Murata GCJ188R71H222KA01 Series User manual

Other Murata Industrial Electrical manuals

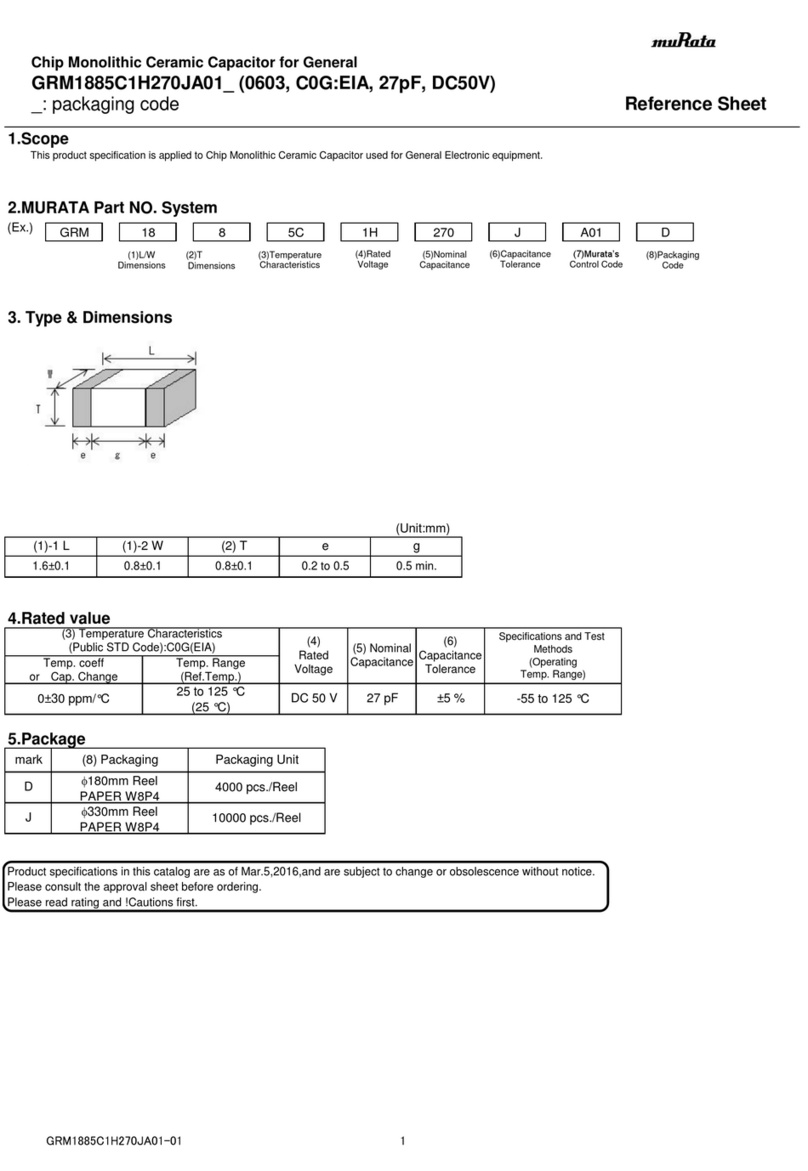

Murata

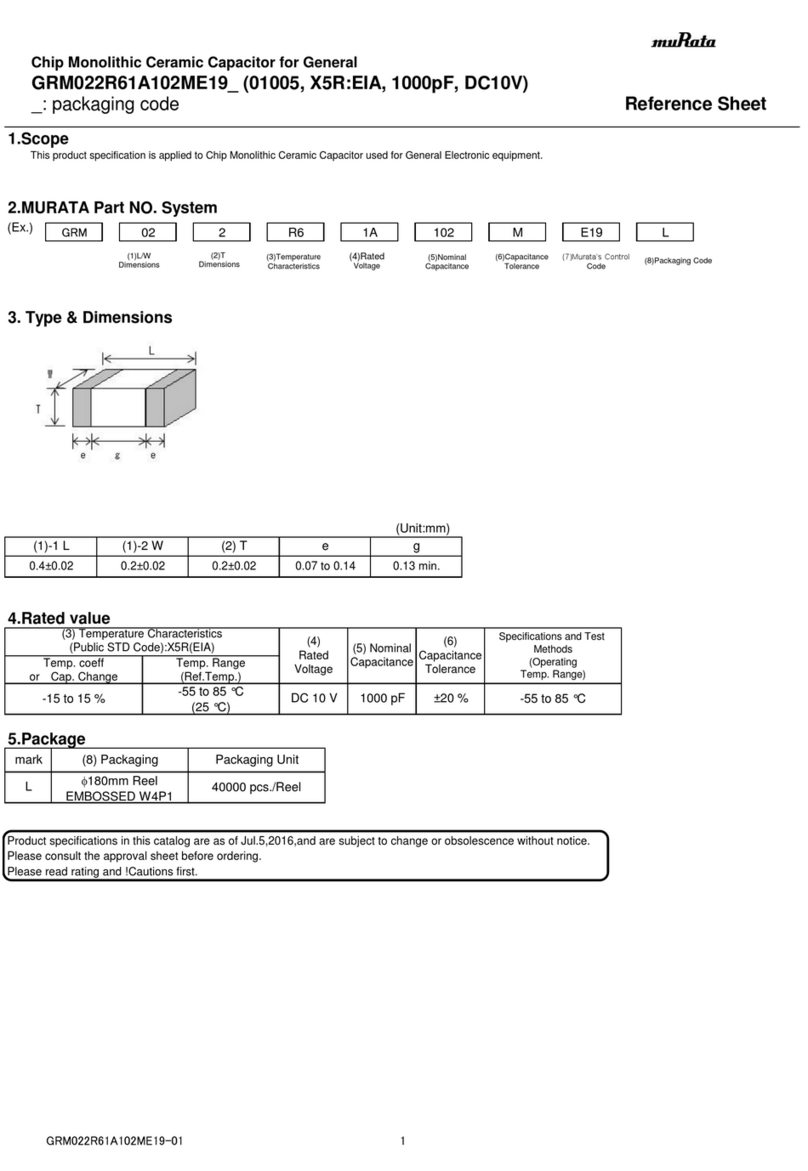

Murata GRM022R61A102ME19 Series User manual

Murata

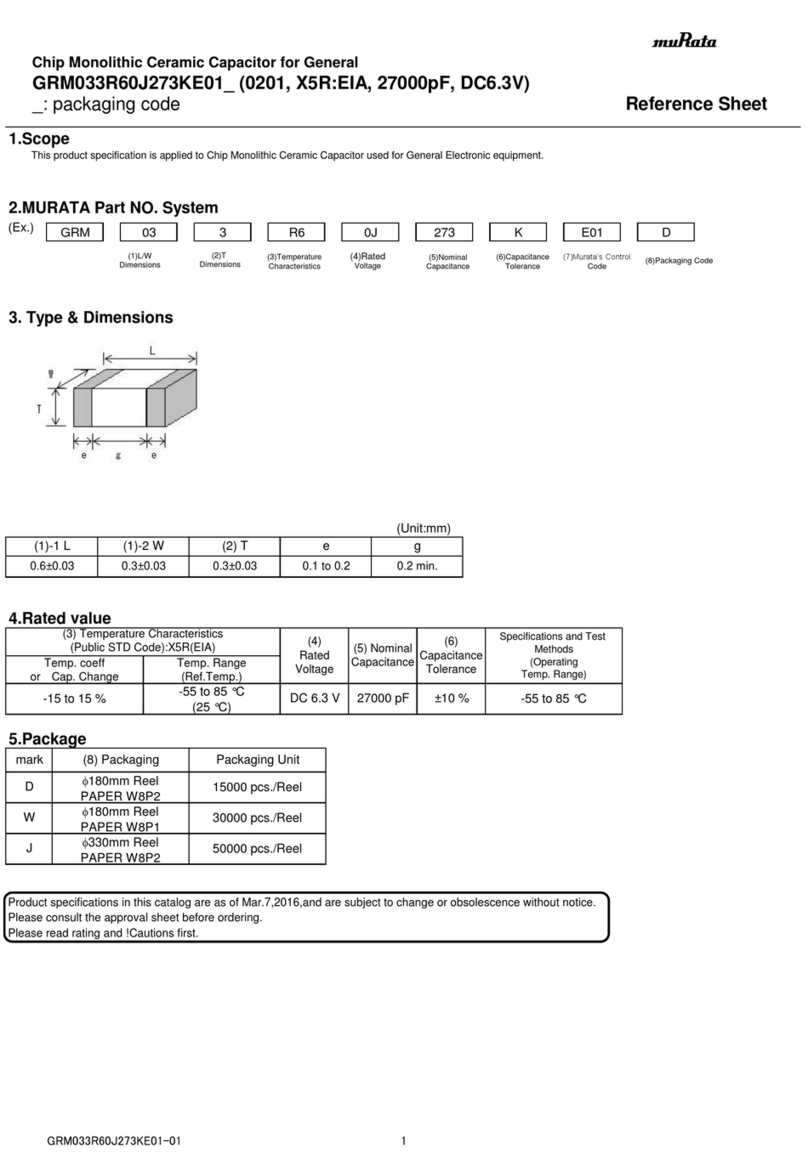

Murata GRM033R60J273KE01 Series User manual

Murata

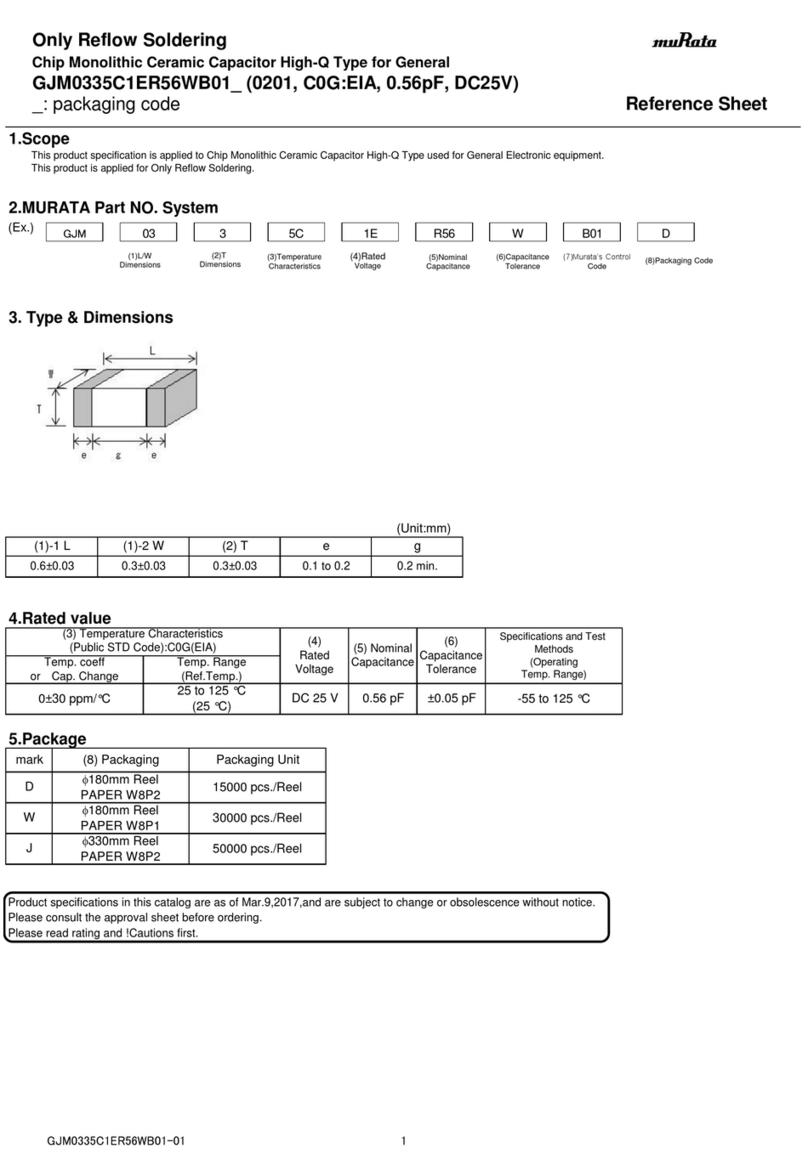

Murata GJM0335C1ER56WB01 Series User manual

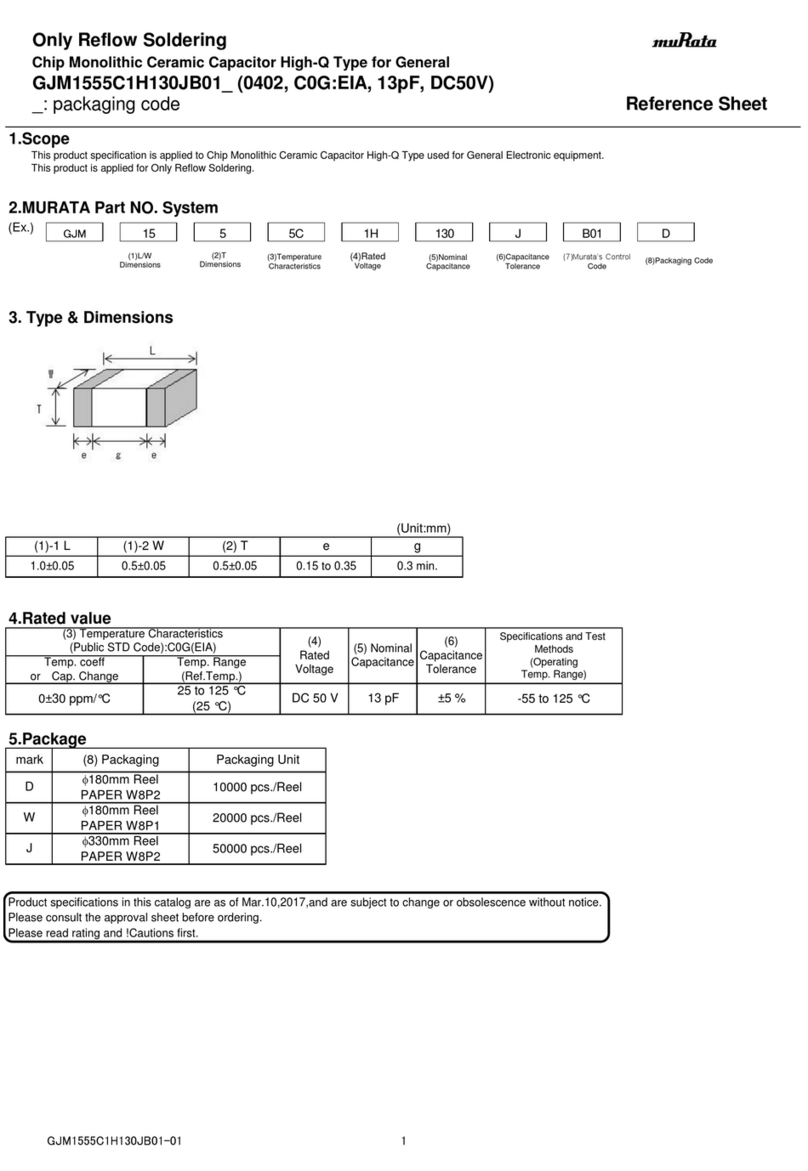

Murata

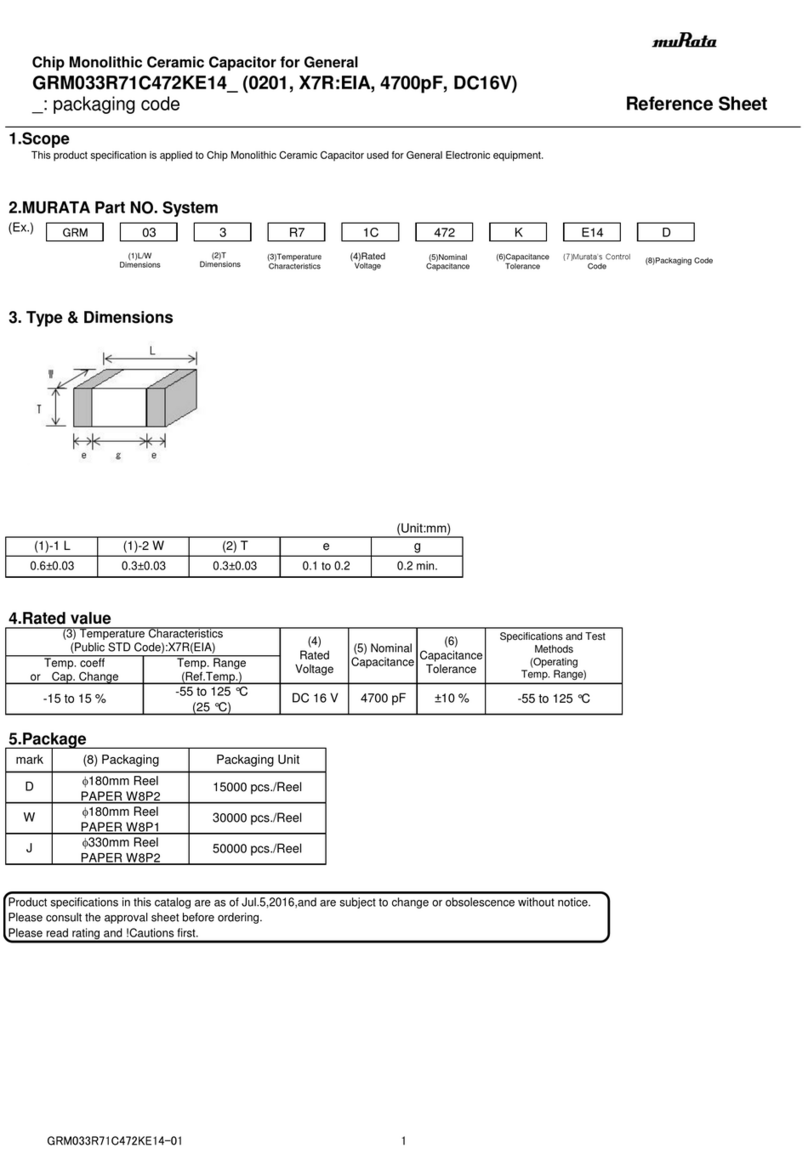

Murata GRM033R71C472KE14 Series User manual

Murata

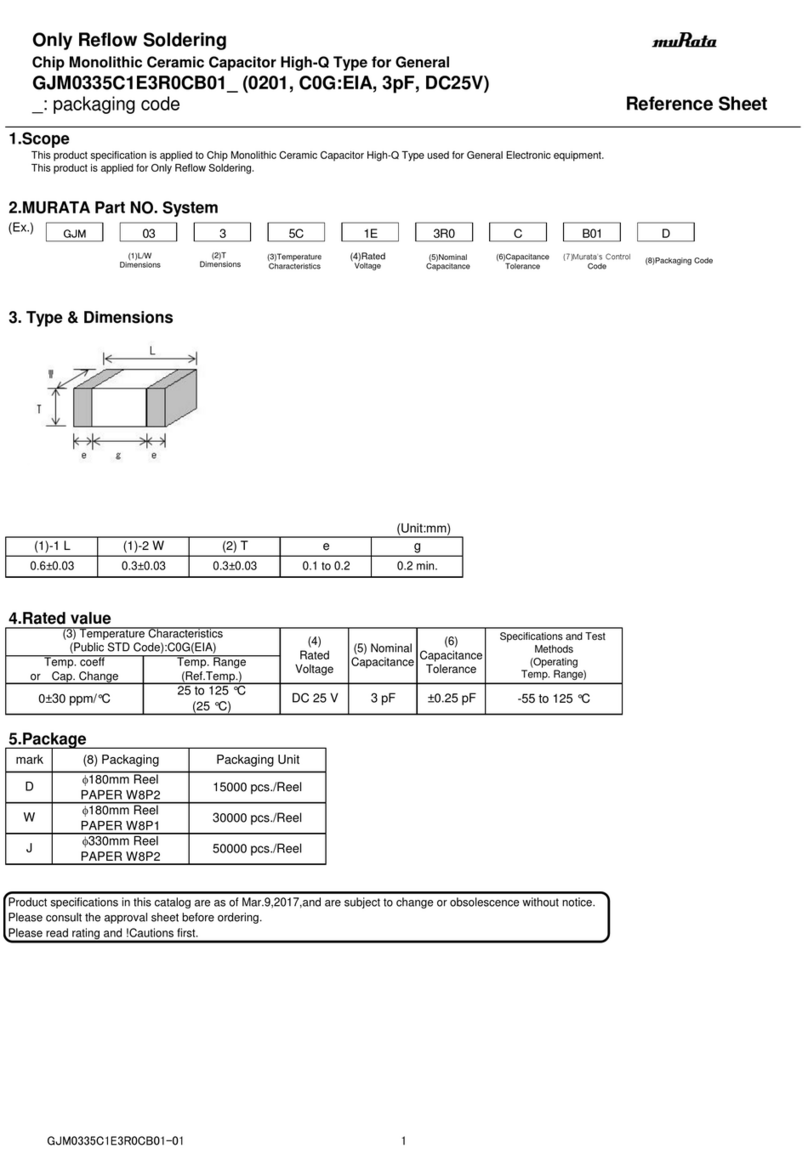

Murata GJM0335C1E3R0CB01 Series User manual

Murata

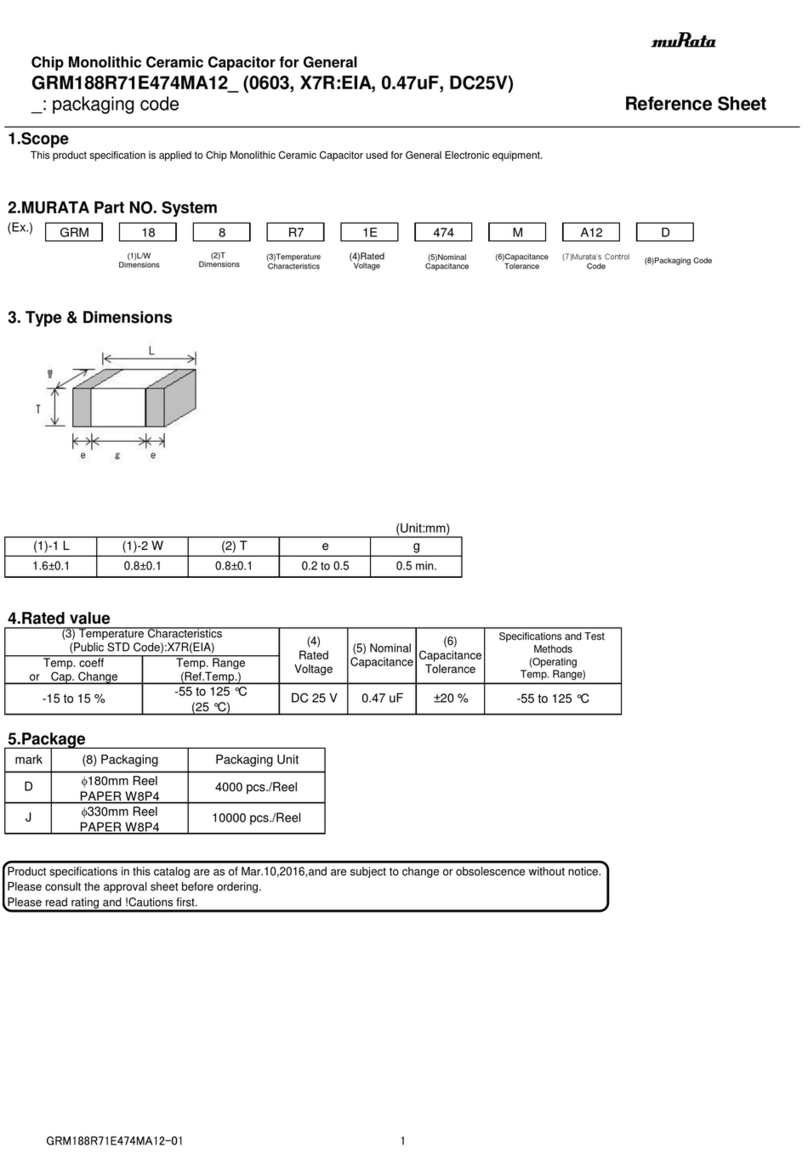

Murata GRM188R71E474MA12 Series User manual

Murata

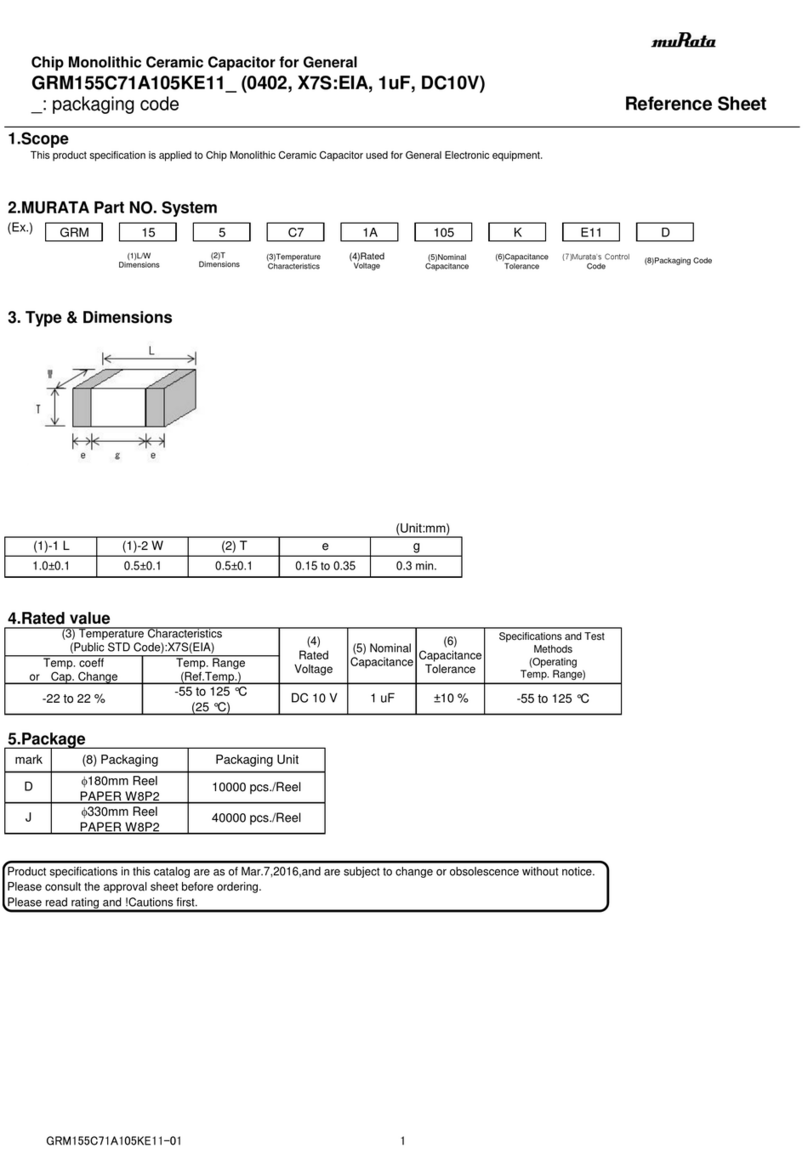

Murata GRM155C71A105KE11 Series User manual

Murata

Murata GRT21BR60J475KE13 Series User manual

Murata

Murata GRM188R71H472JA01 Series User manual

Murata

Murata GRM033R60J225ME15 Series User manual

Murata

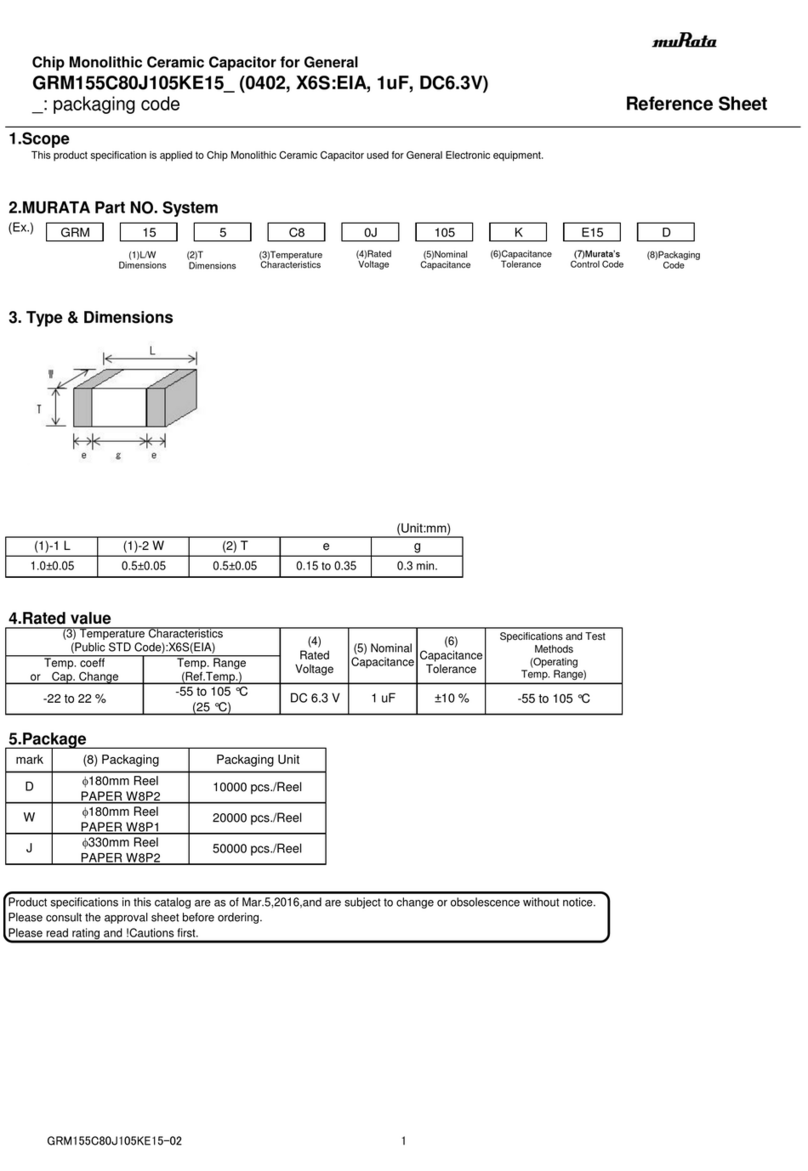

Murata GRM155C80J105KE15 Series User manual

Murata

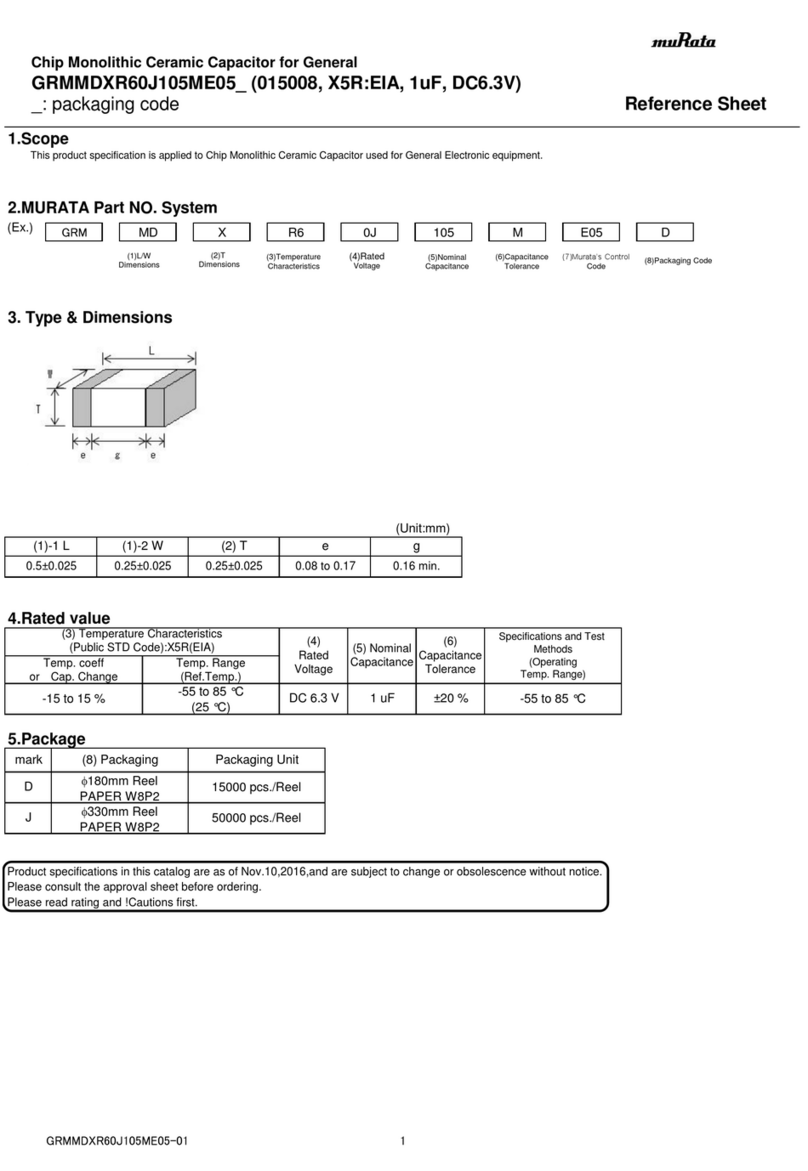

Murata GRMMDXR60J105ME05 Series User manual

Murata

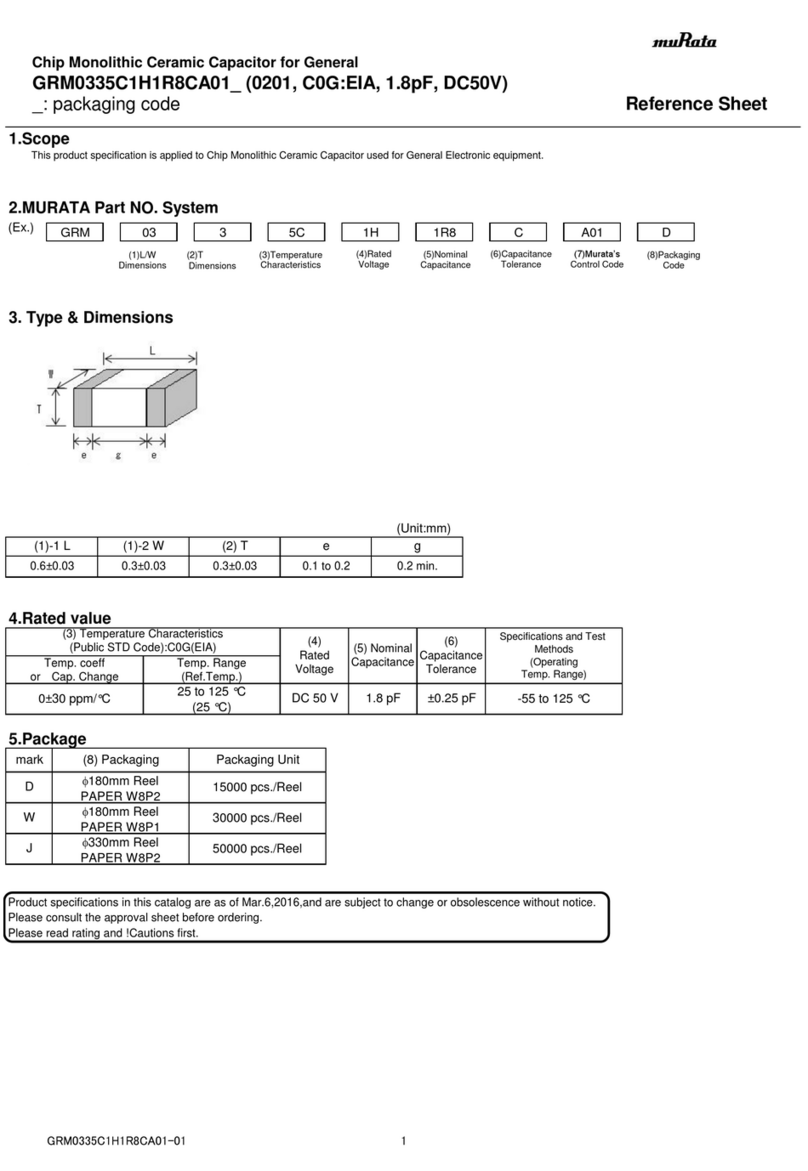

Murata GRM0335C1H1R8CA01 Series User manual

Murata

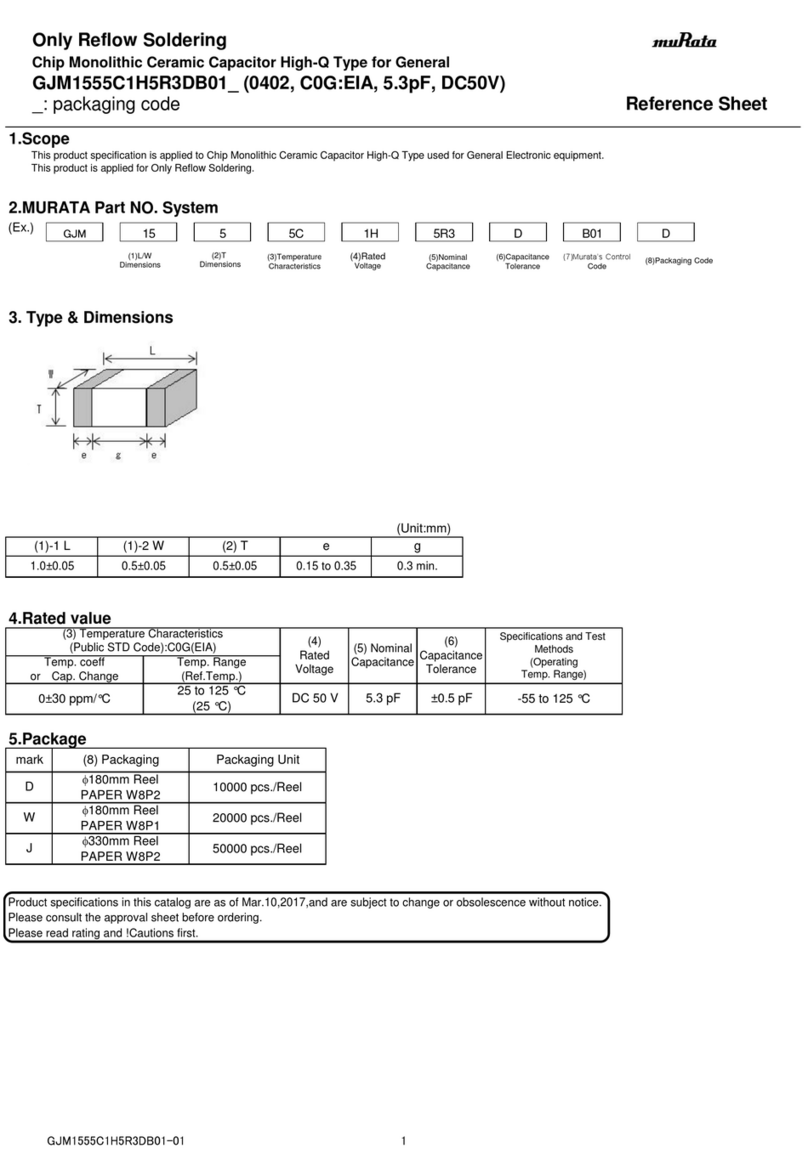

Murata GJM1555C1H5R3DB01 Series User manual

Murata

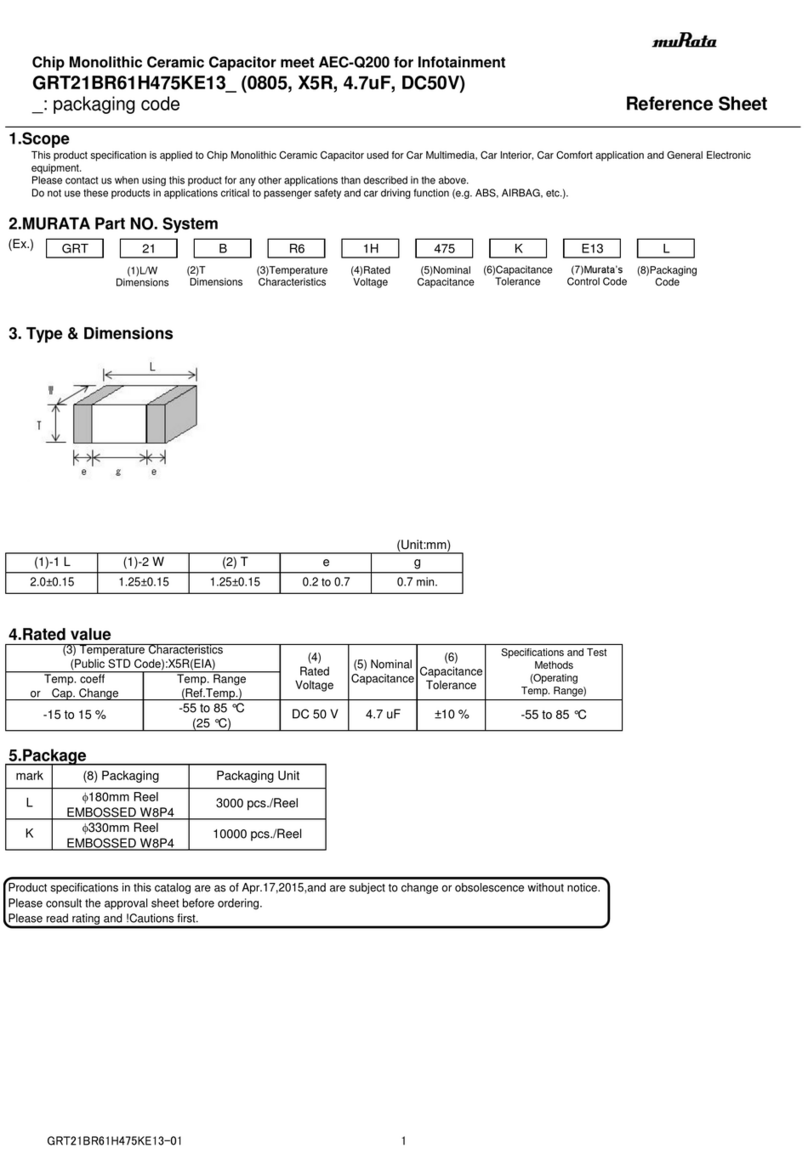

Murata GRT21BR61H475KE13 Series User manual

Murata

Murata GRM1555C1H3R1WA01 Series User manual

Murata

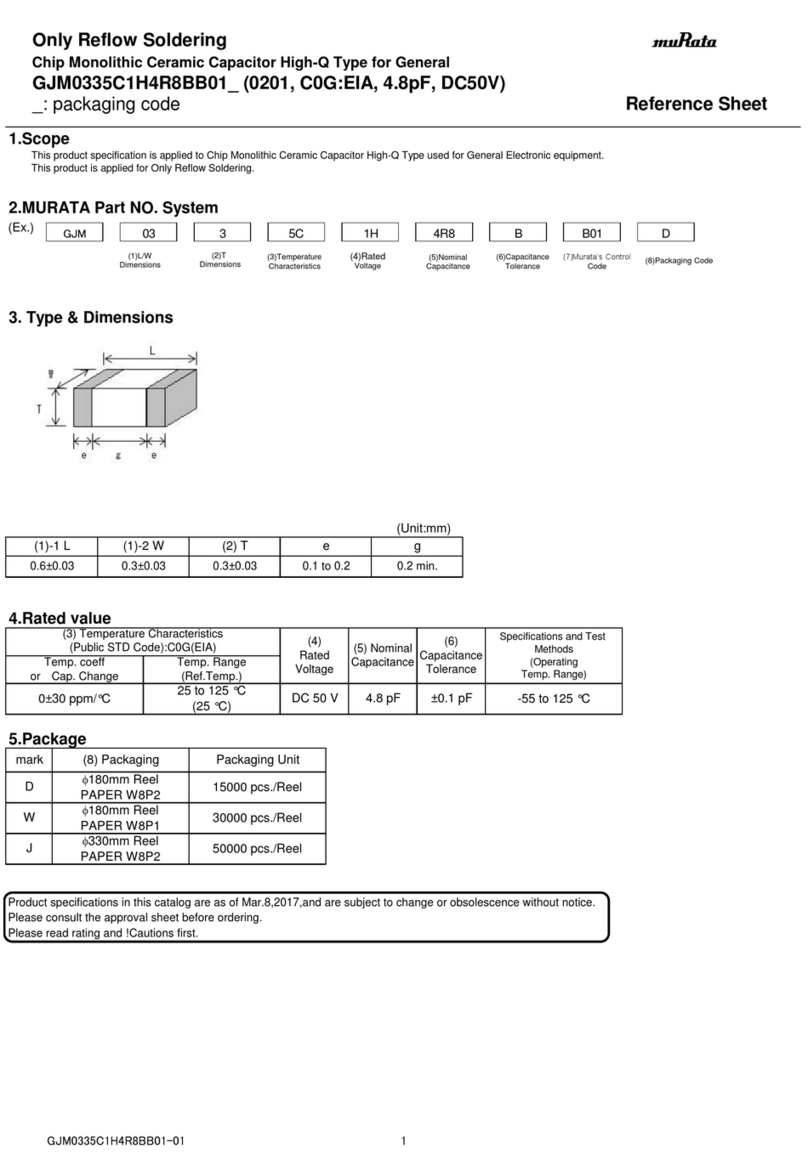

Murata GJM0335C1H4R8BB01 Series User manual

Murata

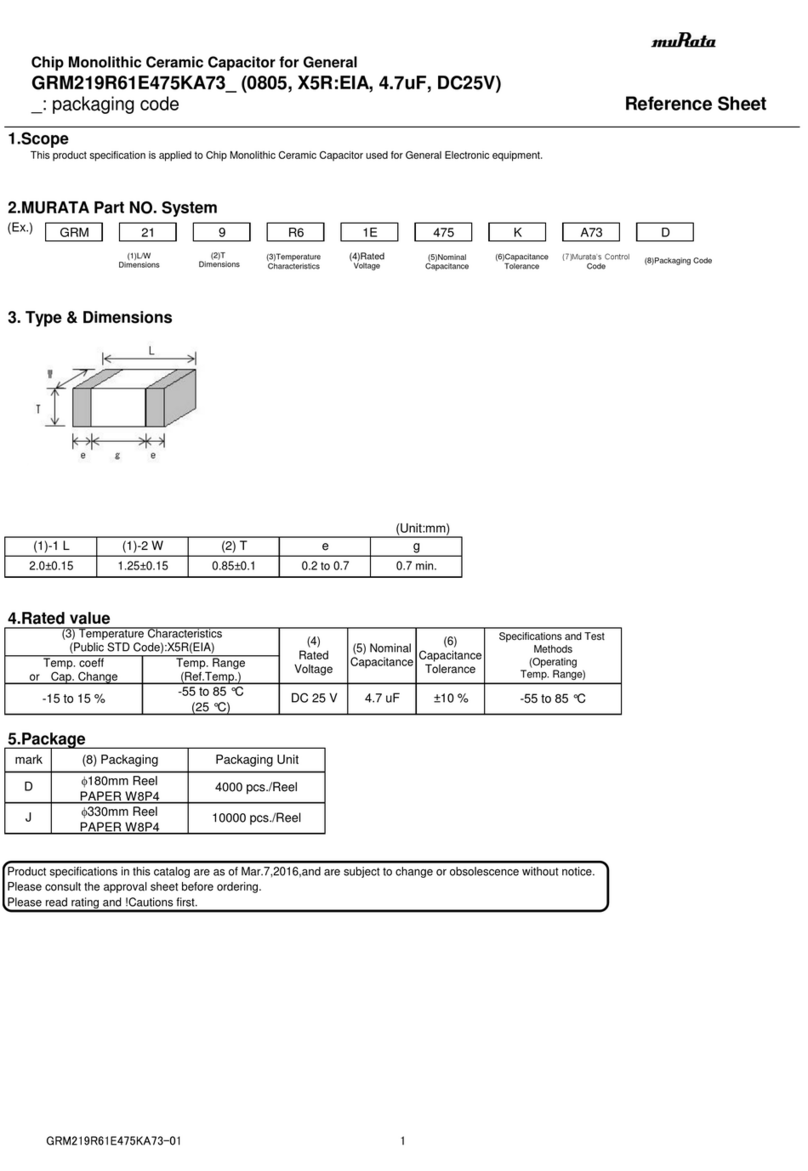

Murata GRM219R61E475KA73 Series User manual

Murata

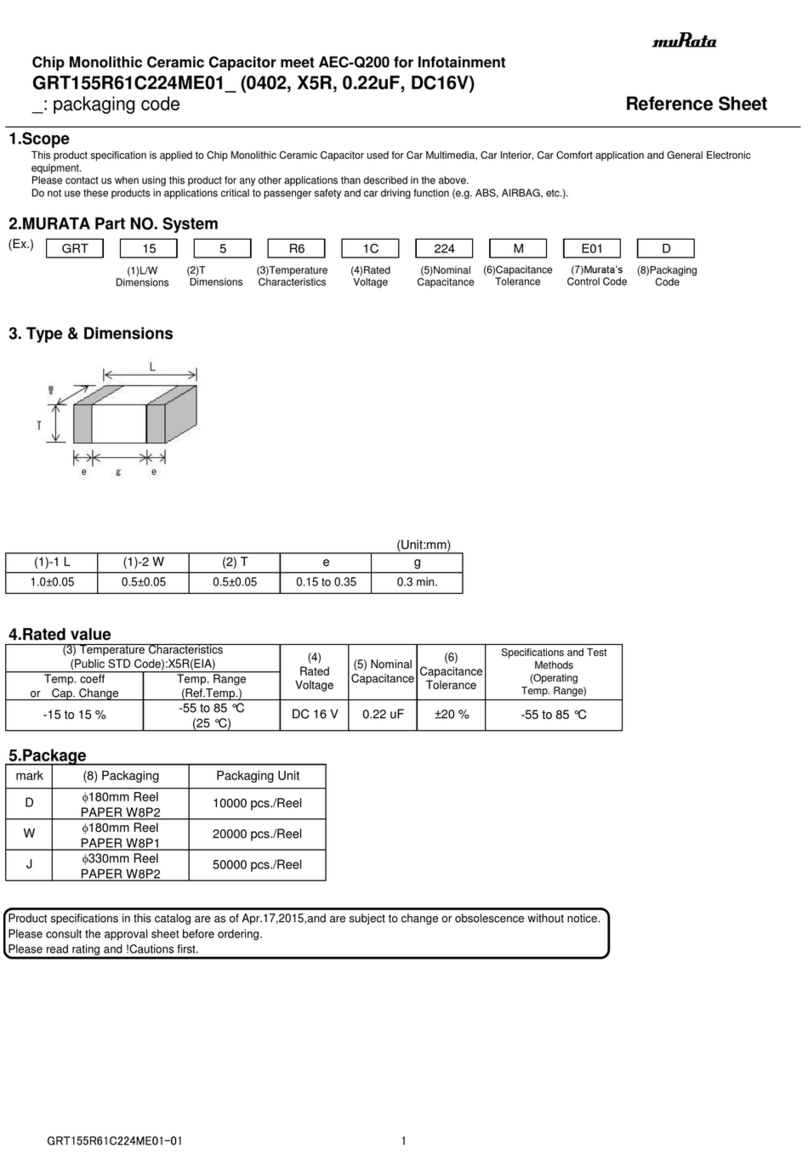

Murata GRT155R61C224ME01 Series User manual

Murata

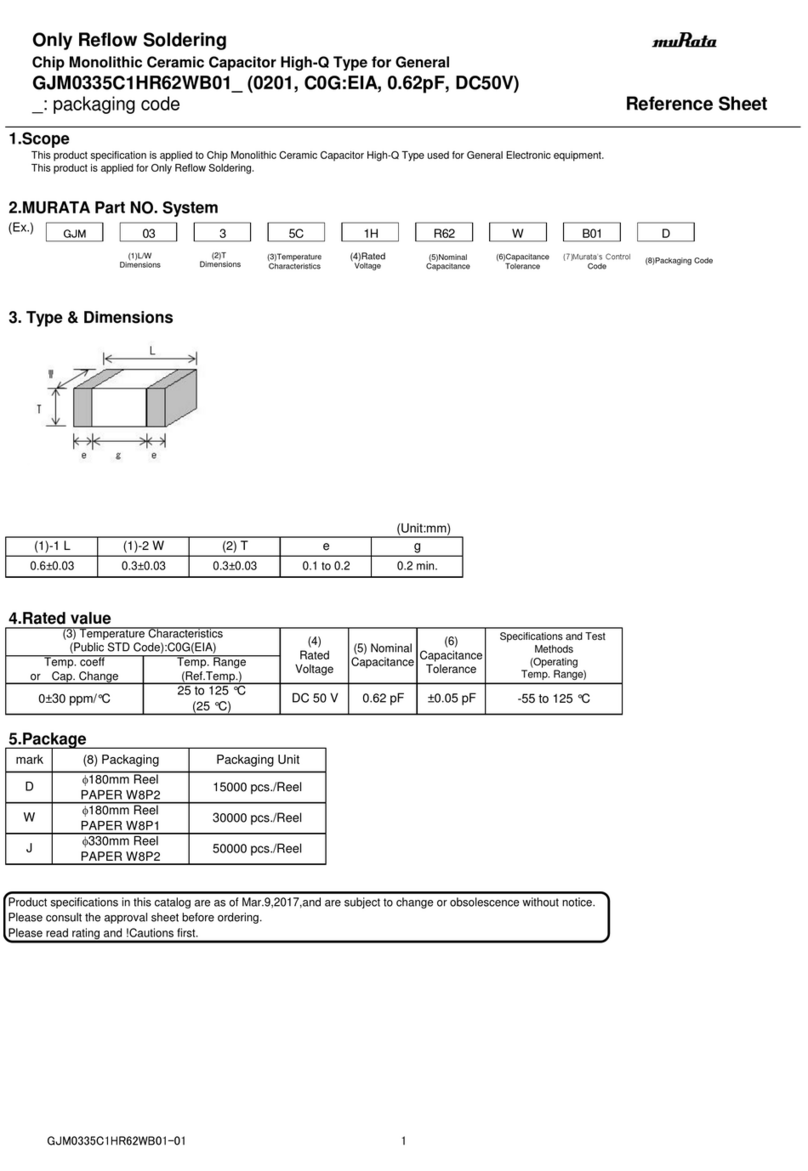

Murata GJM0335C1HR62WB01 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

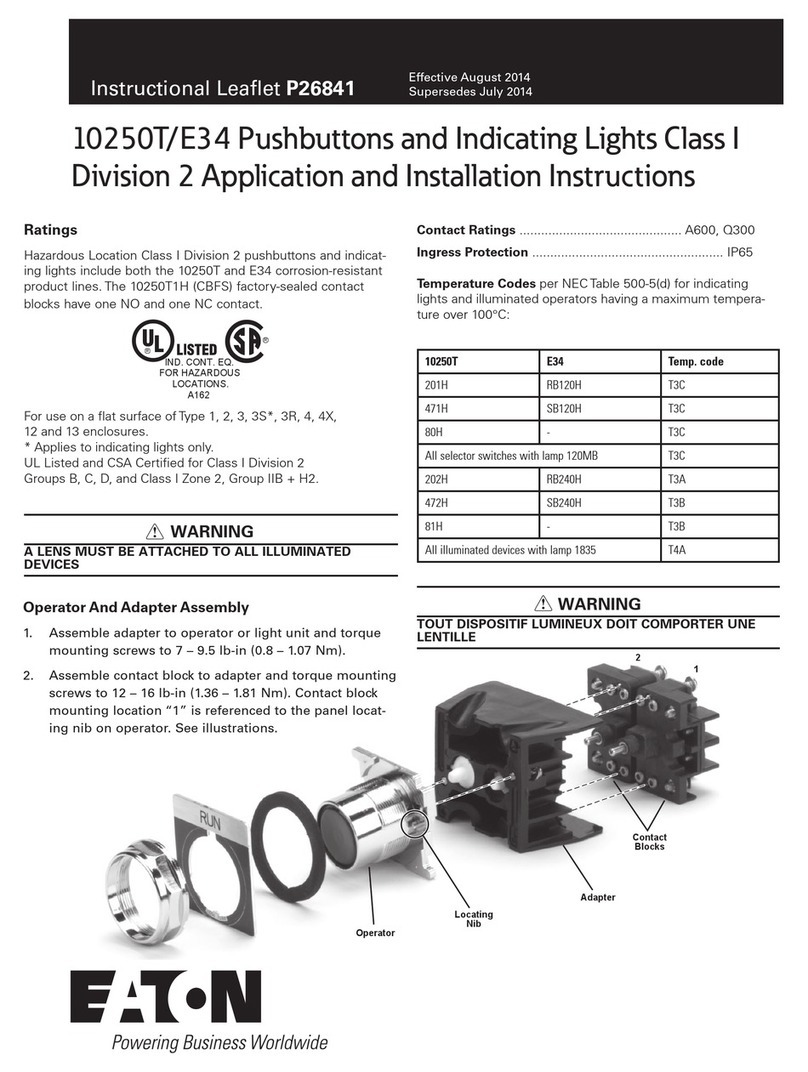

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

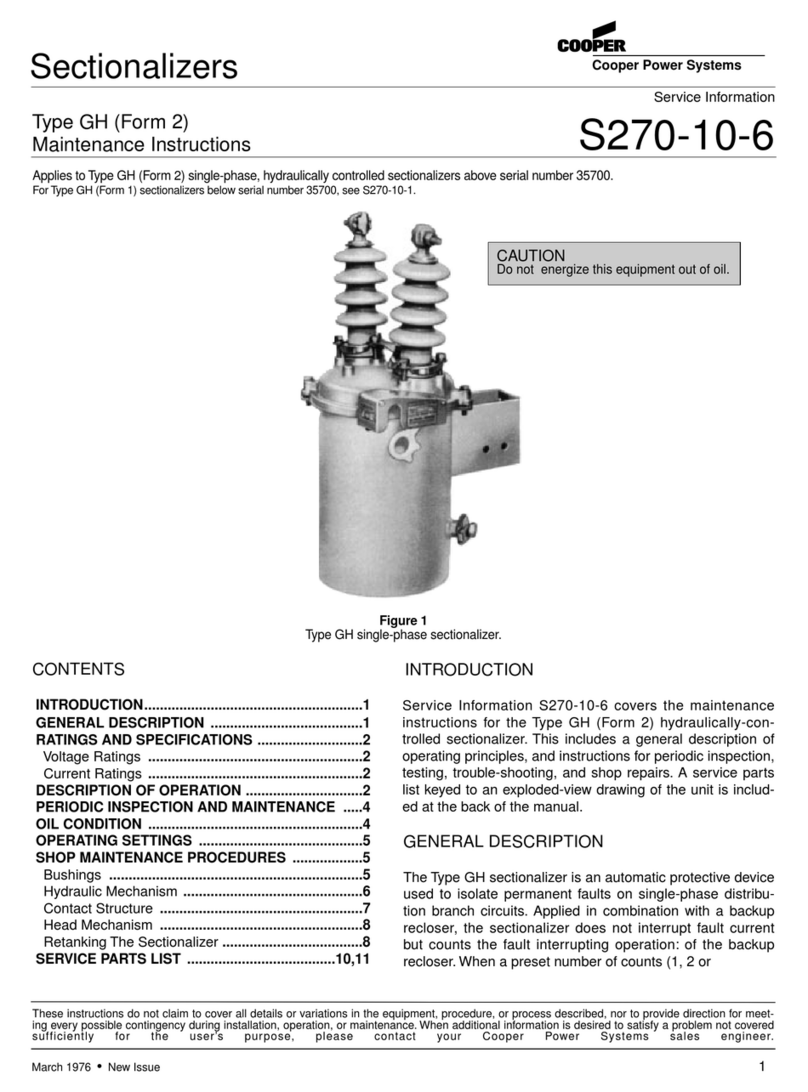

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions