Page 1 of 2

Product’s Use

Service

Service must be done exclusively by skilled workers using only original Veloci replacement parts.

To correctly reassemble, follow the drawing listed in the exploded view in this manual.

WARNING: The components need to be properly reassembled to restore to the original conditions of the product. Veloci is

not responsible or liable for any loss, damage or injury, direct or consequential, arising from improper, use, reassembly or

service by unskilled workers and/or users.

The Professional Foam Cannon combines a high pressure water flow mixed with detergent and air to produce thick clinging

foam. With the adjustable intake you may increase or decrease the amount of detergent drawn into the water flow adjusting

the amount of foam created. Furthermore, the Professional Foam Cannon has a variable angle spray pattern that with a

simple twist goes from a 0 degree focused jet to 50 degree fan pattern.

To correctly install, use, and service this product, carefully read and follow the instructions and warnings contained in this

manual. Please ensure these instructions are included in the final user’s manual of any machine in which the product is

assembled.

Any improper use of or alteration of this product may cause damage, loss or injury. Veloci is not responsible or liable for

any loss, damage, or injury, direct or consequential, arising from improper use or alteration and disclaims all liability for

its functioning and safety. Before using, user shall determine the suitability of the product for its intended use and user

assumes all risk and liability whatsoever in connection therewith. Veloci makes no warranty whatsoever with respect to

the product, including any warranty of merchantability or warranty of fitness for a particular purpose.

The product described here complies with the rules and the lines in force that you can find in the Veloci CONFORMITY

DECLARATION.

Veloci declines all responsibility and liability in the case that the compliance and regulations stated in this manual are not fol-

lowed or respected.

Veloci reserves the right to make any modification to both products and manuals without notice.

Further Instructions

With a 1.25mm/3.5 orifice installed, a minimum of 1.8 GPM and a minimum of 1,100 PSI is required for the product to

operate correctly.

With a 1.1mm/3.0 orifice installed, a mimimum of 1.4 GPM and a minimum of 1,100 PSI is required for the product to operate

correctly.

Use fresh clear water, with common detergents. We recommend that any impure fluid be adequately filtered before it is used.

Detergents with suspended particles can clog the filter and the product will fail to operate properly.

Veloci Performance Products, Inc. (“Veloci”) does not manufacture or supply any of the chemicals used with the product and

is not responsible for their effects. Because of the large number of chemicals that could be used (and their different chemical

reactions), the user of this equipment should determine compatibility of the materials used and any of the potential hazards

involved.

NOTE: Always remember to carefully read the chemical manufacturer’s label and follow all directions.

WARNING: This product is meant for use with the Veloci Professional Foam Cannon only and not intended for use during

spray down. This product is to only be used as advertised; do not install any additional attachments. Check to ensure that

the product is compatible with the system’s operating specifications and do not exceed the maximum flow, pressure, and

temperature ratings of the product that are listed in this manual (see Technical Chart).

Installation must be done exclusively by skilled workers. Veloci is not responsible or liable for any loss or damage arising

from improper installation or installation done by unskilled workers and/or users.

** AFTER EVERY USAGE, AND PRIOR TO STORAGE, RINSE AND THOROUGHLY FLUSH WITH CLEAR WATER. FAILURE

TO THOROUGHLY RINSE AND FLUSH CHEMICALS WILL CAUSE THE FILTER TO CLOG AND THE PRODUCT WILL FAIL TO

OPERATE PROPERLY. THIS FAILURE CAN OCCUR AFTER THE FIRST USE. USE REPLACEMENT FILTERS IF CLOG OCCURS**

1.Remove 1 liter bottle

2.Pull trigger on spray gun

3.Allow clean clear water to thoroughly flush out chemicals in filter for a few minutes

14.5012 Professional Foam Cannon - Users Manual

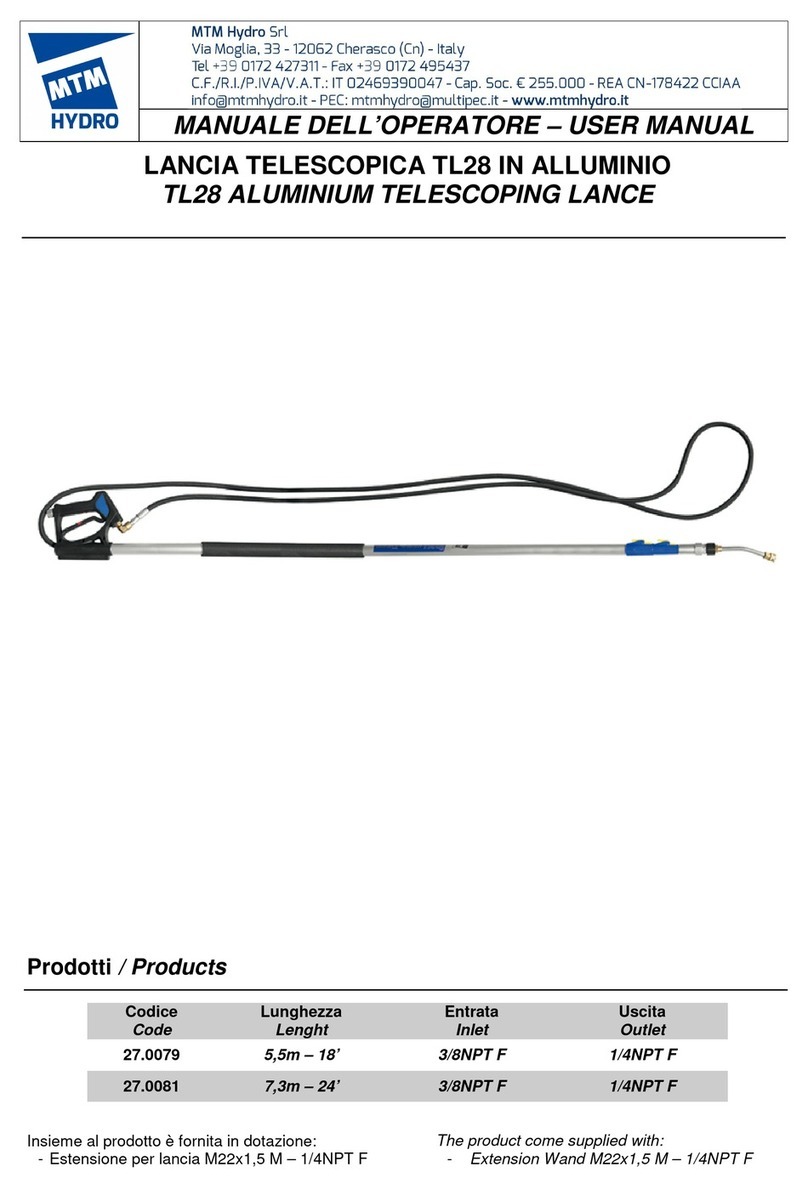

1.25mm/3.5 orifice installed, 1.1mm/3.0 orifice not installed, and two replacement stainless steel filters