Safety Information & Precautions

The following safety instructions should be observed at all times when opening the MotorVac BRAKEVAC-II.

• Perform a visual inspection before each use. If the unit shows defects or damage, do not use! Have

your equipment repaired by an authorized MotorVac Service Center.

• The MotorVac BRAKEVAC-II is to be used only in accordance with the operator’s manual.

• The MotorVac BRAKEVAC-II is to be used only for the maintenance and repair of hydraulic brake uid

and clutch systems.

• Fill the MotorVac BRAKEVAC-II with BRAKE FLUID ONLY! Do not mix the dierent DOT standards

together. Never use the unit with any uid other than BRAKE FLUID!

• WARNING! USE OF FLUIDS OTHER THAN BRAKE FLUID CAN DAMAGE THE SEALS IN THE

PUMPS! USE OF OTHER FLUID CAN VOID THE WARRANTY!

• Follow all instructions from the Brake Fluid Manufacturer. Read all cautions on the container. Use proper

precautions when coming into contact with brake uid.

• Keep your MotorVac BRAKEVAC-II clean. Wipe your bleeder with a clean rag and non-ammable

solvent. Wipe all residual uids from the bleeder before use.

• Do not put oil, gasoline, or solvent soaked rags on the bleeder, as this will create a re hazard.

• Use only manufacturer’s recommended adapters and accessories. Always follow the vehicle

manufacturer’s service and maintenance instructions.

Brake Flush Service Procedure

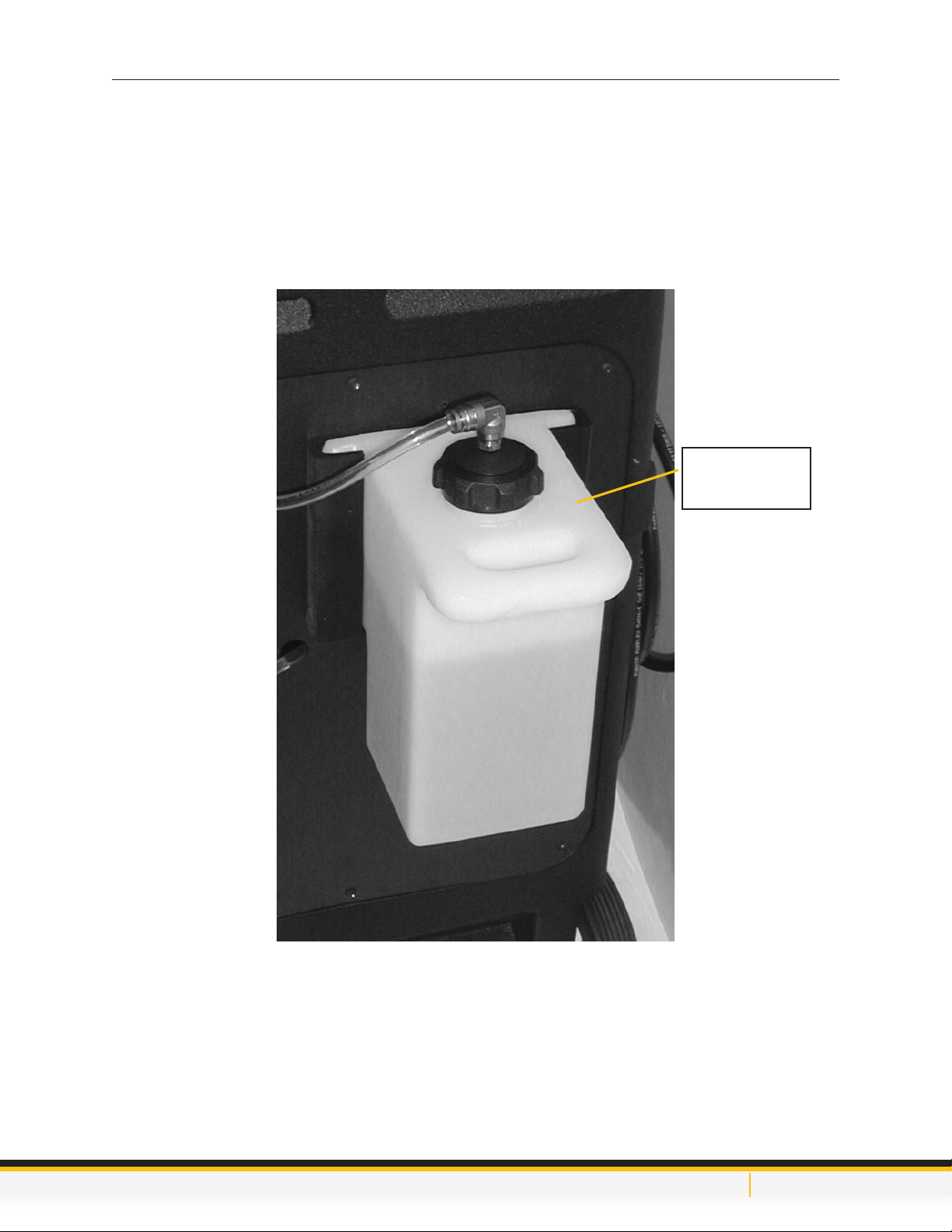

1. Remove the ll cap from the MotorVac BRAKEVAC-II clean uid tank and ll with new brake uid. You

can observe the uid level by looking at the level indicator window at the front of the unit. Replace the ll

cap.

2. Attach the power cord to a good 12 volt DC power source.

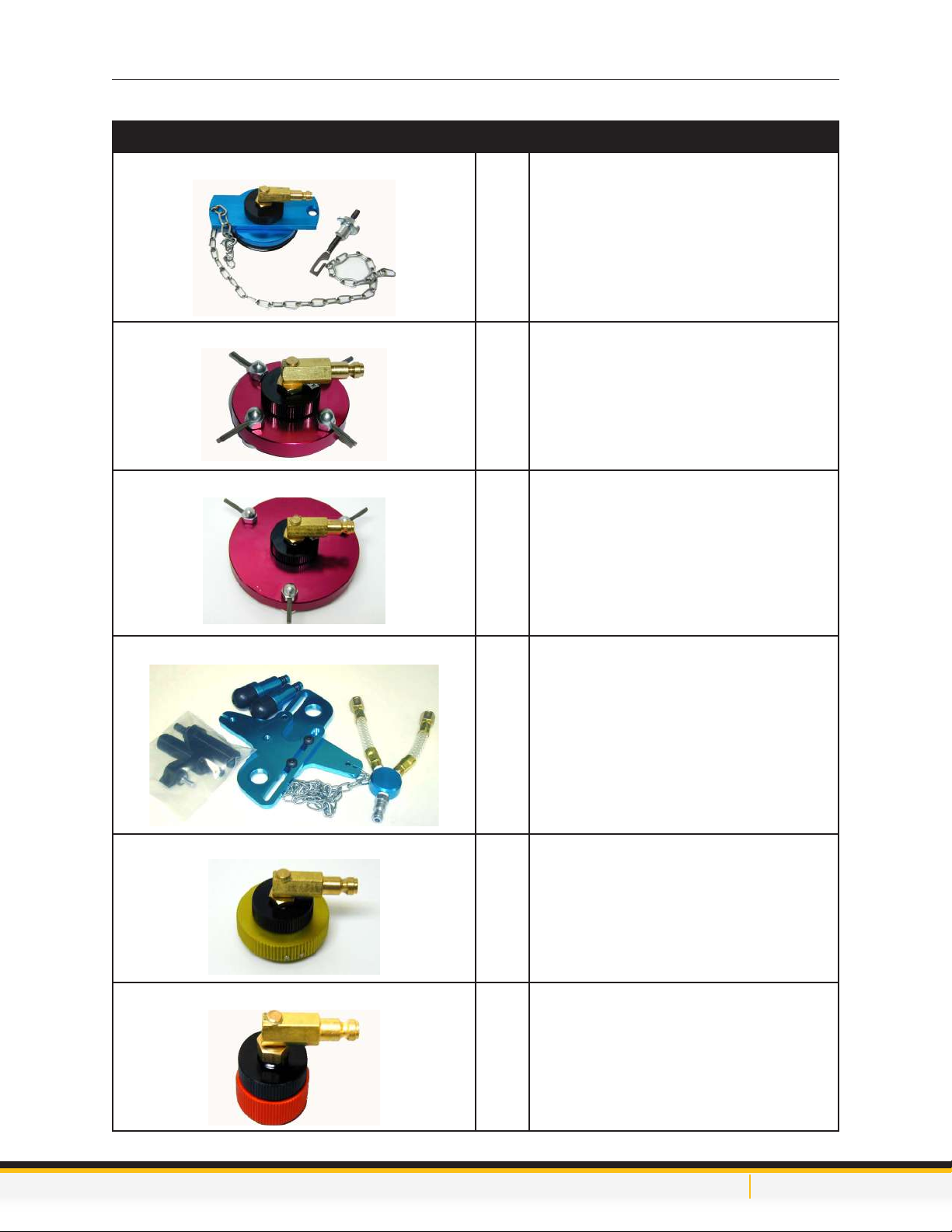

3. Install the proper master cylinder reservoir adapter and connect the black pressure hose coupling to the

adapter.

4. Turn the pressure switch to the ON position and check for leaks.

5. Adjust the pressure regulator until the desired pressure is reached. (45 lb. maximum). Do not over

pressurize the reservoir as it may become damaged. To set pressure, relieve any residual pressure from

the service hose by inserting the ‘ll’ adapter into the coupler at the hose end. Open the regulator valve

‘counter-clockwise’ before starting the pump. If control knob is locked, pull outward slightly until knob

clicks o the locking tab. After starting the pump adjust the regulator in ‘clockwise’ until the correct

pressure reading is obtained. Control knob can be locked by pushing knob ‘in’ towards control panel.

6. Attach the transparent (vacuum) hose to the bleeder adapter and connect to the vehicle’s rst wheel

bleeder valve in the sequence. Turn on the “Vacuum” switch. Open the bleeder valve and observe the

uid ow. When the uid is clean, close the bleeder valve.

7. Bleed the brake system according to manufacturer’s recommended sequence by moving the vacuum

3