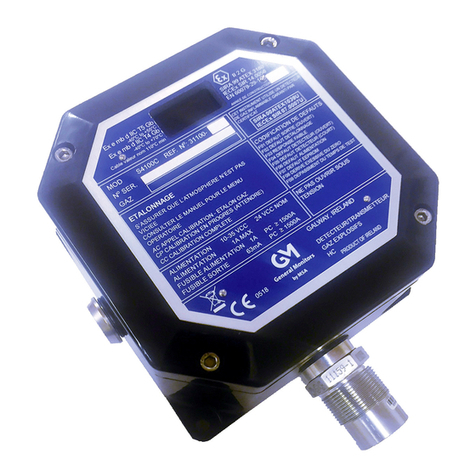

Model S4100T

i

Warranty Statement

General Monitors warrants the Model S4100T to be free from defects in workmanship or

material under normal use and service within two (2) years from the date of shipment.

General Monitors will repair or replace without charge any equipment found to be

defective during the warranty period. Full determination of the nature of, and

responsibility for, defective or damaged equipment will be made by General Monitors’

personnel. Defective or damaged equipment must be shipped prepaid to General

Monitors’ plant or the representative from which shipment was made. In all cases this

warranty is limited to the cost of the equipment supplied by General Monitors. The

customer will assume all liability for the misuse of this equipment by its employees or

other personnel. All warranties are contingent upon proper use in the application for

which the product was intended and do not cover products which have been modified or

repaired without General Monitors’ approval or which have been subjected to neglect,

accident, improper installation or application, or on which the original identification marks

have been removed or altered. Except for the express warranty stated above, General

Monitors disclaims all warranties with regard to the products sold, including all implied

warranties of merchantability and fitness and the express warranties stated herein are in

lieu of all obligations or liabilities on the part of General Monitors for damages including,

but not limited to, consequential damages arising out of/or in connection with the use or

performance of the product.

Warnings

The instrument should be calibrated at least every 90 days. See sub-section 4.1.

Take note of sub-section 3.4 Sensor Poisons.

Install and maintain all hazardous area equipment in accordance with the relevant

regulations and practices of the country concerned. See Section 3 Installation.

The S4100T must be protected by in-line 500mA PC≥1500A Char “T” fuse is required if

voltage at unit is between 18VDC and 35VDC in the 24 VDC supply line. This is

necessary to fully comply with approval requirements and good installation practices.

Note: General Monitors series of Trip Amplifiers have the 500mA fuse as standard.

The S4100T must be protected by an in-line 63mA; PC1500A Char “F” fuse in the

analogue output line. This is necessary to fully comply with approval requirements and

good installation practices.

WARNING - Installation and Maintenance must be carried out by suitably skilled and

competent personnel only.