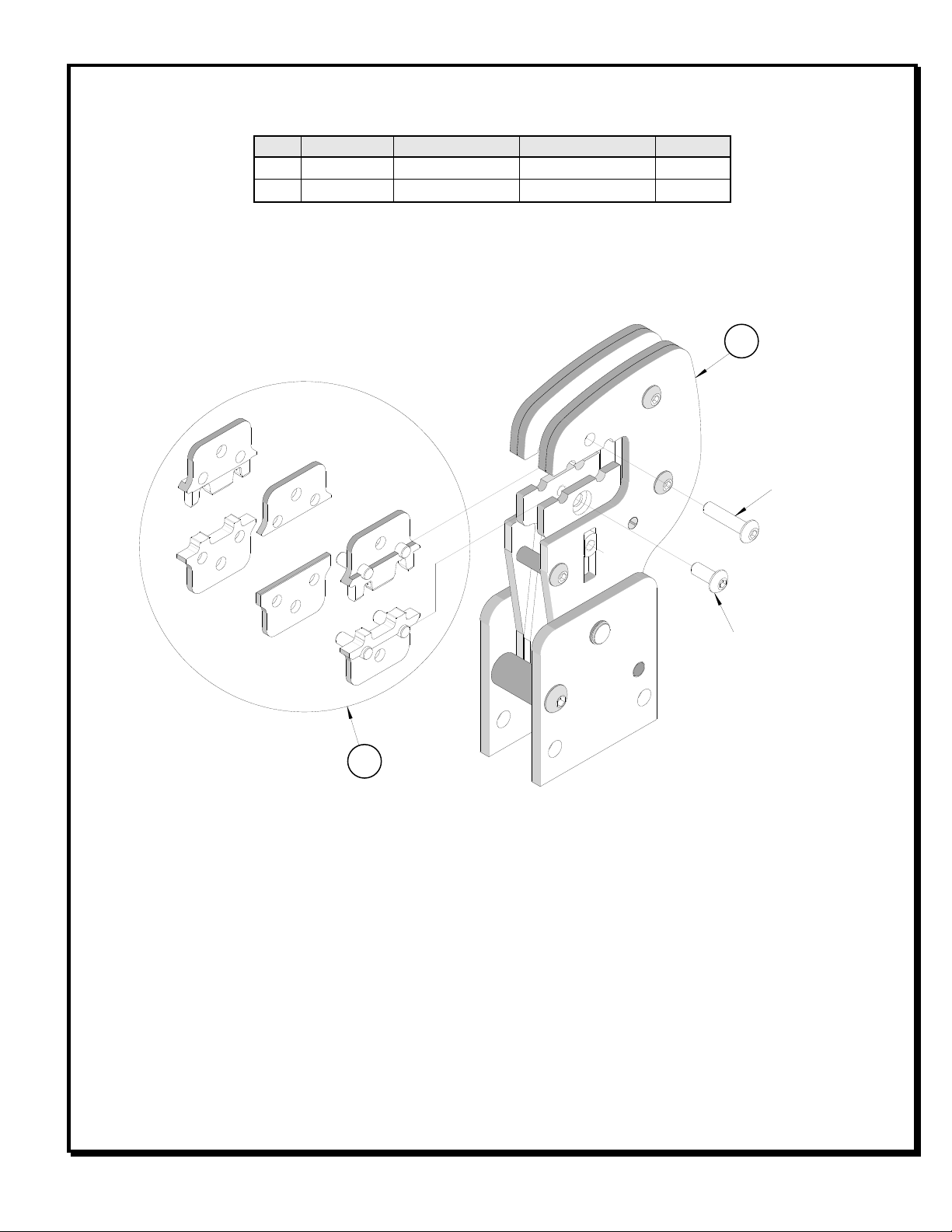

2. Before attempting to crimp any terminals, make sure all the upper

tooling is correctly placed into the upper jaw. The desired nest

being used for the proper wire size should be in the forward

position, (The marking on the upper tooling “A” for 0. mm ² or “B”

for 0.5mm²). This is done by removing the knurled fastener that

holds the upper tooling in place and then rotating it 1 0° to the correct position. Then, re-installing the

fastener. See Figure 2.

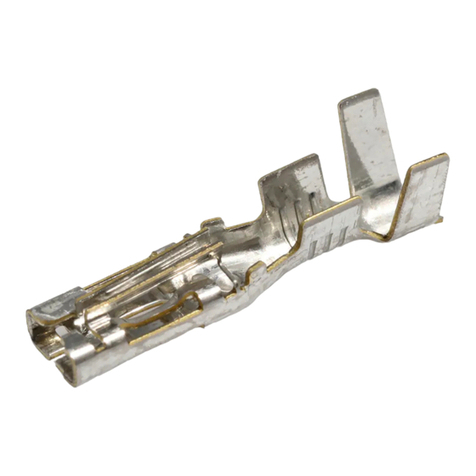

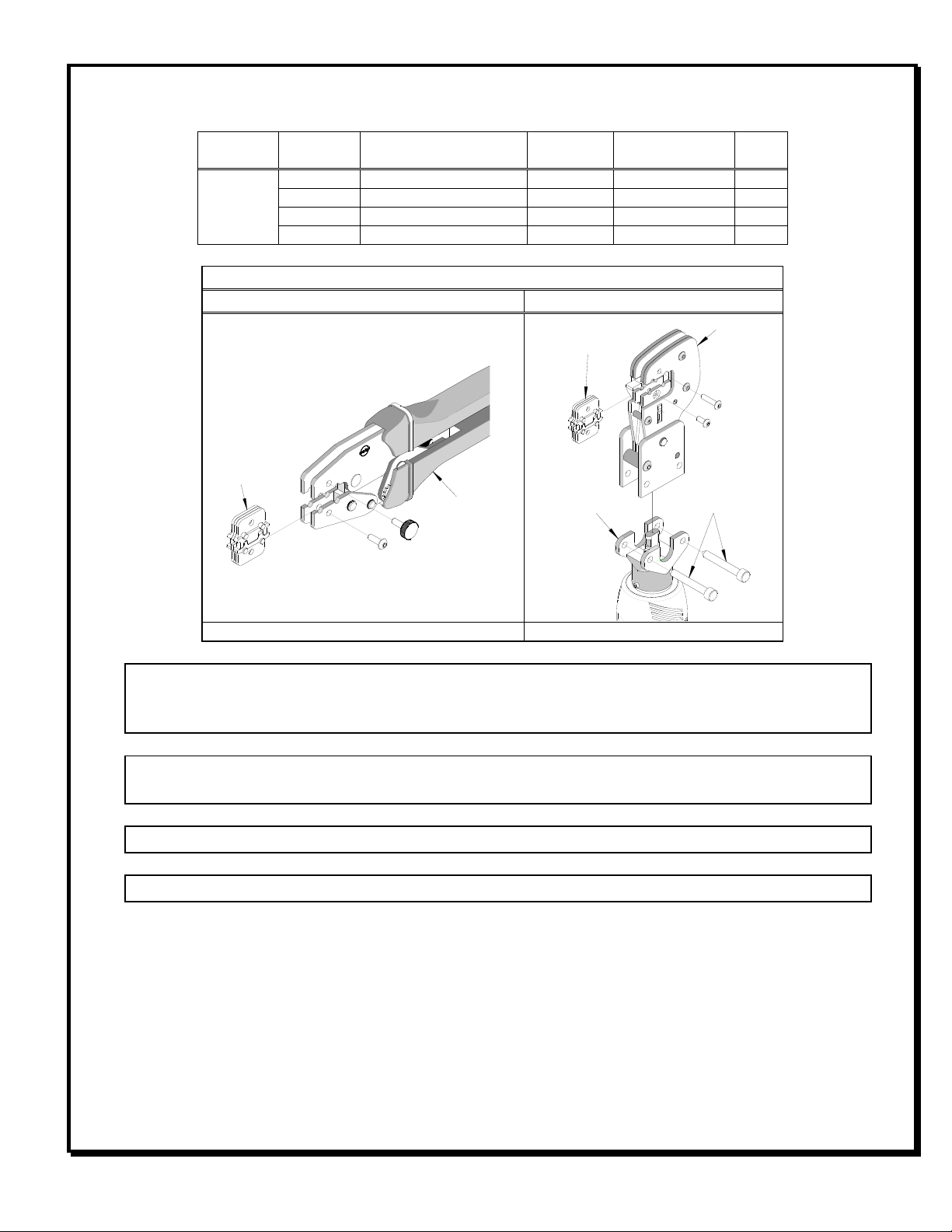

3. Place the terminal into the nest profile, centered on the nest as shown, with the outer edges of the crimp grips

flush with each side of the crimp die and the opening in the terminal centered below the forward leg of the right

punch. See Figure 3.

4. Partially close the tool until the terminal is held in place and re-position the terminal as necessary.

5. From the left side of the tool, insert the pre-stripped wire into the terminal until the conductor is centered, front

to rear, in the crimp grips. See Figure 3.

6. Compress the terminal by squeezing the tool handles until the ratchet mechanism cycle has been completed.

Release handles to open the jaws.

Note: The tamper proof ratchet action will not release the tool until it has been fully closed.

7. Remove the crimped terminal. Inspect for proper

crimp location, and check for insulation closure.

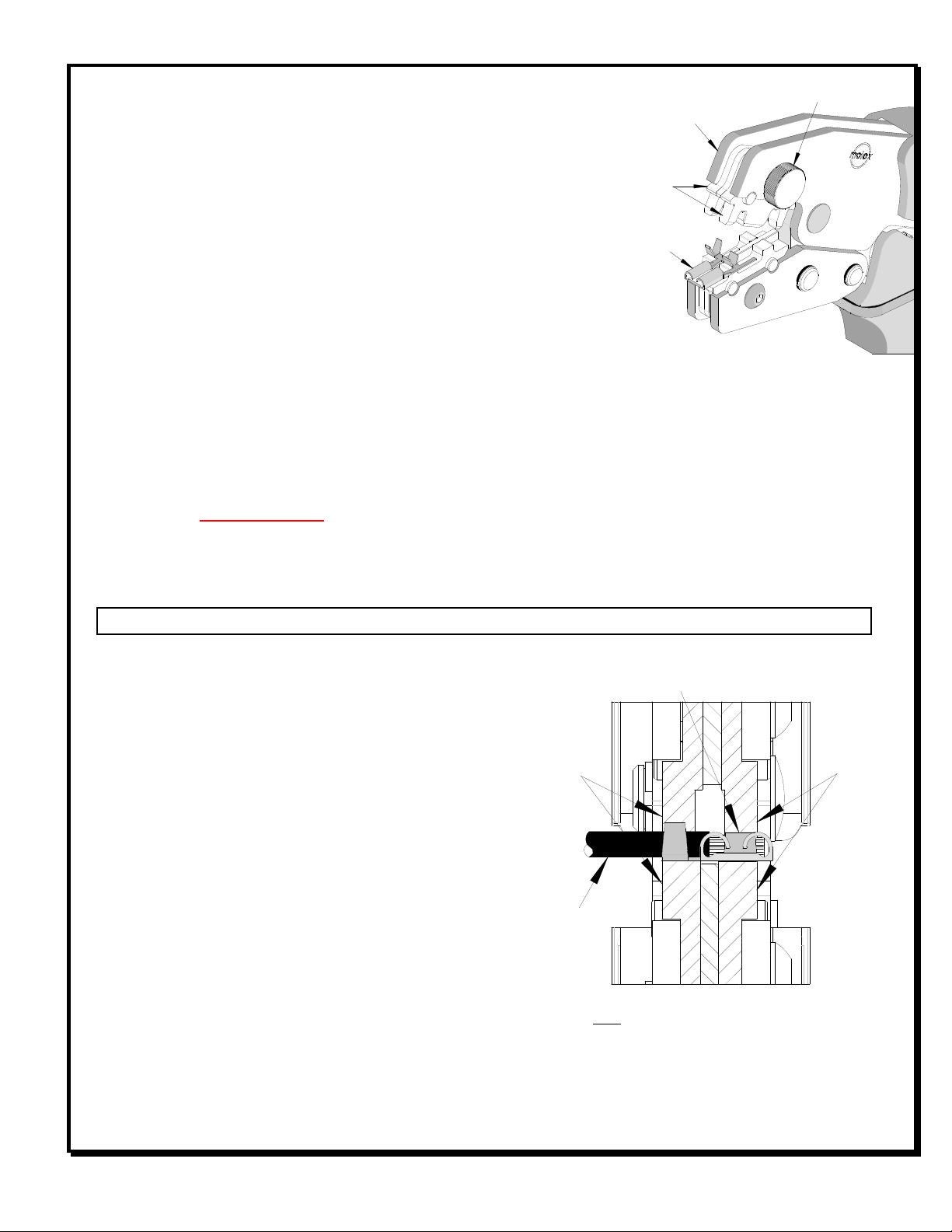

For the Battery Power Tool:

1. Cycle the Battery Power Tool to crimp the terminal

to the wire.

2. Remove the crimped terminal from the terminal

locator by pressing down on the wire stop and

gently pulling on the wire. The terminal locator can

be in either position.

3. Visually inspect the crimped terminal for proper

crimp location.

Maintenance

It is recommended that each operator of the tool be

made aware of, and responsible for, the following

maintenance steps:

1. Remove dust, moisture, and other contaminants

with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

Figure 3

Note: The Terminal should be centered in

crimp nests with the outer edges of the crimp

grips flush with the jaws on both sides.

WIRE

CONDUCTOR OF THE TERMINAL CENTERED

IN CRIMP GRIPS FRONT TO REAR

SEE NOTE

BELOW

SEE NOTE

BELOW