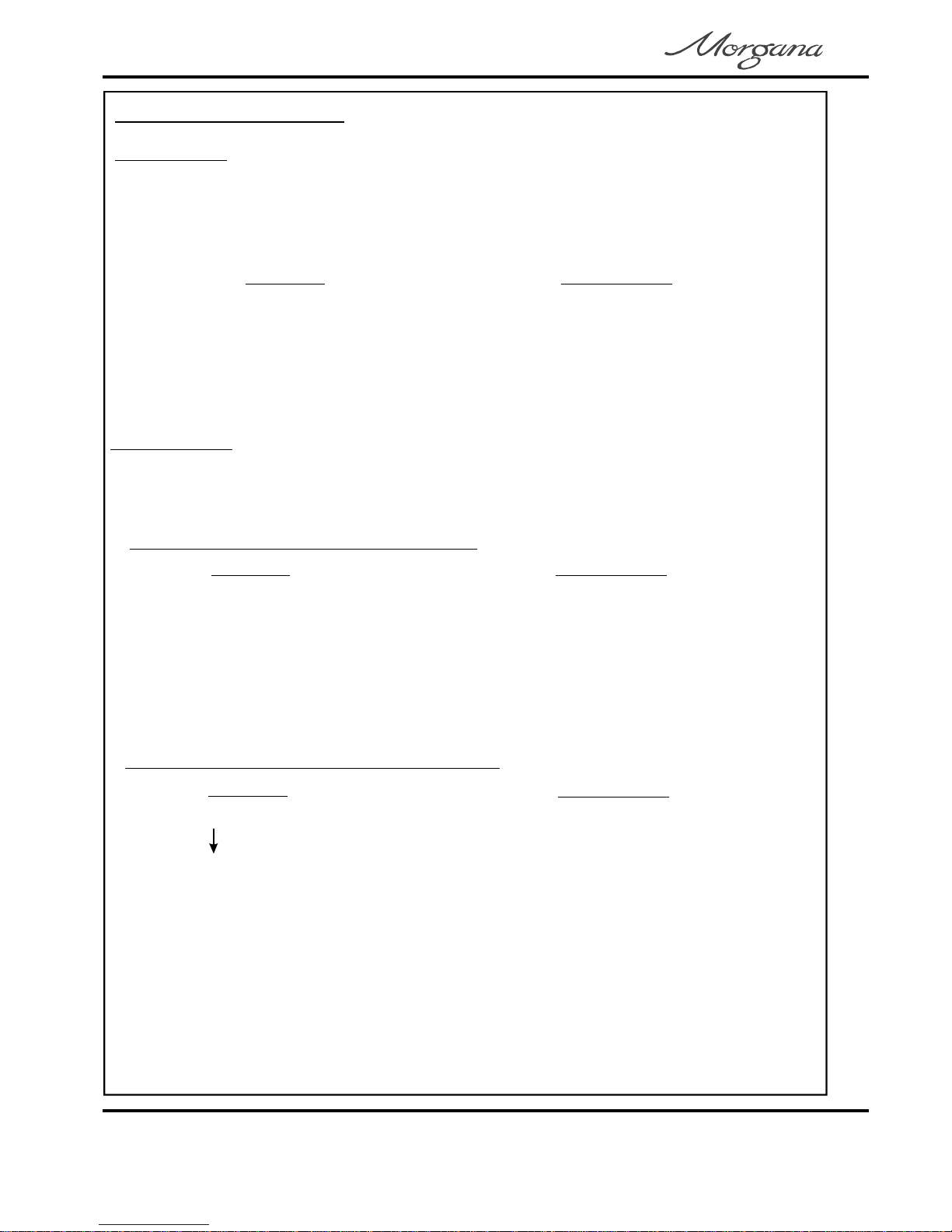

INTRODUCTION

INTRODUCTIONANDSPECIFICATION

must

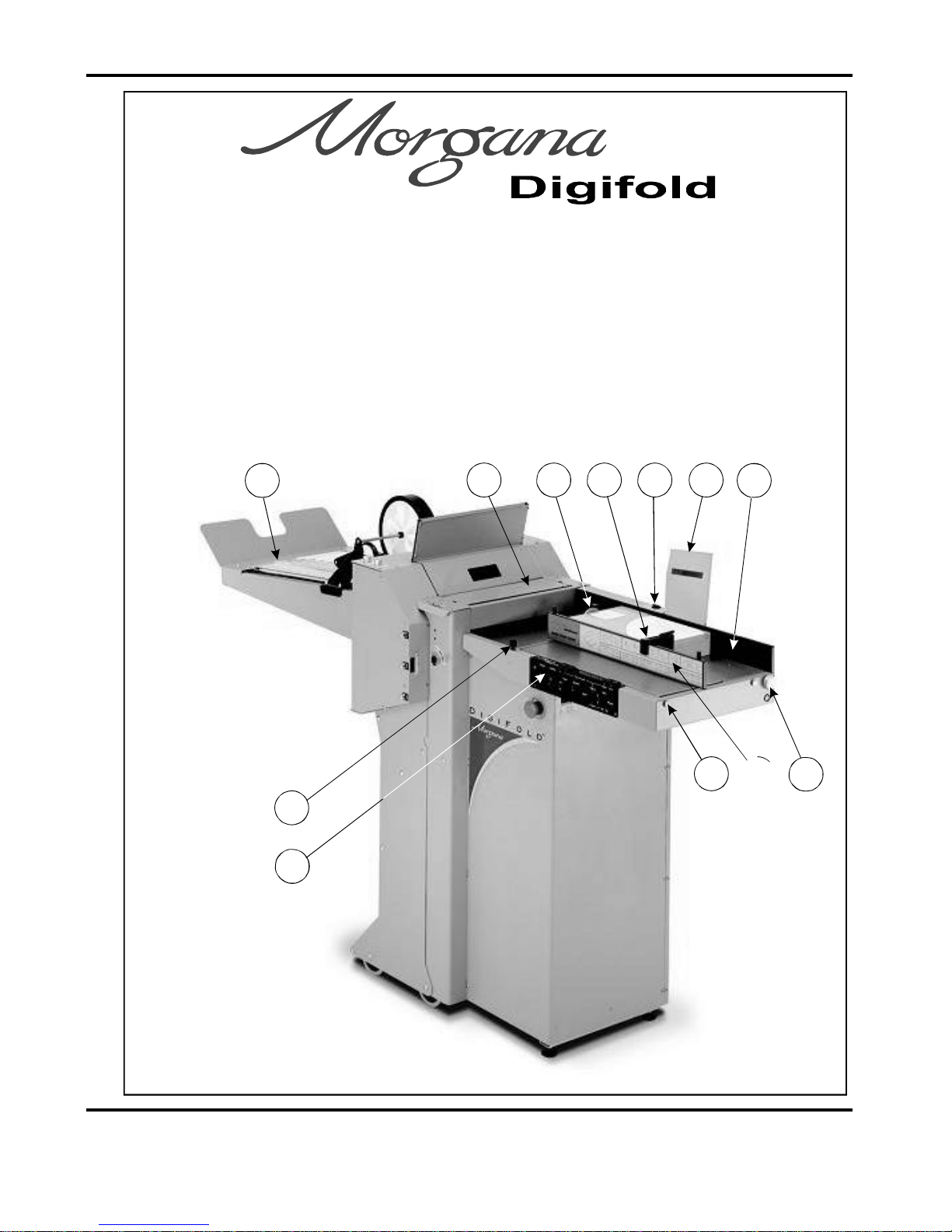

DigiFold

DigiFold

IMPORTANT

isaregisteredtrademarkofMorganaSystemsLtd.Theuniquepatented

creasingandfoldingsystem,makesitpossibletofoldmostdelicatestocksfrom90gsm,

uptoandoftenabove300gsm.Thereducesthepossibilityofscratching,marking

orcrackingappearingonthesubstrate,asisoftenassociatedwithconventionalfolding

machinemethods.Amaximumpaperweightcannotbespecified,asthiscanbegoverned

bythehardnessofthesubstrateorthetypeoffoldrequiredtobeproduced.

Itistonotethattopreventcracking,whenusingdryinkortonerbasedprint

engines,thematerialbefullyacclimatisedforatleast48hoursbeforeputtingan

imageontothepaper.

FeedingSystem................................................Bottomsuctionfeed

Max.SheetSize................................................630mmx330mm

Min.SheetSize.................................................140mmx160mm(dependantonstiffness

ofpaperandtypeoffold).

Max.PaperWeight...........................................300gsm(variesaccordingtohardness,

typeoffold,andsubstrate).

Min.PaperWeight............................................120gsm

Max.No.CreasesperSheet............................9

Max.No.FoldsperSheet..................................2

Max.No.StoredProgrammes...........................6

Min.RepeatCreaseDistance...........................4mm(dependingonpaperweight)

Min.RepeatFoldDistance................................70

Min.CreaseDistancefromLeadingEdge........25mm

Min.FoldDistancefromLeadingEdge.............70mm(dependingonpaperweight)

SpeedperHour(A4Material)OneCreaseorOneFold..........1800sheets

SpeedperHour(A4Material)TwoCreasesorTwoFolds......1400sheets

IMPORTANT

Note:

theoperatingenvironmentshouldbecontrolledtoatemperaturebetween

16°Cand27°CMaximum.

mm(dependingonpaperweight)

Min.CreaseDistancefromTailEdge...............25mm

Min.FoldDistancefromTailEdge....................70mm(dependingonpaperweight)

Max.FoldLength..............................................560mm

Min.FoldLength...............................................70mm

SpeedperHour(A4Material)OneCrease&OneFold..........1800sheets

SpeedperHour(A4Material)TwoCreases&TwoFolds.......1400sheets

SpeedperHour(A3Material)OneCreaseorOneFold.........1440sheets

SpeedperHour(A3Material)OneCrease&OneFold..........1440sheets

SpeedperHour(A3Material)TwoCreasesorTwoFolds......1200sheets

SpeedperHour(A3Material)TwoCreases&TwoFolds......1200sheets

Dimensions.......................................................L:1830mmH:1185mmW:555mm

Weight...............................................................180Kgs(+50Kgspacking)

PowerRequirement..........................................1phase220/240v

+

Specification

Theproductionspeedvariesaccordingtothematerialsizeand

thenumberofcreasesorfoldsonthesheet.

Page4 CREASING/FOLDING