IMPORTANT CONSUMER SAFETY INFORMATION

WARNING: RIDING A BIKE IS DANGEROUS. NOT PROPERLY

MAINTAINING OR INSPECTING YOUR BIKE AND ITS

COMPONENTS IS EVEN MORE DANGEROUS. IT IS ALSO

DANGEROUS TO NOT READ AND FOLLOW THESE

INSTRUCTIONS.

Thank you for choosing MRP. This owner’s manual is your

reference guide to using and fine-tuning your suspension fork

for optimum performance and comfort. It also provides important

information about the proper maintenance of your fork. Carefully

read this manual before installing your fork. If you need further

assistance, our experienced team is able to advise and assist you

to find the exact set up to meet your personal needs.

The fork is an important part of your mountain bike and

this owner’s manual explains how to install and use it properly.

We recommend that it be installed by a qualified bicycle

mechanic. Improperly installed forks might cause serious harm

to you and may severely damage your mountain bike. Never

take any chances with your safety. Before installing and using

your new fork, carefully read this owner’s manual to learn the

correct installation and adjustment procedures and avoid the

consequences of an incorrect installation or improper adjustment.

When your fork requires an oil change or other internal

maintenance, MRP and experienced suspension service centers

are best qualified to provide the necessary service or repairs.

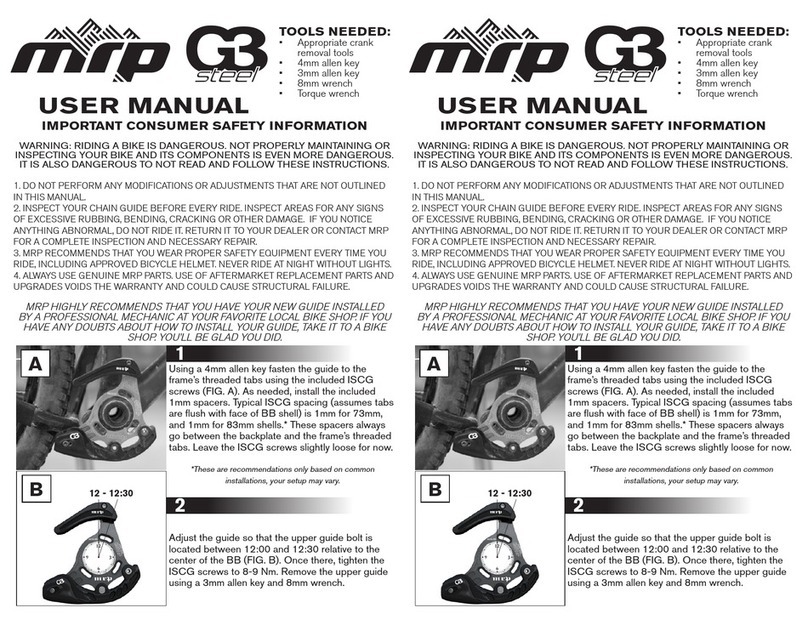

FORK INSTALLATION

1. Remove your old fork from the bicycle. Measure the diameter and

length of your old fork’s steerer tube to ensure that your new steerer

tube is the correct diameter and sucient length for the installation.

If your MRP fork has a tapered steerer tube, be sure to leave enough

room above the taper to allow for proper stem installation.

2. Remove the crown race from your old fork.

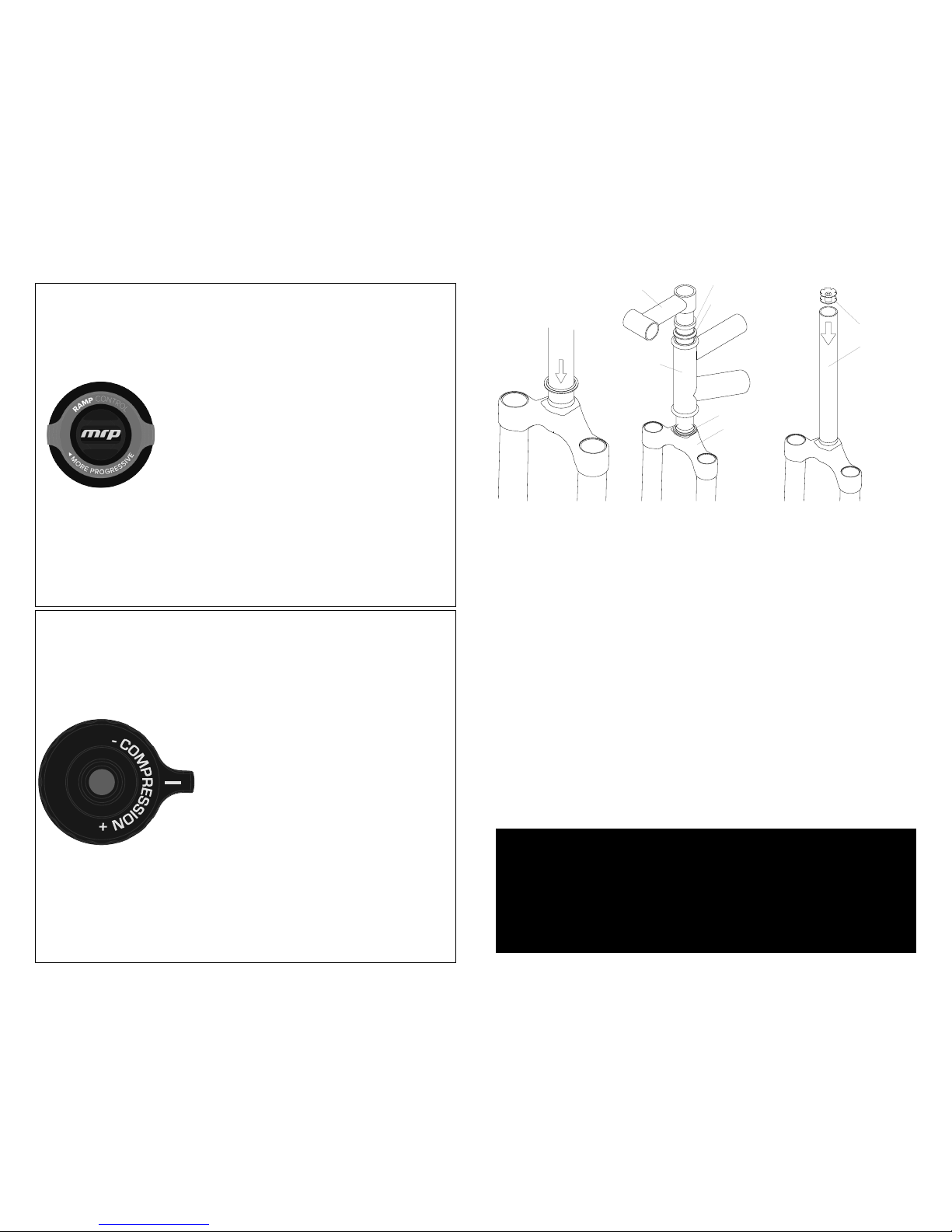

3. Press the crown race onto your new fork. (See Figure #1)

4. Preassemble the fork on the bike with the headset, stem, and spacers

(optional). Refer to your stem manufacturer’s instructions to determine

how much room is needed to clamp the stem.

5. Mark the steerer tube at the top of the stem. The steerer tube will now

need to be cut to the correct length. Disassemble and cut 3mm (1/8”)

below the mark. Consult your dealer or mechanic if you don’t have the

proper tools to cut the steerer tube.

WARRANTY:

MRP suspension products are the highest quality and as such are

warranted to be free from defects in materials and workmanship

for a period of one year from the date of purchase for the original

purchaser. If date of purchase cannot be verified by product

registration or proof of purchase then the warranty is one year from

the date of manufacture. On receipt of the product by MRP, if it is

found to be defective, MRP will determine replacement or repair of the

product at its sole discretion. MRP shall not be liable for any indirect,

special or consequential damages. Warranty does not apply to any

product that has been installed improperly or adjusted using methods

not outlined in this manual. Warranty also does not cover products

that have been misused or products that have missing/altered serial

numbers. This warranty does not cover breakage or damage that

may result from crashes, falls, or abuse. Normal wear and tear items

such as; seals, wipers, bushings, stanchion coating, stanchions, piston

bands, foam rings, bottom out and top out bumpers, or damage

caused by lack of proper maintenance as outlined in this manual is not

covered by this warranty.

What to do if you need warranty inspection or service:

1. Go to MRPbike.com and locate the warranty contact form in the

support section of the site. Alternatively, call or email MRP (info@

mrpbike.com) about the troubles you are having and to set up a RA#

(Return Authorization Number).

2. Carefully pack and ship your product, be sure to insure the package in

case it is lost or damaged in transit. Clearly write the RA number on the

outside of the box. (Only the return shipping to the customer is covered

under warranty)

MAINTENANCE LOG

DATE PROCEDURE