3/13 Ausgabe 01.2016/Rev.0 MUNSCH Kunststoff-Schweißtechnik GmbH

Contents

Technical data: .............................................................................................................................3

Safety............................................................................................................................................4

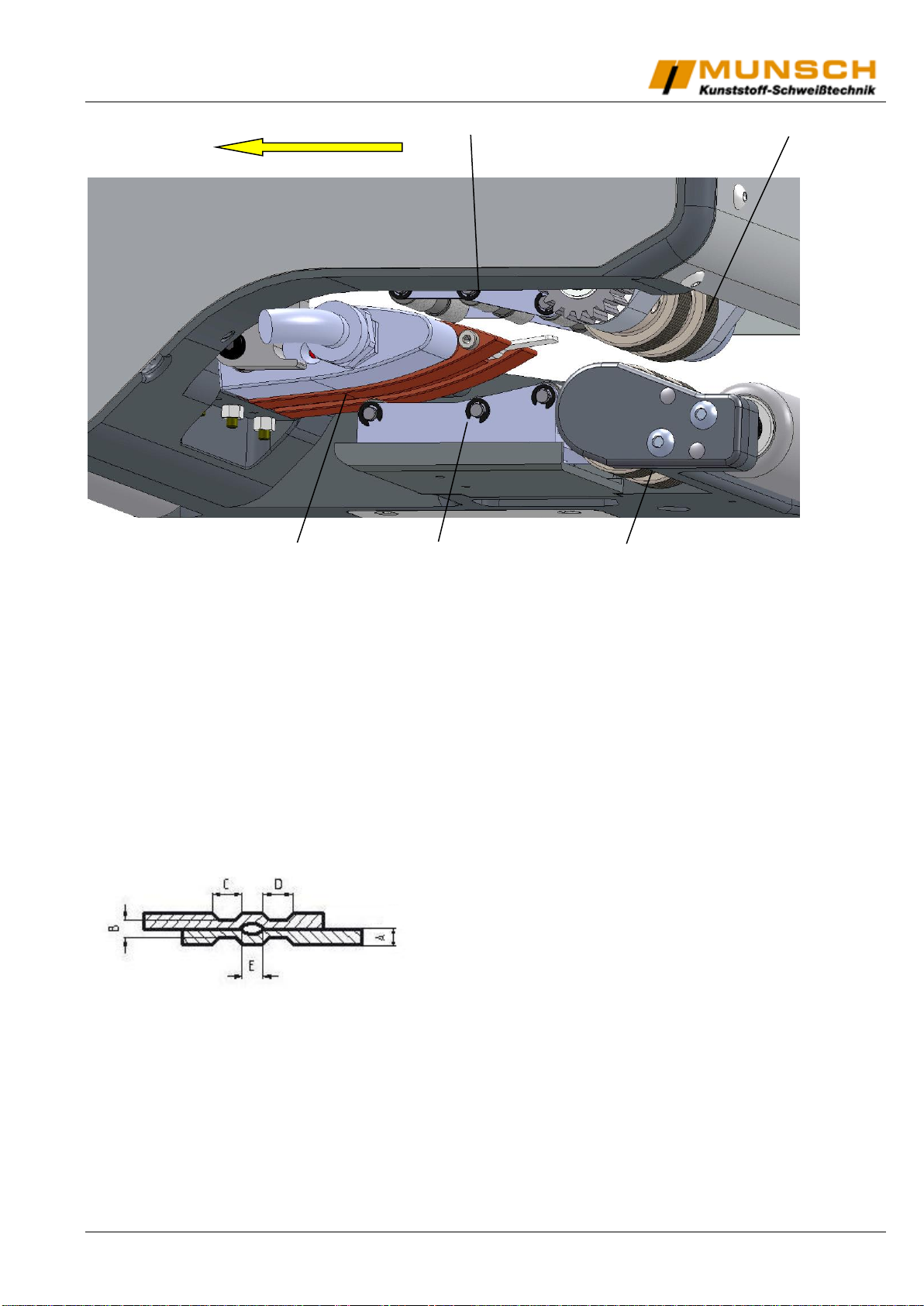

Product description.......................................................................................................................5

Function........................................................................................................................................7

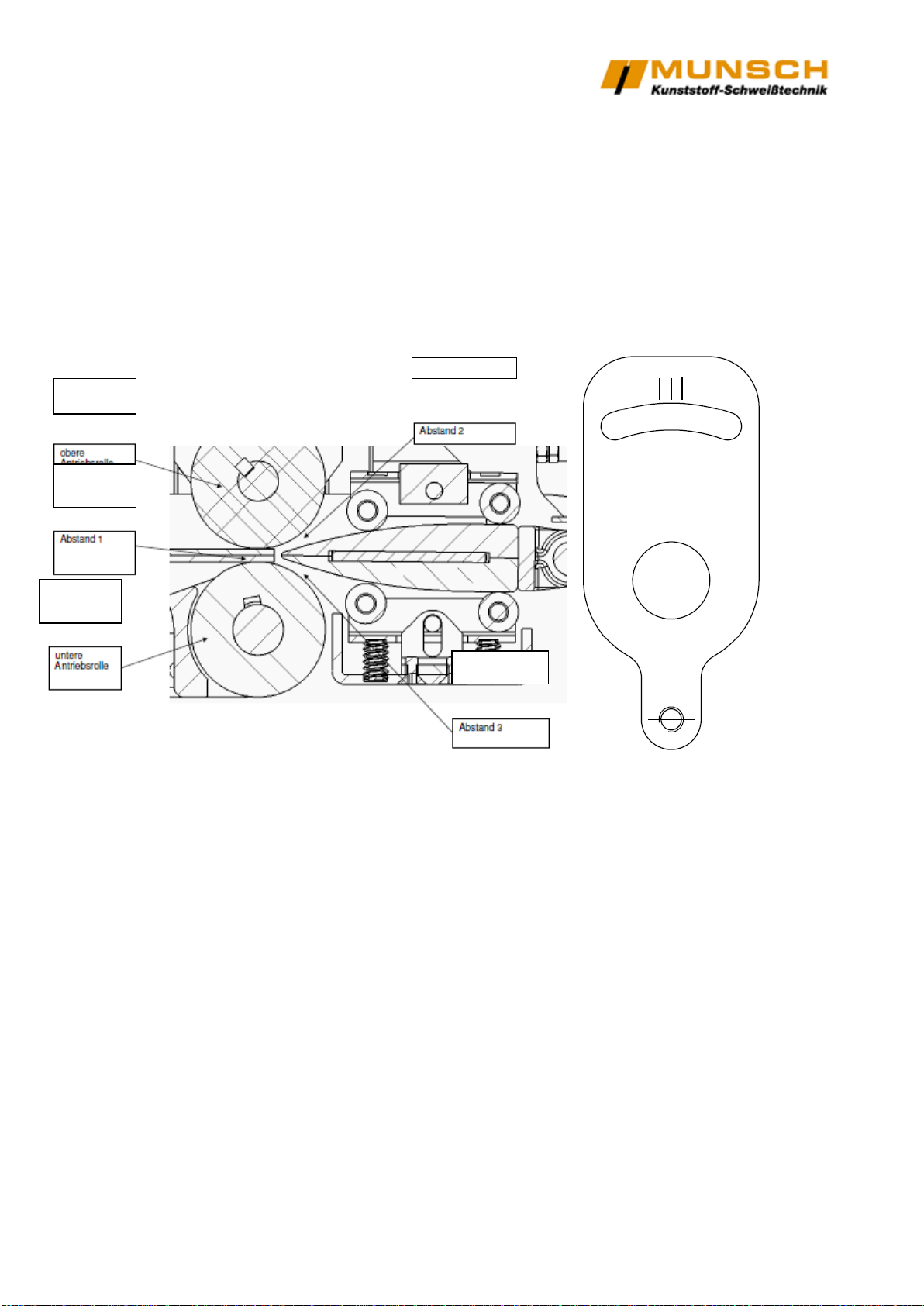

Preparation of the Unit..................................................................................................................8

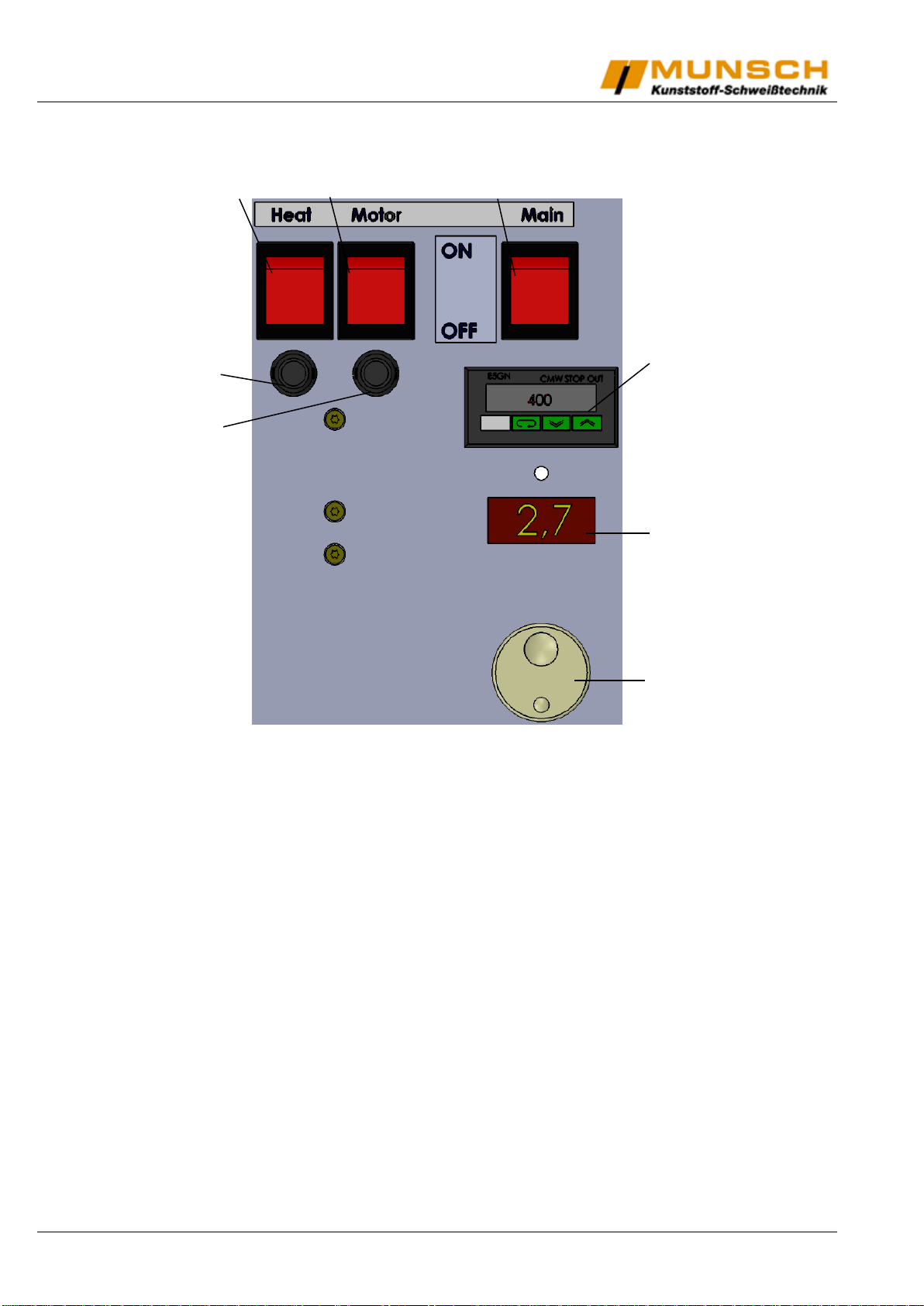

Temperature setting....................................................................................................................10

Speed setting..............................................................................................................................10

Welding.......................................................................................................................................10

Temperature alignment...............................................................................................................11

Transport / Storage.....................................................................................................................12

Service and repair.......................................................................................................................12

EC-Declaration of Conformity by the Manufacturer ....................................................................13

Note: These operating instructions must always be available to the machine operators.

Make sure to read them carefully before placing the unit in service.

Very important!

Switch off the heating wedge whenever the unit is out of service for prolonged periods.

This will prevent heating up of the machine due to radiating heat. Otherwise some ma-

chine components may develop high surface temperatures.

Additional cooling of the heating wedge is not allowed

(water, chilling agents or similar).

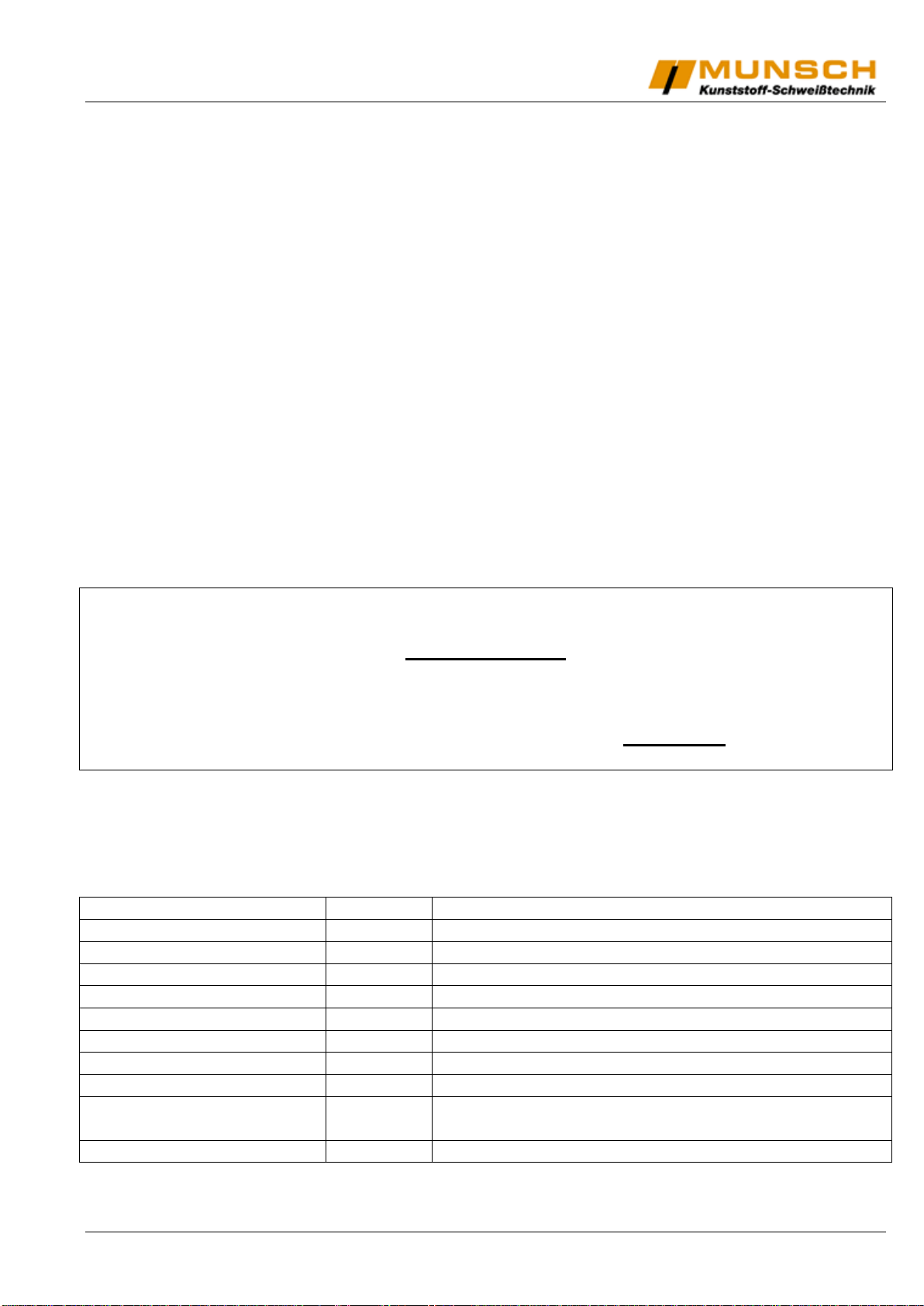

Technical data:

Max. 450 (842), infinitely variable

PVC (with stainless steel wedge)