N Gauge Synchronized

Diesel Sound Decoder with

19 Accessory Sound Functions

Item #0001636

Thank you for purchasing our highly advanced DCC locomotive

sound decoder. Combined with any DCC System, our new

decoder with authentic diesel sound truly will make your model

railroad come to life.

•Synchronized diesel prime mover with randomly

associated locomotive sounds

•User selectable 15 different horns and 8 bells

•19 accessory functions allowing more sound control

than ever

•Programmable individual sound volumes

•0.75 amp capacity

•Programmable for either 2-digit (1-127) or 4-digit

(1-9999) addresses

•Programmable start voltage

•Programmable acceleration rate

•Programmable deceleration rate

•Programmable top voltage

•Programmable 14, 28, 128 speed steps

•Selectable factory default speed curve

•Directional lighting (FO) at 0.2 amp rate

•Supports advanced consisting (CV19)

•Supports programming on the main (OPS mode)

•Compatible with NMRA DCC standards

•Complies with Part 15 of FCC

•13x18mm speaker included

•PCB size: 70 x 9.2 x 5.8mm

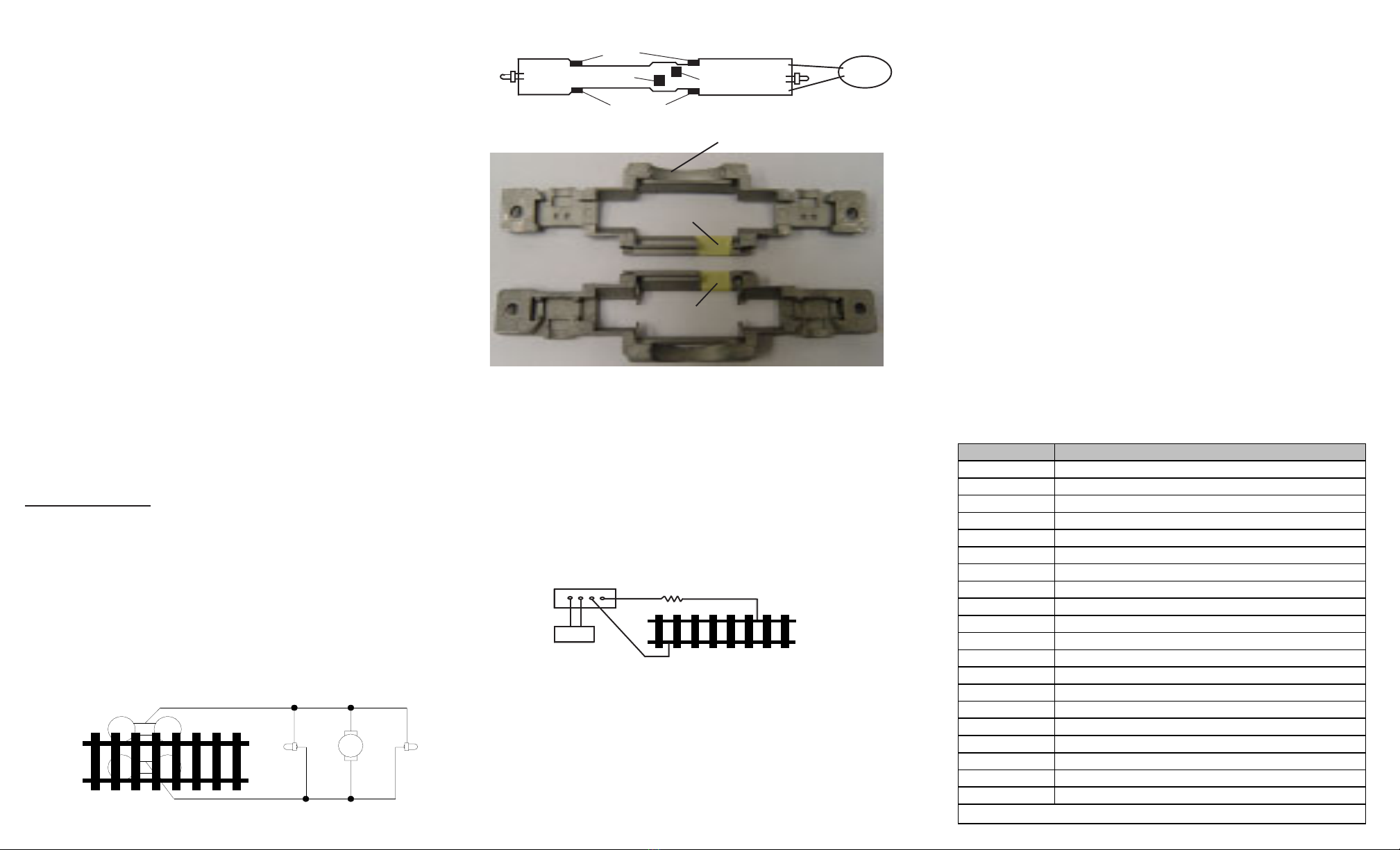

• Directly replaces most Atlas N scale loco’s PC boards

Note: Bell, Dynamic Brake and Rail Wheel Clack cannot play at the same time. If you

active the Bell sound [F1], while either the Dynamic Brake or Rail Wheel Clack

sounds are activated, the Bell sound will override the other 2 sounds. Rail Wheel

Clack cannot play while the loco is in idle. When you turn off Dynamic brake and

Rail Wheel Clack sound there will be one second delay.

TROUBLE SHOOTING

The MRC 0001636 N diesel sound decoder should perform well with all DCC

systems. See your DCC system manual to learn how to program and operate the

decoder. For more information about register/CVs and their functions, please

refer to the NMRA DCC Standard & Recommended practices, RP-9.2.2 this is

available directly from the NMRA or their website at www.nmra.org.

Due to the nature of all sound decoders, the CV read back is not 100% correct. So

this feature is not supported in the decoder. This is not a defect of the decoder or

your DCC system.

Whenever the decoder doesn’t work please use program track to re-program the

loco address or program CV# 125 with value 1 to restore the decoder to factory

setting. This should bring the decoder to life.

FCC COMPLIANCE

This device complies with the part 15 of FCC rule. Operation is subject to the

following two conditions. (1) This device may not cause harmful interference,

and (2) This device must accept any interference received, including interfer-

ence that cause undesired operation.

RETURN PROCEDURE

If it should become necessary to return your decoder, unplug the decoder and

return the decoder only. Please include a letter (printed clearly) with your name,

address, a daytime telephone number, and a detailed description of the problem

you are experiencing. Please also include a $15.00 check for shipping and

handling. Be certain to return only the decoder.

Send the decoder to:

Model Rectifier Corporation

Attn: Parts & Service

80 Newfield Avenue

Edison, NJ 08837-3817 U.S.A

PROGRAMMING

This decoder supports all programming methods including: register, paged CV,

direct CV, and programming on the main (ops mode programming).

2005 MODEL RECTIFIER CORPORATION

80 NEWFIELDAVENUE

EDISON, NJ 08837-3817

NOTE: Due to limitations in older DCC systems, some of the sound functions or

light effects functions may not accessable. ALSO, you might be limited to

factory default CV values. Printed in USA

CV Register Description Range Default

CV1 R1 Short address 1-127 3

CV2 R2 Start voltage 0-32 0

CV3 R3 Acceleration 0-32 0

CV4 R4 Deceleration 0-32 0

CV5 --- Top voltage 0-32 32

--- R6 Page number --- ---

CV29 R5 Basic configuration --- 2

CV7 R7 Manufacturer version num ber --- 32

CV8 R8 Manufacturer ID --- 143

CV17 --- Long address upper byte 192-231 192

CV18 --- Long address lower byte 0-255 3

CV19 --- Advanced consist address 0-127 0

CV49 Sound on/off(1=on) 0-11

CV50 --- Horn type 0-15 4

CV51 --- Horn volume 0-3 3

CV52 --- Bell type 0-9 3

CV53 --- Bell volume 0-3 3

CV54 --- Bell ring rate 0-50 3

CV55 --- Dies el rum ble volum e 0-3 3

CV56 --- Brake squeal volum e 0-3 3

CV57 --- Dynamic brake volume 0-3 3

CV58 --- Air release volum e 0-3 3

CV59 --- Air pump volume 0-3 3

CV60 --- Safetypop valve volum e 0-3 3

CV61 --- Engine cooling fan volume 0-3 3

CV62 --- Coupling volum e 0-3 3

CV63 --- Random noise volume 0-3 3

CV64 --- Rail wheel clack 0-3 3

CV105 --- User identification num ber 0-255 0

CV106 --- User identification num ber 0-255 0

CV115 --- Auto brake squeal enable/disable 0-1 1(enable)

CV116 --- Coupling sound type 0-2, 2=off 1

CV117 --- Lights enable/disable 0-1 1(enable)

CV119 Coupling fire volum e 0-3 3

CV120 Brake release volume 0-3 3

CV121 random noise enable 0-1 1(enable)

CV122

Diesel sound type (0=off, 1=rpm &

notch synchro to speed, 2=linear rpm

synchro to speed, 3=notch up/down

(F8=notch down, F9=notch up))

0-3 1

CV124

Speed curve select (0=linear, 1=slow

increase at slow speed, 2=fast

increase at slow speed

0-2 0

CV125 --- Factory default setting: Programming to 1

will restoreall CV'stodefault setting

---0

CV21---0

When CV21=0,allaccessory functions will

follow its ow n address. When CV21=1, all

functionswill followtheconsistaddress

---