The Specialist In Drum Handling Equipment

MODEL 82A-125

Mobile-Karrier / Palletizer

with DC Power Lift

Operator’s Manual for Model 82A-125 Morse Mobile-Karrier / Palletizer

Serial Number 0509 to 1110 (MMYY)

MorseDrum.com

Copyright 2010 - Morse Mfg. Co., Inc. Form PL82A-125 (0509-1110) (Updated December 2, 2010 8:30 AM) 5

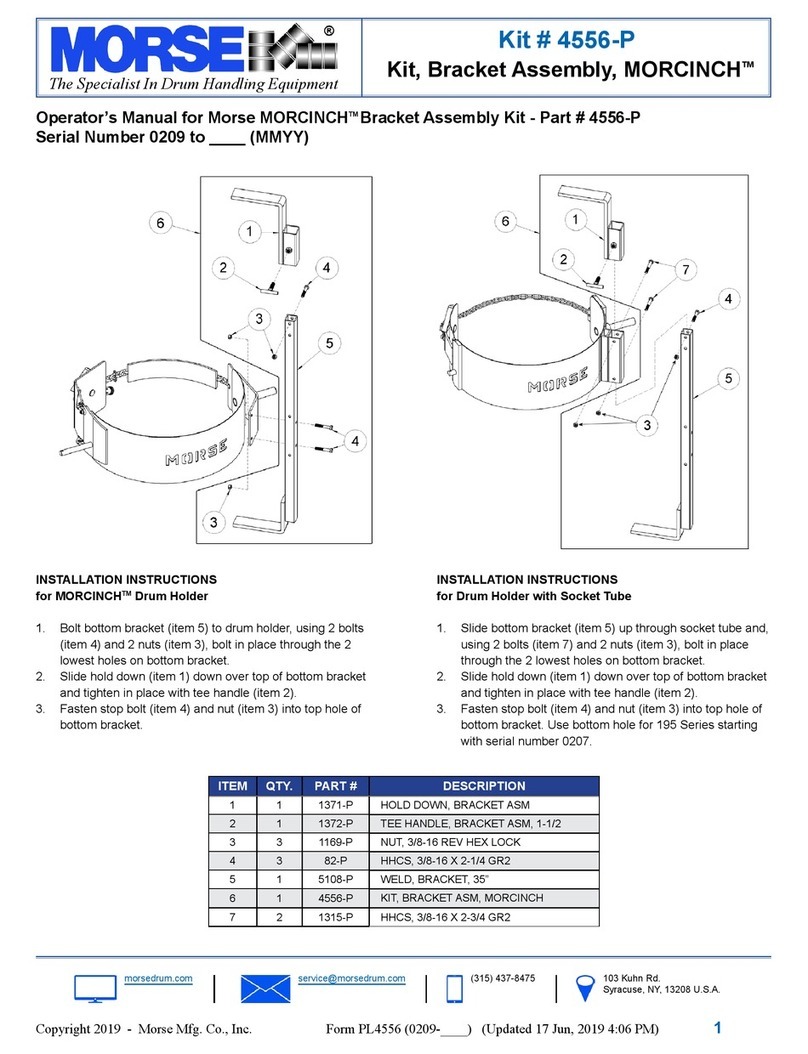

ITEM QTY. PART # DESCRIPTION

1* 2 8160-P WHEEL,6”,3/4”BRG,81,82

2* 2 705-P CAP,HUB,PUSH-ON,3/4”

3 2 83-P GRIP, HANDLE, 1-1/4 X 4-1/2

4* 2 3308-P CASTER,4”SWIVEL,DBLRACE

5 8 35-P HHCS, 5/16-18 X 1 GR2

6 8 1570-P WASHER, 5/16 USS 7/8 OD

7 8 1650-P WASHER, 5/16 SPLIT LOCK

8* 4 3194-P BEARING,3/4ID,82,500,600

9 4 166-P SNAP RING, EXTERNAL, 82

10 1 3343-P RISER WELD, 82 SERIES

11 1 3371Z-P OVERHEAD ASM, 82A

12 2 64-P ROLL PIN, 3/16 X 1-1/4

13 4 17-P WASHER, 5/8 SAE FL 1-5/16 OD

14 2 91-P NUT, 1/2-13 FIN HEX

15 2 1644-P WASHER, 1/2 SPLIT LOCK

16 1 3611-P CYLINDER, 1 X 24, SAE 82

17 1 8260-P PIN, CLEVIS, CYL, 5/8, 82

ITEM QTY. PART # DESCRIPTION

18 1 3612-P HYD FIT, SAE ADAPTER

19 2 82-P HHCS, 3/8-16 X 2-1/4 GR2

20 2 1474-P WASHER, 3/8 SPLIT LOCK

21 1 3694-P HYD HOSE ASM, 35” 82 PL

22 1 765-P HYDFIT,MALEELBOW,FLARE400

23 1 3177-P VALVE, P.C. FLOW CONT .75 GPM

24 1 1108-P HYD FIT, PIPE NIPPLE, 1/4

25 1 M301-P HYD POWER PACK, -125

26 1 1729-P BOTTOM,BATTERYBOX,400

27 4 4168-P WASHER, 7/32, 1-1/2 OD, FENDER

28 4 193-P SCREW, 12-14 X 3/4 3 PT TEK

29 1 388-P BATTERY,12VDC

30 1 403-P HARNESS,BATTERYCABLE,20/30

31 1 1728-P TOP,BATTERYBOX,400,285A-BP

32 1 404-P HARNESS,PUMPCABLE,20/20

33 1 389-P CHARGER 12V 50HZ 60HZ 100-240V

* Recommended spare parts.