REBOUND

The rebound adjustment controls the speed with which the

shock will return to its initial extended state after being compressed

by an impact. If the rebound adjustment properly set, the rear wheel

should keep maximum traction by tracking the ground without

catapulting the rider o the bike.

gets too slow, the shock absorber will not have time to returne to its

initial position when a series of close bumps is encountered. In this

case, the bike will run out of travel (packing), possibly bottoming out,

and may give the impression of the compression being too soft. When

the rebound adjustment is set too fast, the rear end of the bike will kick

and move from side to side after hitting a series of close bumps and

the rider will feel catapulted by the bike.

To increase the rebound damping, thus making the shock

return slower upon an impact, turn the rebound adjustement

clockwise (screw in). To reduce the rebound damping, thus making

the shock return faster upon an impact, turn the rebound adjuster

knob counterclockwise (unscrew). The rebound adjustment range is

appoximtely two complete rotations.

If you cannot achieve appropriate rebound speeds, a change

to the internal shimstack may be needed. Contact MRP if this is the

case.

IMPORTANT NOTE:

MRP’S REBOUND VALVING IS TUNED IN SUCH A WAY THAT IT PROVIDES MORE

DAMPING (SLOWER RETURN) WHEN DEEP WITHIN THE STROKE TO PREVENT THE

RIDER FROM BEING CATAPULTED OFF THE BIKE UPON MAJOR IMPACTS.

LOW-SPEED COMPRESSION

The low-speed compression adjustment controls the damping

level (resistance) for slow movement of the shock’s shaft (low velocity),

such as under pedaling, when cornering and when preloading the

suspension for jumping. The low-speed compression damping level

provides the overall stiness feeling of the bike’s suspension, making it

either plush and comfortable or firm and fast rolling.

You should start in the middle of the adjustment range

(approximately 15 clicks

back

from max). To adjust properly, turn the

adjuster one click at a time and take a test ride. The adjustment is

more sensitive towards the max position (firmest). When the low-speed

not to damage your frame, and also for frames that require dierent

mounting hardware sizes for each end of the shock. For three piece

hardware, start with the steel sleeve and insert it through (the correct

side) the bushing in the eyelet and center it on the eyelet as best as

you can. Take the frame spacers and insert the provided seals into

the flanged side of the spacer. With the seals installed slide the frame

spacers over the sleeve so that the seal rests against the eyelet of the

SPRING REMOVAL & INSTALLATION

To remove the spring, start by turning the preload adjuster ring

counterclockwise to remove all preload until the spring become loose.

Push down on the spring retainer clip then slide it o the shock, being

careful not to damage the shaft with the sharp sides of the spring clip.

Once the clip is removed, you can slide the spring o the shock.

IMPORTANT NOTE:

ALWAYS MAKE SURE THAT THE END OF THE SPRING’S COIL IS ALIGNED ON

THE OPPOSITE SIDE OF THE SLOT IN THE SPRING RETAINING CLIP. THIS WILL

PREVENT THE SPRING FROM BENDING THE CLIP.

PRELOAD

Spring preload is the compression applied to the shock’s spring

when at rest, using the preload adjuster ring. The preload adjustment

is used to achieve the optimal amount of sag and proper ride height.

To increase the preload on your spring, turn the preload

ring clockwise. Increasing the preload will increase the ride height,

thus reducing the sag. This will result in a more responsive ride. Be

careful not to apply too much preload. This can cause “coil binding”,

which is when the coils of the spring rub against each other under

full compression. This can damage the spring, the shock, and can be

dangerous for the rider.

To reduce the preload on your spring, turn the preload ring

counter-clockwise. Reducing the preload will decrease the ride height,

thus increasing the sag. This will result in a more comfortable ride.

Make sure to apply enough preload so the spring is firmly held in place

and does not spin freely on the shock.

IMPORTANT NOTE:

IF MORE THAN 5MM OF PRELOAD (5 TURNS) IS NEEDED TO ACHIEVE PROPER

SAG, IT IS RECOMMENDED TO CHANGE TO A HIGHER SPRING RATE. IF SAG

IS NOT ENOUGH WITHOUT ANY PRELOAD APPLIED TO THE SPRING, IT IS

RECOMMENDED TO CHANGE TO A LIGHTER SPRING RATE.

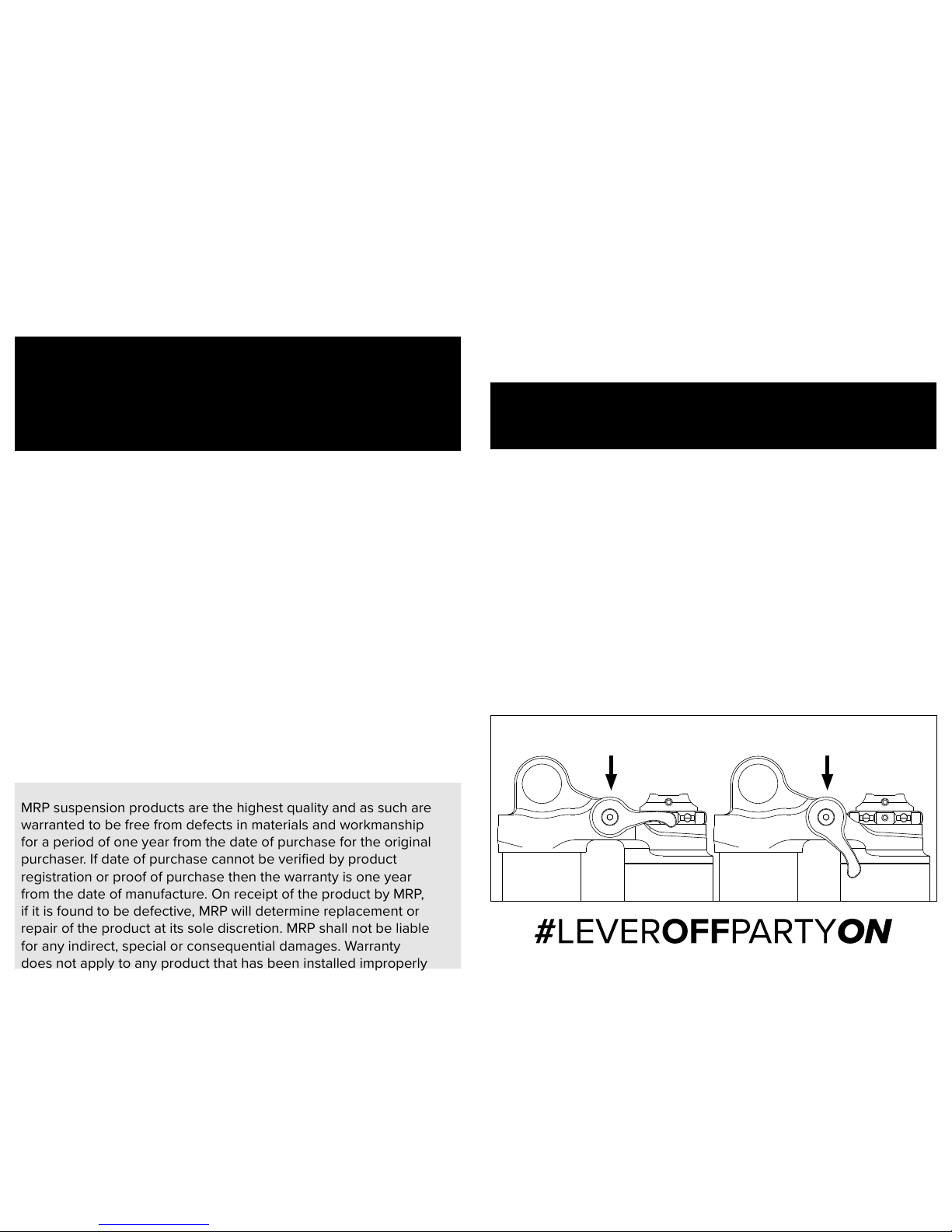

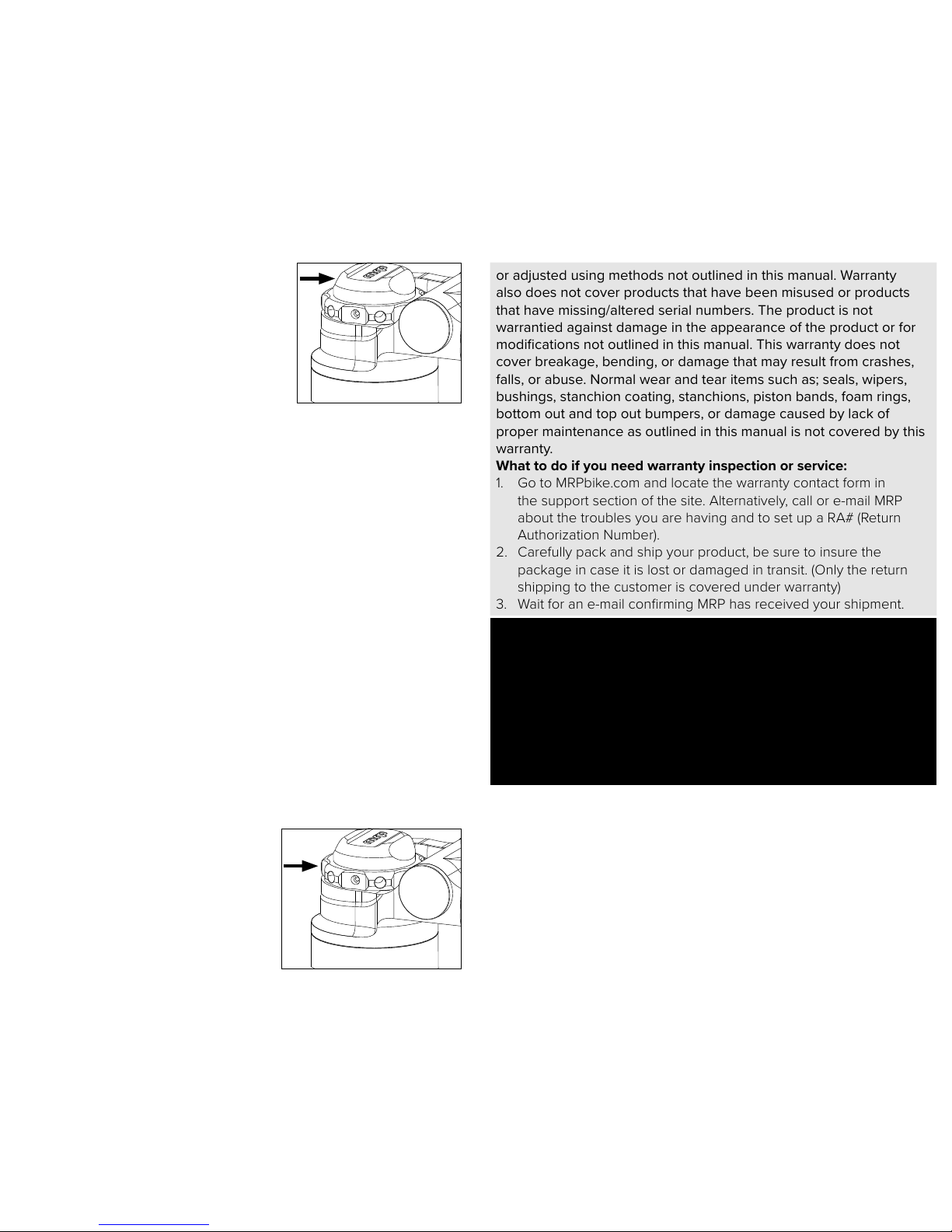

The rebound adjustment on the Hazzard

uses requires a 3mm hex key. You should start in

the middle of the adjustment range, one complete

rotation counterclockwise from max rebound

(fully in). To adjust properly, turn the adjustment

appoximately 1/8 of a turn at a time and take a test

ride. The adjustment is more sensitive towards the

fully in position (slowest). When the rebound setting