SECTION

C

Before

installing

your

heater,

be

sure

to

check

and

comply

with

local

and

statebuilding

and

electricalcodes

that

may

apply

to

ventedheaters

in

your

area.Permanentwiringmust

be

installed

bya

licensedelectrician.

TOOLS

NEEDED

FOR

HEATER

INSTALLATION

Check

the

followingcharts

tobe

sure

you

have

allthe

toolsrequired

to

installyourMonitor2400HeatingSystem.

STANDARD

TOOLSAPPLICATION

PhillipsHeadScrewdriver

Installation

of

HeaterParts

Steel

TapeMeasureTakingMeasurements

Penor

PencilMarkingDrilling

Location

Exterior

CaulkCaulkingBetween

Packing

and

Wall

Yardstick

or

LongStraightEdgeCheckingAngle

of

Hole

for

FluePipe

Soapy

WaterLubricatingSleeveHardware

SPECIAL

TOOLS

APPLICATION

ElectricDrillAccommodatingHole

Sawand

Drill

Bit

2>2

inchHole

Saw

AttachmentCuttingHole

for

FluePipe

Long

Y±

inchDrill

Bit

DrillingPilotHoleThroughWall

Level

CheckingAngle

of

Hole

for

FluePipe

andfor

checking

heater

level.

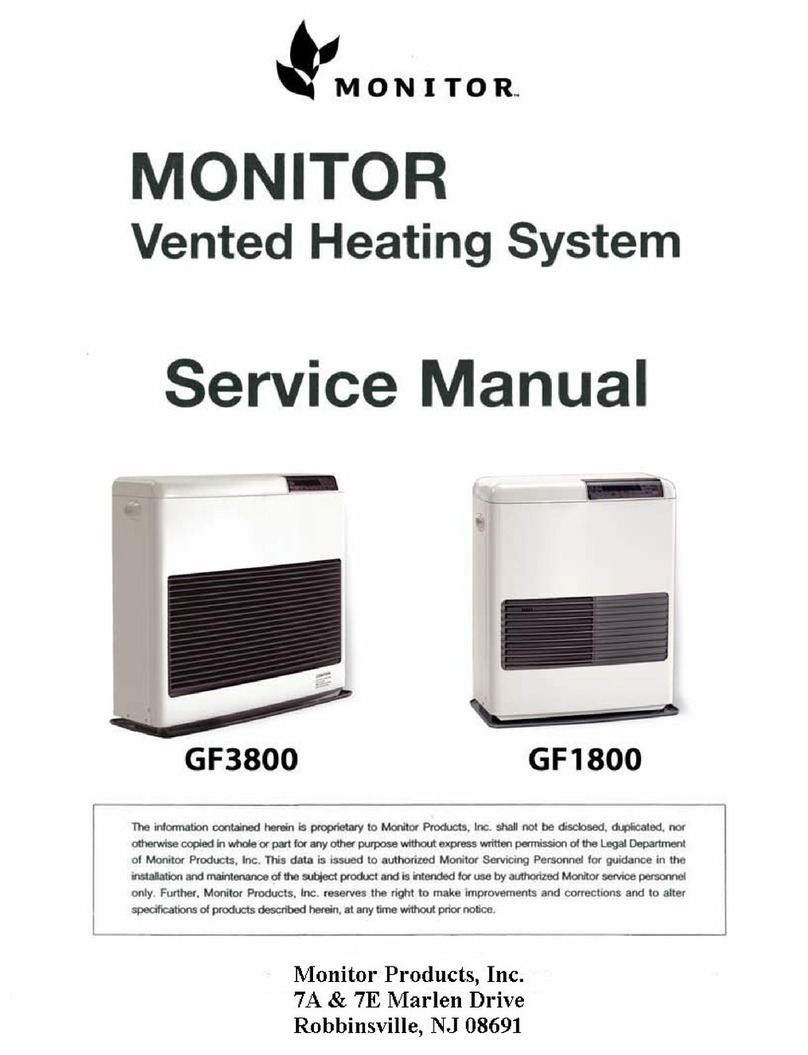

Fig.

1