•The location should be free from dust, moisture, chemical vapors and mechanical vibrations.

•Do not situate the instrument in a warm and/or humid environment.

•Locate the instrument where the operator’s line of vision is not directed towards a window, a lamp or a

well-lit bright wall. The quality of the viewed image from the microscope will deteriorate where there is

significant ambient light.

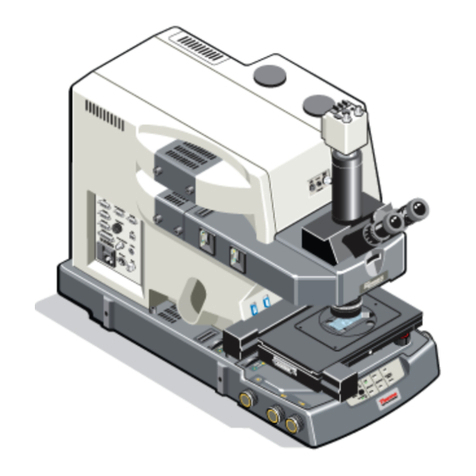

IV Assembling the microscope Input voltage

•Automatic voltage selection works with electrical outlets worldwide. However, always use a power cord

that is rated for the voltage used in your area and that has been approved to meet local safety

standards. Using the wrong power cord could cause fire or equipment damage.

•The use of an extension cord is discouraged and may damage the electrical components of the

microscope.

•In order to prevent electric shock, always turn the power switch on the power supply off before

connecting the power cord.

1 Installing the lamp

•In order to prevent electric shock always turn the power switch off and unplug the power cord before

replacing the lamp.

•Loosen and remove the lamp housing cover clamp screw using a coin. Then remove the lamp house

cover.

•When installing the lamp, do not touch the glass surface of the

lamp with bare fingers. Doing so

will cause fingerprints, grease, etc., to burn onto the lamp surface,

reducing the illumination provided by the lamp. If surface is contaminated, wipe it clean using lens

tissue.

•Firmly insert the lamp into the socket pinholes until it reaches the limit, be careful not to tilt the

lamp when mounting.

•Close the cover and fasten with it with lamp housing cover clamp screw.

2 Mounting the Condenser