INSTALLATION

It is quite a challenge to install the decoder in your loco. You should have some

basic electrical knowledge. If you do not , please ask the dealer for help in the

installation.

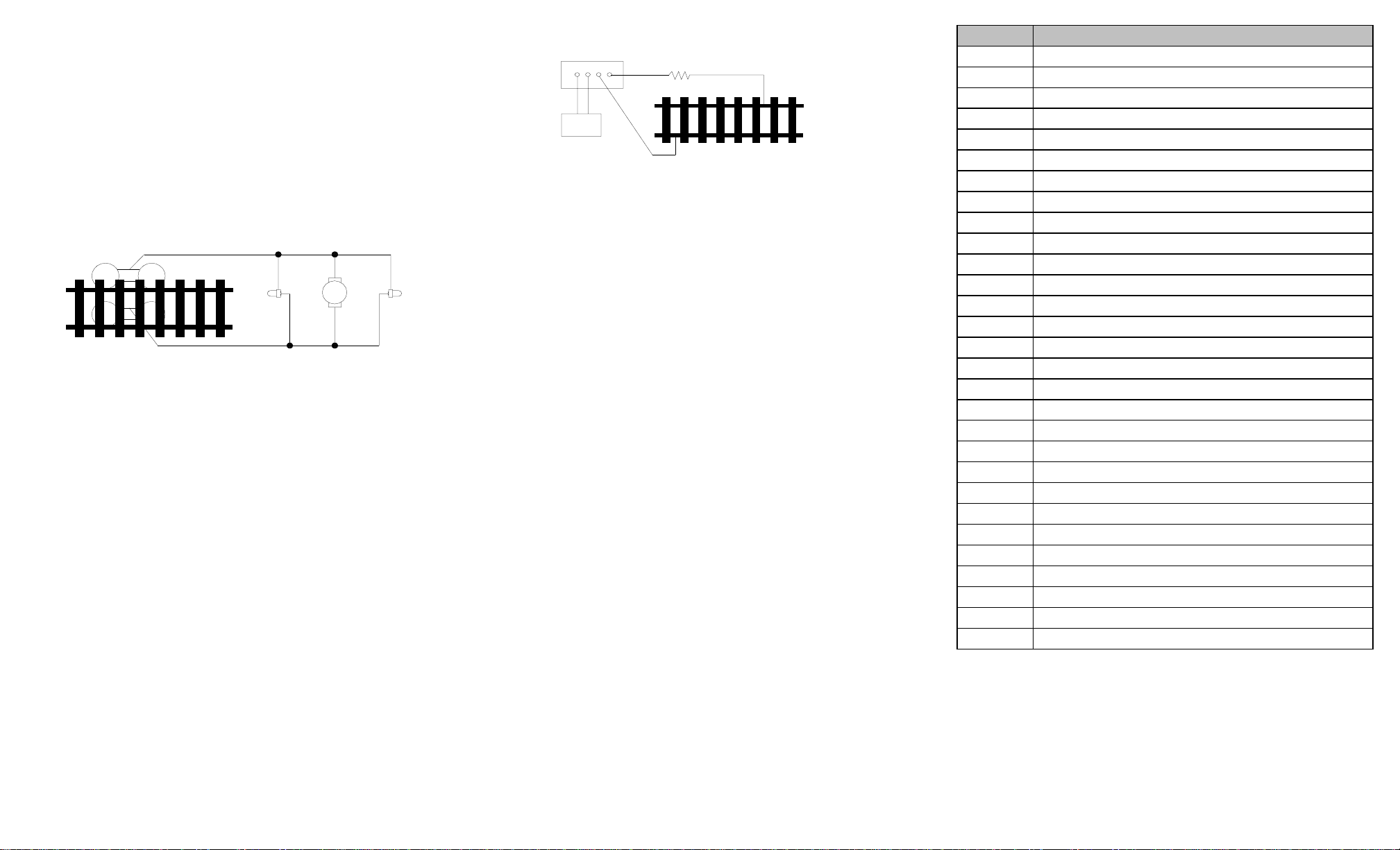

Figure 1 shows the electrical circuit of most standard locos. The terminals of the

motor and lights are directly connected to the wheel pickup. Each type of loco

has its own method of electrical pickup and distribution. There is no standard

rule for installing decoders. It is always better to consult the loco manufacturer

on how to install a decoder in your particular loco. First, figure out your loco’s

electrical wiring and how to disconnect (isolate) the motor and light(s). Label all

wires before you disconnect them.

Figure 1. Connection of standard locomotive. Note: The ‘X’ marks indicate

where to disconnect (isolate).

This decoder is equipped with a wire harness that has an N.M.R.A. 8 pin medium

plug on one end that simply plugs into a dcc ready loco, if you locomotive has a 9

pin JST decoder plug, simply unplug the wire harness of the decoder at the end

of the board and plug the decoder into the 9 pin receptacle.

If your locomotive is not dcc ready and does not have a decoder plug, use the

following directions:

The decoder will be inserted between the wheel pickups and the motor. After

disconnecting the motor terminals from the pickups, connect the right side pickup

wires to the red decoder wire, and connect the left side pickup wires to the

black decoder wire. Connect the right motor terminal to the orange decoder wire,

then connect the left motor terminal to the grey decoder wire.Always use good

soldering techniques, and use shrink wrap to isolate the connections. The white

decoder wire is for the front headlight and the yellow decoder wire is for the rear

light. The blue decoder wire is the light common. The pink and green decoder

wires are for your accessory lights, use the blue decoder wire as the common for

these extra lights. Use double-sided sticky tape to place the decoder in a safe

place. The decoder can’t touch any metal part or bare wires. The 28 mm speaker

should have an enclosure made for a better sound quality.

If you have a 1.5V bulb or LED’s, you should connect a 2k ohm resistor in series to

one of the light leads to limit current.

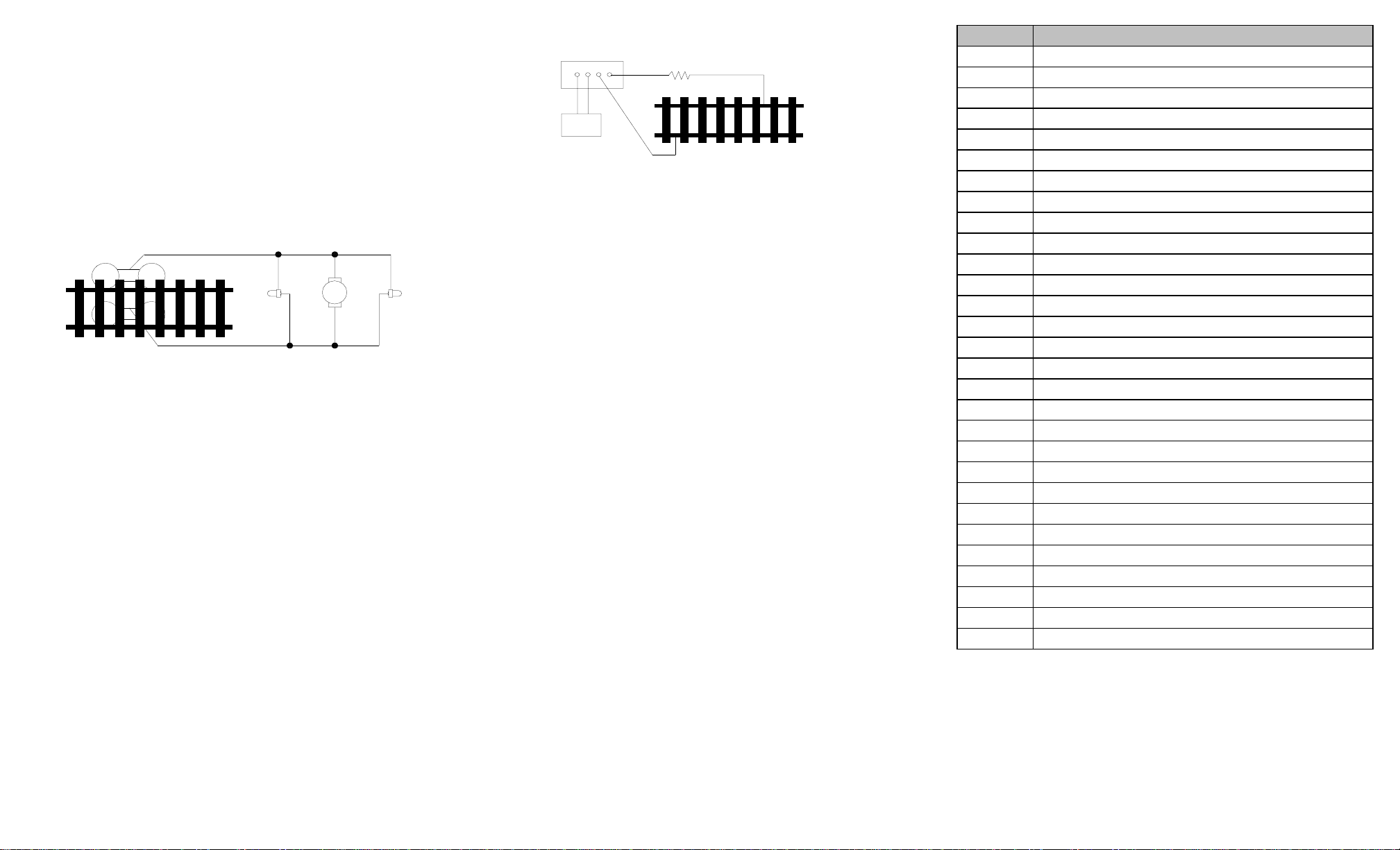

MAKING A TEST TRACK

We strongly recommend building a test track with a 27 ohm resistor to limit current.

Only test your installed decoder on the test track. The test track will reduce the

chance of damaging your decoder due to an incorrectly installed decoder. Note- The

test track is not your program track.

TESTING

The decoder has been programmed to address #3, 28/128 speed steps.To test,

place the loco on the test track. Select address #3 and 28 speed steps. Move up

the throttle and the loco should move. Push the light button [F0] and headlight

should come on. Change the direction of the loco and the loco should change

direction. The loco cannot reach full speed, due to the resistor. If all the above

occurs, you passed the test. Congratulations! Do not run the loco for an extended

period of time on the test track or the resistor will overheat. If your installed decoder

does not pass the test, find the problem, correct it and test it again. As long as you test

the decoder on the test track there is little chance of damaging the decoder. This is why

the test track is so important.

OPERATION

The decoder has 20 types of chuff sounds (10 single and 10 double). You can

use F24 to select them or F6 to turn the chuff off. With our unique double chuff

enable, (CV122), you can also have 10 articulated chuff sounds. You can use F19 to

select 17 different whistles. You can also use F18 to select 7 different bells. With

MRC ProdigyAdvance2DCC which has 28 functions, you can easily setup and

access all the decoder’s functions. With all other DCC systems you have to use CV

programming to setup the decoder.

BACK EMF LOAD CONTROL (PID CONTROLLER)

This decoder is equipped with adjustable back EMF load control feature. It is a

closed loop speed control. With back EMF load control the locomotive will maintain its

speed regardless of pulling up hill or driving down hill. You may program the back EMF

load control intensity, CV124, to a lower value to get less back EMF load control. This

will enable the locomotive to slow down during uphill travel like real locomotive.

The PID controller contains three components: proportional gain (CV113); the

integral gain (CV114); and derivative gain (fixed). Fine tuning a PID controller is

difficult and experimental on part of the end user, so we optimized these settings

at the factory, but still give the customer the ability to make final adjustments. We

recommend that you do not change these settings. Too much gain may cause the

motor to oscilate (become unstable). Too little gain may cause slow

response. Additional knowledge of PID feedback control is required before

attempting to adjust CV113 and CV114. If CV113 and CV114 are programmed

incorrectly, the locomotive will not run smothly. Program CV125 to “1” will automati-

cally restore the default PID controller settings.

Right side pickup

Front

light Motor Rear

light

Left side pickup

X X

X X X

X

Figure2. Diagram of test track

DCC base unit

Power supply Test track

27 ohm resistor

Function Idle/Moving

F0 Headlight on/off

F1 Bell on/off

F2 Whistle

F3 Accessory lights on/off, Long air release

F4 Coupling 1

F5 Brake squeal (moving) and brake release (idle)

F6 Chuff sound on/off (Drifting) -all other sounds on

F7 Fire box open/close

F8 Water injector

F9 Metal crank sound on/off (moving), steam associated sound (idle)

F10 Water filling

F11 Blower hiss

F12 All sounds on/off

F13 Master volume reduce by 2

F14 Master volume increase by 2

F15 Flange noise

F16 Shoveling

F17 Coal auger

F18 Bell type select (total 7 different ones)

F19 Whistle type select (total 17 different ones)

F20 Air hose firing/uncoupling lever

F21 Flange noise

F22 Associated loco sound

F23 Flange noise

F24 Chuff type select

F25 Long air release

F26 Sand dropping

F27 Associated loco sound

F28 Associated loco sound