The Specialist In Drum Handling Equipment

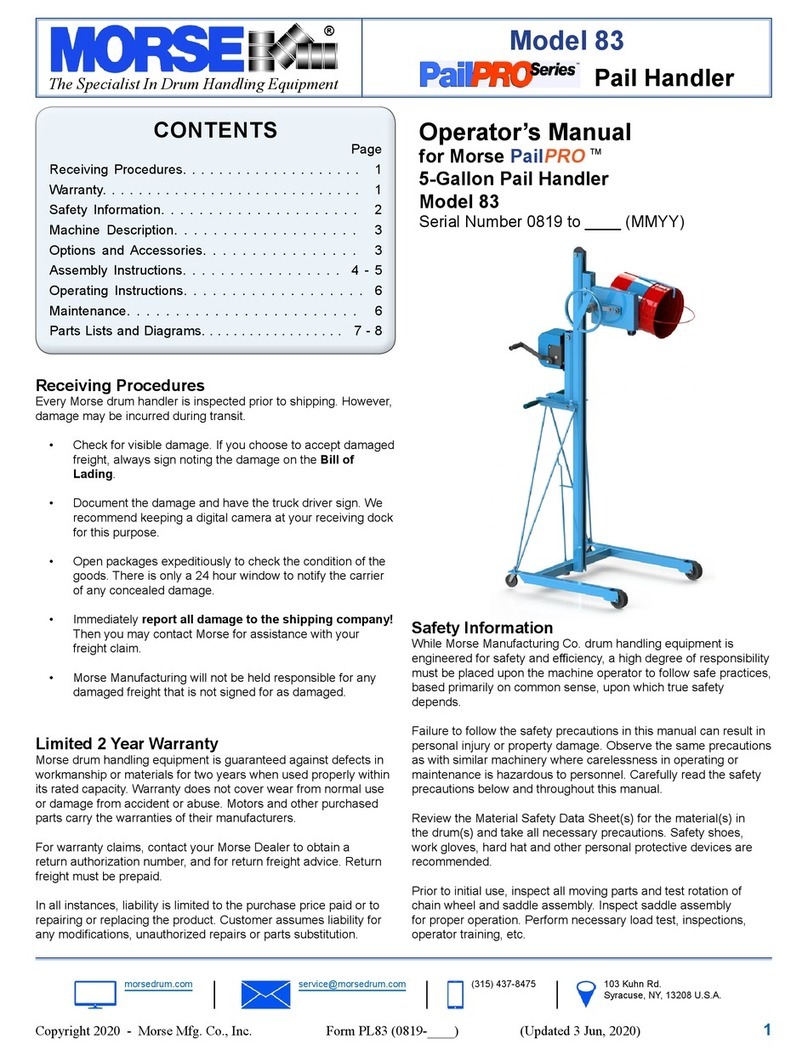

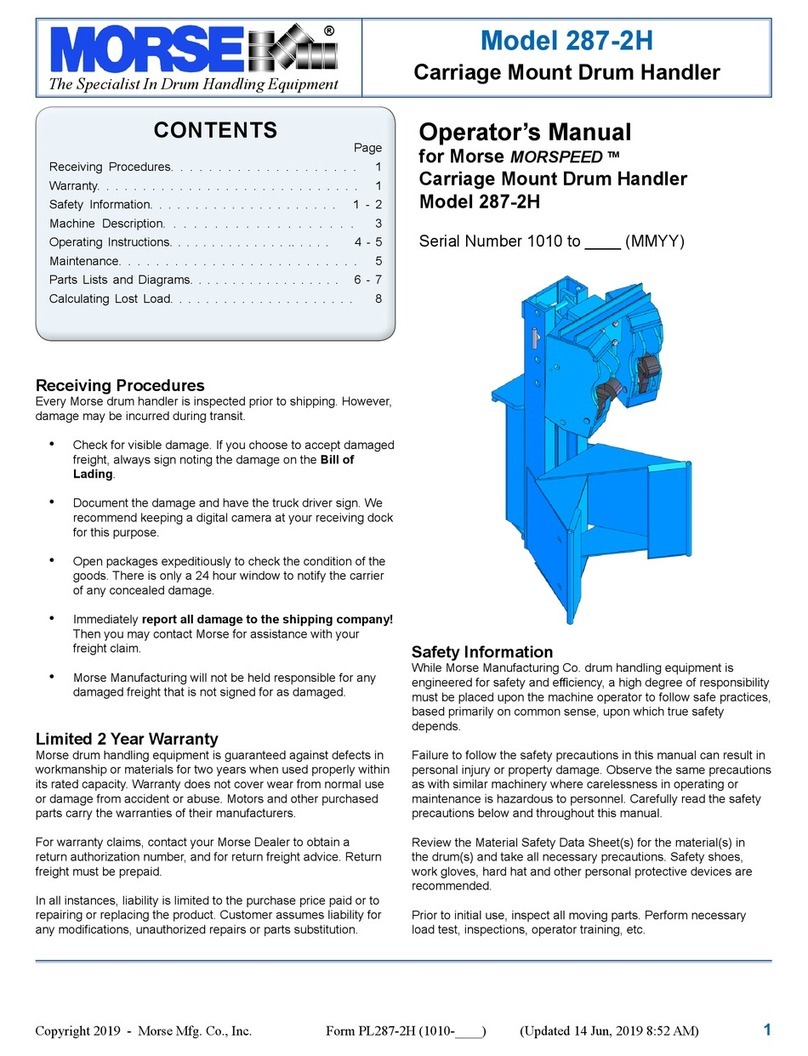

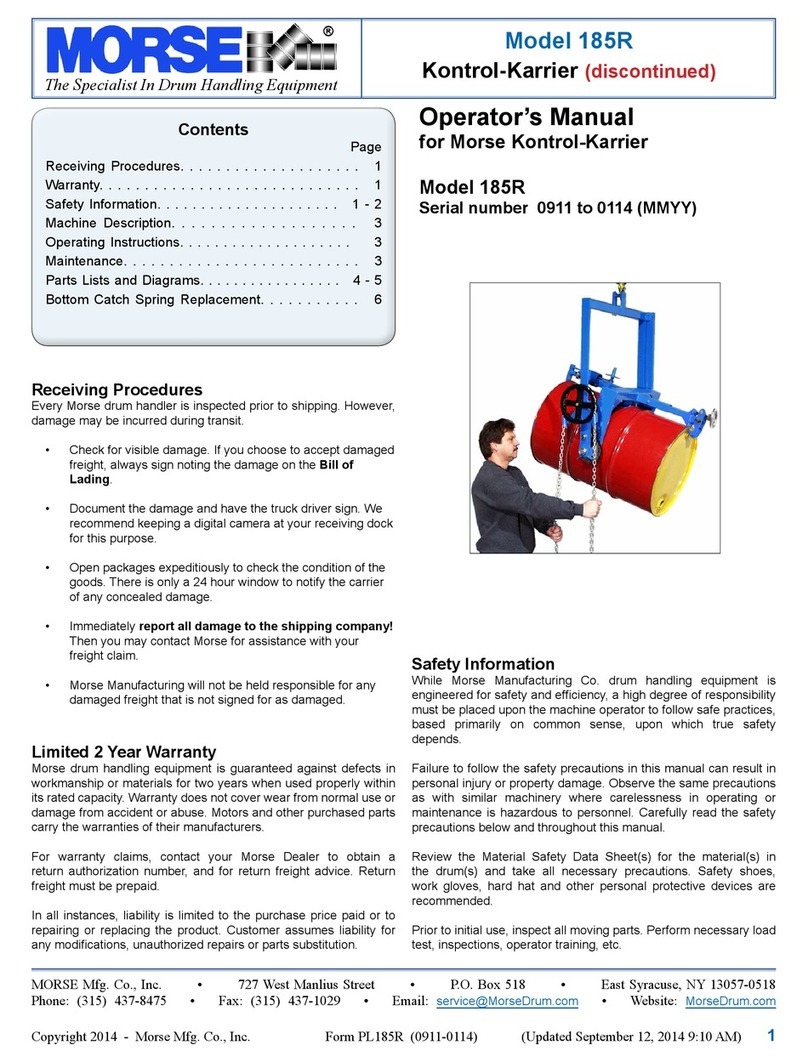

Model 185G

Kontrol-Karrier with 3-Piece Drum Holder

Operator’s Manual for Morse Model 185G Kontrol-Karrier with 3-Piece Drum Holder

Serial number 0398 to 0209 (MMYY)

www.morsedrum.com

Copyright 2009 - Morse Mfg. Co., Inc. Form PL185G (0398-0209) (Updated March 15, 2018 2:21 PM) 3

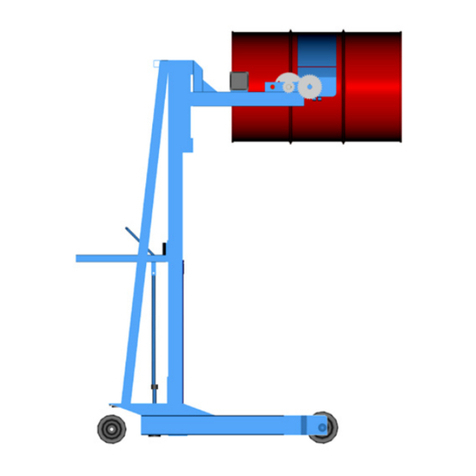

Machine Description

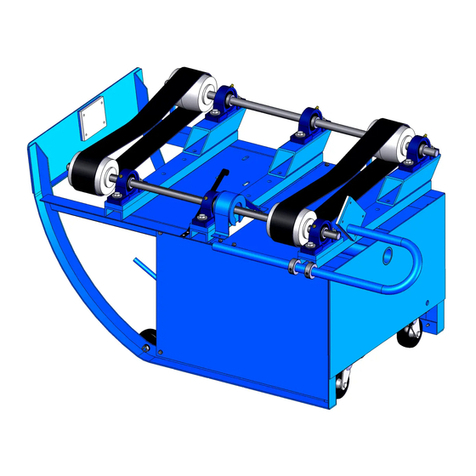

Model 185G Kontrol-Karrier is designed to lift, transport and

dispense a standard 55-gallon steel drum 22.5” in diameter. The

maximum capacity is 800 Lb.

Important

Review the Material Safety Data Sheet(s) for the material(s) in1.

the drum(s) and take all necessary precautions. Safety shoes,

work gloves, hard hat and other personal protective devices are

recommended.

Please read all instructions thoroughly before attempting to2.

operate your new Morse drum handler.

The185SeriesKontrol-Karriershaveamaximumcapacityratingof800Lb.foraFULLdrumand500Lb.foraHALF-FULLdrum,and3.

are designed to lift and move a drum of the size and type noted above. DO NOT exceed this rating. Exceeding this rating or handling

drums other than those mentioned above is unsafe and could result in equipment damage, excessive wear, awkward or dangerous

handling.

When loading, unloading, operating, or maintaining your MORSE drum handler, always use care and good judgment. Maintain secure4.

footingandarmhold.Keephandsandlooseclothingawayfromallmovingparts.Neverallowanyonetobebelowanypartofaraised

drum handler or drum. Read operating instructions and review the pictures in the sales brochure before operation.

The185Seriesarea“Group1structuralandmechanical”below-the-hookliftingdevicewhicharecoveredbytheAmericanNational5.

StandardASMEB30.20.Theusershouldcomplywithallaspectsofthisstandard.

Operating Instructions

StartwithKontrol-Karrierontheoor.LowerhoistandengagehoisthooktoliftKontrol-Karrier.1.

RaisehoisttoliftKontrol-Karrierclearofoorandtransportittothedrum.2.

Suspend Kontrol-Karrier at a height which aligns drum saddle with center of drum.3.

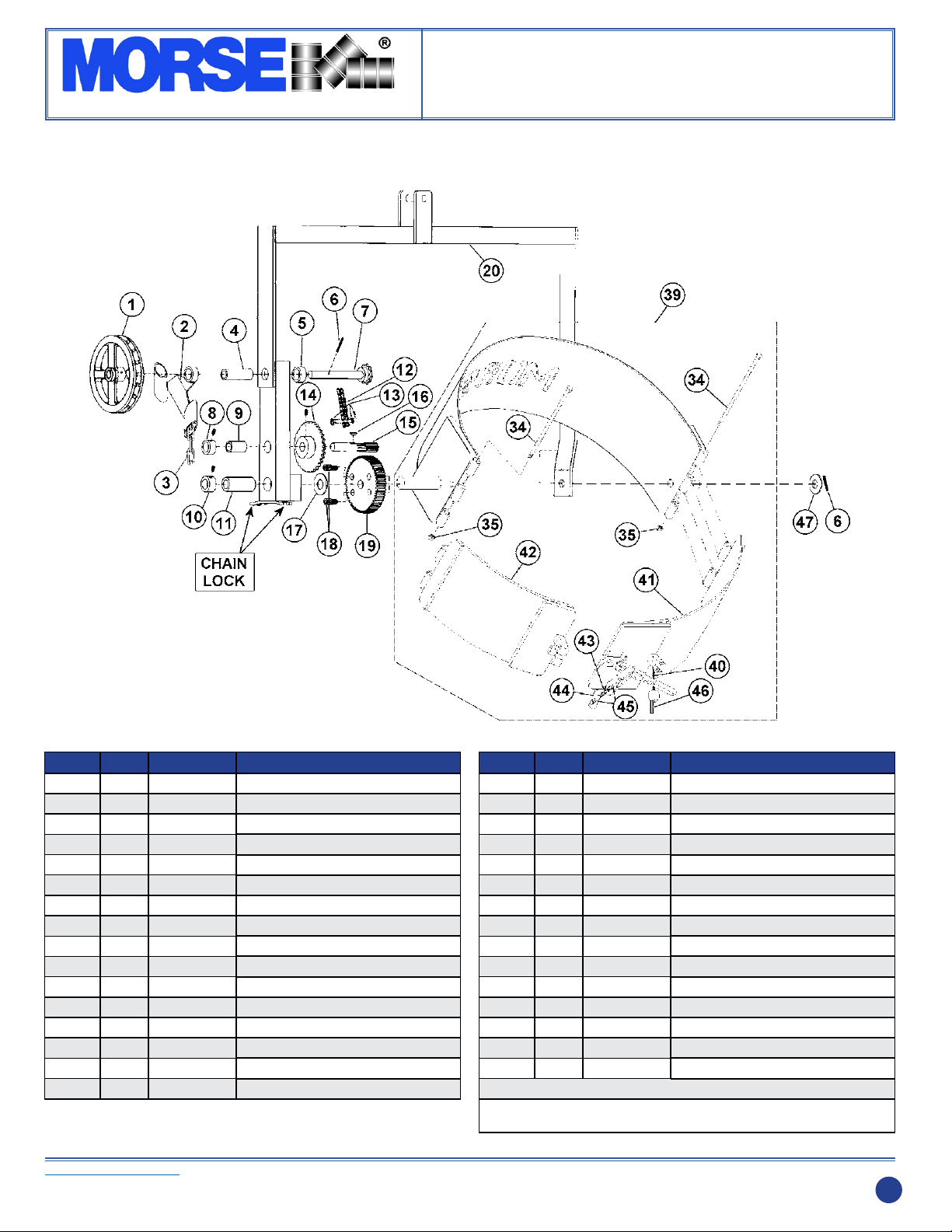

Pull the linch pin (item 46), open the toggle clamp and swing both hinged bands to the open position. Push Kontrol-Karrier against4.

drum so that saddle will encircle drum.

Secure the drum: Close the two hinged bands around the drum, latch the toggle clamp and insert the linch pin.5.

Raise hoist and position drum at pouring station.6.

Pour the drum by pulling on the pull chain (item 3) and rotating the drum to a suitable pouring angle. For best control of drum pouring7.

angle, pay out one side of the chain loop while pulling in the other side, thus being able to hold back the drum rotation. The chain lock

on the bottom of the power arm can be used to prevent drum rotation. To do so, criss cross the chain and insert in each slot of the chain

lock.IfthedrumhandlerisequippedwiththeMORStopTilt-Brake,thereisnoneedtoholdtensiononbothsidesofthechainloop.

Brakingisimmediateandselfactuating,withoutadditionalstepsbytheoperator.ToaddtheMORStopTilt-Braketoyourdrumhandler,

orderpart#3900-Pforaeldinstallationkit.

Afterpouringiscompleted,rotatedrumbacktoverticalpositionandlowerhoisttoreturndrumtooor.8.

To remove drum: Pull the linch pin, open the toggle clamp and swing both hinged bands to the open position.9.

Maintenance

Lubricate gear teeth and roller chain.1.

Clean and oil saddle hinges and other moving parts periodically to maintain free action and reduce wear. Clean and lubricate more2.

often in environment where dust, dirt or other foreign particals will effect the performance of moving parts.

Periodically inspect all moving parts, framework and contact areas for signs of wear, fatigue or loosening. Tighten, adjust or replace3.

parts as necessary to prevent failure and maintain proper function.