Murata GCJ21BR71H683KA01 Series User manual

Other Murata Industrial Electrical manuals

Murata

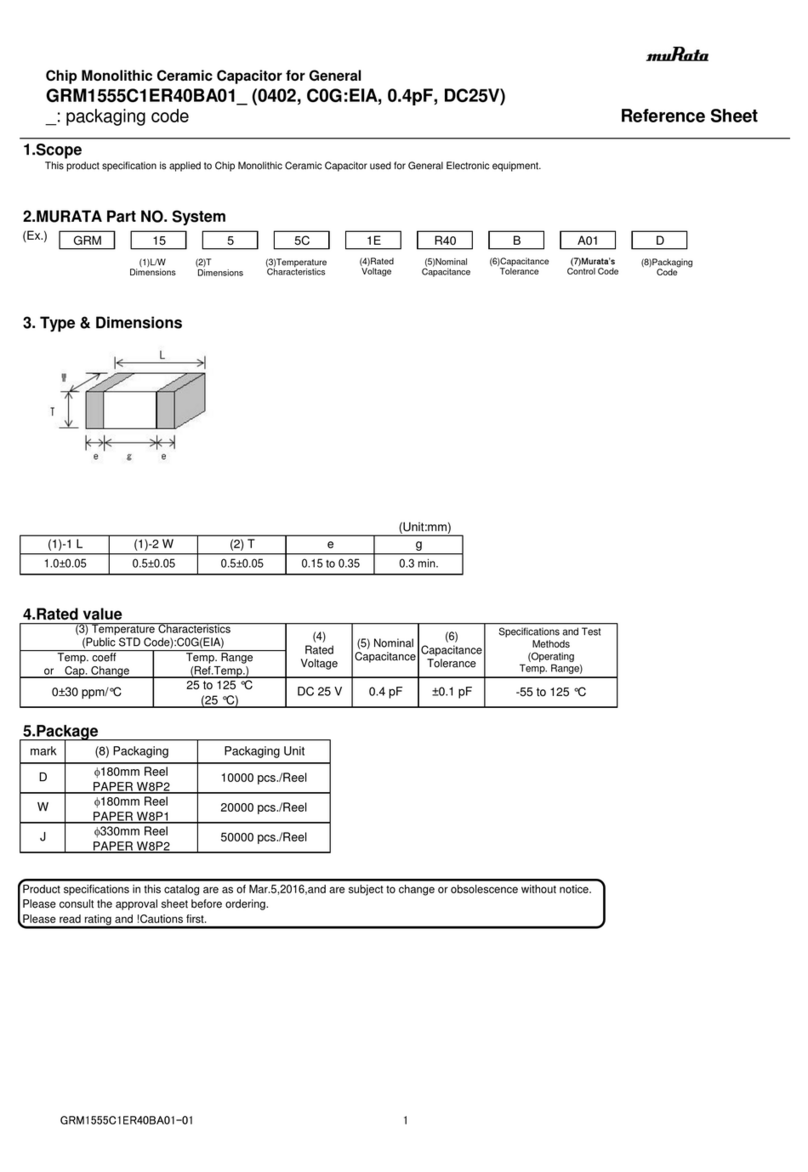

Murata GRM1555C1ER40BA01 Series User manual

Murata

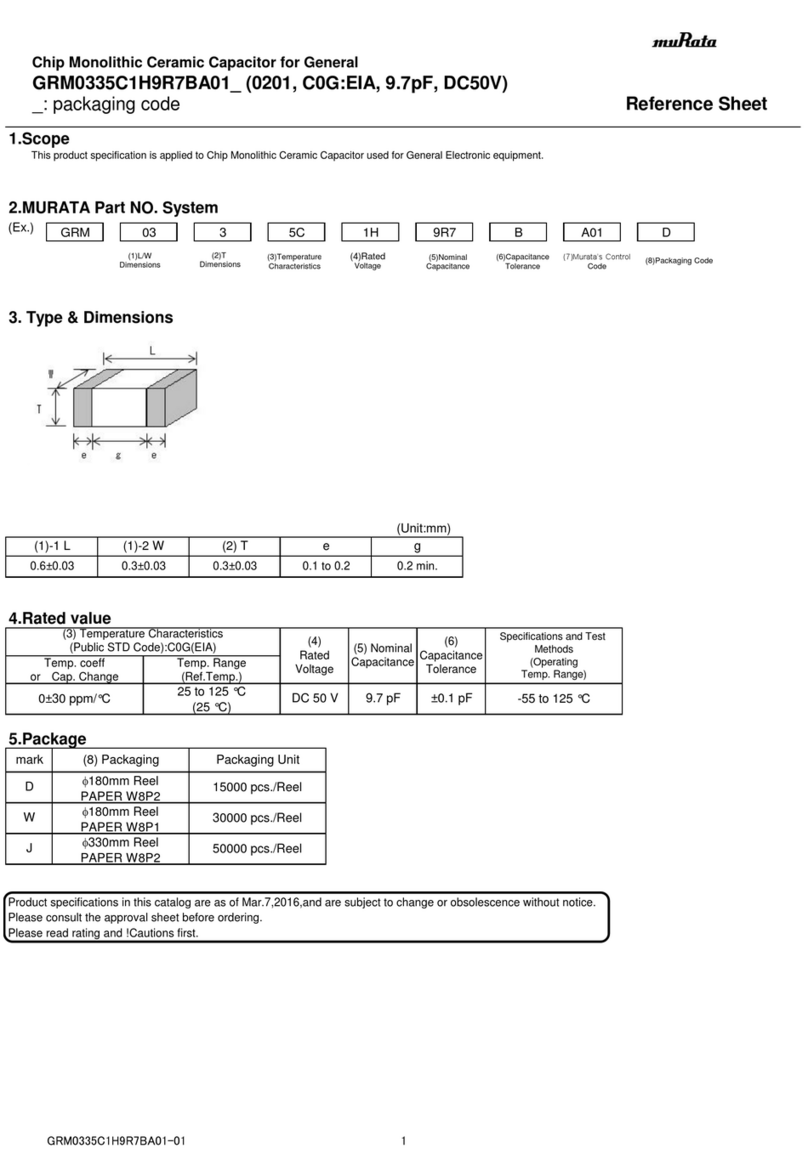

Murata GRM0335C1H9R7BA01 Series User manual

Murata

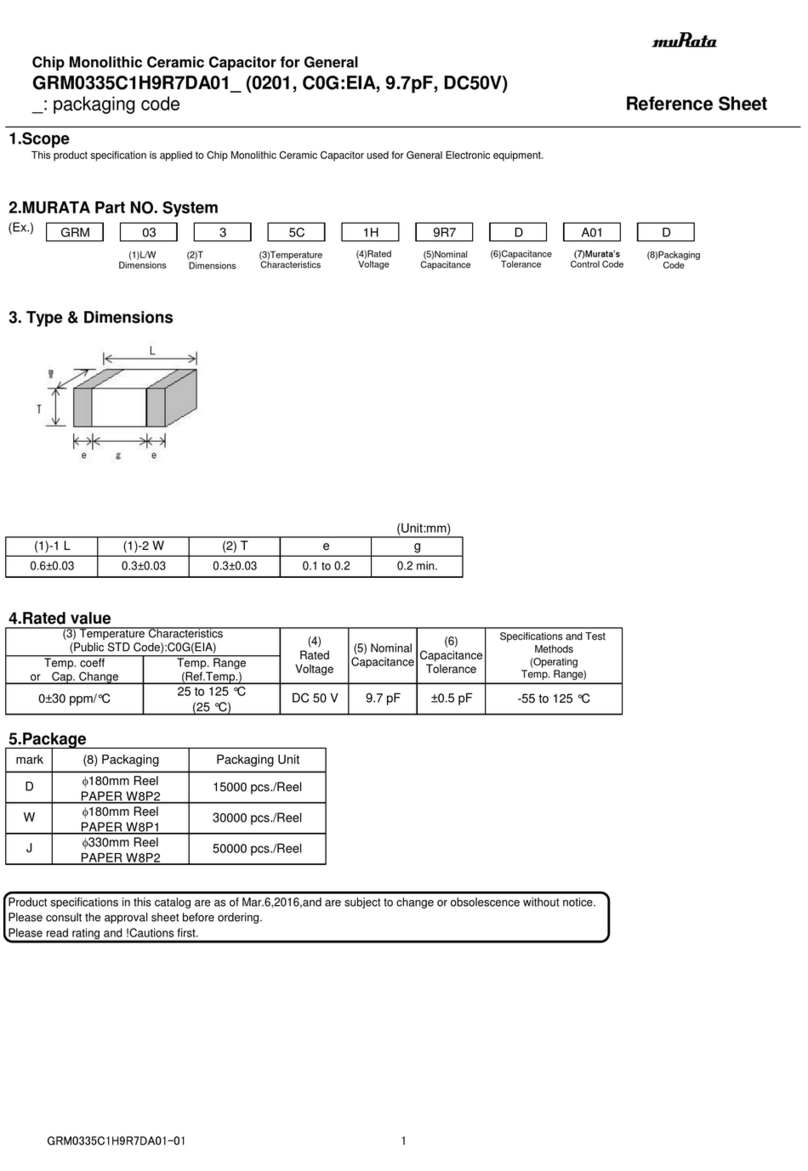

Murata GRM0335C1H9R7DA01 Series User manual

Murata

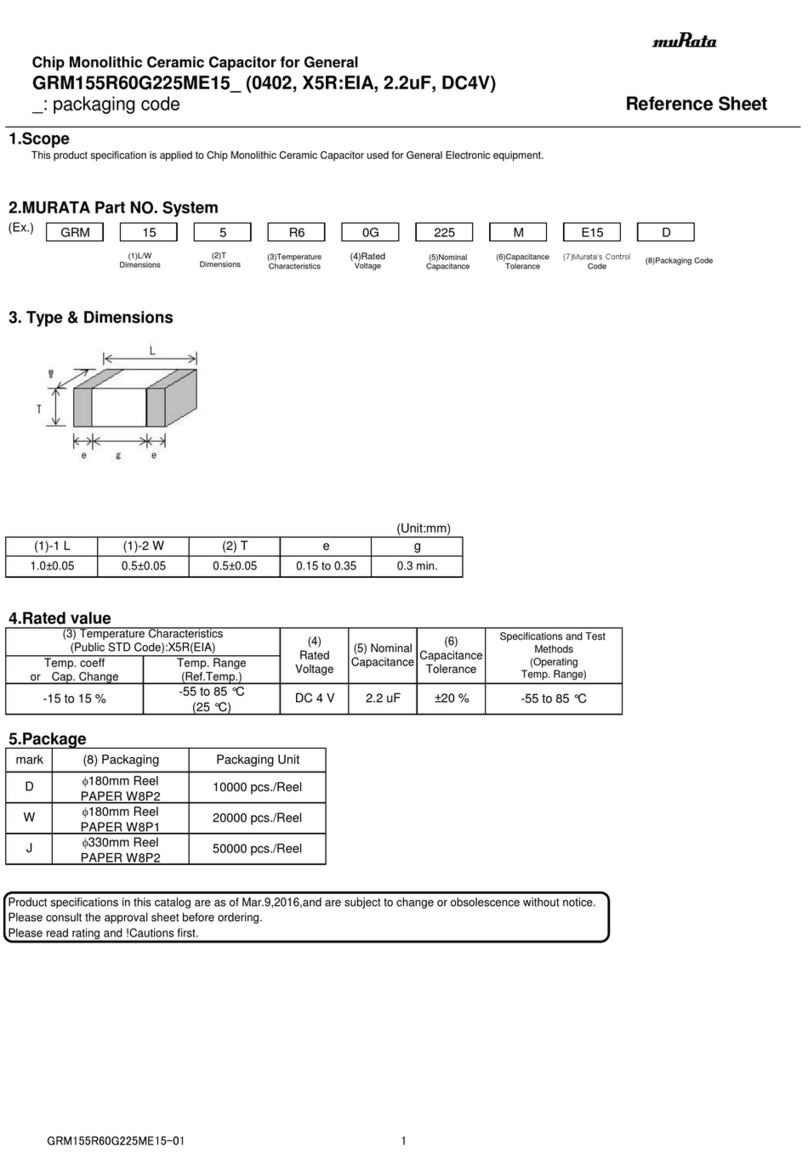

Murata GRM155R60G225ME15 Series User manual

Murata

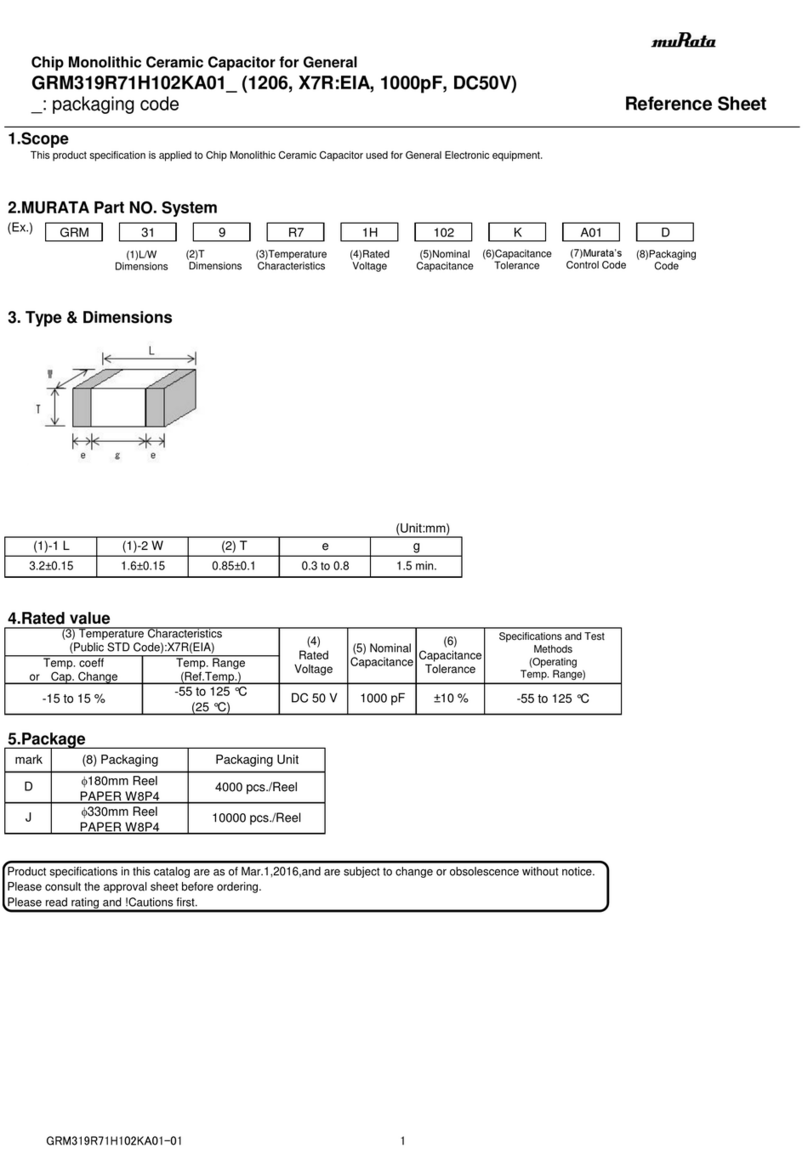

Murata GRM319R71H102KA01 Series User manual

Murata

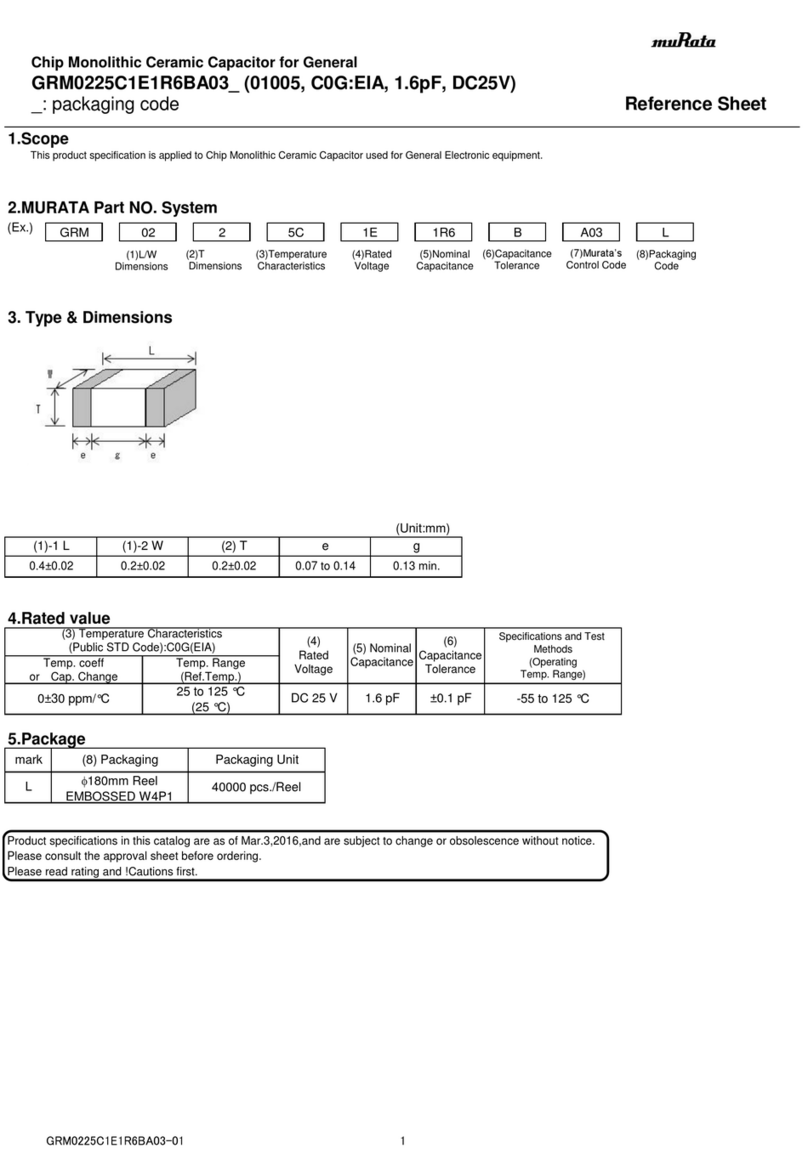

Murata GRM0225C1E1R6BA03 Series User manual

Murata

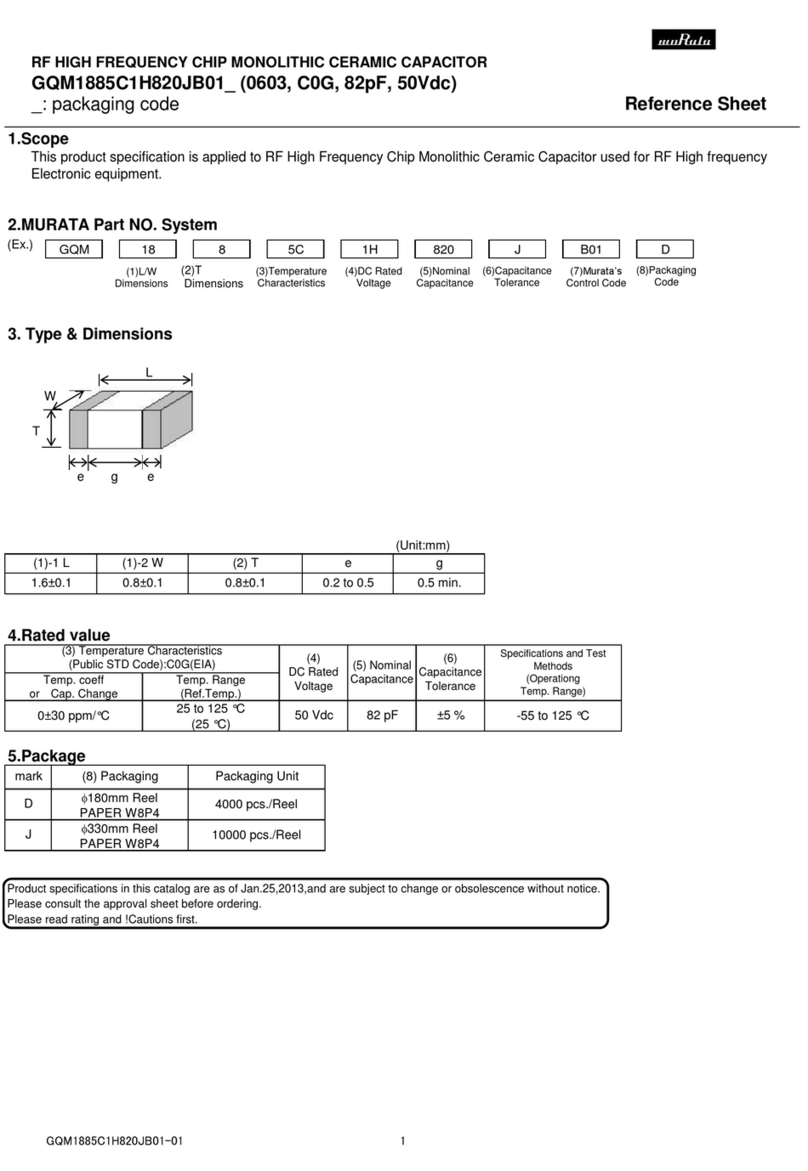

Murata GQM1885C1H820JB01 Series User manual

Murata

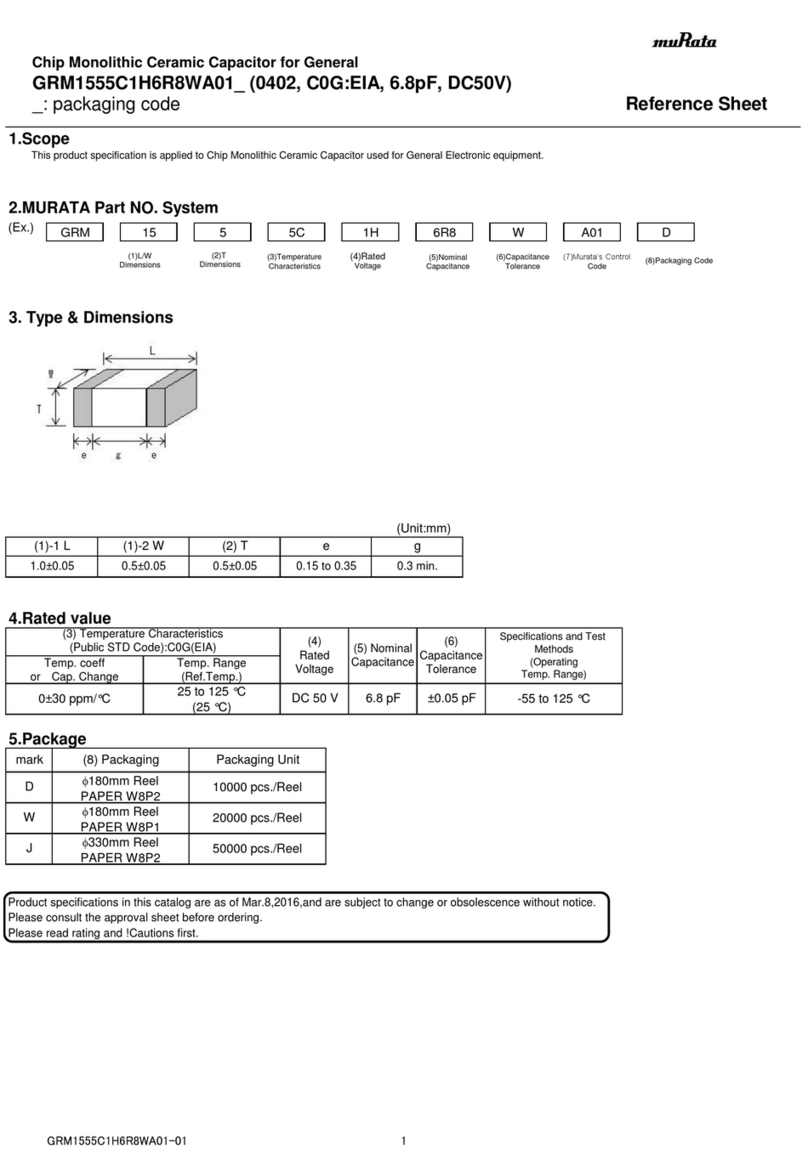

Murata GRM1555C1H6R8WA01 Series User manual

Murata

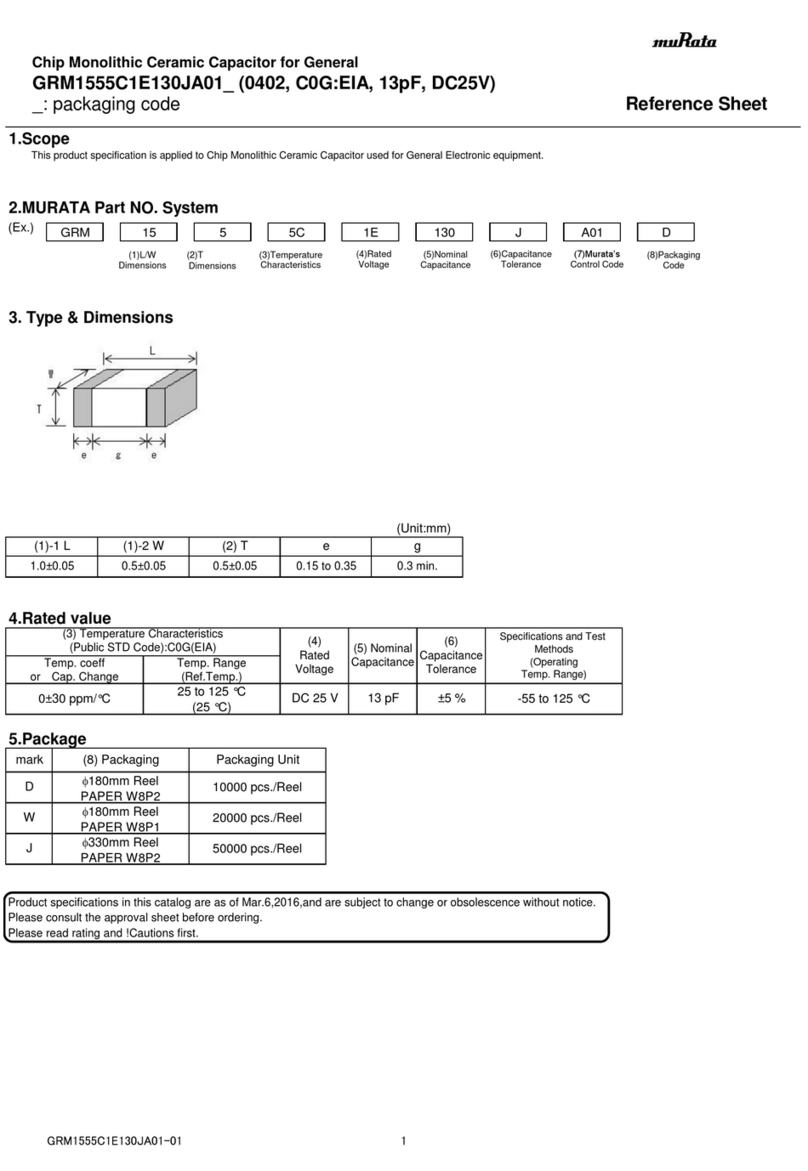

Murata GRM1555C1E130JA01 Series User manual

Murata

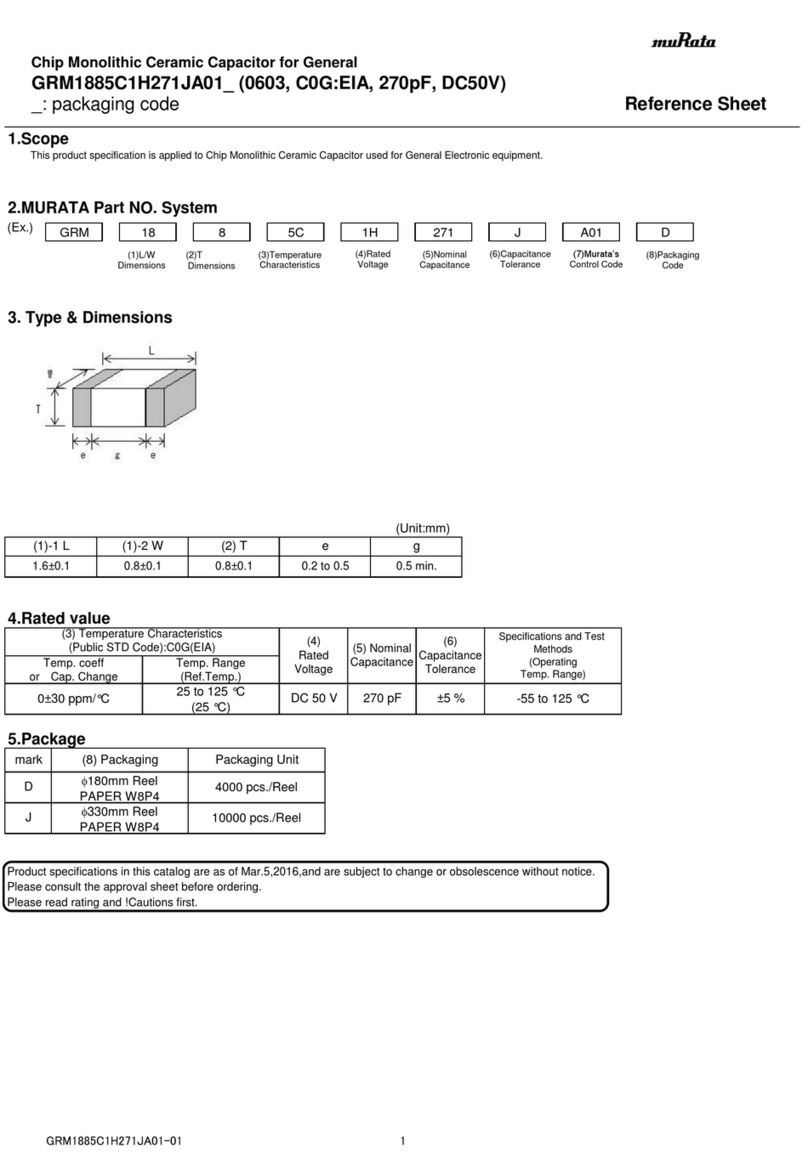

Murata GRM1885C1H271JA01 Series User manual

Murata

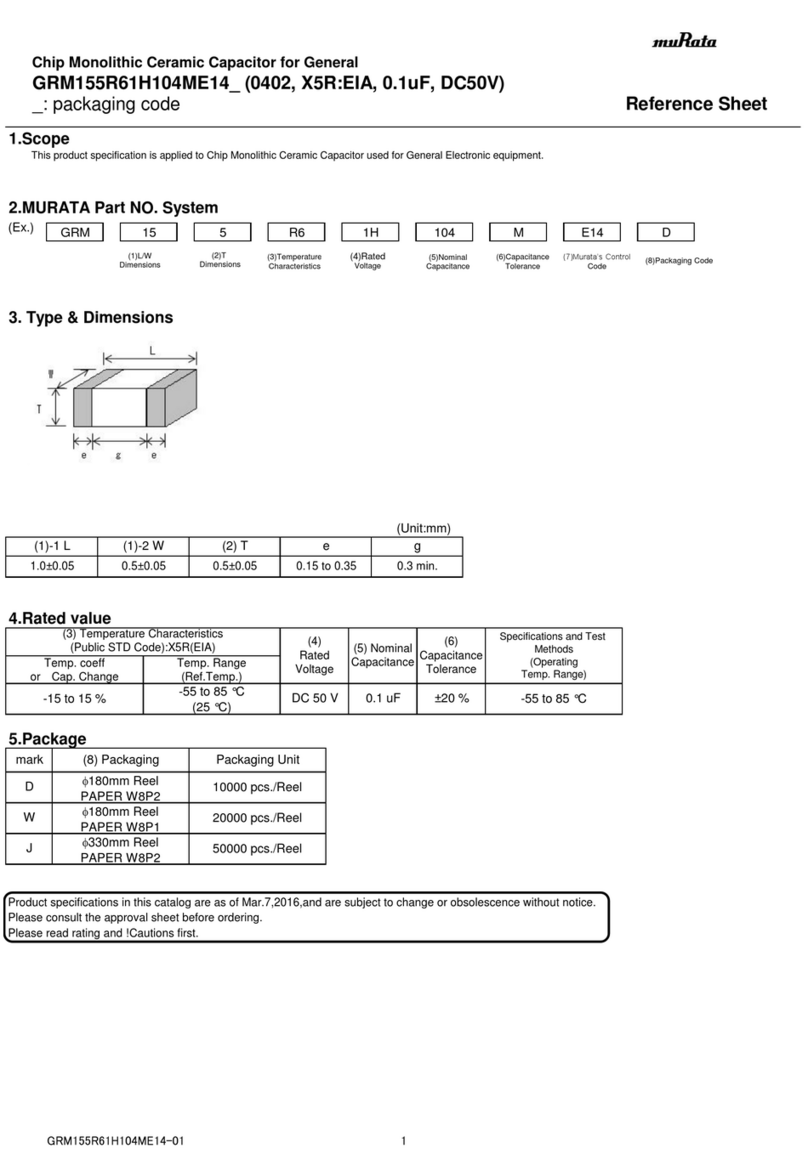

Murata GRM155R61H104ME14 Series User manual

Murata

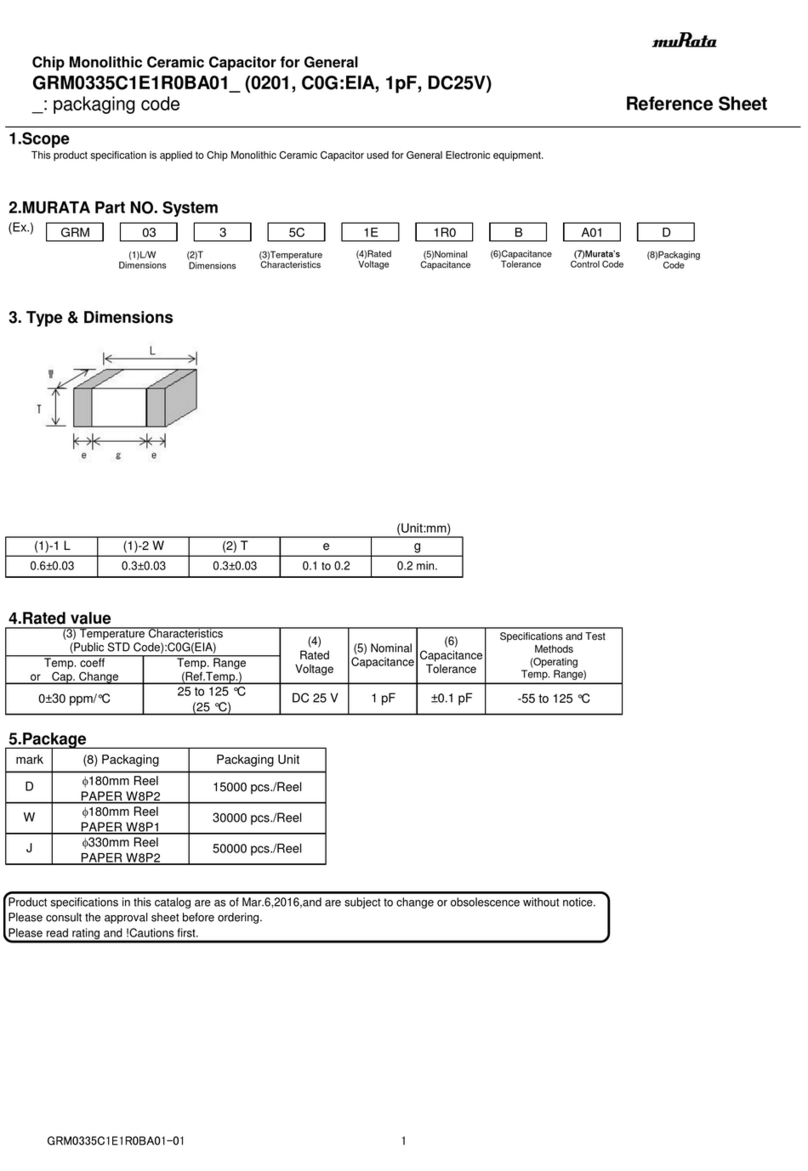

Murata GRM0335C1E1R0BA01 Series User manual

Murata

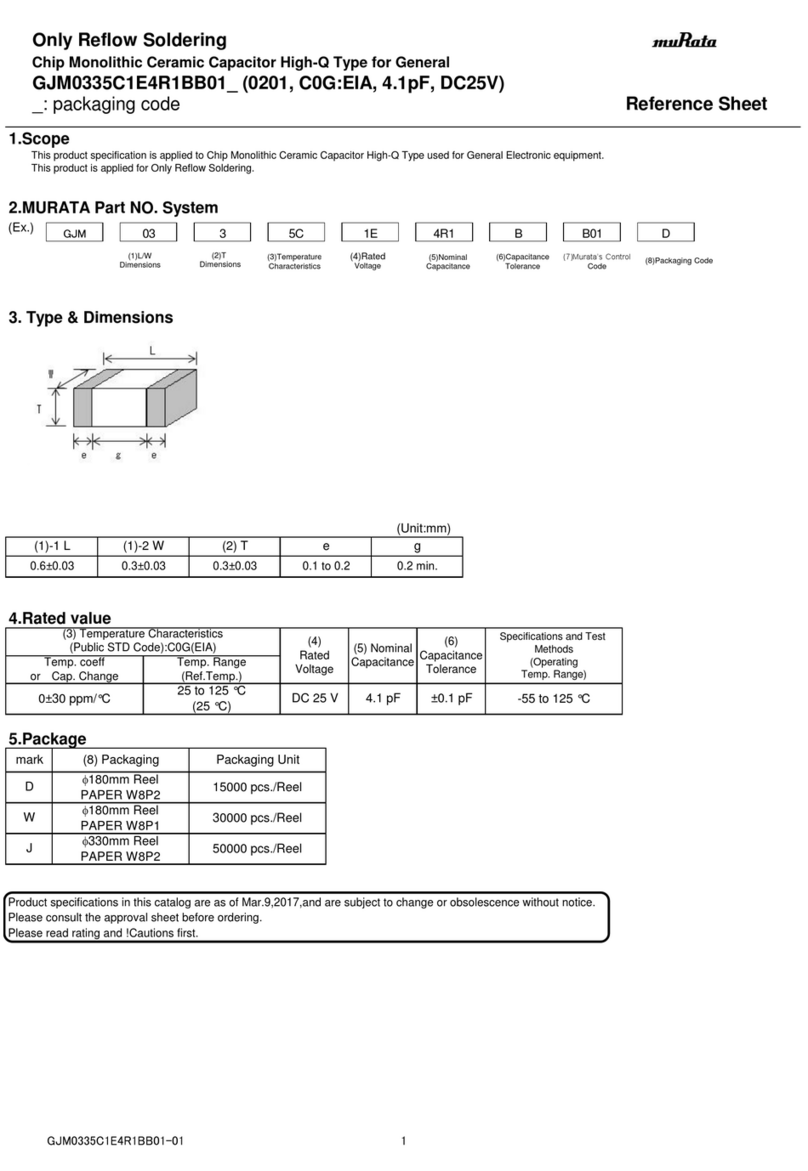

Murata GJM0335C1E4R1BB01 Series User manual

Murata

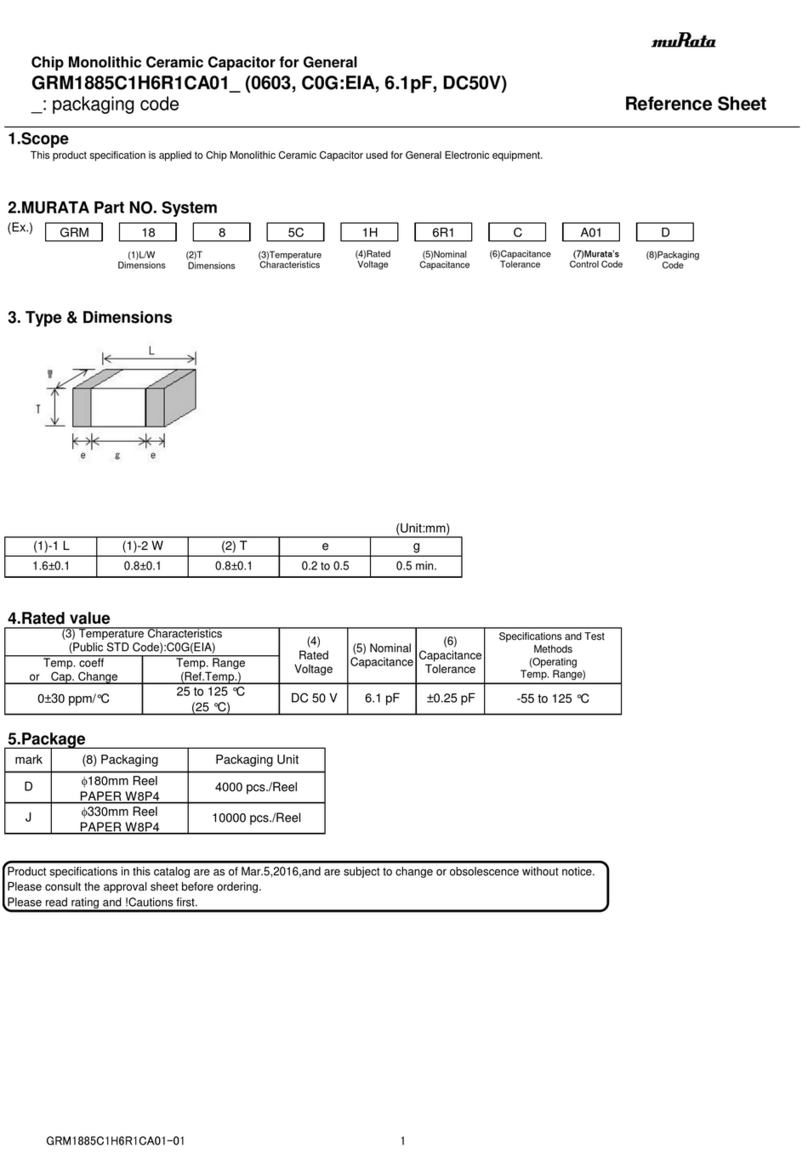

Murata GRM1885C1H6R1CA01 Series User manual

Murata

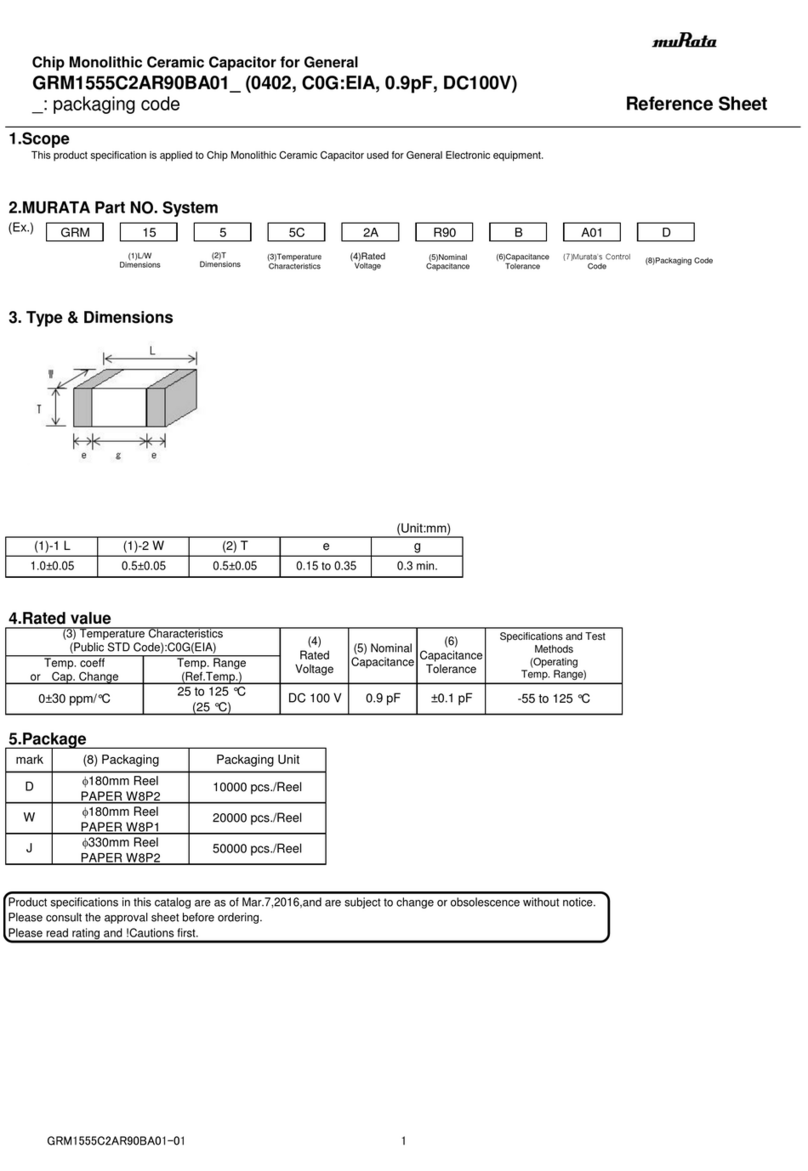

Murata GRM1555C2AR90BA01 Series User manual

Murata

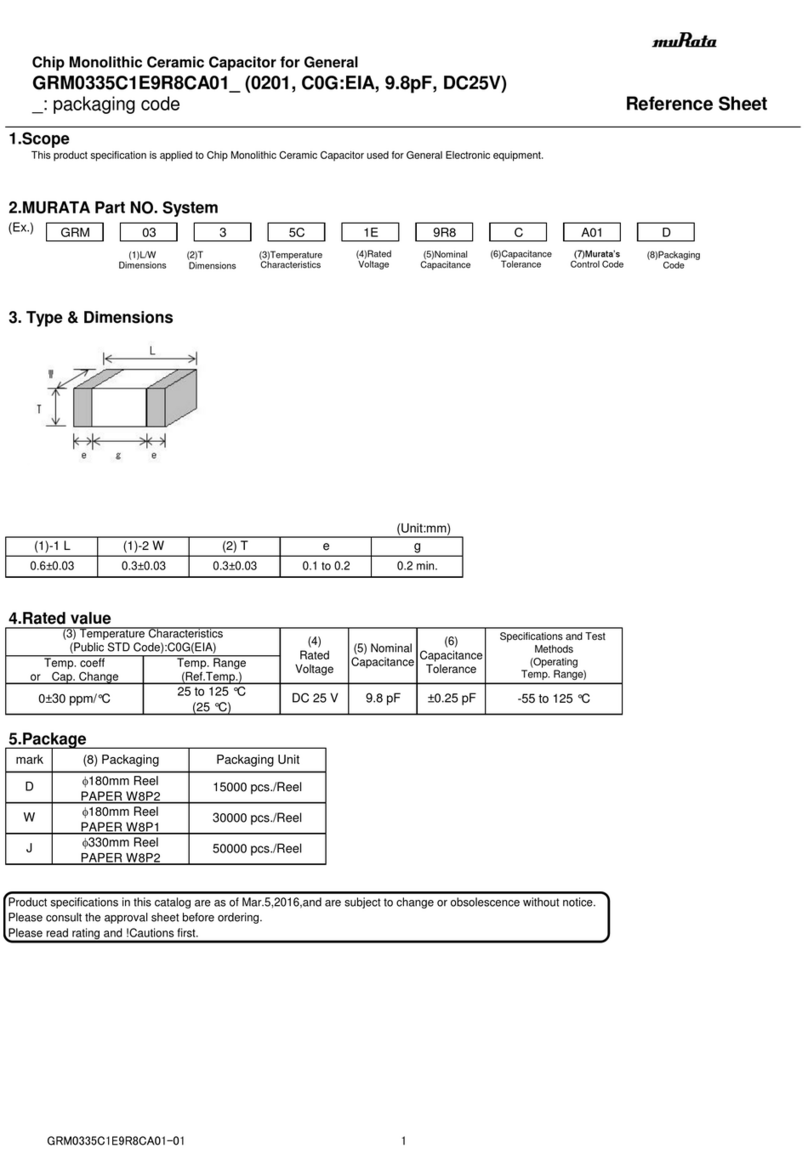

Murata GRM0335C1E9R8CA01 Series User manual

Murata

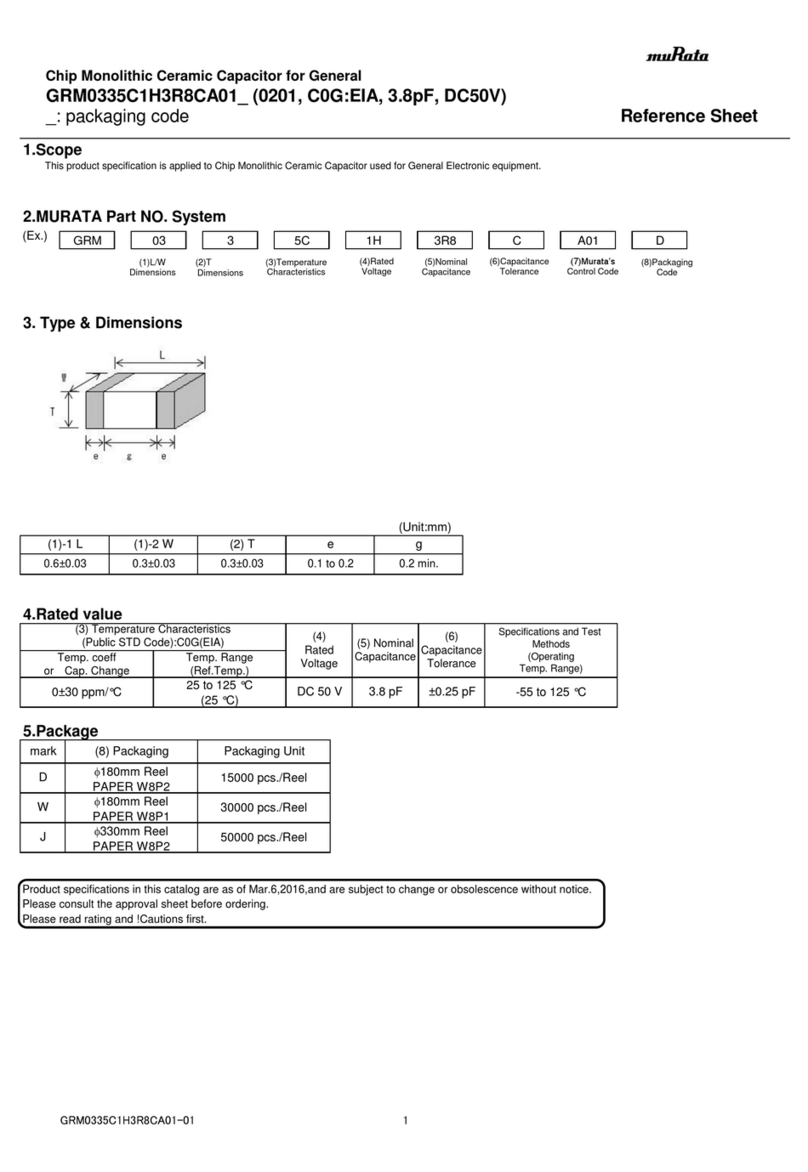

Murata GRM0335C1H3R8CA01 User manual

Murata

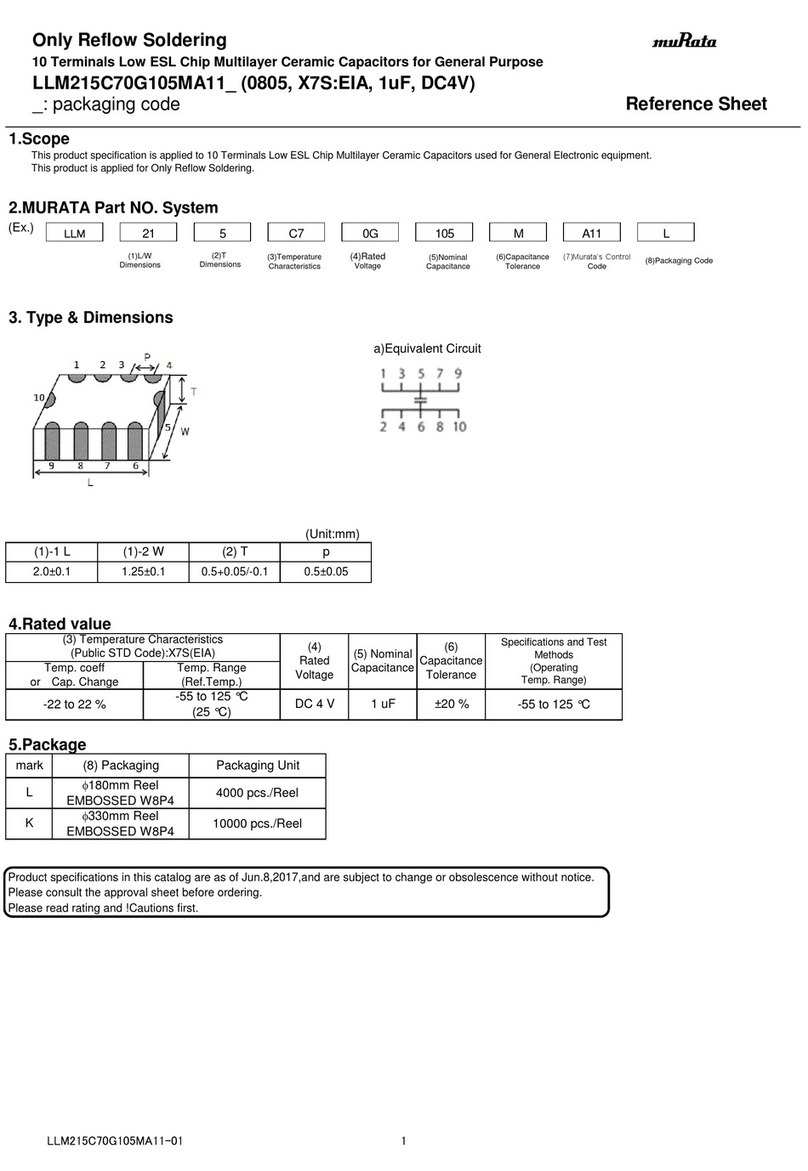

Murata LLM215C70G105MA11 Series User manual

Murata

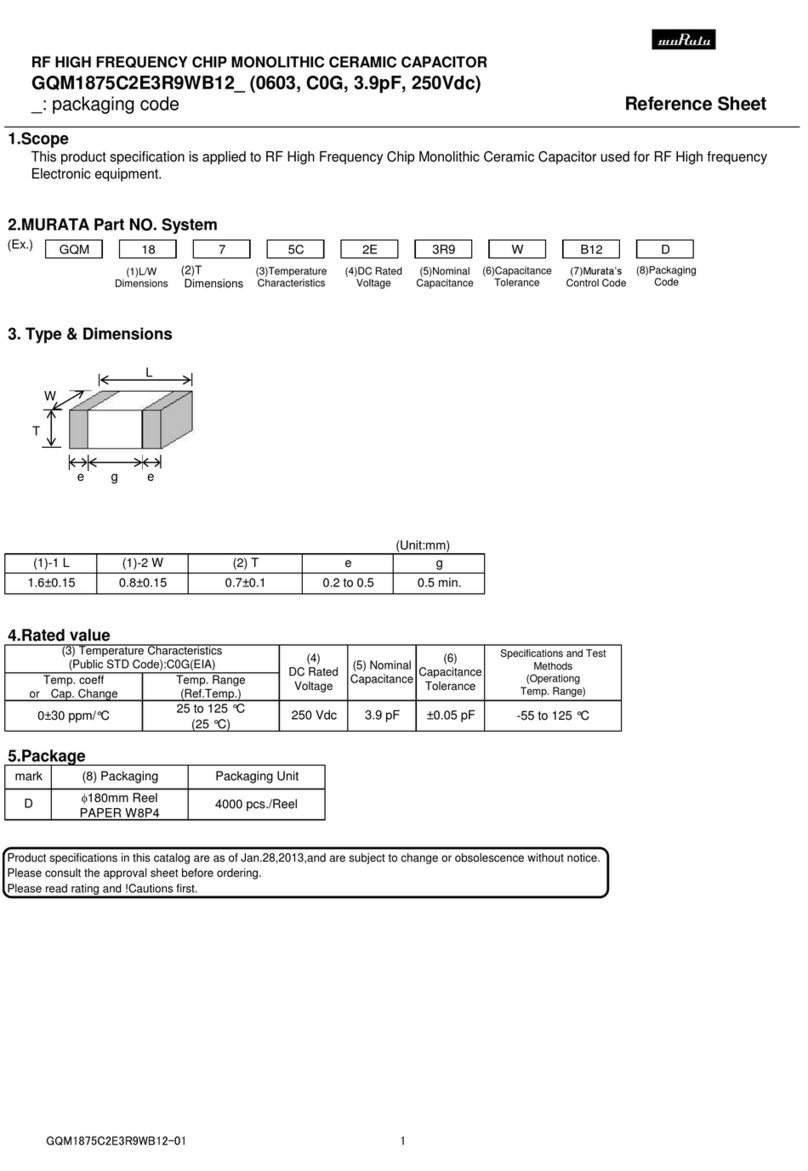

Murata GQM1875C2E3R9WB12 Series User manual

Murata

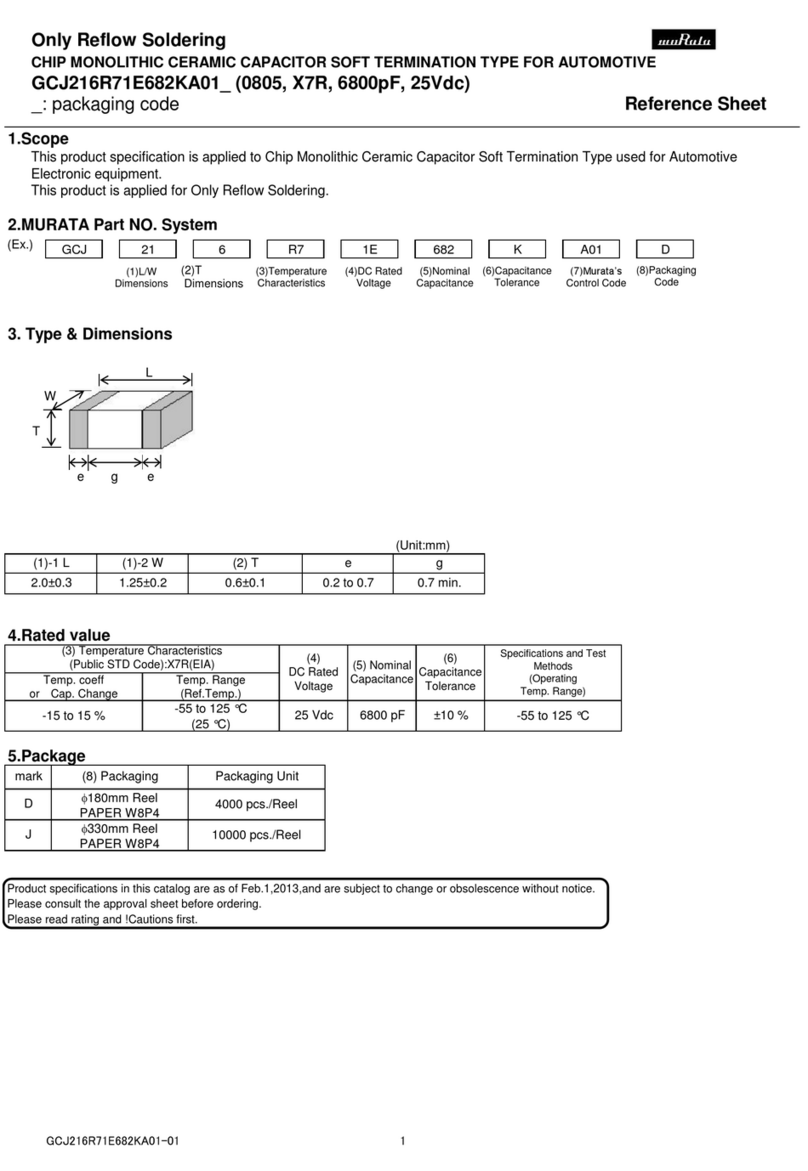

Murata GCJ216R71E682KA01 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

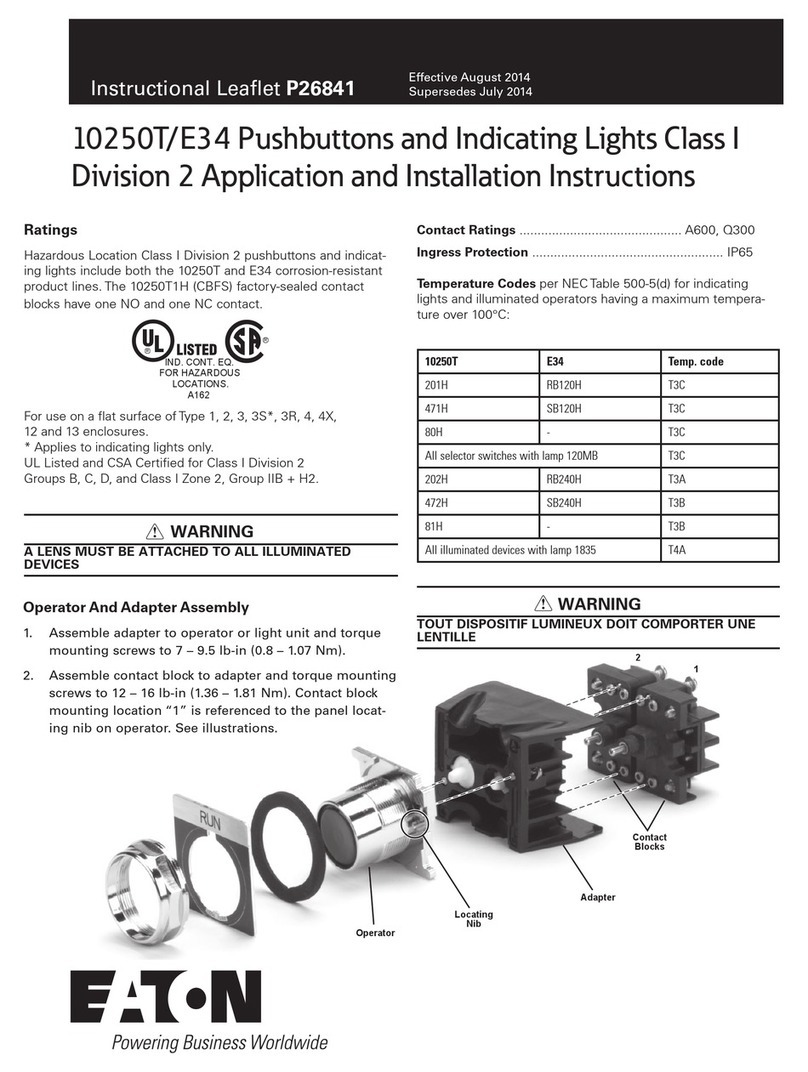

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

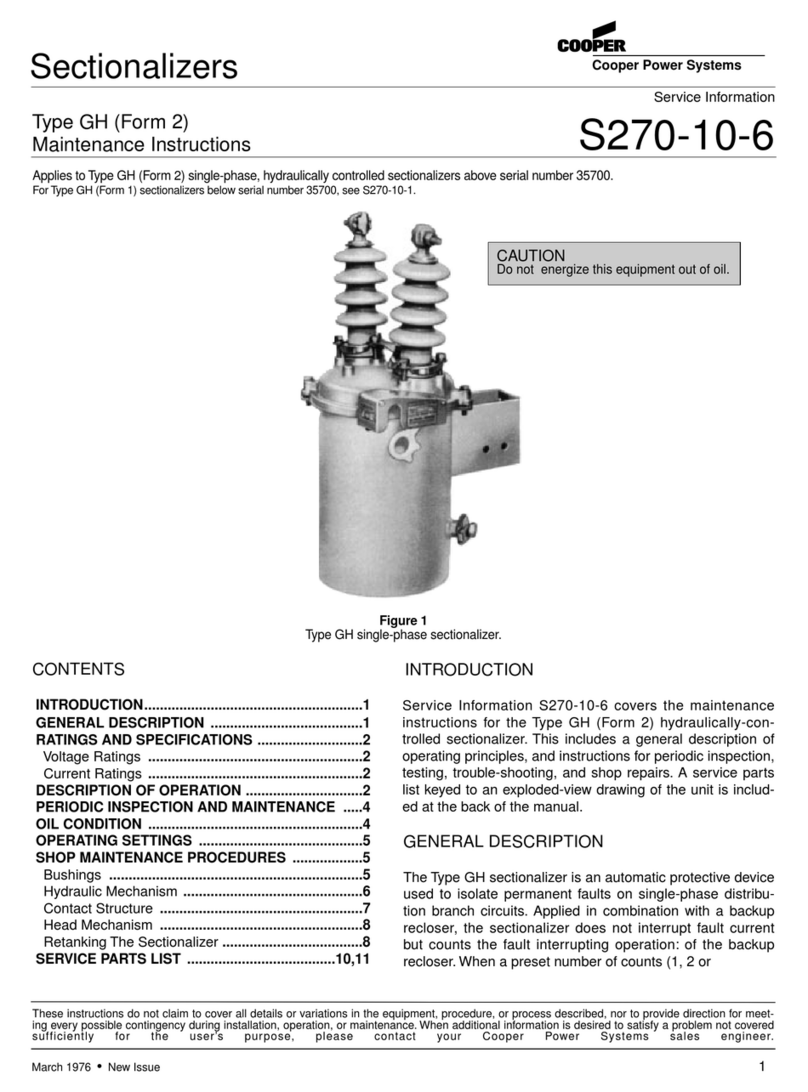

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions