3

MB300 XL Pro

rev.0.2ID03570

CONTENTS

1. INTRODUCTION .................................................................................... 5

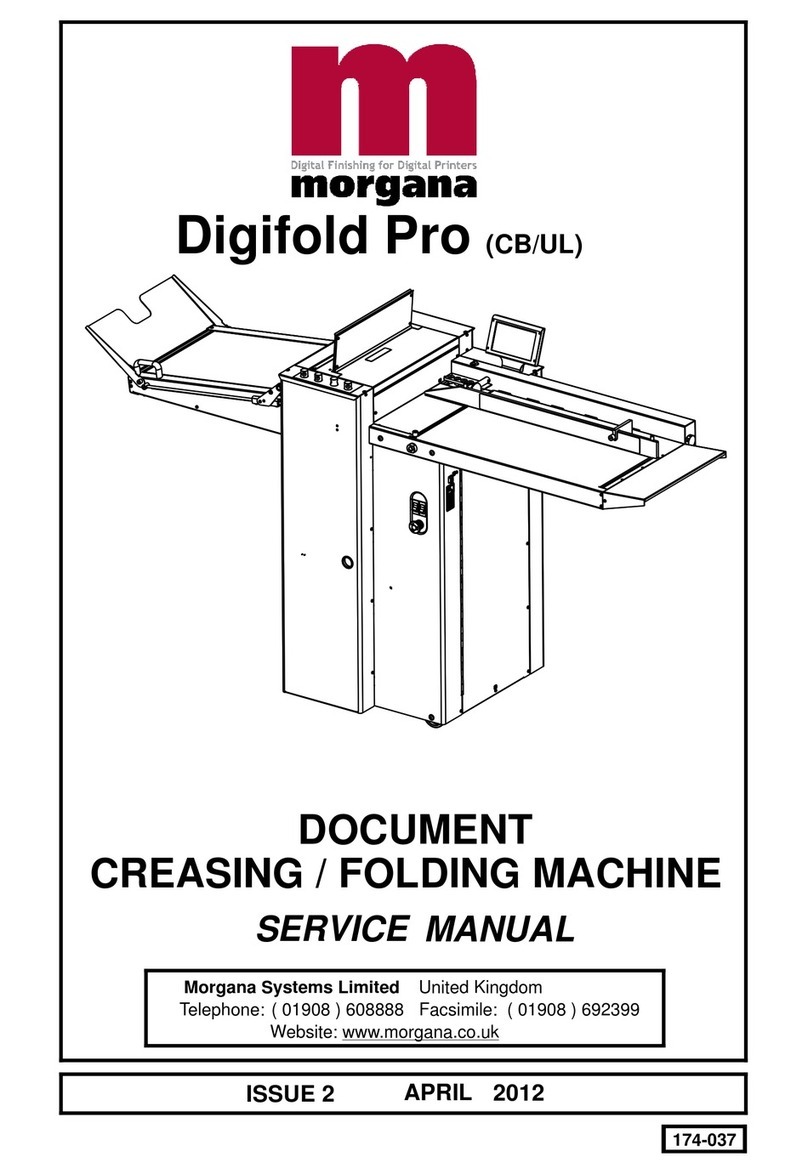

1.1 DECLARATION OF CONFORMITY...............................................................6

1.2 CAUTION LABELS.........................................................................................7

1.3 SAFE OPERATION.........................................................................................8

1.3.1 GENERAL................................................................................................................. 8

1.3.2 USER QUALIFICATION ......................................................................................... 8

1.3.3 MACHINE OPERATORS......................................................................................... 8

1.3.4 GUIDELINES FOR SAFE OPERATION................................................................ 9

1.3.5 PERSONAL PROTECTIVE EQUIPMENT.............................................................. 10

1.4 RESIDUAL RISKS...........................................................................................11

1.5 INTENDED USE ..............................................................................................12

2. TRANSPORT.......................................................................................... 13

3. DISPOSAL.............................................................................................. 14

4. STORAGE............................................................................................... 15

5. GENERAL DESCRIPTION ................................................................... 16

5.1 TECHNICAL SPECIFICATIONS....................................................................16

5.2 ELECTRICAL SPECIFICATIONS..................................................................17

5.3 PNEUMATIC SPECIFICATIONS....................................................................18

5.4 NAME OF THE MAIN PARTS ........................................................................19

5.4.1 VICE UNIT................................................................................................................. 19

5.4.2 MILLING UNIT.......................................................................................................... 20

5.4.3 GLUE UNIT............................................................................................................... 20

5.4.4 PRESS UNIT............................................................................................................. 21

5.4.5 GLUE TANK AND CLEANER ................................................................................. 21

5.4.6 SHAVINGS EXTRACTOR MACHINE..................................................................... 22

5.4.7 COMMAND DEVICES AND INDICATORS ............................................................ 22

5.4.8 ACCESSORIES SUPPLIED.................................................................................... 23

5.5 OPERATOR PANEL........................................................................................24

5.5.1 MAIN PAGE .............................................................................................................. 24

5.5.2 CART PARAMETERS PAGE (2)............................................................................. 25

5.5.3 GLUE UNIT PAGE (3).............................................................................................. 27

5.5.4 PRESS OPERATION PAGE (4)............................................................................... 28

5.5.5 ADVANCED SET-UP PAGE (7)............................................................................... 30

5.5.6 ALARMS PAGE (8)................................................................................................... 35

5.5.7 PROCESSING RECIPES PAGE (10)...................................................................... 36

5.5.8 BOOKS COUNTER PAGE (12)............................................................................... 37

5.5.9 PROCESSING TYPE PAGE (14)............................................................................. 38

5.6 SAFETY DEVICES..........................................................................................39