TM-3000UniversalPress

OrderNo63801-7299 ReleaseDate:06-06-05 UNCONTROLLED COPY Page8of29

Revision:A RevisionDate:06-06-05

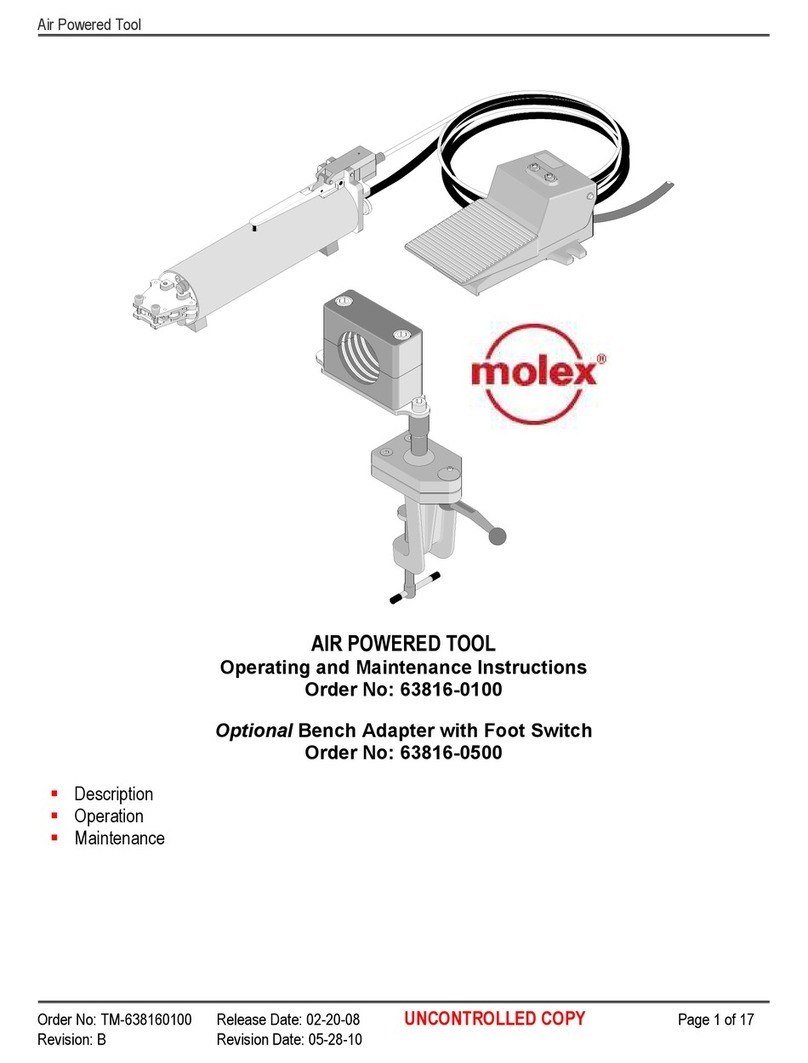

POWER

CORD PLUG

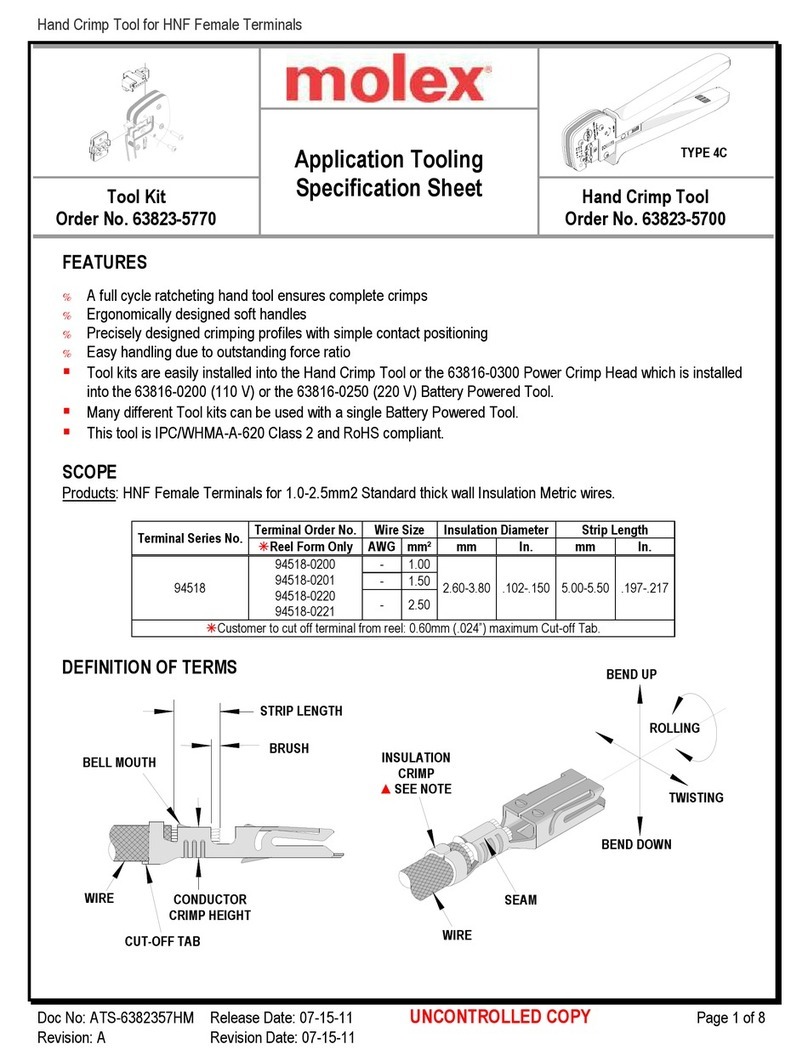

Figure 2-2

FOOTSWITCH

CORD

PULL UP FROM

HOLE, ROTATE AND

SLIDE DOWN INTO

REPOSITION

TERMINAL GUIDE

Figure 2-3

REMOVE M6 BHCS

AND REMOVE

TERMINAL GUIDE

LOOSEN

M10 SSS IN

FRONT OF

PRESS

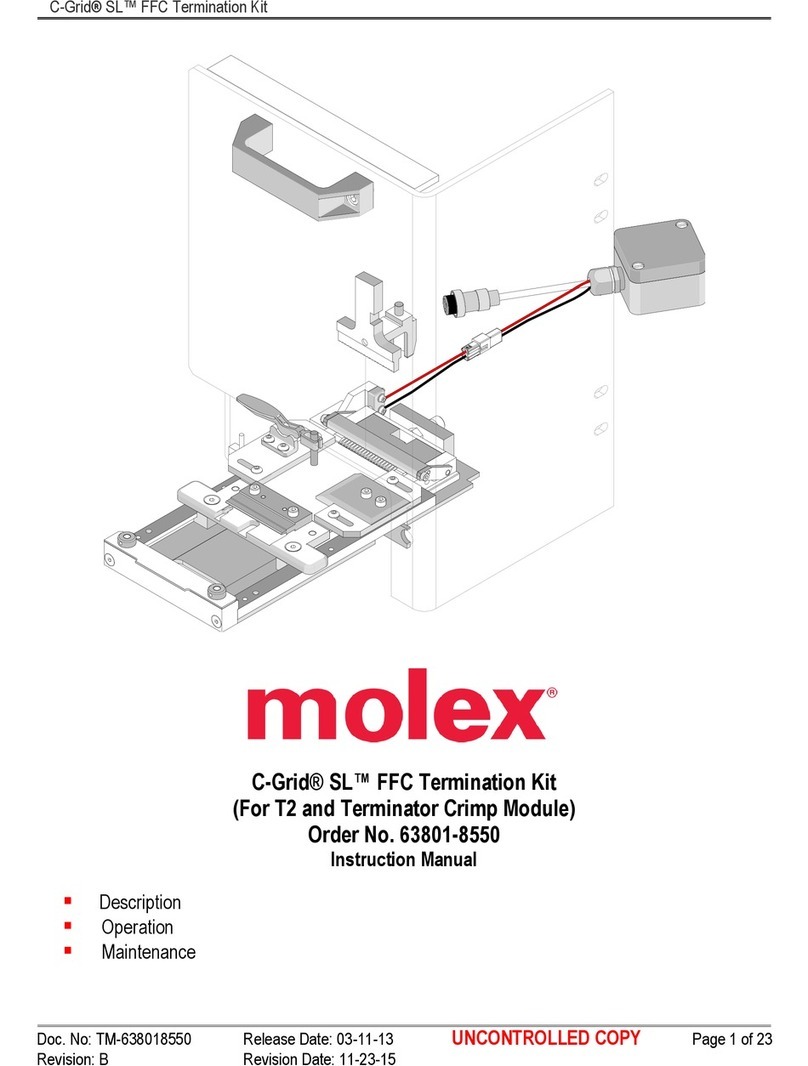

2.4 Pneumatic Supply Hook-Up

Acompressedairsupplyis requiredifairfeedorotherair

poweredapplicatorswillbe used. TheTM3000presscomes

equippedwithanair supplysystem,whichconsists offilter,

regulator,lubricatorand avalve toactuate theairfeedsatthe

propertime inthe presscycle.

Duetotheconsiderabletypesofairconnectionandquick

connectfittingsavailable;Molex onlysuppliesthe TM3000press

witha1/4NPTfemalethreadedfitting. Thecustomermay

attachwhatevertypeofairconnectionsthatare commonlyused

intheirplanttothisport.

Theminimumflexibletubesizeusedtoconnectthepressshould

be8mmor5/16”toassureadequateflowrate.

Afilter-regulator-lubricatorunit issuppliedtoproperlycondition

theincoming air. Thefilter will remove particulate and moisture

fromtheairthatcandamageorreducethelife ofcylindersand

valves. Thisfilterandbowlshould beservicedonaregular

schedule. (Seesection 4.1) Thefilter has anautomatic drainat

thebottomofthebowlthatwillautomaticallyopenandexpel

fluidwhenthebowlisgettingfull. Itisrecommendedthat, a

6mmor1/4”flexibletube,beattachedtothedrainhosebarb

andruntoacontaineriftheairsystem containsexcessive

moisture.

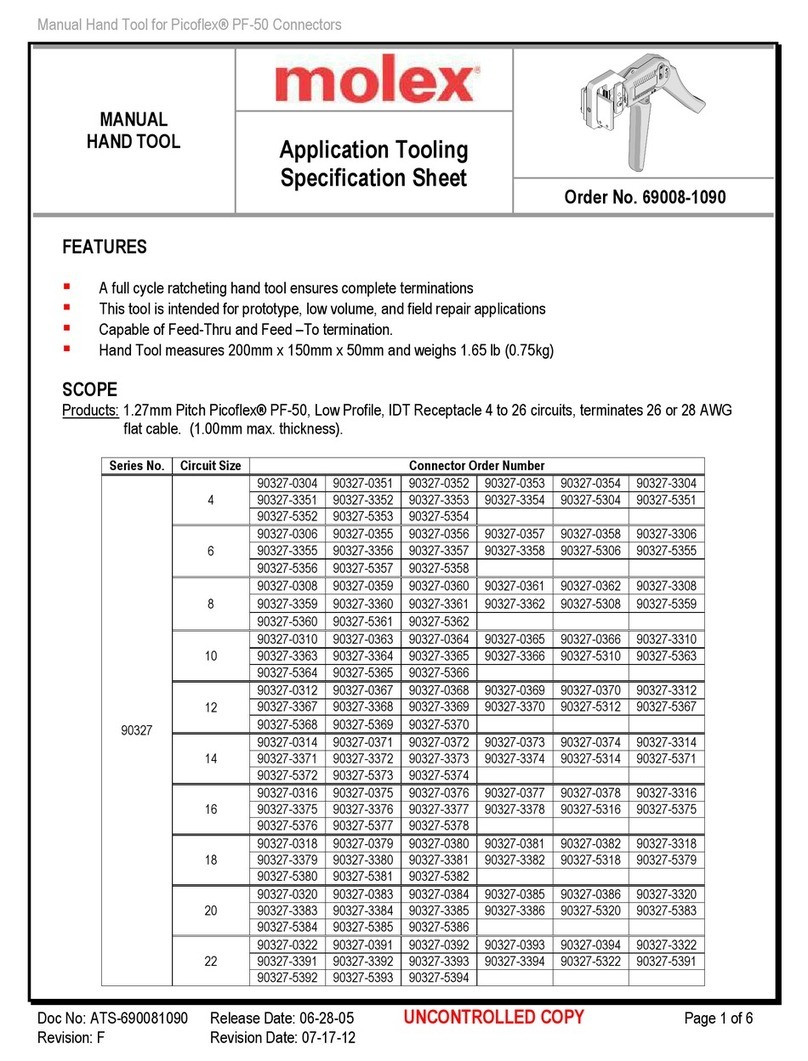

Theregulatoradjuststhepressureof theincomingair towhat

theapplicatorsrequireusually60-80PSI(refertotheapplicator

manualforrecommended pressures.) Adjustmentis

accomplishedbypullingupontheknob,rotatingituntilthe

gaugeindicatesthedesiredpressure,thenpushingitdownto

lockthesetting.

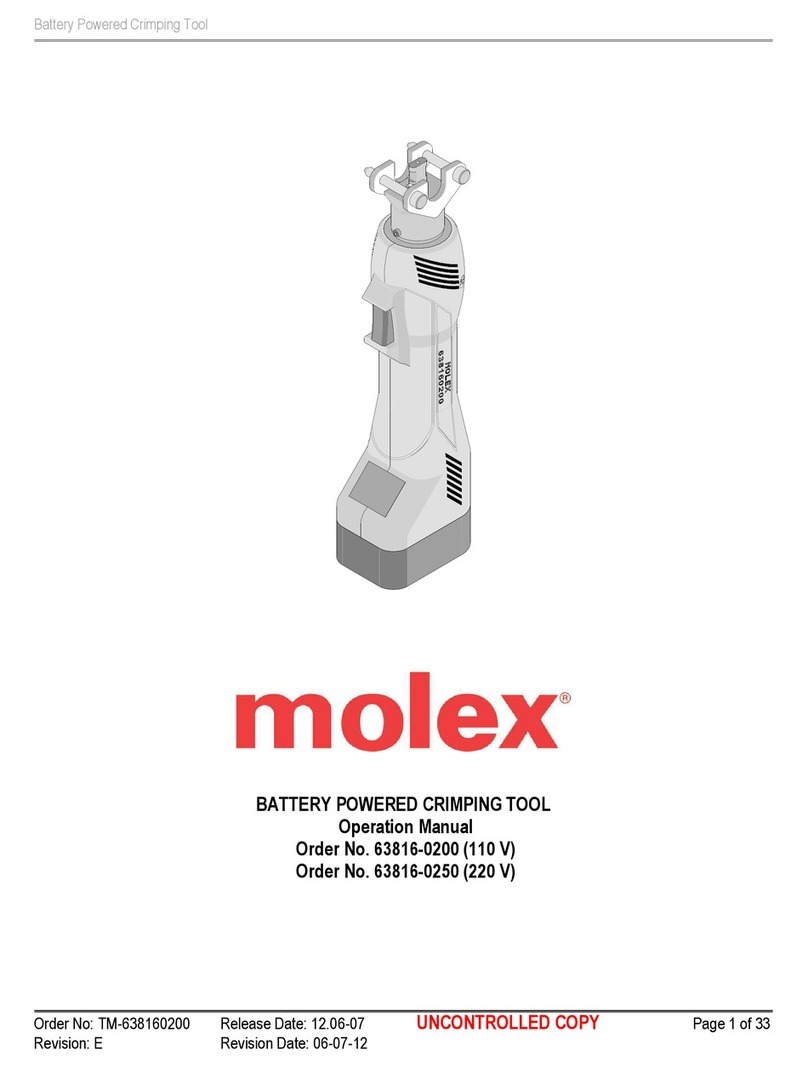

Alubricatorissuppliedforthoseapplicatorairfeedsthatneed

lubrication. Molexair-feedapplicatorsdonot require

lubrication.Thelubricatorisshippedwithoutlubricantinit. To

use,fillthelubricator(makesurethemainairsupplyis

disconnectedorthattheslidevalveprovidedisintheoffposition

beforeaddinglubricant)throughthe fillplugonthetopofthe

unit,withahighqualitySAE10Woil. Thelubricatorhasa

graduateddialontop,turnthedialtothe1or2setting.

Caution:Donotoverlubricate. Onlyaverysmallamountof

lubricantisrequiredto assuresmoothoperation. Excesslubricant

isexhaustedtotheatmosphere.

Iflubricationisnotrequiredsetthedialto0toturn off the

lubricator.

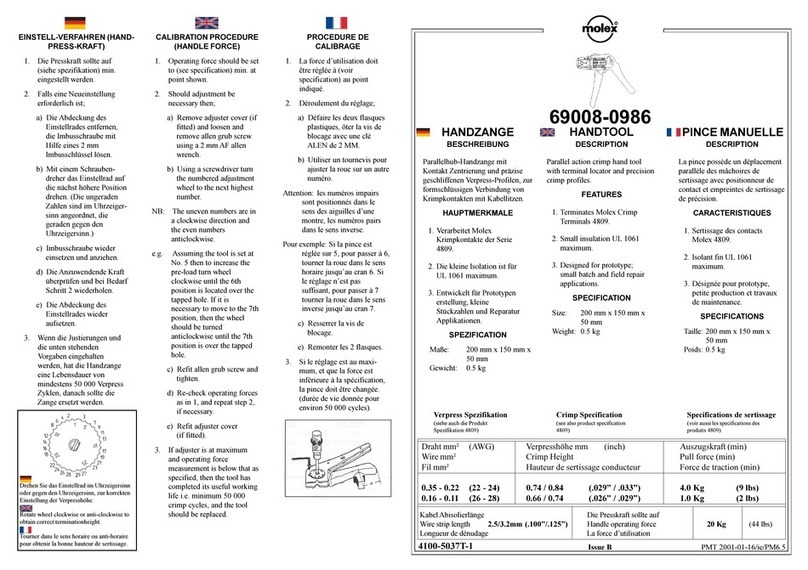

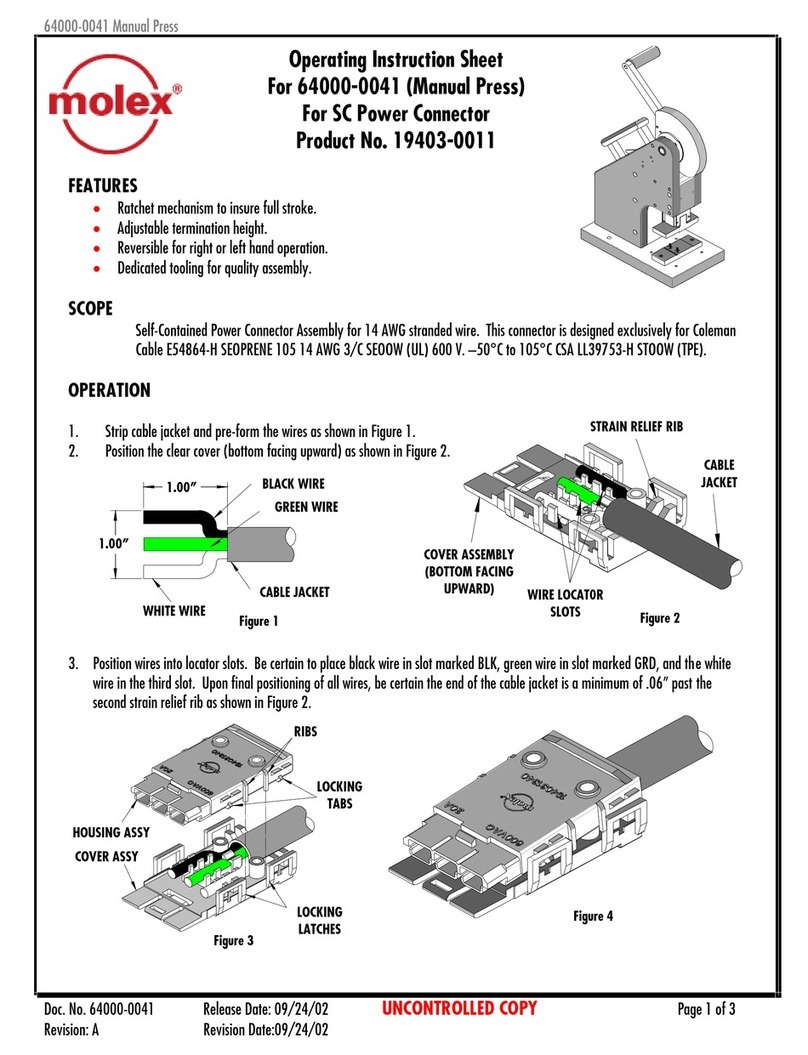

2.5 Terminal Feed Guide

Depending on side or rear-feedapplications,theterminal

guideplateandbracketmustberepositioned.

TheTM-3000pressissetforside-feedapplicatorswhen

shippedfromthefactory. Whenrear-feedapplicatorsare

used,thetwoM6BHCSfromtheterminalguide-mounting

bracketaretoberemoved. SeeFigure2-3. Theguide

bracketisrotated180 degreesandtheassembly isthen

mountedonthetwostandoffsintherearofthepresswiththe

twoM6SHCS. SeeFigure2-3.