MRH800DS ROLLER — OPERATION AND PARTS MANUAL — REV. #4 (11/07/18) — PAGE 3

MRH800DS VIBRATION

ROLLER

Proposition 65 Warning ............................................. 2

Here's How To Get Help ............................................ 3

Table Of Contents ..................................................... 4

Parts Orderirocedures .............................................. 5

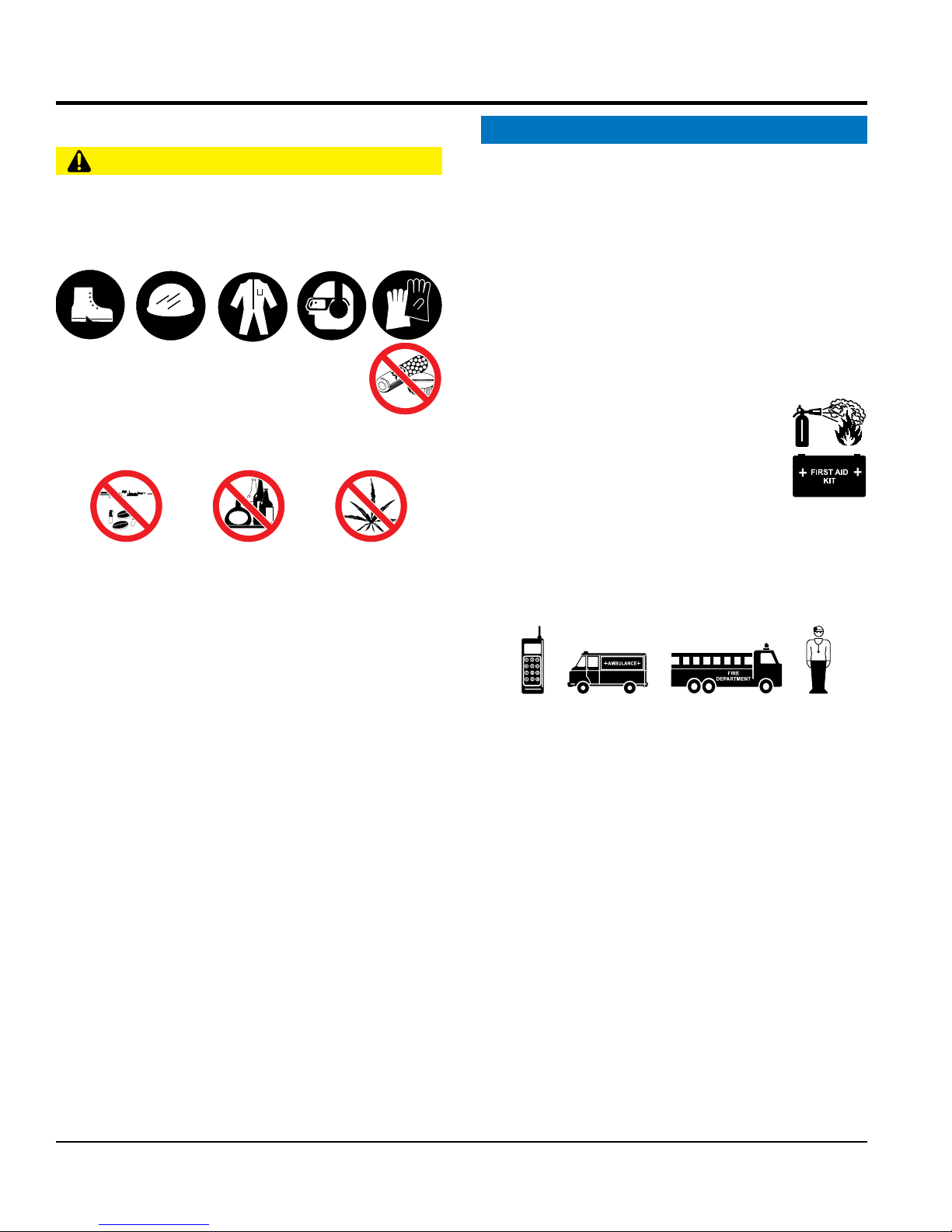

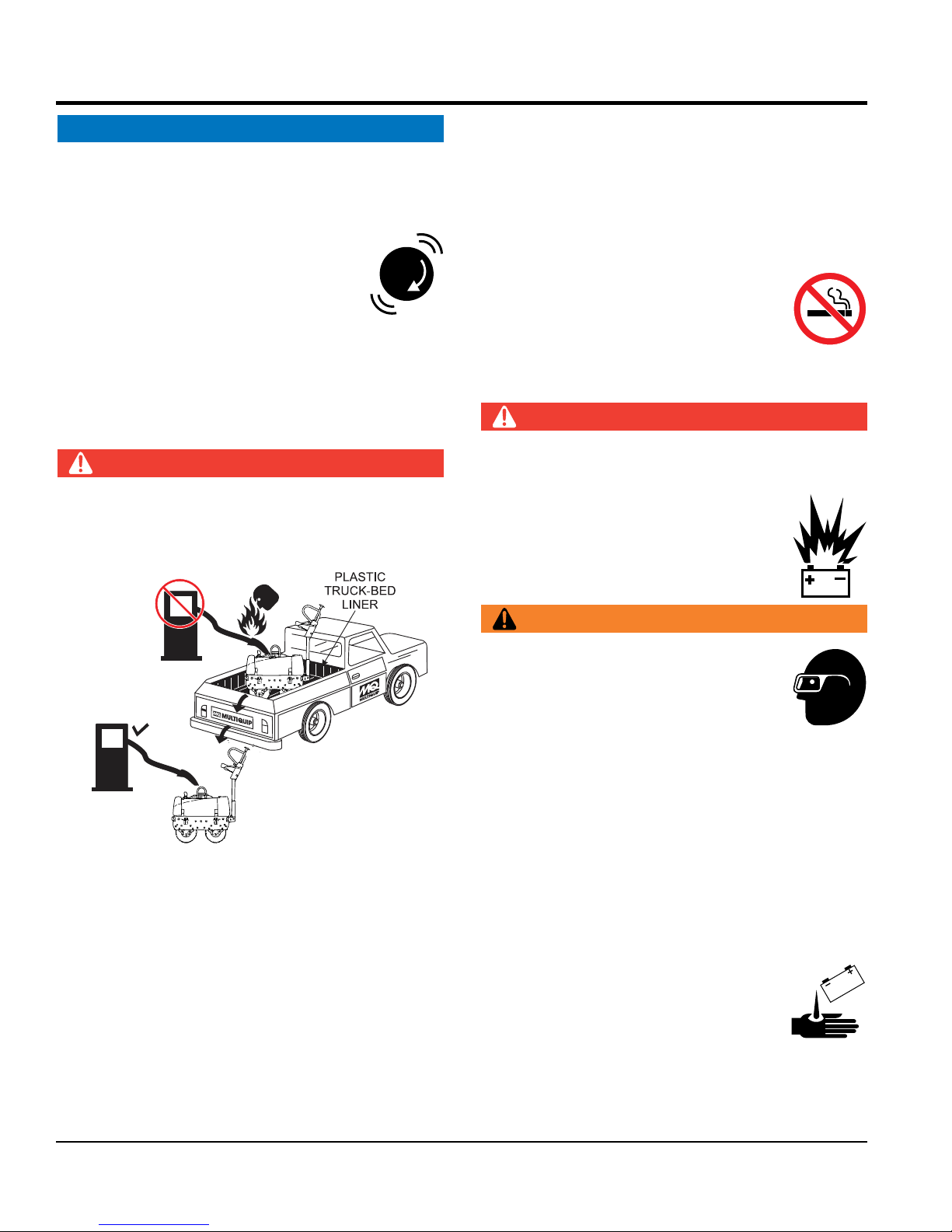

Safety Message Alert Symbols .............................. 6-7

Rules for Safe Operation ........................................ 8-9

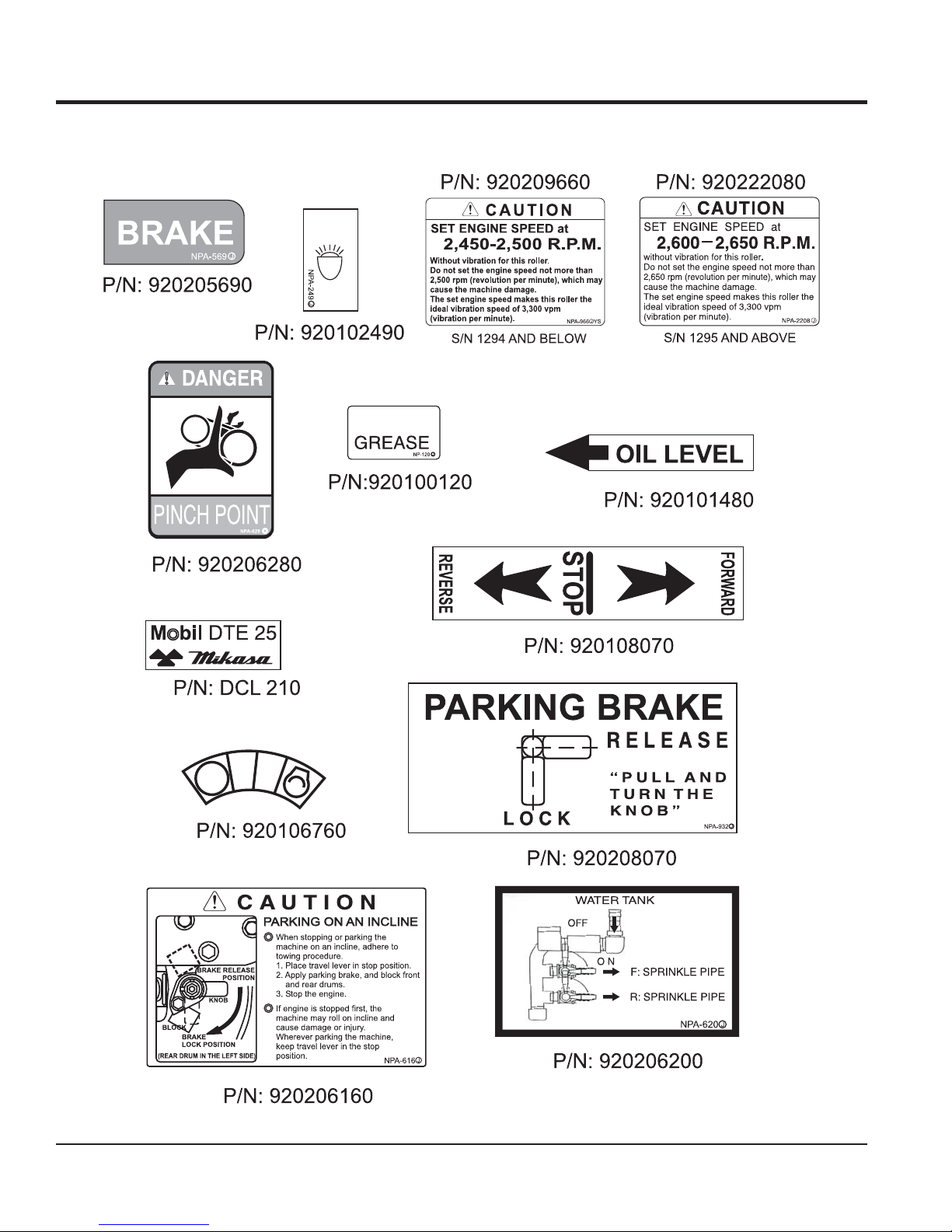

Operation and Safety Decals ............................. 10-11

Roller Specifications ................................................ 12

Engine Specifications .............................................. 13

Dimensions ............................................................. 14

Features .................................................................. 15

Vibration roller Components .............................. 16-17

Handle Bar/Lever Components.......................... 18-19

Engine Components ............................................... 20

Inspection ........................................................... 22-23

Initial Startup ...................................................... 24-25

Operation ........................................................... 26-27

Maintenance ...................................................... 28-33

Roller Troubleshooting ....................................... 34-35

Engine Troubleshooting...................................... 36-37

COMPONENT DRACOMPONENT DRA

COMPONENT DRACOMPONENT DRA

COMPONENT DRAWINGSWINGS

WINGSWINGS

WINGS

Explanation Of Code In Remarks Column .............. 38

Suggested Spare Parts ........................................... 39

Decal Placement ................................................ 40-41

Axle Assembly .................................................... 42-43

Base Assembly .................................................. 44-45

Front Guard Assembly ....................................... 46-47

Side Cover Assembly ......................................... 48-49

Water Tank Assembly ......................................... 50-51

Hydraulic System Assembly ............................... 52-55

Hydraulic Oil Tank Assembly .............................. 56-57

Engine Assembly ............................................... 58-59

Electric Device Assembly ................................... 60-61

Clutch (Vibration) Assembly .............................. 62-63

Vibrator Assembly .............................................. 64-65

Upper Control Arm Assembly ............................ 66-69

Lower Control Arm Assembly ............................ 70-71

Yanmar L100EE-DEVMK2 Engine

Cylinder Block Assembly .................................... 72-73

Cylinder Head and Cover Assembly .................. 74-75

Muffler Assembly ............................................... 76-77

Air Cleaner Assembly......................................... 78-79

Crankshaft, Piston and Camshaft Assembly ..... 80-81

Lub. Oil Pump and Governor Assembly ............. 82-83

Cooling and Starting Device Assembly .............. 84-85

Fuel Injection PumpAssembly ............................ 86-87

Fuel Tank and Fuel Line Assembly .................... 88-89

Starting Motor and Dynamo Assembly .............. 90-91

Tool Label and Gasket Set Assembly ................ 92-93

Terms and Conditions of Sale ................................. 94

TABLE OF CONTENTS

Specification and part number are subject to

change without notice.

NOTICE