Westward Heavy Duty Wheel Dolly

Operating Instructions & Parts Manual 5ML74A

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

®

Description

Westward heavy duty wheel dolly is designed to remove, transport and replace tire and

wheel assemblies on trucks, buses and trailers. It is a labor saving device useful in auto

shops, bus barns and fleet service. This wheel dolly is designed to meet applicable

ANSI/PALD Standards.

Specifications

Overall Size Rollers Lifting Tilt

Model Capacity (L X W X H) Distance Range Degree

5ML74A 3/4 Ton 45-1/8” X39-1/2” X34 5/8” 26” 2-1/2” ~ 8-3/8” 5°

(1500 Lbs)

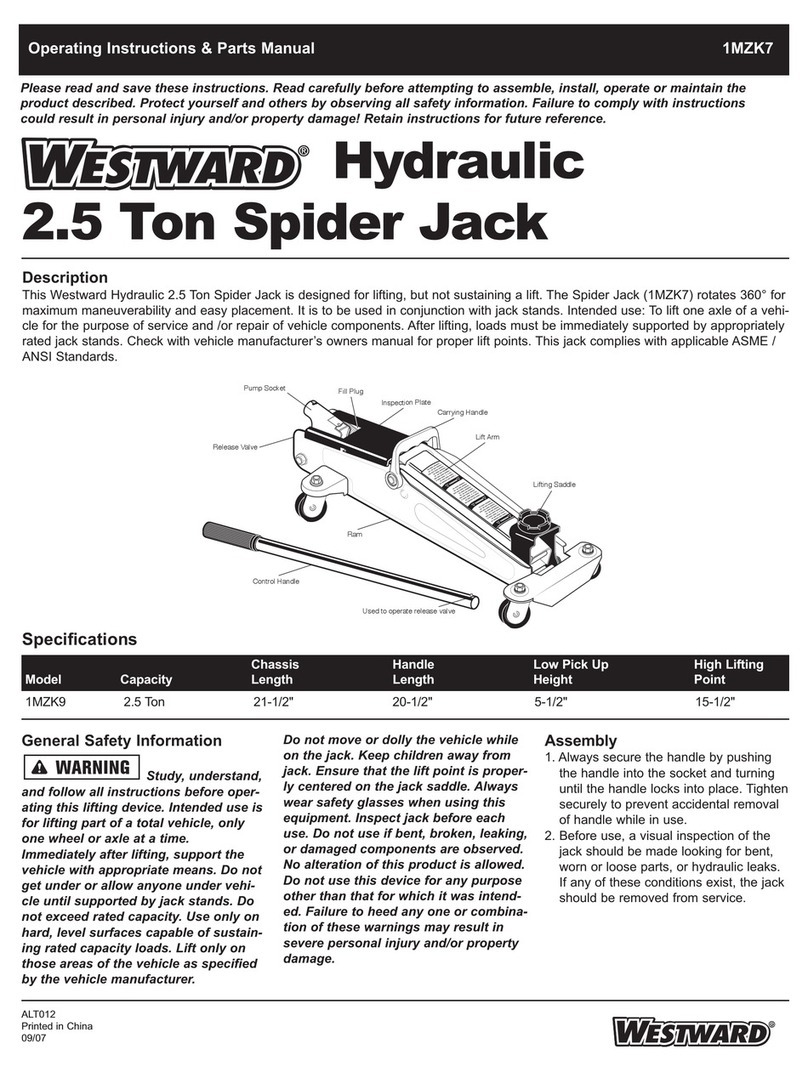

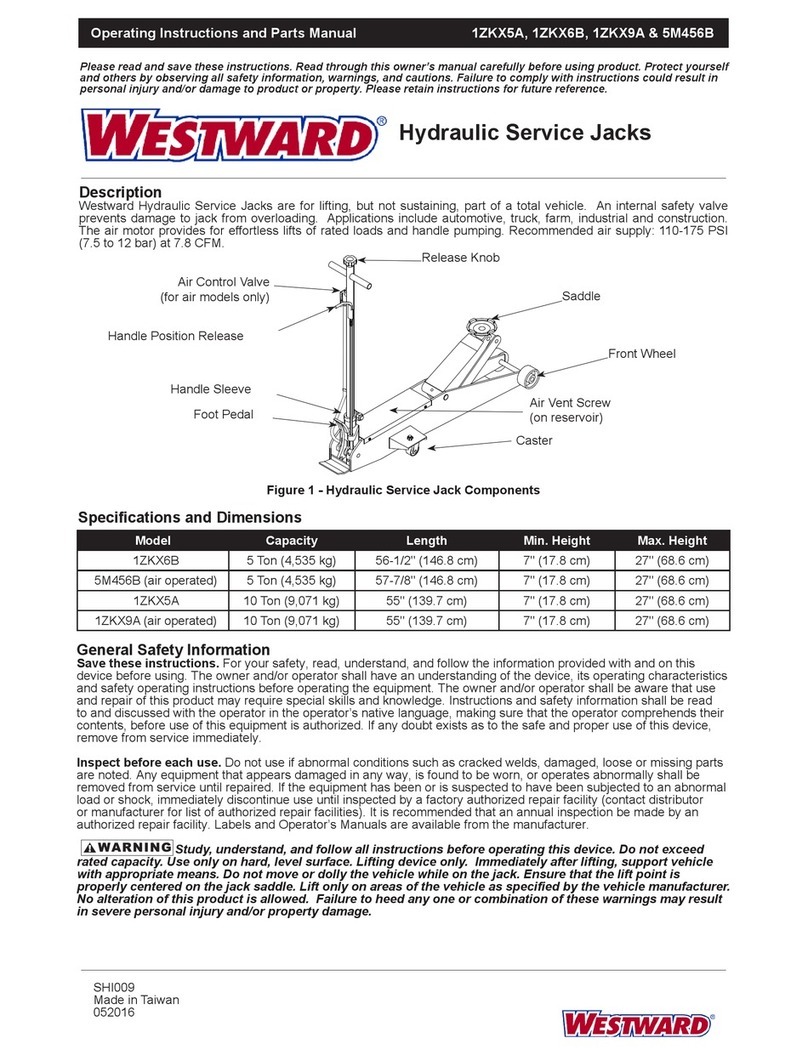

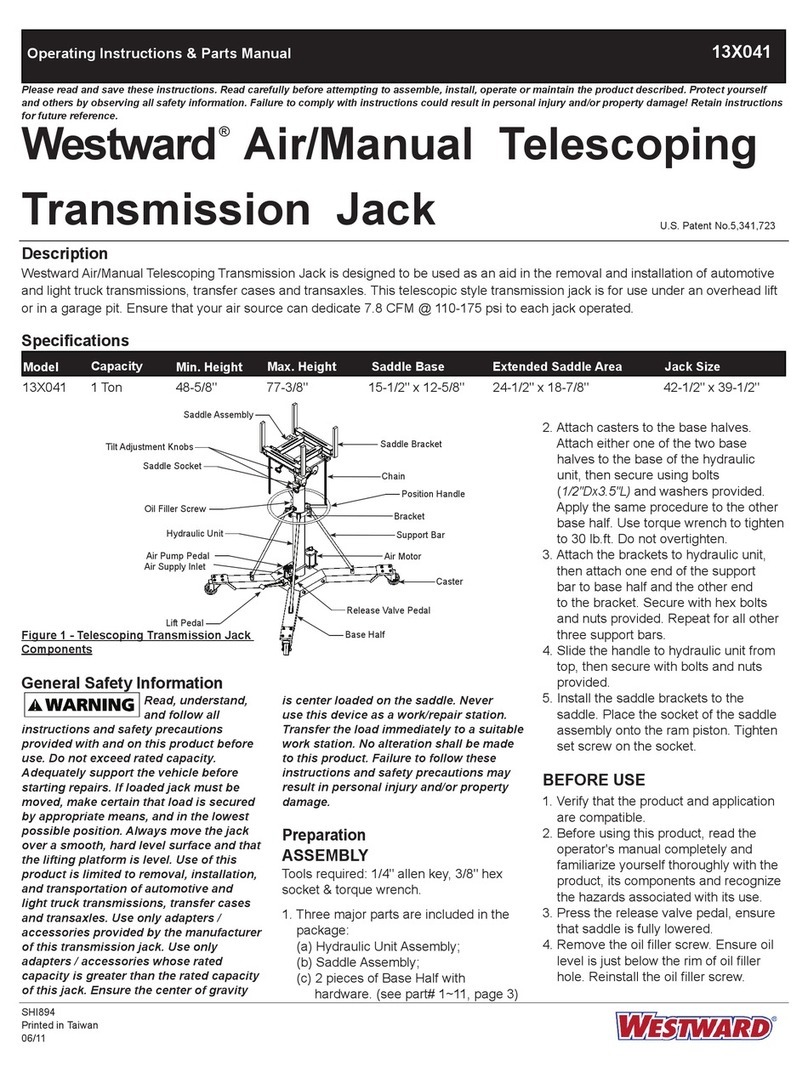

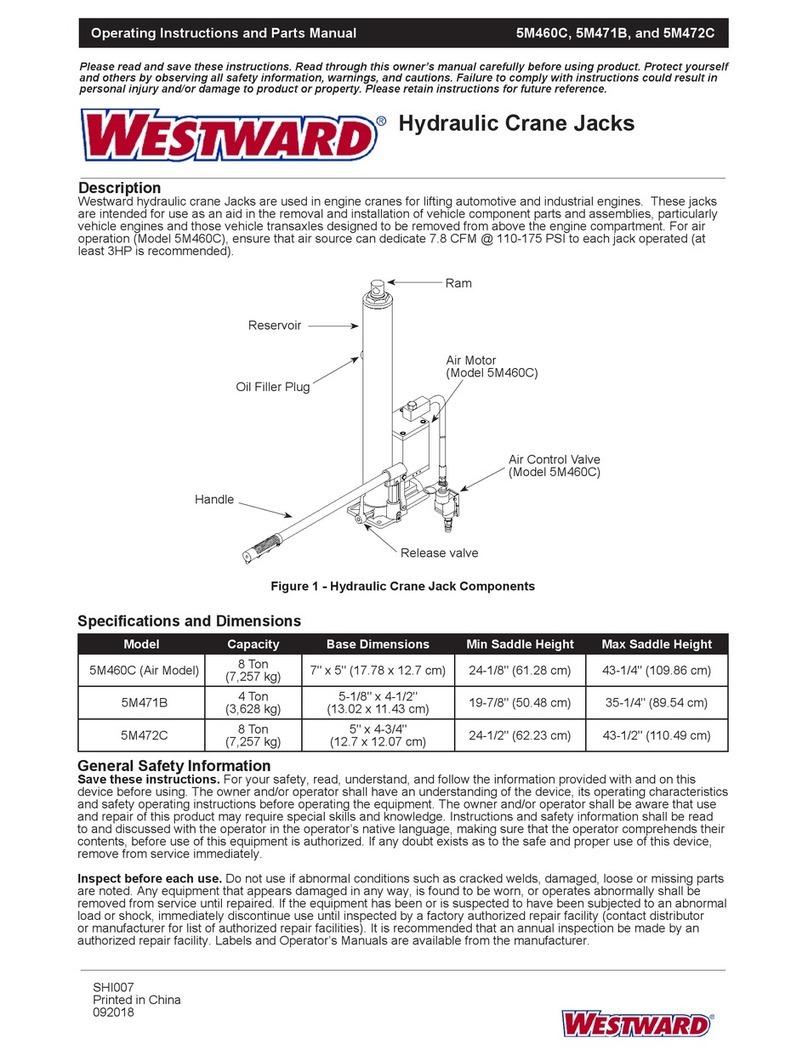

Hydraulic Unit

Front Wheel

Chain

Figure 1 - Wheel Dolly Components

General Safety Information

Read and understand

all warnings and

instructional material provided on and with

this product. Do not exceed rated capacity.

Thoroughly familiarize yourself with this

product before use. Use only on smooth

hard, level surfaces capable of sustaining

the load. Before moving, lower the load to

the lowest possible point and assure that

the load is centered and secured with a

load restraint device. Apply load as close

to the vertical position of the lifting

member as possible. No alterations shall

be made to this product. Do not use this

device for any purpose other than that for

which it is intended. Failure to heed this

warning may result in severe, injury as

well as property damage.

ASSEMBLY

Refer to Figure 2 on page 2

1. Attach leg assemblies (Ref. No. 2) to

main frame (Ref. No. 1) using

M12x1.75x70L &

M12x1.75x120L bolts, M12x1.75 nuts

& M12x3t washers (Ref. Nos. 3, 15, 4

& 5).

2. Install caps (Ref. No. 17) to cover the

holes on the main frame (Ref. No. 1).

3. Loosen all four of the M12x1.75x70L

bolts (Ref. No. 8) and tighten the

M10x1.5x60L bolts (Ref. No. 11) to

expand the roller insert hole.

Note: Do not overtighten the bolts (Ref.

No. 11). Adjust bolt’s tightness until it is

expanded enough for accepting the

roller (Ref. No. 6).

4. Slide roller (Ref. No. 6) into the roller

insert hole on frame (Ref. No. 7) until it

is aligned with the edge of the hole.

5. Loosen the M10x1.5x60L bolts (Ref.

No. 11) and tighten all the

M12x1.75x70L bolts (Ref. No. 8) to

secure the roller onto the frame.

6. Attach the frame (Ref. No 7) to main

frame (Ref. No. 1) using the pin, c-clip

and roller. (Ref. No. 12, 13 & 14).

7. Install hydraulic unit (Ref. No. 18) in

between the frame and main frame

(Ref. No. 7 & 1).

8. Attach hooks (Ref. No. 21) to chain

(Ref. No. 20).

9. Attach one end of hook (Ref. No. 21)

through angle frame hole and attach

another hook to the other hole.

BEFORE USE

1. Inspect before each use. Do not use if

bent, broken, leaking or cracked

components are noted. Ensure that

casters, rollers and lift arm moves

freely. Check and tighten any loose

assemblies.

2. Verify that the product and the

application are compatible.

3. Read, understand and follow vehicle

manufacturer’s recommended tire

change procedures.

4. With jack in fully lowered position,

locate and remove oil filler plug. This

purges the hydraulic system of

pressurized air trapped in reservoir.

Check fluid level. Proper level is even

with filler plug hole.

5. Reinstall oil filler plug.

HOW TO USE

1. Set emergency brake, chock tires of

diagonally opposed wheel(s) in both

directions AND take every precaution

necessary to ensure setup is stable

and prevent inadvertent vehicle

Main Frame

Load Leveler

with Caster

(not shown)

SHI 021

Printed in China

11/09

Angle Frame

Roller