#65060/INTL-K-10.2020 MORIA 2

This instruction manual is for EVOLUTION 3E with serial numbers 5000 and above.

For the EVOLUTION 3E with serial numbers below this number, please refer to user manual (#65051).

The most recent version of this user guide and additional information on your keratome are available on

MORIA website: http://www.moria-surgical.com.

I. DISCLAIMER

A. MAINTENANCE AND WARRANTY

The EVOLUTION 3E system has been designed for optimal operation, provided that the recommendations

listed in this user manual are followed carefully.

The lifetime of the Evolution 3E system is 5 years. This lifetime can be extended to 15 years if the maintenance

plan described above is strictly followed. The maintenance operations in the fth and tenth years (M5 and

M10) must be carried out by Moria. They guarantee the electrical safety and operating performance of the

Evolution 3E Console and thus the user’s and the patient’s safety.

The other annual, intermediate maintenance operations will be carried out by Moria or by its representative

who will have been previously trained and authorized by Moria. This representative must have a valid training

certicate and must use only spare parts supplied by Moria.

MORIA shall not guarantee the performance of the Evolution 3e system and patient and user safety if the

maintenance plan is not followed.

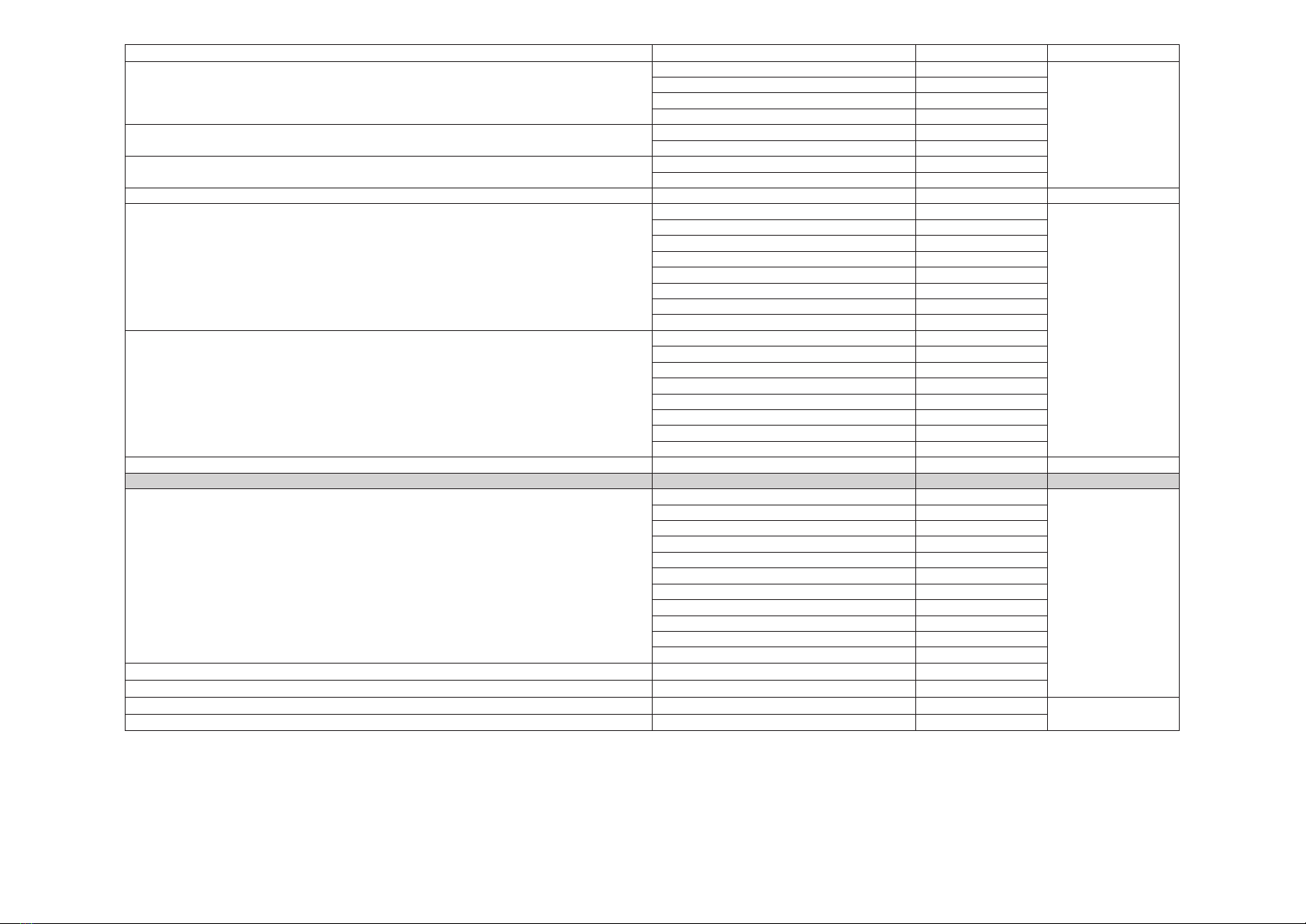

Years Ref. Check Electrical

safety

Remplacement

of the primary

circuit

Battery

change

Turbine

gasket

change

Pump

change

Tubing

change

Engine board

change

Vacuum

solenoid

valve change

1M1 yes no no no yes no yes no no

2M2 yes no no no yes no no no no

3M3 yes no no no yes no yes no no

4M4 yes no no no yes no no no no

5 M5 yes yes no yes yes yes yes no no

6M6 yes no no no yes no no no no

7M7 yes no no no yes no yes no no

8M8 yes no no no yes no no no no

9M9 yes no no no yes no yes no no

10 M10 yes yes yes yes yes yes yes yes yes

11 M11 yes no no no yes no no no no

12 M12 yes no no no yes no yes no no

13 M13 yes no no no yes no no no no

14 M14 yes no no no yes no yes no no

15 No maintenance

If, for any reasons, the system does not perform properly, have it checked immediately by MORIA. MORIA

strongly recommends having the system thoroughly inspected by MORIA on a routine basis every year.

The use of materials and/or components of a brand other than MORIA with the EVOLUTION 3E system will

immediately nullify the MORIA warranty. MORIA may not be held responsible for any damage resulting from

the use of materials and/or components of a brand other than MORIA.

As only MORIA and its agents are fully expert in MORIA products, servicing and maintenance must be carried

out by MORIA or its approved agents.

MORIA shall not be held liable for any malfunction or damage to the apparatus, poor results, or surgical

complications due to maintenance being having been carried out by an unqualied operator or third party.

Any such unauthorised intervention shall render the guarantee and any maintenance contract null and void.

B. USE OF GENERIC PRODUCTS AND REUSE OF SINGLE-USE CONSUMABLES

Single-use devices should not be re-used. Doing so will negatively affect their clinical performance and

increase the potential for adverse events.

The reuse of single-use products, or the use of consumables other than those supplied by MORIA, may entail

serious surgical consequences for the patient and dama ge the microkeratome.

MORIA shall not be held liable in the event of a malfunction or damage to the microkeratome, poor results or

surgical complications due to the reuse of a single-use product, or the use of consumables other than those

supplied by MORIA.

MORIA handpieces must only be connected to MORIA devices (console unit, heads, suction rings, etc.).

All warranties become null and void if the microkeratome degrades or malfunctions due to such practices.

The most recent version of this user guide and additional information on your keratome are available on

MORIA website: http://www.moria-surgical.com.

II. GUIDANCE AND MANUFACTURER’S DECLARATION: ELECTROMAGNETIC

EMISSIONS AND IMMUNITY

Refer to annexe document (#65073).

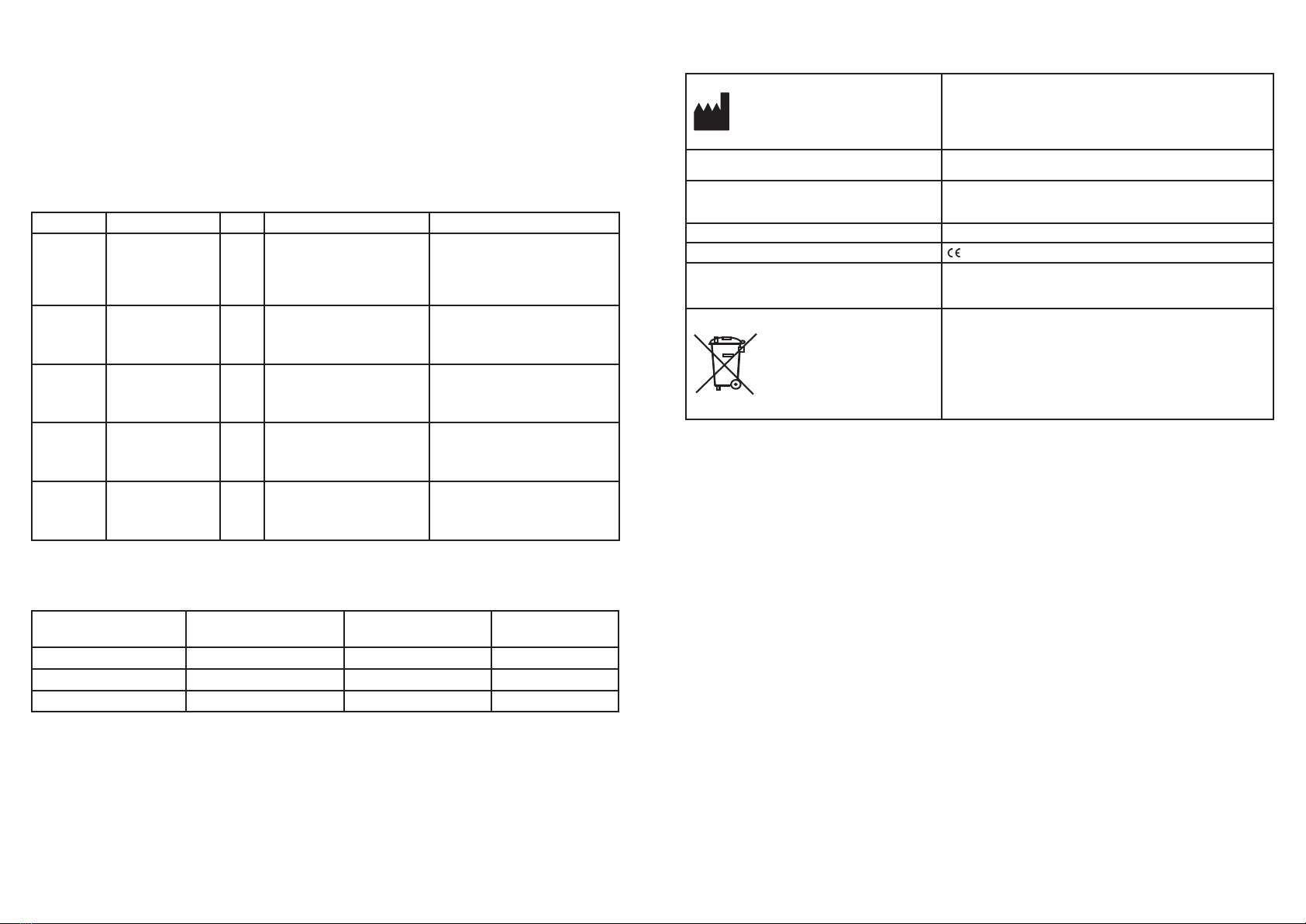

III. EQUIPMENT AND ACCESSORIES LIST

A. EQUIPMENT LIST

Designation Regulatory

designation

MORIA

reference

EVOLUTION 3E Console (S/N above 5000) EVOLUTION 3e CONTROL

UNIT

19380

EVOLUTION 3-3E Control Footpedal FOOT PEDAL FOR

EVOLUTION

19361

EVOLUTION 3E Control Footpedal Epi-K™ EVOLUTION 3e

FOOTSWITCH

19381

Evolution 3E Footswitch - China EVOLUTION 3e

FOOTSWITCH

19381C

Evolution 3E footswith - Japan EVOLUTION 3e

FOOTSWITCH

19381J

EVOLUTION 3 Supply Cords (CEE) (2.50m) / Cable (CEE) EVOLUTION 3 SUPPLY

CORD (EEC)

19362

EVOLUTION 3 Supply Cords (USA) (2.50m) / Cable (USA) EVOLUTION SUPPLY

CORD (USA)

19363

EVOLUTION 3 Supply Cords (UK) (2.50m) / Cable (UK) EVOLUTION 3 SUPPLY

CORD (UK)

19364

EVOLUTION 3 Supply Cords (China) (2.50m) / Cable (China) EVOLUTION 3 SUPPLY

CORD CHINA

19516

EVOLUTION 3 Supply Cords (Brazil) (2.50m) / Cable (Brazil) EVOLUTION 3 SUPPLY

CORD BRAZIL

19521

Supply cord USA SUPPLY CORD (USA) 19451

Carrying Case N/A 19511

User manual N/A 65060/INTL

User manual - China N/A 65060/ZH

User manual- Brazil N/A 65060/BR

Annexe “Guidance and manufacturer’s declaration: electromagnetic emissions and

immunity”

N/A 65073