7/20 Ausgabe 01.2017/Rev.00 MUNSCH Kunststoff-Schweißtechnik GmbH

Set-Up Procedure

Initial Set-up –Various mil thickness tolerances:

The initial set-up of the Wedge-It is by far the most critical aspect of not only quality welding results, but also wear

and tear on the unit itself.

Adjusting the Wedge-It too tightly can result in excessive wear on drive-train parts, such as gears, chains and

sprockets, etc.

The recommended Set-Up Procedure before heating up the unit is as follows:

From the same mil thickness material as that to be welded, cut 2 pieces app. 4x18” (ca. 100 x 450mm) and 2 small-

er pieces app. ½ x 2” (ca. 13 x 50mm). These 4 pieces of material will be used as „gauges“, for setting the 3 ad-

justments.

Adjustment 1: Wedge Centering

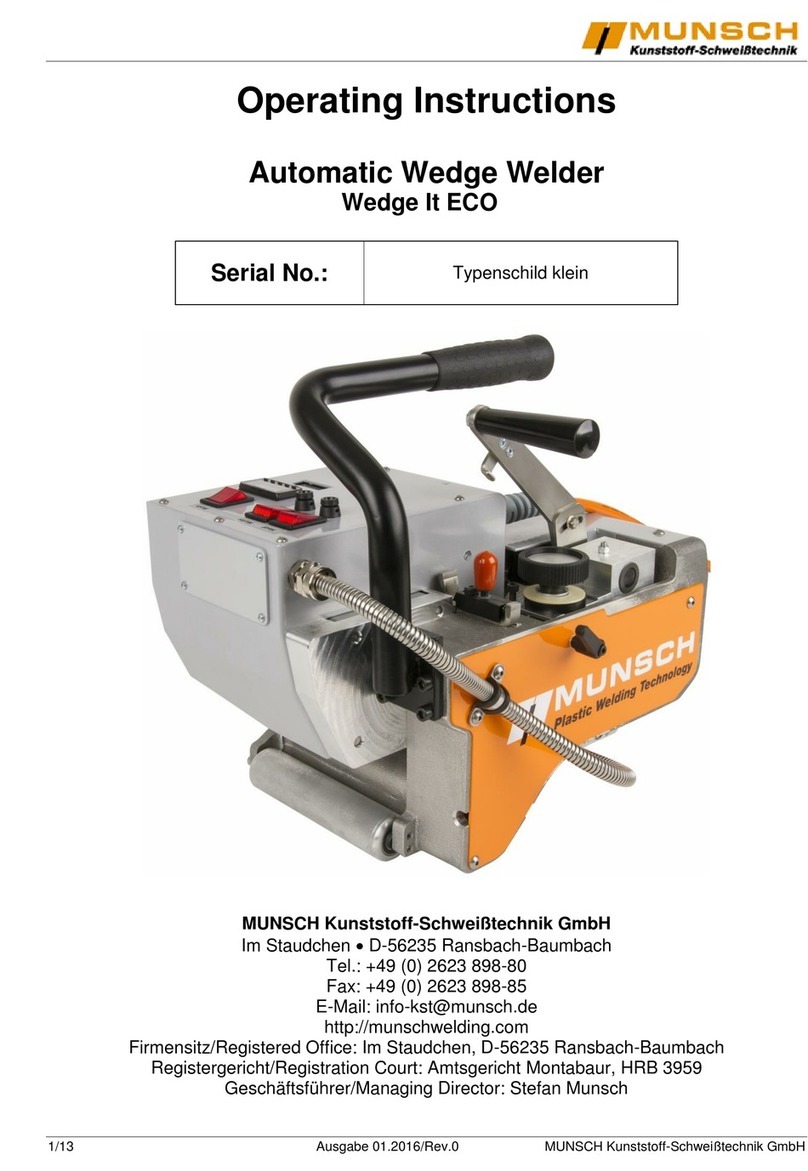

Place the two smaller pieces of material, each folded in half, between the two nip rollers (figure 2). This is to simu-

late 2 layers of material between the rollers. Be sure these pieces do not extend past the Nip Rollers into the ma-

chine. Rotate the Nip Pressure Cam to do first positioning by rotating the Nip Pressure Cam Lever clockwise, until

reaching the mark showing the thickness of your welding sheet.

Move the wedge (figure 4) to the engaged position by rotating the wedge movement handle (figure 2) counterclock-

wise. Adjust the wedge with a 5mm hex wrench by turning the centering adjustment, so that the wedge gets into the

centered between upper and lower nip roller.

Adjustment 2: Wedge forward travel

This adjustment determines how close the wedge is to the nip rollers when it is in the engaged or welding position.

To set clearance, pull out the wedge retract plunger on the wedge movement handle (figure 2), rotate the handle to

a central position between the hold down screws (figure 2), loosen the screws and rotate the handle counter-

clockwise until the retract plunger drops into the lock-in hole.

NOTE: The distance from the upper tip of the wedge to the upper nip roller should be the same distance as between

the two nip rollers. This same clearance should also be maintained between the lower tip of the wedge and the low-

er nip roller.

To lock down the setting, hold down the wedge lock-in plate, pull the retract plunger out, and rotate the handle to

central location between hold-down screws (figure 2). Tighten hold-down screws and move lock-in plunger back to

lock-in hole.

Adjustment 3: Upper and lower contour rollers

Remove the lower contour roller adjustment cover, to expose the adjustment. With a 10mm box end wrench, loosen

the lock-nut. With ad 3mm hex wrench, back off the adjustment until it bottoms out.

With a 10mm wrench, loosen the lock-nut on the upper contour roller adjustment (figure 4). Turn the adjustment

counter-clockwise, raising the upper contour roller assembly out of the way.

With the wedge locked into the engaged position, and the ½ x 2” pieces of material still between the nip rollers, you

are ready to make adjustments.

Insert one of the 4” x 18” pieces of material between the lower contour roller assembly and the wedge. This piece

should extend out of the front of the machine (opposite end from the nip rollers).

Adjust the lower contour rollers up, clockwise, until the wedge begins to move up slightly. Now insert the other 4” x

18” piece of material between upper contour assembly and wedge (figure 4). Adjust the upper contour rollers down,

clockwise, to obtain the desired tolerance.