2

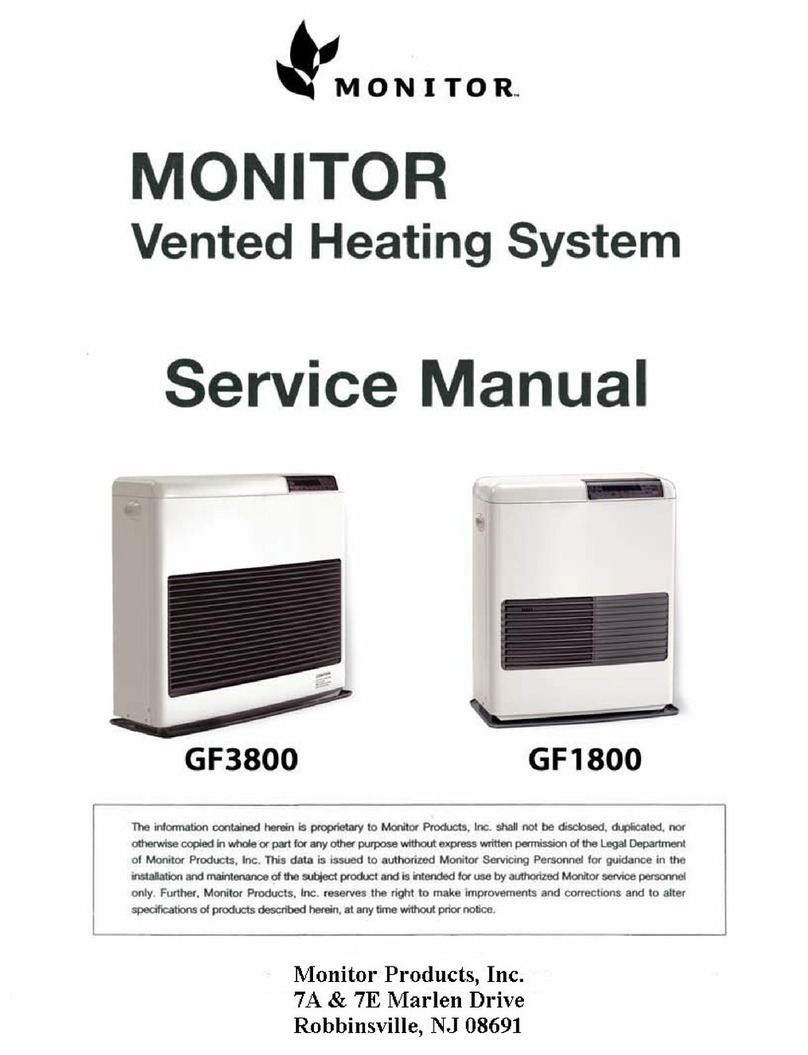

FCX INSTALLATION AND SERVICE MANUAL

FCX INSTALLATION AND SERVICE MANUAL

TABLE OF CONTENTS

I. INTRODUCTION

1 - PRODUCT DESCRIPTION

Model FCX oil fired heating system utilizes a sealed combustion

systemthatoperates at a temperature at which the flue products

willcondense.Howmuchtheunitcondensesdependsonreturn

watertemperatures.Thelowerthetemperaturethemoretheunit

condenses and the high the efficiency. The flue products

temperature is so low that the unit is suitable for use with PVC

intake / Polypropylene exhaust flue pipes, which are offered as

standardoptionsforinstallation.TheFCXisapprovedforinstallation

with zero clearance to combustible materials by Intertek Testing

Services to the UL Standard for Oil Fired Storage Tank Water

Heaters(UL 732).

The FCX is completely assembled and provides standard parts

as follows:

• An enameled steel cabinet with thick insulation

• A completely unitized, thick shelled heating system with

combustion chamber and a heat exchanger with a system of

removablebaffles

• A stainless steel condenser, with condensate drain

• A high efficiency, low emission, gun type oil burner with

combustion air fan, integral oil pump, oil heater and primary

control

• A control panel assembly and all electrical controls for

operation of the heating system, including a water

temperature thermometer in circuit 1

• Amanualwater-mixingvalvethatcan bemotorized ifdesired

• Asafetypressurereliefvalve

• An expansion tank

• A water circulating pump

• Completeinternalwaterpiping terminatinginconnectionsfor

two independent water heating circuits.

• Complete internal air piping terminating in a connection to a

coaxial flue/combustion air intake system.

Front

View

Side

View

Rear

View

I-INTRODUCTION ..............................................................2

1-PRODUCTDESCRIPTION ...........................................2

2-DESIGNATIONOFCOMPONENTS.............................3

3-HEATING SYSTEM OPERATION ................................3

4-PRODUCTSTANDARDRATINGS. ..............................4

5-DIAMETEROF PIPE CONNECTIONS.........................4

II - INSTALLATION.............................................................4

1-OPENING THE UNIT .................................................4

2-LOCATION OFTHE UNIT ..........................................4

3- FLUECONNECTIONSANDROUTING ......................5

4-ALTERNATIVEFLUECONNECTIONS .......................8

5- CONDENSATEDRAINCONNECTION.....................10

6- WATER CIRCUITCONNECTIONS...........................10

7- ELECTRICALCONNECTIONS ................................13

8- FUELOILSUPPLYCONNECTIONS .......................13

III - START-UPAND OPERATION ....................................13

1- PRE-STARTFINALSYSTEM CHECK.....................13

2-START-UPANDOPERATION ..................................13

3-ADJUSTINGTHEOILBURNER...............................14

4- CHECKING THE SAFETY DEVICES ......................14

IV - MAINTENANCE .........................................................14

1- CLEANING THE SYSTEMSHELL ..........................15

2-CLEANINGTHECONDENSER ...............................15

3-BURNER MAINTENANCE .......................................15

4-ADDITIONALCOMPONENTMAINTENANCE ........ 15

5-EXPANSIONTANK PRE-INFLATIONPRESSURE.

CHECK .........................................................................15

6-COMBUSTION PRODUCT FLUE.............................16

7-CHANGINGATHERMOSTATORTHE ..................

THERMOMETER ...................................................16

V - OPERATING ...............................................................16

VI - MONITOR PRODUCTS, INC. (“MPI”) LIMITED .....

WARRANTIES ...........................................................17

VI - FCX PARTS BREAKDOWN. .....................................18

VIII - HEAT WISE BURNER ..............................................21

1-BURNERWARRANTY ............................................21

2-OPERATINGINSTRUCTIONS .................................22

3-SERVICINGTHE BURNER .....................................24

4-WIRINGDIAGRAM..................................................26

5 - PARTS BREAKDOWN ............................................28

6-HONEYWELLCONTROLS......................................30

7- SUNTEC PUMP ......................................................44

8-BS INDIRECTSTORAGETANK ..............................45

Standardoptions available from Monitor include:

• Coaxial balanced flue system components for connection to

theheatingsystemtoprovideventingoftheflueproductsand

combustion air intake.