Function Idle/Moving

F1 Bell on/off

F2 Horn

F3 Accessory light on/off, air release

F4 Coupling 1

F5 Brake release (idle) / brake squeal (moving)

F6 Dynamic brake on/off

F7 Air hose firing/uncoupling lever

F8 3 times will shut down when in idle / Manual notch down

F9 Engine cooling fan / Manual notch up

F10 Rail wheel clack (only moving)

F11 Traction air compressor

F12 Change prime diesel mover type (CV123, 6 types)

F13 Master volume reduce by 1 / air release when reach minimal

F14 Master volume increase by1/ air release when reach maximal

F15 Air com pres s or

F16 Flange squeal

F17 Air release

F18 Change bell type (8 types plus off)

F19 Horn type select (total 22 different horns plus off)

F20 Associated loco sound

F21 Change bell volume and turn on the bell

F22 Change horn volume

F23 Change diesel rumble volume

F24 Safety valve pop

F25 Air re leas e

F26 Flange noise

F27 Sand drop

F28 Air release

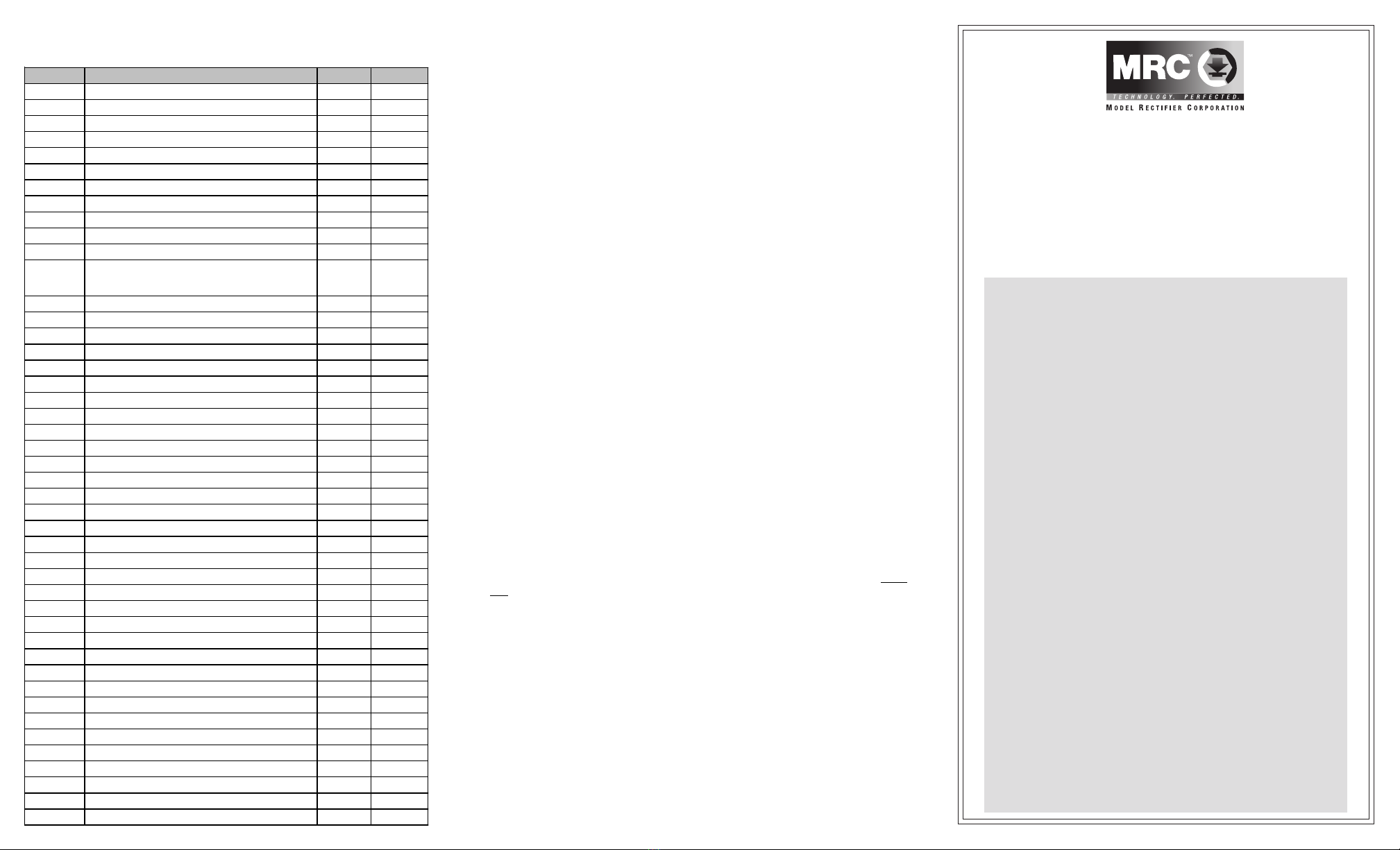

CV118/119 value ACC#1/ACC#2 Light effect

0 Ditch light

1 Gyra light

2Marslight

3 Prime strato light

4 Single strobe light

5 Double strobe light

6 on/off

motor pin

(orange)

pickup pin (red)

com for light

(blue)

ACC1 pad

rear light pin

(yellow)

pickup pin

(black) motor pin

(gray)

front light pin

(white)

ACC2 pad

com pad for

ACC1/ACC2

(blue)

CV123 Prime mover

SD39, SD40, SD40A, SD40-2, SD40T-2, SD45. SDP45, SD45X, SD45-2,

SD45T-2, F45, FP45, DDA40X, GP15T, GP39, GP39-2, GP40, GP40-2

SW1000, SW1001, SW1500, SW1504, MP15DC, MP15AC, MP15T,

GP38, GP38-2, SD38, SD38-2, GP15AC, GP15-1

2 EMD710 SD70AC, SD70M-2

3 ALCO 244

4 ALCO 539T

F2A/B, F3A/B, F7A/B, F9A/B, BL1, BL2, FP7, FL9, FT, GP7, GP9, GP18,

GP28, E6, E7, E8, E9, NW2, NW3, NW4, SW1, SW7, SW8, SW9, SW600,

SW900, SW1200

Suitable for the locomotive

RS-3, PA1, PB1

S-2, S-4, RS-1, RSC-1, RSD-1, DL-105, DL107, DL-108, DL-109, DL-110

0 EMD645E

1 EMD645

5 EMD567

INSTALLATION

If your loco has an NMRA DCC 8 pin socket all you need to do is remove

the dummy plug and plug in the decoder. If the loco travels in wrong

direction you should change the decoder’s orientation. If you can not

change the decoder’s orientation due to the space limitation, you have to

program CV29’s bit 0 to value of 1. This will reverse the loco’s direction. If

you don’t know how to program CV29’s bit 0, you can simply read back

the value of CV29 (an even number) and add 1 to the value. And then

program the odd number back to CV29. For example, if the orignal value

of CV29 is 6, program 7 to CV29. If your locomotive does not have a NMRA

8 pin receptacle, you need order a NMRA 8 pin receptacle/harness from

your local hobby dealer and hard wire this into the loco.

We do not reccomend soldering wires to the pins themselves.

SPEAKER

The decoder comes with 20mm speaker. You may use 28mm round

speaker (0001511) for a wide body loco or use a 16x35mm speaker

(0001513) for a narrow body loco. The bigger 28mm speaker will improve

the overall sound.

DCC OPERATION

The decoders have been factory programmed with address #3, 28/128

speed steps and maximum top voltage. Select the “Run” mode of your

DCC system and select or acquire address #3. Move up the throttle and

the loco should move.

The decoder has 6 types of diesel prime mover sounds. You can use F12

to change the prime mover sounds. You can also program CV123 to

value of 0 to 5 to select the prime mover for your type of diesel engine.

The CV123 table shows the 6 prime mover sounds and their associated

locomotive types.

The decoder has a start up and shut down feature. If the loco has been

previously shut down, you have to start up the engine by simply pressing

any numbered function button. To shut down the engine you must bring

the loco to idle and then press F8 three times.

This decoder has 22 different horns. You can use F19 or program CV50

to select these 22 horns. You can also use F18 or program CV52 to

select different 8 bell sounds.

Most of the sounds have their own volume control CV. There is also a

master sound volume control CV49. Also F13 will reduce the master

volume by 1 (you will hear an air release when you reach CV49=1).

Pressing F14 will increase volume by 1 (you will hear an air release

when you reach CV49=16). Programming CV49 to 0 will shut the sound

off.

The decoder is default to automatic notching. You can program CV122

to 3 to set manual notching for realistic operation. Then use F9 to notch

up and use F8 to notch down. This simulates the way a real locomotive

operates.

This decoder is equipped with adjustable back EMF closed loop speed

control. Its proportional gain (CV113), integral gain (CV114) and deriva-

tive gain (fixed) are pre-tuned for most locomotives. We recommend that

you do not change these settings. Too much gain may cause the motor to

oscilate (become unstable). Too little gain may cause slow response.

Please get some basic knowledge of PID feedback control before trying to

adjust CV113/114.

There are many more program features available with this decoder.

Please refer to the CV Chart to explore other features of the decoder.

Note: Bell, Dynamic Brake and Rail Wheel Clack cannot play at the same

time. If you activate the Bell sound [F1], while either the Dynamic Brake or

Rail Wheel Clack sounds are activated, the Bell sound will override the

other 2 sounds. Rail Wheel Clack cannot play while the loco is in idle.

When you turn off Dynamic Brake and Rail Wheel Clack sound there will

be one second delay.

LIGHT EFFECT PROGRAMMING CHART FOR CV#118/119

You would program CV #118/119 to choose the desired light effect.

CV118 for ACC1 and CV119 for ACC2. For ditch light both CV118 and

CV119 must to 0. F3 control both ACC1 and ACC2. When you solder

wires to ACC1 and ACC2 solder pads please use thin wires and small

solder iron. Please make sure not cause any short circuit.

DC OPERATION

The decoder can also be operated by a regular DC power pack. This

will give you engine sounds only. If you wish to enjoy the full array of

sound functions using your DC power pack, the unique MRC Tech 6 2A,

(#0001200), will allow you to control all of the sounds in your sound

equipped locomotives.