TOOLS REQUIRED:

Torque Wrench • Floor Jacks • Safety Stands • 1/2" Socket • 1/2"

Wrench • 9/16" Socket • 9/16" Wrench • 11/16" Socket • 13/16"

Wrench • Hammer • Ratchet

PARTS LIST:

• See Page 7

AFTERMARKET TRIPLE INSTALLATION INSTRUCTIONS

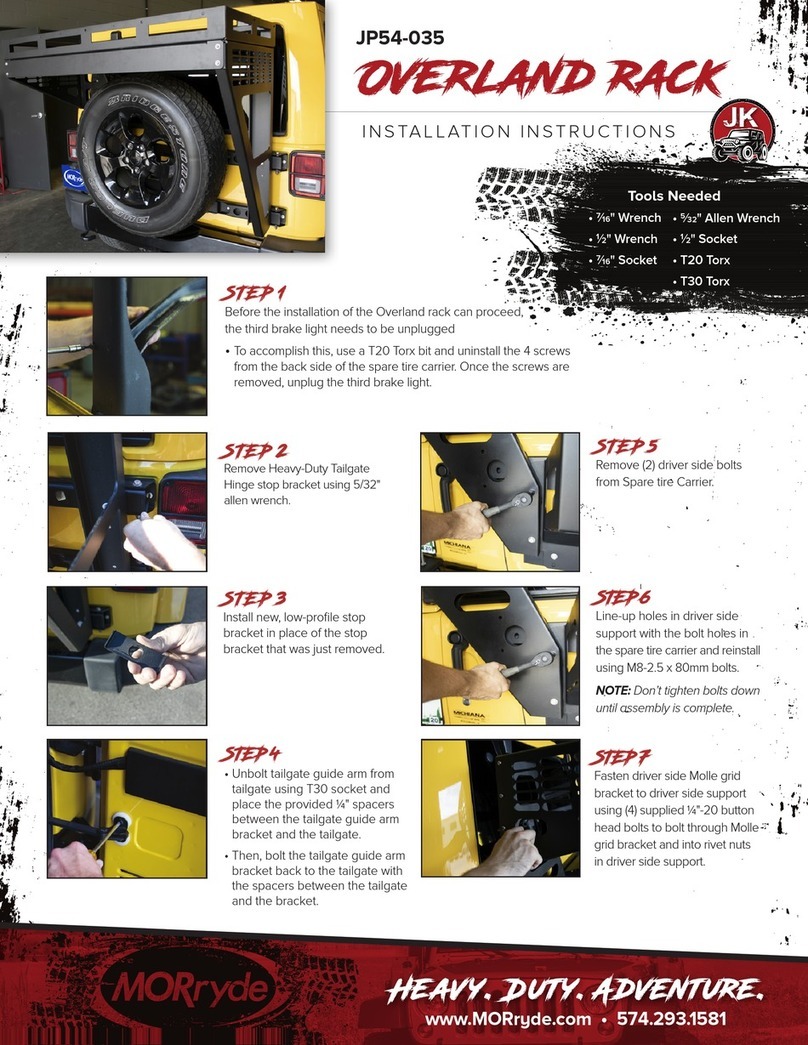

Step 1

Loosen all lug nuts. Using appropriately rated jacks, raise

the unit and support the frame with safety stands. Support

the axles with floor jacks and remove all wheels.

Step 2

On the curbside of the unit, use an 11/16" socket and 13/16"

wrench and remove the shackle links from the front leaf

spring, remove the shoulder bolt from the center leaf

spring, and then remove the shoulder bolt from the top of

the equalizer.

INSTALLATION:

1

st

3

rd

2

nd

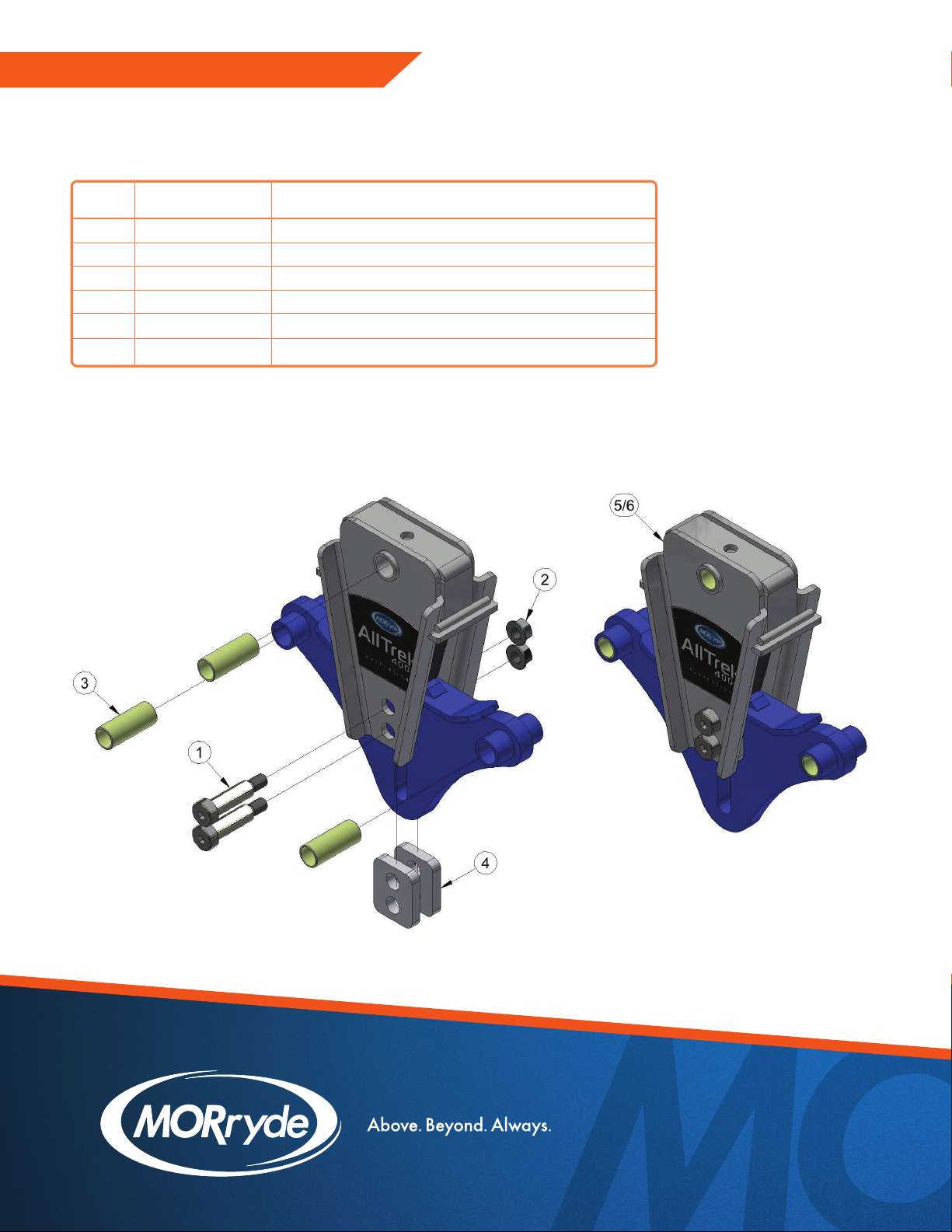

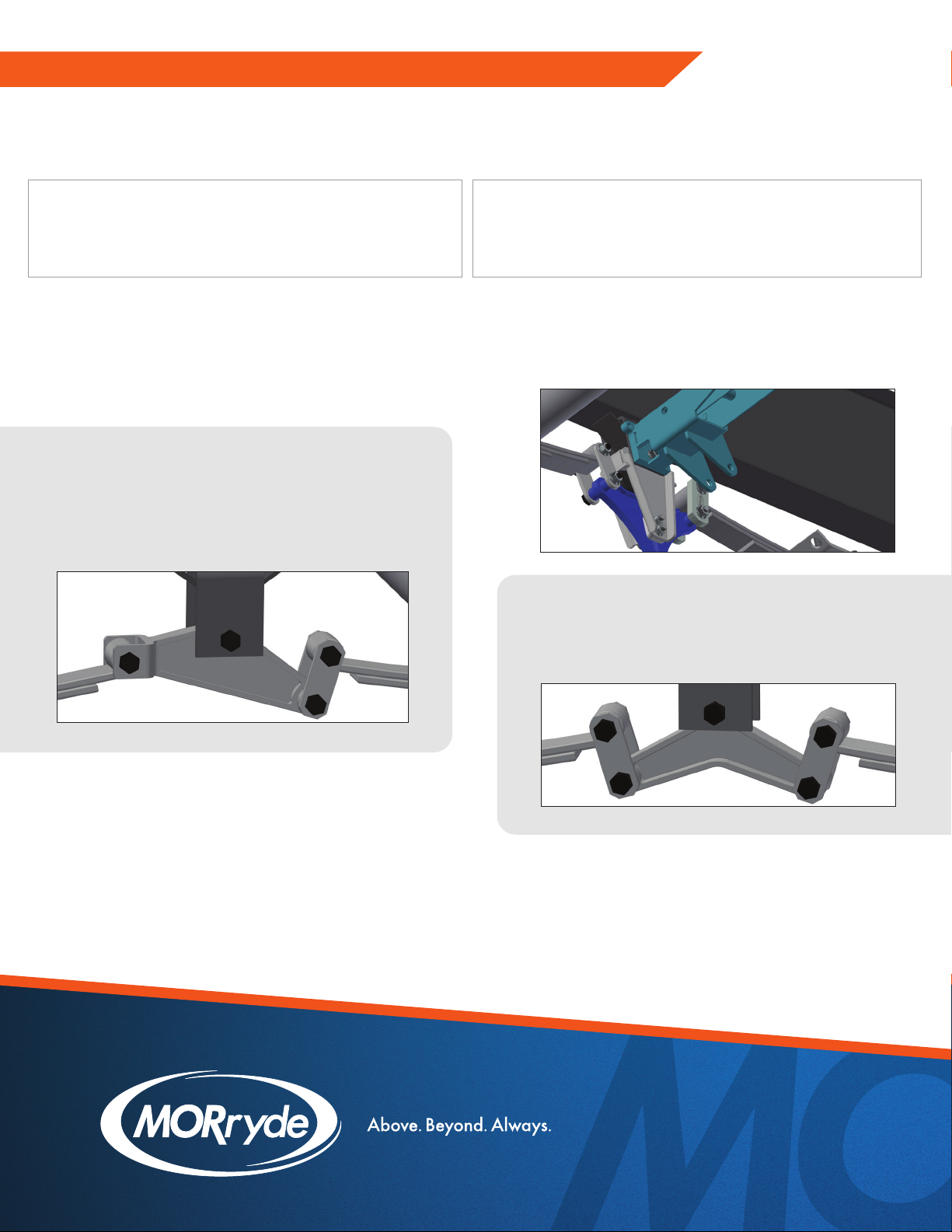

Step 3

Replace the equalizer with the AllTrek 4000™ using one

of the 3.4" long wet bolts (shoulder bolt with grease jerk)

included in the installation kit. The threaded end of the bolt

will face the inside of the trailer. Slide the Outer Torque

Cross Member (cross member with slots and ears) onto

the end of the bolt, then install the 7/16-20 Flange Locknut.

Reinstall the front shackle links and install a new Shackle

Link Assembly and loose Shackle Link along with the 7/16-

20 Flange Locknuts. Do not torque any of the nuts.

NOTE: Use a hammer to pound the wet bolts into the frame hangers. Use

a pipe or small diameter socket to fit over the grease zerk and pound the

bolt in place (it is important not to damage the grease zerk) or remove the

zerk, pound the bolt in place, and reinstall the zerk. Make sure the grease

exit hole in the shoulder of the bolt faces to the side for easy grease flow.

Step 4

Remove the floor jack from the front axle and use it to

support the rear axle. Then, remove the shackle links

from the rear equalizer, then remove the shoulder bolt.

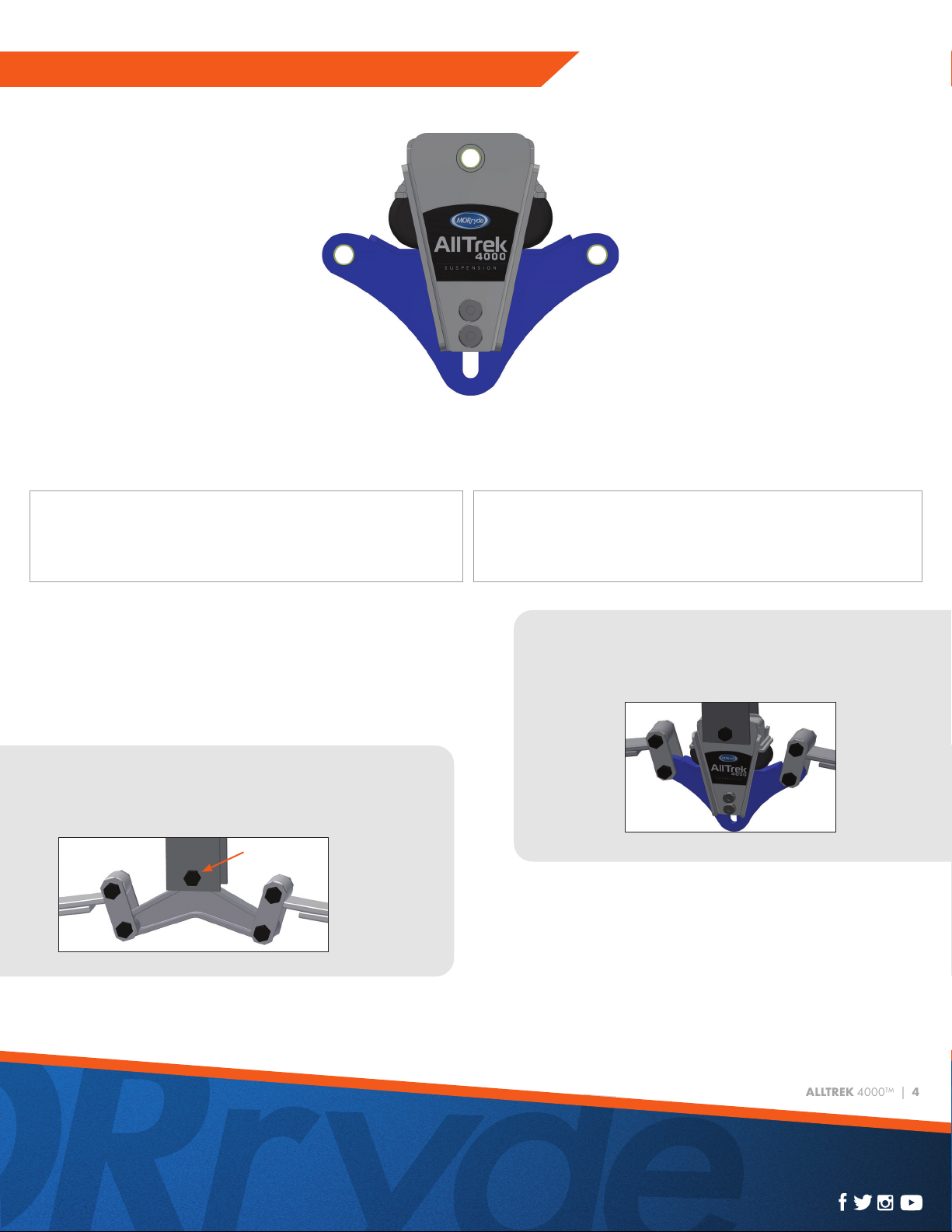

Step 3

Step 5

Replace the stock equalizer with the AllTrek 4000™

using one of the 3.4" long wet bolts. The threaded end

of the bolt will face the inside of the trailer. Slide the

Inner Cross Member (cross member with holes) onto the

end of the bolt, then install the 7/16-20 Flange Locknut.

Reinstall the shackle links.

* Triple axle AllTrek 4000™ cannot be used with Correct Track.

* Triple axle AllTrek 4000™ cannot have items hanging down under the frame between the equalizer hangers.