INTRODUCTION

It is to note that to prevent cracking, when using dry ink or toner based print

engines, the material be fully acclimatised for at least 48 hours before putting an

image onto the paper.

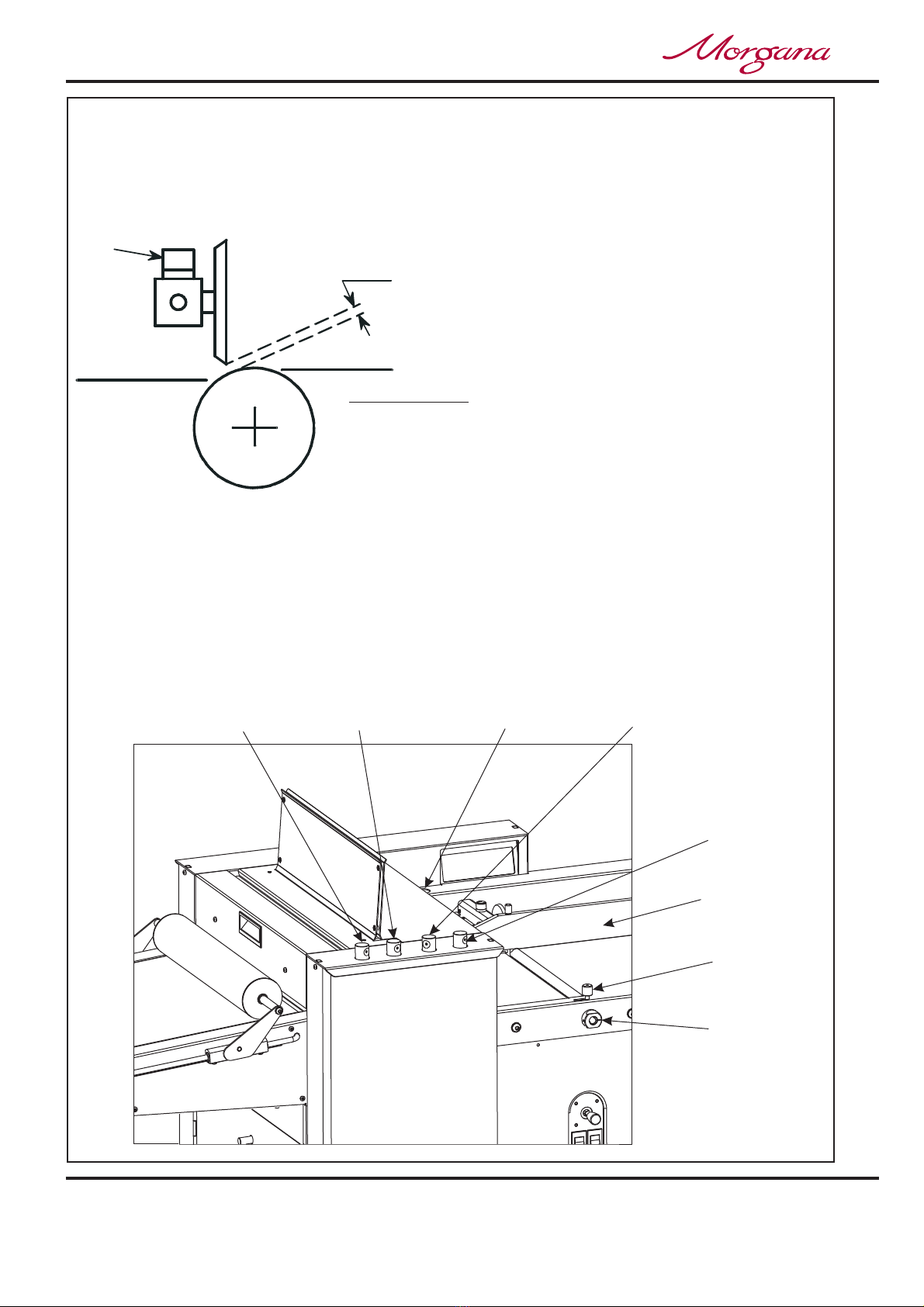

Feeding System ................................................ Bottom suction feed

Max. Sheet Size ................................................700mm x 385mm (27.5” x 15”) [900mm x

385mm (35.4” x 15”) with Optional

extension table].

Min. Sheet Size .................................................210mm x 140mm (8.3” x 5.5”) (dependant

on stiffness of paper and type of fold).

Max. Paper Thickness ................................... 0.4mm (varies according to hardness,

type of fold, and substrate).

Min. Paper Thickness ....................................... 0.11mm

Max. No. Creases per Sheet ............................ 9

Max. No. Folds per Sheet.................................. 2

Max. No. Stored Programmes ...........................9

Min. Repeat Crease Distance ........................... 40mm (1.6”)

Min. Repeat Fold Distance ................................70

Min. Crease Distance from Leading Edge ........ 50mm (1.96”)

Min. Fold Distance from Leading Edge .............50mm (1.96”) (depending on paper weight)

IMPORTANT

must

IMPORTANT

Note:

the operating environment should be controlled to a temperature between

16° C and 27° C Maximum.

(varies according to hardness,

type of fold, and substrate).

mm (2.75”) (depending on paper weight)

Min. Crease Distance from Tail Edge ............... 50mm (1.96”)

Min. Fold Distance from Tail Edge .................... 50mm (1.96”) (depending on paper weight)

Min. Fold Length ............................................... 70mm (2.75”)

Speed per Hour (A4 Material)............................ 5000 sheets

Dimensions ....................................................... L: 1980mm H: 1265mm W: 655mm

L: (78”) H: (49.8”) W: (25.8”)

Weight ...............................................................190Kgs (+50Kgs packing)

Power Requirement .......................................... 1 phase 220 / 240v

Specification

The production speed varies according to the material size and

the fold type.

Page 4 CREASING / FOLDING

Digifold 5000P

INTRODUCTION AND SPECIFICATION

DigiFold 5000P

DigiFold 5000P

is a registered trade mark of Morgana Systems Ltd. The unique patented

creasing and folding system, makes it possible to fold most delicate stocks from 100gsm,

up to 400gsm. The reduces the possibility of scratching, marking or

cracking appearing on the substrate, as is often associated with conventional folding

machine methods. A maximum paper weight cannot be specified, as this can be governed

by the hardness of the substrate or the type of fold required to be produced.