5

Moog Components Group • www.moog.com/components 5

For technical application assistance: 800-577-8685 ext. 3539 • +1-828-837-5115

3. External Voltage Control (Optional)

ByapplyingaDCvoltagebetween3(SV)and2(Gnd),thefollowingconditionsareobserved:

A. 0to0.5volts–speed = 0.

B. 0.5 to 5.0 volts – speed range in control operation.

C. 5.0 to 10.0 volts – no pulse-width-operation-control works in simple commutation mode.

D. On-board speed potentiometer must be set fully CCW.

Note: Some power supplies used to supply this external voltage may contain large amounts of ripple. If speed control is unstable, please

install a 10μF electrolytic capacitor across 9 (Spd) and 8 (Gnd). BE SURE TO OBSERVE POLARITY WHEN INSTALLING THIS

CAPACITOR; 9=Positive, 8=Gnd.

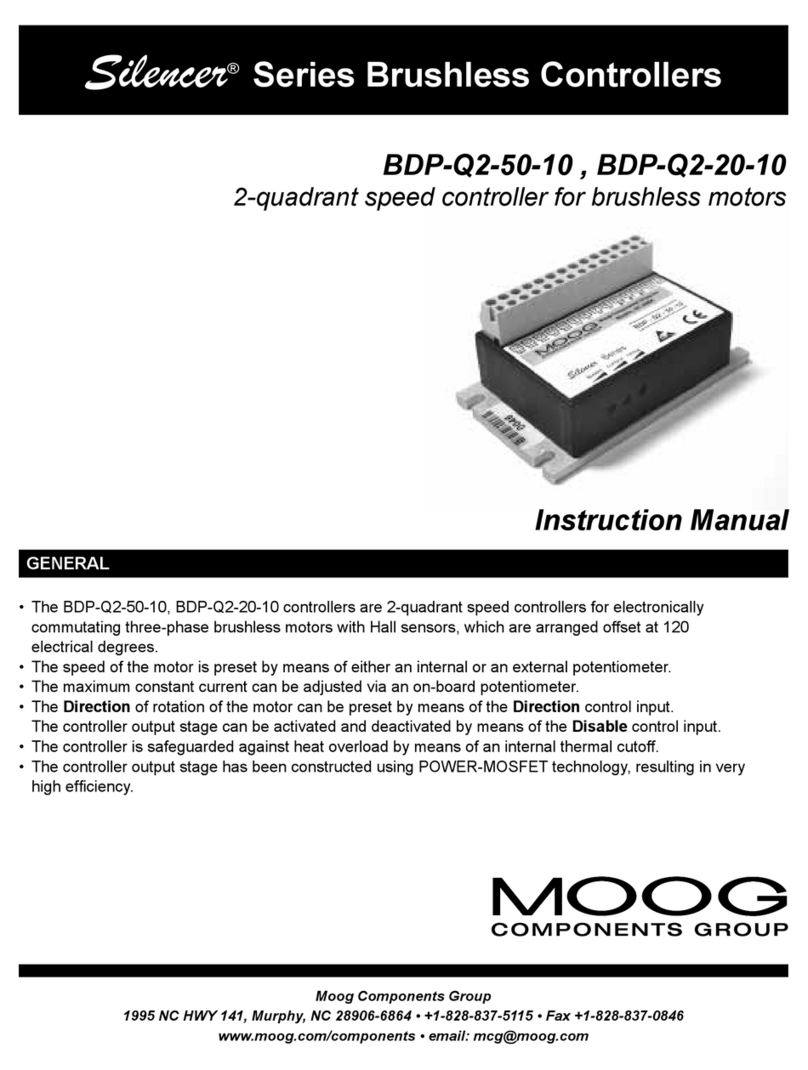

CURRENT LIMITING

Current limiting is available via the on-board current potentiometer. The settings are as follows:

Fully CCW – maximum setting

Fully CW – minimum setting

FUSING

Proper overcurrent protection (fusing) is required for the protection of this controller. We recommend a 5 amp – 120 volt – non-time delay

fuse. This fuse should be connected in series with the + Input line going to the controller.

Note: Considerations regarding the power supply:

Output voltage: > 12 V and < 40V with a residual voltage of < 5%

Output Current: corresponding to the necessary torque and possible reserves for acceleration

Note: Procedure for calculating the necessary minimum supply voltage:

Default: Torque MB[mNm]

Operating speed nB[min–1]

Rated voltage of the motor UN[V]

IdlingspeedwithUNn0[min-1]

Characteristic curve slope Δn[min-1mNm]

ΔM

Result: Vcc = *( nB+ *MB) + 4V

HOOK-UP PROCEDURE

1. Connect motor connections (φA, B, and C).

2. Connect Hall sensors (S1, S2, and S3), as well as the Hall voltage supply (Vcc and Gnd) of Hall sensors.

3. Connect the control inputs according to the requirements (Rev., Dis., and Brake).

4. Connect the supply voltage (+ input and gnd).

5. Set up the speed control for the controller (depending upon which method of speed control is used - see Speed Control).

6.Aftercompletionofstep#5,speedcontrolisnowactive.

7. Set the maximum current via the on-board speed potentiometer (current).

UN

n0

Δn

ΔM

Specicationsandinformationaresubjecttochangewithoutpriornotice.

©2014MoogInc.MS3124,rev.111/16