AD322 “G” Gauge

Diesel Sound Decoder

with MRC Light Effects

Thank you for purchasing our highly advanced DCC locomotive

decoder. Combined with any DCC System, our decoder will

make your model railroad more realistic and exciting.

•8 amp capacity, 3 accessory functions at 0.1 amp

rate (F1 – F3)

•4 sound functions, (bell, long horn, short horn,

uncoupling), plus diesel idle and diesel rumble

•Programmable for either 2-digit (1-127) or

4-digit (1-9999) addresses

•Programmable start voltage

•Programmable acceleration rate

•Programmable deceleration rate

•Programmable top voltage

•Programmable 14, 28, 128 speed steps

•Directional lighting control for front and rear lights

at 0.2 amp rate

•Supports advanced consisting (CV19)

•Supports programming on the main

•Compatible with NMRADCC standard

•Complies with the part 15 of FCC

•2 wired quick disconnect plugs for easy decoder

installation

•2 inch speaker included

•Dimensions: 36mm x 88mm x 23mm

•Suitable for either 1 motor or 2 motor locomotives

The MRC AD322 decoder should perform well when used with other brand

command systems. See your DCC command station’s manual to learn how to

program and operate the decoder. For more information about register/CVs and

their functions, please refer to the NMRA DCC Standard & Recommended prac-

tices, RP-9.2.2 This is available directly from the NMRA or their website at

www.nmra.org.

FCC COMPLIANCE

This device complies with the part 15 of FCC rule. Operation is subject to the

following two conditions. (1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that

cause undesired operation.

RETURN PROCEDURE

If it should become necessary to return your decoder, unplug the decoder and

return the decoder only. Please include a letter (printed clearly) with your name,

address, a daytime telephone number, and a detailed description of the problem

you are experiencing. Please also include a $15.00 check for handling and shipping

fee. Be certain to return the decoder only.

Send the decoder to:

Model Rectifier Corporation

Attn: Parts & Service

80 Newfield Avenue

Edison, NJ 08837-3817 U.S.A

2003 MODEL RECTIFIER CORPORATION

80 NEWFIELD AVENUE

EDISON NJ 08837-3817

Tel. 732-225-6360

PRINTED IN CHINA

INS-2269

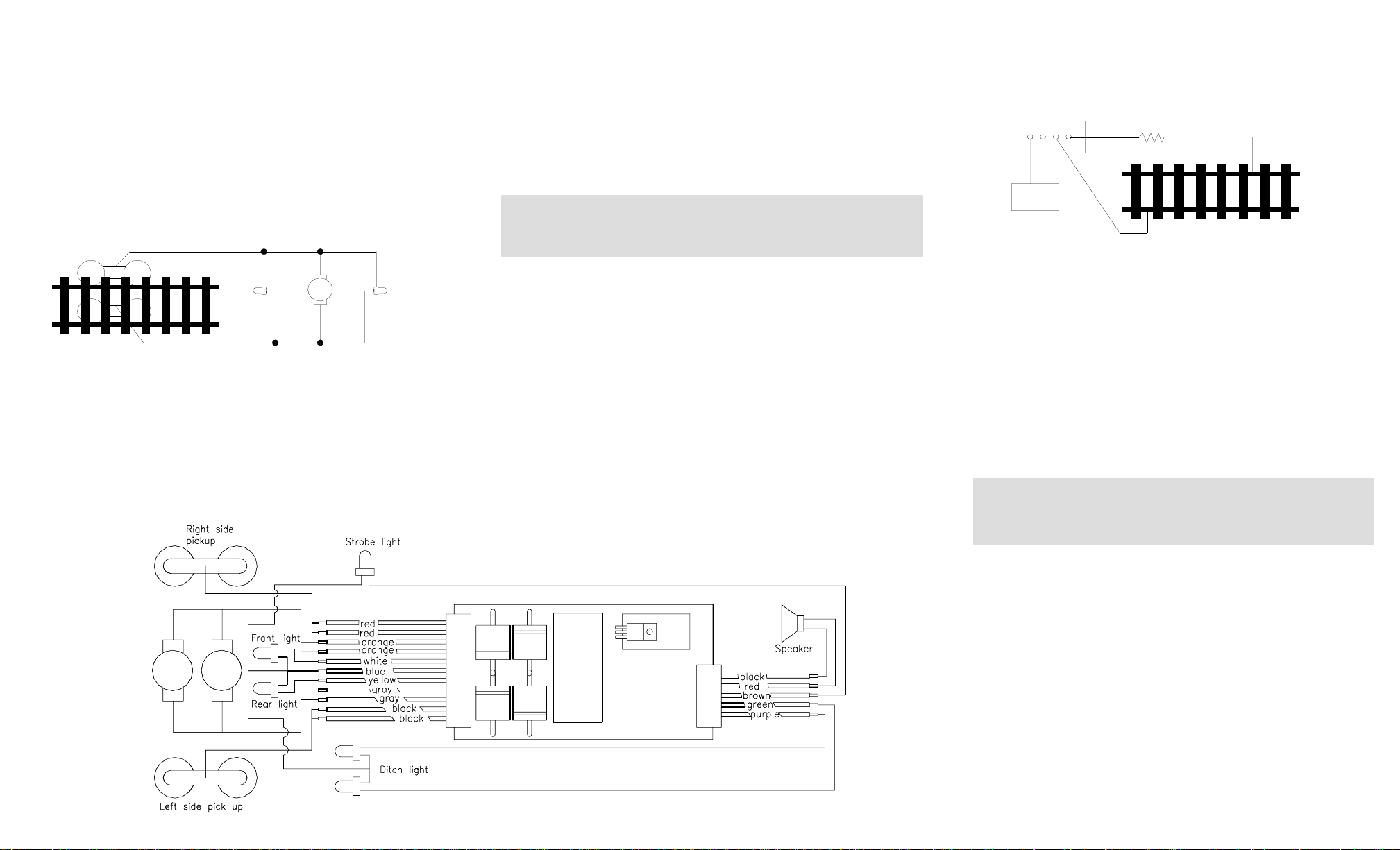

2. MRC Light Effects:

A.“Rule 17” directional headlights: Headlights on/off, (F0), light button. One

light is bright to indicate direction of travel and the other is dim. Also in

this mode, the (F0) light button turns on the strobe light if hooked up.

Normal headlight wiring is used for “Rule 17” lighting (white, yellow & blue

common wire).

B.Ditch lights: Use of the long horn (F2) or short horn (F3) buttons will

activate ditch lights with horn sounds. Ditch lights will flash 5 times after

horn sound ceases. If your DCC system has an F5 button, you can use it

to turn ditch lights steady on/off. Otherwise you must use the uncoupling

button (F4) to turn ditch lights steady on/off. When horn is activated, the

ditch lights will flash. To wire ditch lights, use green and purple accessory

wires with blue (headlight) common wire.

C.Strobe light: This light simulates the rooftop strobe light on some

locomotives. In the MRC Light Effects mode, the strobe will flash when

“Rule 17” headlights are on regardless of loco direction. To wire strobe

light, use brown accessory wire with blue (headlight) common wire.

When hooking up accessory lighting, regardless of mode being used,

use light bulbs rated at maximum track power. The bulbs receive full

track power when the functions are activated. Auxiliary factory

installed locomotive lighting that use LEDs or 1.5-volt bulbs will need

a resistor placed in line to prevent them from burning out.

HOW TO SELECT THE MRC LIGHT EFFECTS

The AD322 is shipped from the factory in the normal/default mode (address #3)

normal lights & functions. There are two ways to access the MRC Light Effects:

1. The MRC EZ way (for all DCC systems except the MRC Command 2000):

Place your locomotive on a programming track. Program your locomotive to

address #1. This step turns our MRC Light Effects on. Final step: Now

program in your locomotive running address, either 2 or 4 digit, and adjust

the rest of your running parameters (momentum, start voltage, etc). That’s

it! To turn off the MRC Light Effects, simply program the locomotive to

address #3 and then follow the final step above.

You cannot run a locomotive on address #1 and retain normal lights/

function or run a locomotive on address #3 with MRC Light Effects.

These two addresses are reserved for turning the functions on and off,

but a locomotive will still be able to run on these addresses.

2. The other way:

If your non-MRC DCC system has the ability to program CVs, you can go

directly to CV 64 to turn on your MRC Light Effects. You can use the

register/ CV chart we have provided for you in this instruction booklet or visit

the National Model Railroad Association website at www.nmra.org for a

more comprehensive understanding of CVs and registers.

PROGRAMMING

The AD322 decoder supports the following register and CV programming.

MRC PRODIGY DCC and MRC Command 2000 users do not need to

know all these register/CV numbers because the MRC DCC systems use

model railroading terminology. It is easy to understand and easy to

program.

CV Register Description Range Factory

Value

CV1 R1 Shortaddress 1-127 3

CV2 R2 Start voltage 0-32 0

CV3 R3 Acceleration 0-32 0

CV4 R4 Deceleration 0-32 0

CV5 --- Maxvoltage 0-32 0

CV29 R5 Basic configuration --- 2

CV7 R7 Manufacturer version number --- 32

CV8 R8 Manufacturer ID --- 143

CV17 --- Long address upper byte 192-231 192

CV18 --- Long address lower byte 0-255 3

CV19 --- Advanced consistaddress 1-127 0

CV64 ---

(0=special light effect/1=normal light effect) 0-1 1

CV105 --- User identifier number 0-255 0

CV106 --- User identifier number 0-255 0

--- R6 Page number 0-31 1