Return Loss ......................................................................................................................................... 23

Advanced Settings .......................................................................................................................... 23

Calibration....................................................................................................................................... 23

SOLT ............................................................................................................................................ 23

Gating.......................................................................................................................................... 24

Return Loss Measurement.............................................................................................................. 25

Table of Figures:

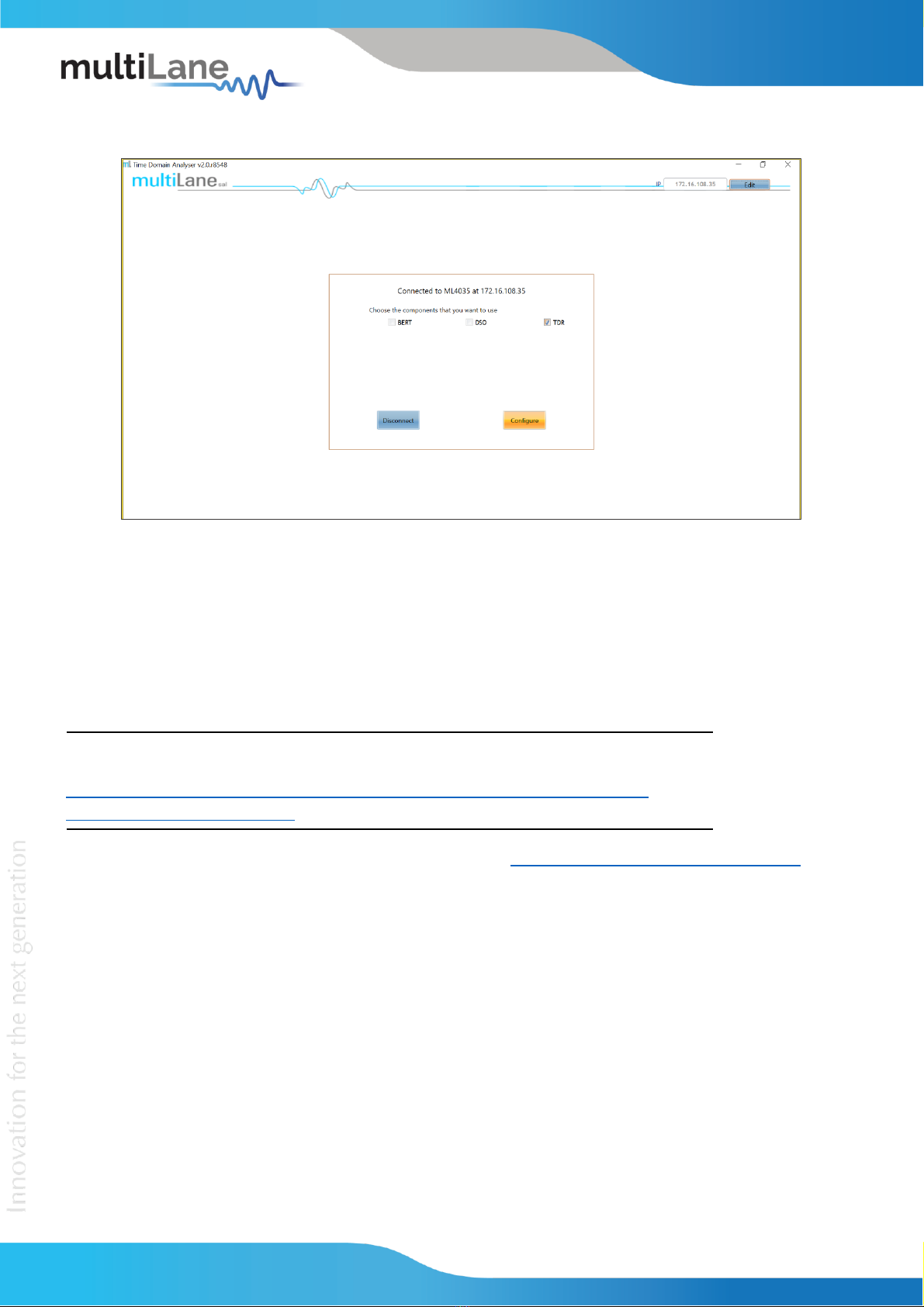

Figure 1: ML4035 GUI Main Page ............................................................................................................... 10

Figure 2: ML4035 Front View ..................................................................................................................... 11

Figure 3: ML4035 connected to PC via Ethernet........................................................................................ 12

Figure 4: ML4035 connected to PC Wirelessly ........................................................................................... 12

Figure 5: ML4035 with USB connection ..................................................................................................... 13

Figure 6: Connect Via Ethernet................................................................................................................... 14

Figure 7: Ethernet Configuration................................................................................................................ 15

Figure 8: Mode Selection............................................................................................................................ 16

Figure 9: Calibration.................................................................................................................................... 16

Figure 10: Add TDR Channels...................................................................................................................... 17

Figure 11: Cable Matching.......................................................................................................................... 18

Figure 12: TDR Measurement..................................................................................................................... 18

Figure 13: Velocity of Propagation ............................................................................................................. 19

Figure 14: Advanced Options...................................................................................................................... 19

Figure 15: Adding TX/RX Channels & Calibration ....................................................................................... 20

Figure 16: S21 Calibration Wizard .............................................................................................................. 21

Figure 17: S21 Calibration Plot ................................................................................................................... 21

Figure 18: S21 Measurement ..................................................................................................................... 22

Figure 19: IL Measurements ....................................................................................................................... 22

Figure 20: ILD & IL Fitted ............................................................................................................................ 22

Figure 21: De-Embedding ........................................................................................................................... 23

Figure 22: S11 Advanced Options............................................................................................................... 23

Figure 23: SOLT Calibration......................................................................................................................... 24

Figure 24: Calibration Wizard (Gating) ....................................................................................................... 24

Figure 25: Applying Markers....................................................................................................................... 25

Figure 26: Return Loss Measurement ........................................................................................................ 26

Figure 27: S11 Measurements.................................................................................................................... 26

Figure 28: Return Loss Mask....................................................................................................................... 26